Monitoring PCB Factories in China: The Latest Updates

By:Admin

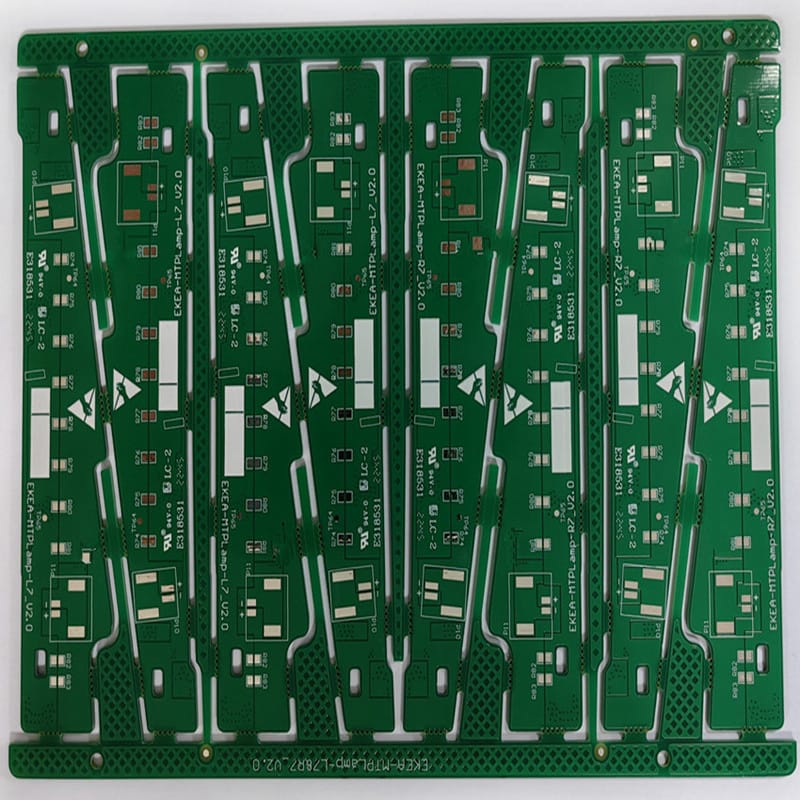

China is known for its thriving electronics industry, with numerous PCB factories spread across the country. These factories play a crucial role in the global supply chain, supplying printed circuit boards (PCBs) to electronic manufacturers around the world. However, with the increasing demand for high-quality PCBs, there is a need to monitor and improve the efficiency of these factories to ensure a smooth and reliable supply chain.

In response to this need, [Company Name] has announced its plans to closely monitor and work with PCB factories in China to enhance their efficiency and quality standards. As [Company Name] is a leading electronic manufacturing company, specializing in the production of cutting-edge electronic devices, their initiative to monitor and improve PCB factories in China is expected to bring positive impacts to the entire supply chain.

With decades of experience in the electronic manufacturing industry, [Company Name] understands the importance of having reliable and high-quality PCBs for the production of their electronic devices. By closely monitoring the PCB factories in China, [Company Name] aims to ensure that these factories meet the highest standards in terms of production quality, efficiency, and environmental sustainability. This initiative is part of [Company Name]'s commitment to delivering top-notch electronic products to their global customers while also contributing to the improvement of the overall supply chain.

The monitoring process will involve regular visits to the PCB factories by [Company Name]'s team of experts, who will assess the production processes, equipment, and quality control measures in place. By identifying areas that require improvement, [Company Name] will work closely with the factories to implement necessary changes that will enhance their efficiency and ensure the production of high-quality PCBs. This collaborative effort is expected to have a significant impact on the overall supply chain, as it will result in a more reliable and timely delivery of PCBs to electronic manufacturers worldwide.

Moreover, [Company Name] will also provide technical support and guidance to the PCB factories in China, helping them to upgrade their production capabilities and adopt the latest technologies and best practices in PCB manufacturing. By doing so, [Company Name] aims to elevate the standards of PCB production in China, making it a more competitive and reliable source for electronic manufacturers globally.

In addition to improving efficiency and quality, [Company Name]'s initiative to monitor and work with PCB factories in China also includes a strong focus on environmental sustainability. The company is committed to ensuring that the PCB factories adhere to strict environmental standards and practices, minimizing their impact on the environment. This includes the proper disposal of waste materials, the use of eco-friendly production processes, and the adoption of renewable energy sources wherever possible.

By working closely with PCB factories in China, [Company Name] also aims to support the local communities where these factories are based. This will include initiatives to provide training and employment opportunities, as well as to support local businesses and suppliers, contributing to the overall growth and development of the region.

Overall, [Company Name]'s initiative to monitor and improve PCB factories in China is expected to have far-reaching benefits for the entire supply chain. By ensuring the production of high-quality, efficient, and environmentally sustainable PCBs, [Company Name] is not only enhancing their own manufacturing processes but also contributing to the improvement of the global electronics industry. With their expertise and commitment, [Company Name] is set to make a positive impact on the supply chain and the communities where these PCB factories are located.

Company News & Blog

High-Quality PCB Prototyping Factory for Fast Production

Fast PCB Prototyping Factory Offers High-Quality and Efficient Manufacturing SolutionsWith the increasing demand for electronic devices across various industries, the need for fast and efficient PCB prototyping and manufacturing has never been greater. Recognizing this need, [Company Name] has established itself as a leading provider of high-quality and efficient PCB manufacturing solutions.[Company Name] is a state-of-the-art PCB prototyping factory that specializes in providing fast and reliable manufacturing services to meet the diverse needs of its clients. The company's commitment to quality, efficiency, and customer satisfaction has earned it a reputation as a trusted partner for businesses in need of PCB manufacturing solutions.Founded in [Year], [Company Name] has quickly become a preferred choice for companies looking to bring their electronic products to market in a timely and cost-effective manner. The company's team of experienced engineers and technicians are dedicated to delivering high-quality PCBs that meet the exact specifications and requirements of each client.The factory is equipped with cutting-edge technology and machinery, allowing [Company Name] to offer a wide range of prototyping and manufacturing services, including quick-turn PCB fabrication, assembly, and testing. Whether it's a small prototype run or a large-scale production order, the company has the capability to meet the demands of any project.One of the key features that set [Company Name] apart from its competitors is its fast turnaround time. The company understands the importance of speed in today's fast-paced business world and is committed to delivering prototypes and production orders in the shortest time possible. This allows clients to minimize lead times and get their products to market quickly.In addition to its quick-turn capabilities, [Company Name] also places a strong emphasis on quality and reliability. The company follows strict manufacturing processes and quality control measures to ensure that every PCB that leaves its facility meets the highest standards of excellence. This dedication to quality has earned [Company Name] a loyal customer base that relies on the company for all their PCB manufacturing needs.Furthermore, [Company Name] takes pride in its commitment to customer service. The company works closely with its clients throughout the manufacturing process, providing them with expert guidance and support to ensure that their projects are successful. Whether it's helping with design optimization, material selection, or any other aspect of the manufacturing process, [Company Name] is there to assist its clients every step of the way.As a testament to its dedication to excellence, [Company Name] holds various industry certifications and adheres to strict quality management standards. This ensures that the company's manufacturing processes are efficient, reliable, and in compliance with industry regulations.With its advanced capabilities, commitment to quality, and dedication to customer service, [Company Name] has positioned itself as a top choice for businesses in need of fast and reliable PCB manufacturing solutions. The company's ability to deliver high-quality prototypes and production orders in record time has made it a trusted partner for companies across a wide range of industries.In conclusion, [Company Name] is a leading PCB prototyping factory that offers high-quality and efficient manufacturing solutions to meet the diverse needs of its clients. The company's state-of-the-art facilities, advanced technology, and dedicated team make it a top choice for businesses looking to bring their electronic products to market quickly and cost-effectively. With its commitment to quality, reliability, and customer service, [Company Name] continues to set the standard for PCB manufacturing excellence.

High-Quality LED Lights for PCB Boards: A Complete Guide

Pcb Board Led Lights are revolutionizing the lighting industry with their energy-efficient technology and high-quality illumination. These lights are the brainchild of {company}, a leading manufacturer of innovative lighting products. The company has been at the forefront of research and development in LED lighting, and their Pcb Board Led Lights are a testament to their commitment to delivering top-notch products to their customers.With a focus on sustainability and eco-friendly solutions, {company} has designed the Pcb Board Led Lights to be highly energy-efficient, helping businesses and households reduce their electricity consumption and carbon footprint. These lights are built with high-quality printed circuit boards (PCBs) that provide reliable performance and longevity, making them a cost-effective and environmentally friendly lighting solution.One of the key features of {company}'s Pcb Board Led Lights is their superior brightness and color rendering. The company has leveraged its expertise in LED technology to develop lights that offer unparalleled brightness and clarity, creating a well-lit environment for various applications such as commercial, industrial, and residential settings. Whether it's for office spaces, warehouses, or homes, these LED lights are designed to deliver optimal lighting performance.In addition to their impressive lighting capabilities, {company}'s Pcb Board Led Lights also boast a sleek and modern design that adds aesthetic value to any space. The company understands the importance of style and functionality in lighting design, and their Pcb Board Led Lights are a perfect combination of both. With their slim profile and versatile mounting options, these lights can seamlessly integrate into any architectural design, enhancing the overall ambiance of the space.Furthermore, {company} has prioritized user convenience and safety in the development of their Pcb Board Led Lights. The lights are equipped with advanced features such as dimmable options and built-in safeguards against voltage fluctuations, ensuring a hassle-free and secure lighting experience for the users. Additionally, the company offers a range of customization options for their LED lights, allowing customers to tailor the lighting design according to their specific requirements.With a dedication to quality and innovation, {company} has earned a reputation for being a trusted provider of LED lighting solutions. The company's Pcb Board Led Lights are backed by rigorous testing and quality control measures, ensuring that they meet the highest standards of performance and reliability. This commitment to excellence has garnered {company} a loyal customer base and solidified its position as a leading player in the lighting industry.The launch of {company}'s Pcb Board Led Lights has been met with enthusiasm from customers and industry experts alike. The lights have been praised for their exceptional performance, energy efficiency, and aesthetic appeal, making them a popular choice for various lighting projects. From large-scale commercial installations to residential lighting upgrades, {company}'s Pcb Board Led Lights have emerged as a go-to solution for lighting needs.In conclusion, {company}'s Pcb Board Led Lights represent a milestone in the evolution of LED lighting technology. With their cutting-edge design, energy-efficient operation, and superior performance, these lights are setting new benchmarks in the industry. As {company} continues to push the boundaries of innovation, it's evident that their Pcb Board Led Lights are poised to make a lasting impact in the lighting market, offering customers a compelling and sustainable lighting solution.

Understanding the Different Classifications of PCBs and How They Impact Electronics Manufacturing

Title: Advanced Pcb Classification Technology Revolutionizes Electronics IndustryIntroduction (100 words):In an era driven by technological advancements, the electronics industry has witnessed remarkable growth. Behind every electronic device lies a Printed Circuit Board (PCB), an essential component that connects and supports an array of electronic components. As a leading technology company focused on innovative solutions, our company has recently developed groundbreaking Pcb Classification technology that promises to transform the electronics industry fundamentally. By simplifying manufacturing processes, improving efficiency, and enhancing product reliability, this cutting-edge solution ensures faster and more cost-effective production of high-quality PCBs.1. The Significance of PCB Classification (150 words):PCBs serve as the backbone of modern electronic devices, providing a reliable platform for interconnecting electronic components such as transistors, capacitors, and resistors. With the aim to enhance the performance and functionality of electronic products, our company has invested substantial resources in developing advanced PCB Classification technology.Historically, the PCB manufacturing process relied on manual sorting and classification of components, resulting in time-consuming processes, higher costs, and increased chances of human errors. However, our proprietary technology streamlines and automates this process, leveraging machine learning algorithms to accurately identify and categorize various PCB components within seconds. By efficiently classifying components based on their specifications, our technology reduces production time and costs significantly, ultimately improving the overall productivity of PCB manufacturing.2. Key Features and Benefits of PCB Classification Technology (200 words):Our revolutionary PCB Classification technology is built on a comprehensive dataset of PCB components, encompassing a vast range of industry standards. Leveraging cutting-edge machine learning algorithms, our software analyzes and classifies PCB components based on their unique characteristics, such as size, shape, material, and technical specifications.The key features and benefits of our PCB Classification technology include:a) Improved Efficiency: By automating the classification process, our technology eliminates the need for manual inspection, accelerating the production process. This results in faster turnaround times and allows manufacturers to meet tight deadlines.b) Cost and Resource Optimization: By reducing the need for manual labor involved in traditional classification methods, our technology significantly decreases production costs. Additionally, accurate categorization minimizes waste and enhances resource optimization, thereby improving the overall cost-effectiveness of PCB manufacturing.c) Enhanced Product Reliability: Our PCB Classification technology ensures the accurate selection of components, minimizing the chances of production errors and faulty connections. This leads to improved product reliability, reducing the risk of product recalls and enhancing brand reputation.d) Streamlined Supply Chain: With standardized classification and component identification, our technology facilitates smooth communication and collaboration in the supply chain. By simplifying component sourcing and procurement processes, manufacturers can optimize inventory management and reduce delays.3. Industry Impact and Future Prospects (150 words):The integration of PCB Classification technology is set to revolutionize the electronics industry. As the demand for smaller, more efficient electronic devices continues to grow, efficient and automated PCB manufacturing processes become increasingly crucial. By eliminating inefficiencies and reducing costs, our technology paves the way for the production of affordable and innovative electronic devices.Furthermore, the versatility of our technology allows its application in various sectors such as consumer electronics, telecommunications, automotive, aerospace, and medical devices. As the electronics industry continues to evolve rapidly, our PCB Classification technology empowers manufacturers to keep pace with the industry's demands.In conclusion, our cutting-edge PCB Classification technology represents a significant breakthrough in the electronics industry. By streamlining manufacturing processes, reducing costs, and enhancing product quality, this revolutionary solution has the potential to shape the future of PCB manufacturing and redefine the way electronic devices are produced.

Top Manufacturer of Pcb Solder Resist for High-Quality Circuit Board Assembly

Title: Leading Pcb Solder Resist Manufacturer Poised for Unmatched Growth and InnovationIntroduction:In the ever-evolving field of electronics manufacturing, one company has consistently stood out as a leading innovator in the production of Printed Circuit Board (PCB) solder resist solutions. This manufacturer, renowned for its commitment to quality and cutting-edge technology, has continuously raised the bar in the industry, satisfying the demands of customers worldwide. With an extensive range of products combined with advanced manufacturing techniques, the company has positioned itself for unrivaled growth on a global scale.Expanding Product Line:As a frontrunner in the field, this prominent PCB solder resist manufacturer has an impressive array of products tailored to meet the diverse needs of the industry. From single-sided to multilayered PCBs, the company offers customized solder resist solutions that ensure the highest level of quality and reliability. Moreover, with constant research and development efforts, they have successfully introduced new variations of solder resist materials catering to the ever-evolving demands of modern electronics manufacturing.Advanced Manufacturing Techniques:To maintain their industry-leading position, the manufacturer consistently implements state-of-the-art manufacturing techniques throughout their production process. They leverage cutting-edge automation technologies and machinery to ensure precision and efficiency, resulting in solder resist solutions of unparalleled quality. By investing in advanced equipment and continuously upgrading their facilities, the manufacturer highlights their commitment to delivering products with the highest industry standards.Commitment to Environmental Sustainability:In addition to their focus on product excellence, this leading PCB solder resist manufacturer harbors a strong commitment to environmental sustainability. Recognizing the need for eco-friendly alternatives, they have developed a comprehensive range of environmentally-conscious solder resist solutions. These products adhere to strict regulations regarding hazardous substances, minimizing their environmental impact while maintaining the highest performance standards. Through this dedication, the company helps electronics manufacturers operate responsibly and reduce their carbon footprint.Customer-Centric Approach:At the heart of this manufacturer's success lies its dedication to customer satisfaction. By fostering strong relationships with clients, they understand the unique needs of each partner and provide tailored solutions accordingly. Through close collaboration, the manufacturer ensures the delivery of top-tier products that meet or exceed customer expectations. Additionally, their customer support team provides efficient and reliable assistance, helping clients navigate any challenges they may encounter.Global Reach and Market Presence:Owing to their unwavering commitment to quality, innovation, and exceptional customer service, this PCB solder resist manufacturer has established a robust global presence. Their products are widely recognized for their reliability, making the company the brand of choice amongst top electronic manufacturers across the globe. This market presence reflects the confidence and trust that industry leaders place in the manufacturer’s products, further securing their position as a global industry leader.Future Outlook:In an ever-expanding global marketplace, this leading manufacturer remains at the forefront of technological advancements in the PCB solder resist industry. With plans to enhance production capabilities further and continuously invest in research and development, the company aims to solidify its position as an unparalleled innovator. Their future endeavors include the introduction of new, advanced materials, which will shape the future of electronics manufacturing, ensuring their long-lasting success.Conclusion:With an unrivaled commitment to quality, advanced manufacturing techniques, and a customer-centric approach, this PCB solder resist manufacturer continues to set new benchmarks in the industry. Their dedication to eco-friendly solutions, combined with a global market presence, positions them not just as a manufacturer but also as a trusted partner in the evolving world of electronics manufacturing. As they embark on a journey towards unmatched growth and innovation, the industry eagerly awaits the next groundbreaking developments from this leading player.

Discover the Benefits of Using High-Quality FR-4 PCB Boards

The use of technology has become an integral part of our daily lives. From the way we communicate with each other to the way we work, technology has played a crucial role in our lives. As technology continues to evolve, so do the devices we use. One of the most important components of modern technology is the Printed Circuit Board or PCB.A PCB is used to connect electronic components using conductive pathways or traces etched from copper sheets. These pathways help to provide power and connectivity to electronic devices. PCBs can be found in almost every electronic device we use, from smartphones to laptops to cars.As PCBs have become more complex and smaller in size, there has been a growing demand for high-quality PCBs that offer excellent performance and reliability. This is where Fr4 PCB Board comes in. Fr4 PCB Board is a high-performance PCB that is widely used in various electronic devices.Fr4 PCB Board is made from a fire-retardant material that is known for its excellent mechanical and electrical properties. This type of PCB is extremely durable and can withstand high temperatures and pressure. It is also highly resistant to chemicals, making it an ideal choice for use in harsh environments.Fr4 PCB Board is widely used in a variety of applications, including telecommunication devices, computers, and industrial equipment. The PCB is made using a specialized process that involves drilling holes in the substrate, laminating layers of copper, and etching the copper to create the desired circuit.One company that is leading the industry in the production of high-quality Fr4 PCB Board is {Brand Name Removed}. {Brand Name Removed} is a leading manufacturer and supplier of Fr4 PCB Board, providing high-quality PCBs to customers worldwide.The company prides itself on its commitment to quality and customer satisfaction. It uses the latest technology and manufacturing processes to produce PCBs that meet the highest standards of performance and reliability. {Brand Name Removed} offers a wide range of Fr4 PCB Board products, including single-layer, double-layer, and multi-layer PCBs.The company also provides customization services to meet the specific needs of its customers. This includes designing and building PCBs that are tailored to the customer's requirements. {Brand Name Removed} works closely with its customers to understand their needs and provide solutions that meet those needs.One of the key factors that set {Brand Name Removed} apart from its competitors is its focus on customer service. The company has a team of experienced professionals who are dedicated to providing excellent customer service. This includes offering technical support, product guidance, and after-sales service.In addition to its commitment to quality and customer service, {Brand Name Removed} is also dedicated to environmental sustainability. The company uses environmentally friendly processes to produce its PCBs and works to reduce its carbon footprint.Overall, Fr4 PCB Board is a critical component in the modern electronic devices we use every day. The use of high-quality Fr4 PCB Board, such as those produced by {Brand Name Removed}, helps to ensure the reliability and performance of these devices. With a commitment to quality, customer service, and environmental sustainability, {Brand Name Removed} is leading the industry in the production of high-quality Fr4 PCB Board.

The Importance of PCB Board Thickness in Electronics Manufacturing

Introducing the PCB Board Thickness NewsIn the fast-paced world of technology, Printed Circuit Boards (PCBs) play a crucial role in powering electronic devices. These boards are the backbone of most electronic devices, providing the necessary connections and pathways for electrical components to function seamlessly. The thickness of PCB boards is a critical factor in determining their performance and reliability. In this news release, we will delve into the importance of PCB board thickness and how it impacts the overall functionality of electronic devices.The thickness of a PCB board is a key consideration in its design and manufacturing process. It directly affects the board's mechanical strength, impedance control, and overall performance. A thinner PCB board may offer a reduced form factor and lighter weight, but it may also be more prone to bending or warping, which can lead to electrical issues and component failure. On the other hand, a thicker PCB board provides better mechanical stability and can withstand higher levels of stress and vibration, making it ideal for applications where durability is paramount.In the world of PCB manufacturing, the standard thickness of a PCB board is typically denoted in millimeters (mm) or mils (1/1000 of an inch). The most commonly used PCB thickness is 1.6mm, which is suitable for a wide range of electronic applications. However, the demand for thinner and more lightweight PCB boards has been steadily increasing, driven by the evolution of compact and portable electronic devices. As a result, PCB manufacturers are constantly striving to develop innovative solutions that offer both thinness and durability.{Company Introduction} is at the forefront of PCB manufacturing and has been a pioneer in developing cutting-edge PCB technologies. With a strong focus on quality, innovation, and customer satisfaction, {Company Name} has consistently delivered high-performance PCB solutions to a diverse range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Their state-of-the-art manufacturing facilities and extensive industry experience have positioned them as a trusted leader in the field of PCB manufacturing.Recognizing the growing demand for thinner PCB boards, {Company Name} has dedicated significant resources to research and development efforts aimed at producing ultra-thin yet durable PCB solutions. By leveraging advanced fabrication techniques and materials, {Company Name} has successfully engineered PCB boards with reduced thicknesses while maintaining superior mechanical and electrical performance. These advancements have opened up new possibilities for designing smaller, lighter, and more efficient electronic devices, driving innovation across various industries.{Company Name} understands the critical role that PCB board thickness plays in the performance and reliability of electronic devices. By offering a diverse portfolio of PCB solutions with varying thickness options, {Company Name} ensures that their customers have access to the most suitable PCB boards for their specific application requirements. Whether it's a compact, handheld device or a rugged, industrial application, {Company Name} can tailor their PCB solutions to meet the exacting standards of their customers, providing unmatched reliability and performance.In conclusion, the thickness of PCB boards is a crucial factor that directly impacts the functionality and reliability of electronic devices. As the demand for thinner and more lightweight PCB boards continues to rise, {Company Name} remains committed to delivering innovative, high-performance PCB solutions that meet the evolving needs of the industry. Through their dedication to research and development, {Company Name} is shaping the future of PCB manufacturing, offering advanced solutions that empower the next generation of electronic devices. With a steadfast commitment to quality and excellence, {Company Name} is a trusted partner for businesses seeking cutting-edge PCB solutions.

A Comparison of Hasl and Enig: Which is the better choice?

Hasl and Enig are two of the most commonly used surface finishes for printed circuit boards (PCBs). Both have their own advantages and disadvantages, and the choice between the two often depends on the specific needs of a particular application.Hasl, or Hot Air Solder Leveling, is a widely used surface finish for PCBs. It involves dipping the PCB into a bath of molten solder, and then using hot air to blow off the excess solder, leaving a thin and even coating on the surface of the PCB. Hasl is known for its excellent solderability and relatively low cost, making it a popular choice for many PCB applications.On the other hand, Enig, or Electroless Nickel Immersion Gold, is a surface finish that consists of an electroless nickel plating covered with a thin layer of immersion gold. Enig is known for its excellent corrosion resistance, flatness, and suitability for fine pitch components. It is often chosen for applications that require a high level of reliability and performance.Recently, a debate has emerged in the PCB industry regarding the relative merits of Hasl and Enig. Some industry experts argue that Enig is superior to Hasl in terms of overall performance and reliability, especially for high-frequency and high-speed applications. They point to Enig’s superior flatness and excellent solderability as key advantages over Hasl.On the other hand, proponents of Hasl argue that it is a cost-effective and well-established surface finish that has been used for decades with great success. They also argue that Hasl is easier to inspect and repair compared to Enig, making it a more practical choice for many applications.In light of this debate, {company name} has been at the forefront of developing and providing advanced PCB surface finishing solutions that meet the diverse needs of their customers. With extensive experience in the PCB industry and a strong track record of innovation, {company name} is well-positioned to provide expert guidance on the choice between Hasl and Enig.{company name} offers a comprehensive range of PCB surface finishing options, including both Hasl and Enig, as well as other advanced surface finishes such as OSP (Organic Solderability Preservatives) and Immersion Silver. Their team of experts works closely with customers to understand their specific requirements and recommend the most suitable surface finish for their PCBs.In response to the ongoing debate between Hasl and Enig, {company name} emphasizes the importance of taking a holistic view of PCB surface finishing. They advise customers to carefully consider their application requirements, budget, and long-term reliability needs when choosing between Hasl and Enig. They also highlight the importance of working with a trusted and experienced PCB manufacturer that can provide expert guidance and support throughout the PCB manufacturing process.As the debate between Hasl and Enig continues to unfold in the PCB industry, {company name} remains committed to offering the most advanced and reliable PCB surface finishing solutions to their customers. With a focus on innovation, quality, and customer satisfaction, {company name} is well-equipped to address the diverse and evolving needs of the PCB market.In conclusion, the choice between Hasl and Enig as a PCB surface finish ultimately depends on the specific requirements of a particular application. {company name} stands ready to provide expert guidance and support to customers as they navigate this important decision, ensuring that their PCBs meet the highest standards of performance, reliability, and quality.

Complete Guide to Different PCB Surface Finishes for Electronics

PCB Surface Finish: The Key to Reliable and High-Performance Electronic ProductsThe surface finish of printed circuit boards (PCBs) plays a crucial role in determining the reliability and performance of electronic products. It not only provides a protective coating for the copper traces and vias on the PCB, but also ensures the proper solderability of the components.One of the leading companies in the field of electronic manufacturing, [Company Name], has been at the forefront of developing and refining innovative PCB surface finish solutions. With a strong commitment to excellence and continuous improvement, [Company Name] has established itself as a trusted partner for numerous industries ranging from automotive and aerospace to consumer electronics and telecommunications.The importance of PCB surface finish cannot be overstated. It acts as a barrier against oxidation and corrosion, thereby extending the lifespan of the PCB and the electronic products in which it is used. Additionally, the surface finish directly affects the soldering process during PCB assembly, impacting the overall quality and reliability of the final product.[Company Name] offers a range of advanced surface finish options, each tailored to meet the specific needs and requirements of its customers. Whether it is the industry-standard HASL (Hot Air Solder Leveling), the cost-effective OSP (Organic Solderability Preservative), or the high-performance ENIG (Electroless Nickel Immersion Gold), [Company Name] has the expertise and capabilities to deliver top-notch PCB surface finishes.In addition to these widely used surface finish options, [Company Name] also specializes in advanced and specialized surface finishes such as immersion tin, immersion silver, and hard gold plating. These options are particularly suitable for applications that demand superior conductivity, high reliability, and harsh environmental conditions.The company's state-of-the-art manufacturing facilities and R&D centers are equipped with cutting-edge technologies and processes for applying surface finishes with precision and consistency. This ensures that every PCB produced by [Company Name] meets the highest quality standards and performs reliably in the field.Furthermore, [Company Name] places a strong emphasis on environmental sustainability and regulatory compliance in its surface finish processes. The company strictly adheres to international standards and regulations, and constantly seeks to minimize its environmental footprint through the adoption of eco-friendly practices and materials.With an unwavering dedication to customer satisfaction, [Company Name] provides comprehensive technical support and consultation services to help clients select the most suitable surface finish for their specific applications. The company's team of experts works closely with customers to understand their requirements and challenges, and offers customized solutions that meet and exceed expectations.As the demand for high-performance and reliable electronic products continues to rise, the importance of PCB surface finish will only grow in significance. It is imperative for manufacturers to partner with trusted and experienced suppliers like [Company Name] to ensure that their PCBs are equipped with the most effective and advanced surface finishes available in the market.In conclusion, [Company Name] remains a leading force in the electronic manufacturing industry, particularly in the realm of PCB surface finish solutions. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is well-positioned to continue driving advancements in surface finish technologies and setting new benchmarks for excellence in the field. For manufacturers seeking to enhance the reliability and performance of their electronic products, [Company Name] stands as a reliable and capable partner for all their PCB surface finish needs.

Complete Guide to Circuit Board Soldering Techniques and Tools

Circuit Board Solder, a key component in electronic devices, is a vital part of the production process for innovative companies like {}. Proper soldering is essential for creating reliable connections between electronic components on circuit boards and ensuring the functionality and performance of the finished products.With over [X] years of experience in the electronics industry, {} has established itself as a leading provider of high-quality circuit board solder solutions. The company's dedication to excellence and innovation has earned them a strong reputation among their clients and peers in the industry. Their commitment to quality and customer satisfaction has made them a trusted partner for businesses seeking reliable soldering solutions.One of the key factors that set {} apart from their competitors is their focus on research and development. They continuously invest in cutting-edge technology and processes to stay at the forefront of the industry. This dedication to innovation has allowed them to develop a wide range of solder products that meet the evolving needs of their customers and the ever-changing requirements of the electronics market.In addition to their focus on technological advancements, {} places a strong emphasis on sustainability and environmental responsibility in their manufacturing processes. They adhere to strict environmental standards and work towards reducing their carbon footprint. This commitment to sustainability has not only earned them recognition for their environmental practices but has also positioned them as a preferred supplier for companies that prioritize eco-friendly materials and practices.The company's commitment to quality and environmental responsibility is reflected in their circuit board solder products. They offer a diverse range of solder options, including lead-free solder, traditional solder alloys, and specialty solders tailored to specific applications. Their solder products are designed to provide optimal performance, reliability, and longevity, meeting the stringent requirements of various industries, from consumer electronics to aerospace and automotive.One of the hallmarks of {}'s solder products is their exceptional consistency and reliability. Their state-of-the-art manufacturing processes and stringent quality control measures ensure that each batch of solder meets the highest standards for purity, consistency, and performance. This level of precision and quality assurance has made {} a preferred supplier for businesses that demand nothing but the best for their electronic manufacturing needs.Moreover, {} offers comprehensive technical support and customer service to assist their clients in choosing the right solder for their specific applications, as well as providing guidance on best practices for soldering processes. This commitment to customer satisfaction and support has cemented their position as a trusted partner for businesses seeking reliable and innovative solder solutions.In conclusion, circuit board solder is a critical component in the electronics manufacturing process, and companies like {} are leading the way with their dedication to quality, innovation, and environmental responsibility. With a strong focus on research and development, cutting-edge technology, and a commitment to sustainability, {} is well-positioned to meet the evolving demands of the electronics industry and continue to be a preferred supplier for businesses seeking high-quality solder solutions. Their track record of excellence, reliability, and customer satisfaction makes them a powerhouse in the industry, and their continued dedication to innovation ensures that they will remain at the forefront of the electronic manufacturing sector for years to come.

Top Circuit Board Prototype Factory in China

China Circuit Board Prototype Factory, one of the leading manufacturers of circuit boards in the country, has recently made significant strides in the industry with the development of cutting-edge technology and innovative solutions. With a strong focus on research and development, the company has positioned itself as a key player in the global market for high-quality circuit board prototypes.The company's state-of-the-art facility is equipped with advanced machinery and equipment, allowing for the precise and efficient production of circuit board prototypes. This level of technological sophistication has enabled the factory to meet the ever-increasing demands of the electronics industry, providing customers with superior products that uphold the highest standards of quality and performance.In addition to its technological prowess, China Circuit Board Prototype Factory boasts a team of highly skilled and experienced engineers and technicians who are dedicated to pushing the boundaries of innovation. Their expertise allows for the development of complex circuit board designs and the implementation of intricate manufacturing processes, ensuring that each prototype meets the specific requirements of the client.The company's commitment to excellence is further exemplified by its stringent quality control measures. Each circuit board prototype undergoes meticulous inspection and testing to guarantee its reliability and functionality. This dedication to quality has earned China Circuit Board Prototype Factory a stellar reputation amongst its clientele, who have come to rely on the company for dependable and superior products.Furthermore, the factory's dedication to environmental sustainability is evident in its eco-friendly manufacturing practices. By implementing energy-efficient production methods and utilizing recyclable materials, the company strives to minimize its environmental impact, contributing to a more sustainable and responsible approach to manufacturing.In addition to its domestic success, China Circuit Board Prototype Factory has also made a significant impact on the global market, exporting its products to a wide range of international clients. The factory's ability to consistently deliver high-quality circuit board prototypes has solidified its position as a preferred supplier for companies around the world, further cementing its reputation as a leader in the industry.Looking ahead, China Circuit Board Prototype Factory remains committed to driving innovation and advancing the boundaries of technology in the field of circuit board manufacturing. Through ongoing research and development efforts, the company aims to introduce new and improved solutions that will continue to meet the evolving needs of the electronics industry.With its dedication to technological excellence, superior quality, and environmental responsibility, China Circuit Board Prototype Factory is poised to maintain its position as a prominent and influential figure in the global circuit board manufacturing sector. As the company continues to push the boundaries of innovation, it is poised to make even greater contributions to the advancement of technology and the electronics industry as a whole.