Discover the Benefits of Lead-Free Technology in the Latest News Update

By:Admin

[News Introduction]:

In a world increasingly conscious of the environmental impact of industrial practices, the need for responsible and sustainable solutions has become paramount. Today, we are excited to introduce Hass Lead Free (name removed), a groundbreaking innovation that addresses the issue of lead pollution in an unprecedented way. Developed by an industry-leading company whose commitment to sustainability is second to none, this pioneering technology is set to revolutionize the manufacturing landscape.

[News Body]:

Lead, a highly toxic heavy metal, has long been a subject of concern due to its detrimental effects on human health and the environment. While efforts have been made to reduce its presence in various products, such as gasoline and paint, its integration into manufacturing processes has posed a significant challenge. This is where Hass Lead Free comes in.

Developed by the ingenious minds at a renowned company, Hass Lead Free represents a breakthrough in the quest for safe and sustainable manufacturing practices. Building on years of research and development, this cutting-edge technology eliminates the need for lead throughout the entire manufacturing process, offering a viable alternative that reduces pollution and minimizes health risks.

The implications of this innovation are far-reaching. Not only does Hass Lead Free reduce the environmental impact of manufacturing, but it also ensures safer working conditions for the employees involved. By completely removing lead from the equation, the risk of occupational exposure to this hazardous material is effectively nullified, safeguarding the well-being of all those involved in the production process.

Furthermore, as the global demand for environmentally responsible products continues to rise, companies that embrace sustainable practices gain a competitive edge. Hass Lead Free allows manufacturers to align themselves with the growing consumer preference for eco-friendly products, enhancing their brand reputation and fostering long-term growth.

The company behind this groundbreaking technology understands the importance of collaboration in addressing complex environmental challenges. With a strong commitment to corporate social responsibility, they have actively engaged in partnerships with industry leaders, governmental agencies, and research institutions to ensure the widest possible dissemination and implementation of their innovation. By sharing their knowledge and expertise, they are driving the transition towards a more sustainable future for all.

Hass Lead Free also provides a cost-effective solution for manufacturers. By streamlining production processes, eliminating the need to handle and dispose of lead, and reducing the risk of regulatory non-compliance, companies can significantly decrease their operational costs and increase overall efficiency. This translates into a win-win scenario, where profitability goes hand in hand with environmental responsibility.

Looking to the future, the developers of Hass Lead Free envision a world where lead pollution is a thing of the past. By pioneering this technology, they are setting the stage for a paradigm shift in manufacturing practices, inspiring others to follow suit and make sustainability a core principle of their operations. The potential positive impact on the environment, human health, and the economy is immeasurable.

In conclusion, Hass Lead Free represents a significant step forward in the global effort to create a sustainable and responsible manufacturing industry. This revolutionary technology, developed by a leading company committed to environmental stewardship, has the potential to reshape the way we produce and consume goods. With greater awareness and adoption of such innovations, we can pave the way for a greener and more prosperous future.

Company News & Blog

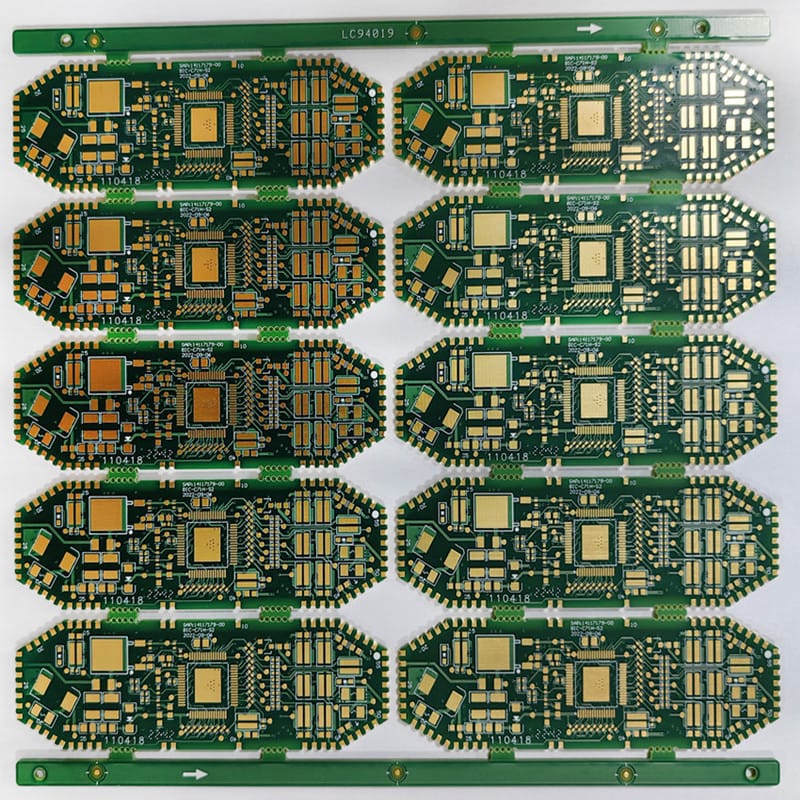

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.

Understanding the Different Classifications of PCBs and How They Impact Electronics Manufacturing

Title: Advanced Pcb Classification Technology Revolutionizes Electronics IndustryIntroduction (100 words):In an era driven by technological advancements, the electronics industry has witnessed remarkable growth. Behind every electronic device lies a Printed Circuit Board (PCB), an essential component that connects and supports an array of electronic components. As a leading technology company focused on innovative solutions, our company has recently developed groundbreaking Pcb Classification technology that promises to transform the electronics industry fundamentally. By simplifying manufacturing processes, improving efficiency, and enhancing product reliability, this cutting-edge solution ensures faster and more cost-effective production of high-quality PCBs.1. The Significance of PCB Classification (150 words):PCBs serve as the backbone of modern electronic devices, providing a reliable platform for interconnecting electronic components such as transistors, capacitors, and resistors. With the aim to enhance the performance and functionality of electronic products, our company has invested substantial resources in developing advanced PCB Classification technology.Historically, the PCB manufacturing process relied on manual sorting and classification of components, resulting in time-consuming processes, higher costs, and increased chances of human errors. However, our proprietary technology streamlines and automates this process, leveraging machine learning algorithms to accurately identify and categorize various PCB components within seconds. By efficiently classifying components based on their specifications, our technology reduces production time and costs significantly, ultimately improving the overall productivity of PCB manufacturing.2. Key Features and Benefits of PCB Classification Technology (200 words):Our revolutionary PCB Classification technology is built on a comprehensive dataset of PCB components, encompassing a vast range of industry standards. Leveraging cutting-edge machine learning algorithms, our software analyzes and classifies PCB components based on their unique characteristics, such as size, shape, material, and technical specifications.The key features and benefits of our PCB Classification technology include:a) Improved Efficiency: By automating the classification process, our technology eliminates the need for manual inspection, accelerating the production process. This results in faster turnaround times and allows manufacturers to meet tight deadlines.b) Cost and Resource Optimization: By reducing the need for manual labor involved in traditional classification methods, our technology significantly decreases production costs. Additionally, accurate categorization minimizes waste and enhances resource optimization, thereby improving the overall cost-effectiveness of PCB manufacturing.c) Enhanced Product Reliability: Our PCB Classification technology ensures the accurate selection of components, minimizing the chances of production errors and faulty connections. This leads to improved product reliability, reducing the risk of product recalls and enhancing brand reputation.d) Streamlined Supply Chain: With standardized classification and component identification, our technology facilitates smooth communication and collaboration in the supply chain. By simplifying component sourcing and procurement processes, manufacturers can optimize inventory management and reduce delays.3. Industry Impact and Future Prospects (150 words):The integration of PCB Classification technology is set to revolutionize the electronics industry. As the demand for smaller, more efficient electronic devices continues to grow, efficient and automated PCB manufacturing processes become increasingly crucial. By eliminating inefficiencies and reducing costs, our technology paves the way for the production of affordable and innovative electronic devices.Furthermore, the versatility of our technology allows its application in various sectors such as consumer electronics, telecommunications, automotive, aerospace, and medical devices. As the electronics industry continues to evolve rapidly, our PCB Classification technology empowers manufacturers to keep pace with the industry's demands.In conclusion, our cutting-edge PCB Classification technology represents a significant breakthrough in the electronics industry. By streamlining manufacturing processes, reducing costs, and enhancing product quality, this revolutionary solution has the potential to shape the future of PCB manufacturing and redefine the way electronic devices are produced.

Discover the Benefits of Quick Turnaround PCB Services for Efficient Electronics Production

Quick Turnaround PCB Company Delivers World-Class Circuit BoardsQuick Turnaround PCB, a leading printed circuit board manufacturer, continues to deliver world-class PCB solutions to meet the growing needs of the electronics industry. With its commitment to excellence and customer satisfaction, the company provides top-quality products that are durable, reliable, and cost-effective.Quick Turnaround PCB has gained a strong reputation for its exceptional services and production capabilities. It offers a vast range of PCB solutions including rigid, flex, and rigid-flex boards, along with PCB assembly services. The company also specializes in quick turnaround services, with the ability to produce PCB prototypes within just a few days.The company has established itself as an industry leader in PCB manufacturing due to its advanced manufacturing technologies, efficient process optimization, and rigorous quality control procedures. Its manufacturing facility boasts state-of-the-art machinery, including automated optical inspection systems, surface mount technology, and X-ray inspection, to ensure that its products meet the highest quality standards.To cater to the diverse needs of its clients, Quick Turnaround PCB provides custom PCB solutions tailored to specific requirements. Its team of professional engineers works closely with customers to identify their needs and develop effective solutions that can meet their needs.Moreover, the company is dedicated to providing customers with exceptional support services to ensure their satisfaction. Customers can reach out to dedicated technicians and engineers at any time to get advice or assistance on any PCB-related issues.Over the years, Quick Turnaround PCB has developed a loyal customer base due to its relentless pursuit of excellence in PCB manufacturing. The company's clients come from various sectors, including automotive, aerospace, medical, and telecommunications. Its products have been used in various applications, ranging from industrial machinery to consumer electronics. Quick turnaround PCB has made a significant investment in research and development activities, with the aim of staying ahead of its competitors and providing cutting-edge solutions to customers. Its engineers are continually exploring new technologies and innovations in PCB manufacturing, such as flexible substrates and additive manufacturing.With its commitment to quality, innovation, and customer satisfaction, Quick Turnaround PCB stands poised to become a leading player in the global PCB industry. As it continues to expand its manufacturing capabilities and broaden its product portfolio, the company is confident in its ability to meet the diverse needs of customers worldwide.In conclusion, Quick Turnaround PCB is a world-class manufacturer of printed circuit boards, known for its commitment to delivering high-quality products and customer satisfaction. Its advanced manufacturing technologies, efficient process optimization, and rigorous quality control procedures set it apart from its competitors. As the company continues to grow and innovate, it is poised to become a leading player in the global PCB industry.

Leading PCB Manufacturing Facility in China Receives UL Certification

Title: Leading Chinese PCB Manufacturer Achieves UL Certification for Enhanced Quality and ReliabilityIntroduction:In an impressive feat of technological advancement and quality control, China PCB UL Factory, one of the country's leading printed circuit board manufacturing facilities, has recently achieved UL certification. This recognition underscores the company's commitment to providing top-notch products while reinforcing its position as a trusted partner for diverse industries such as automotive, telecommunications, consumer electronics, and more. With this new certification, China PCB UL Factory aims to further establish itself as a global leader in the PCB manufacturing industry.Body:1. The Road to UL Certification:China PCB UL Factory has continuously invested in cutting-edge technology and innovative manufacturing processes, enabling the company to produce high-quality PCBs that meet the stringent standards set by UL. The certification process involved rigorous assessments conducted by UL experts, evaluating factors such as design, material selection, manufacturing processes, and product performance. China PCB UL Factory successfully met all the necessary criteria, demonstrating its dedication to excellence.2. Advantages of UL Certification:Obtaining UL (Underwriters Laboratories) certification is no small accomplishment and speaks to a company's commitment to safety, reliability, and environmental sustainability. The UL mark instills trust in customers and reassures them that the products offered have been thoroughly tested and meet the highest industry standards. China PCB UL Factory's certification contributes to the company's reputation for top-tier quality, opening doors to new business opportunities and collaborations with global partners.3. Enhanced Product Reliability:UL certification signifies China PCB UL Factory's ability to manufacture products that adhere to strict quality control methodologies. The rigorous testing and auditing procedures conducted during UL assessments ensure that the PCBs not only meet performance benchmarks but also comply with safety regulations. By acquiring UL certification, the factory has bolstered its reputation for delivering reliable and durable PCBs, crucial components for various industries.4. Benefits for Collaborative Industries:China PCB UL Factory's achievement of UL certification offers many advantages to industries that rely on high-quality PCBs. The automotive sector, for instance, often demands exceptional performance and reliability in circuit boards used in electronic control units, sensors, and infotainment systems. With UL certification, China PCB UL Factory can position itself as a preferred PCB supplier for automotive manufacturers, enhancing its portfolio and expanding its global market share.5. Commitment to Environmental Responsibility:UL certification extends beyond product reliability; it also emphasizes a company's adherence to environmental safety protocols. China PCB UL Factory's compliance with UL standards underscores its commitment to minimizing environmental impact. The factory optimizes its manufacturing processes to reduce waste, supports the responsible disposal of hazardous materials, and promotes energy-efficient technologies. By prioritizing sustainable practices in PCB production, the company aligns itself with environmentally conscious partners and businesses.6. Market Competitiveness and Growth Prospects:The UL certification places China PCB UL Factory among an elite group of manufacturers that have met globally recognized standards for quality and safety. This achievement strengthens the company's position in the highly competitive global PCB market, enabling it to attract customers who prioritize reliability and adhere to stringent industry regulations. By capitalizing on its UL certification, China PCB UL Factory can explore new partnerships and expand its footprint in emerging sectors, such as Internet of Things (IoT), artificial intelligence (AI), and renewable energy.7. Future Outlook and Continued Excellence:Obtaining UL certification serves as a critical milestone in China PCB UL Factory's growth journey, but it is only the beginning of the company's commitment to continuous improvement. The factory plans to invest further in research and development to stay at the forefront of technological advancements, ensuring that its PCBs are compatible with evolving industry needs. By prioritizing customer satisfaction and emphasizing consistent quality, China PCB UL Factory strives to solidify its standing as a trusted PCB manufacturer worldwide.Conclusion:China PCB UL Factory's recent achievement of UL certification highlights its unwavering dedication to producing high-quality, reliable, and environmentally sustainable PCBs. This significant accomplishment positions the factory as a preferred partner for industries seeking superior electronic solutions. Through continued innovation and customer-centric practices, China PCB UL Factory is poised to further enhance its market competitiveness and drive the growth of the global PCB manufacturing industry.

Top Circuit Boards: An Essential Guide to Blank Options for Your Electronics

Blank Circuit Boards: Your Go-To Solution for a Wide Range of Printed Circuit Board NeedsAs the demand for electronic devices continues to grow, the need for reliable printed circuit boards (PCBs) has become more important than ever. A PCB is a vital component of modern electronics and serves as a platform for electronic components to be soldered onto, providing connectivity and functionality to devices. As such, PCBs are used in a broad range of applications, from consumer electronics like smartphones and laptops to military and industrial equipment.Blank circuit boards provide the foundation for building PCBs and are available in a wide range of types, materials, and sizes. Blank circuit boards are essentially unpopulated PCBs that have no electronic components mounted on them. This allows manufacturers to customize these boards to meet specific requirements, making them a versatile and cost-effective solution for electronic projects.At Blank Circuit Boards, we are a leading supplier of high-quality blank circuit boards that are designed to meet the exacting requirements of our customers. Our team of experienced professionals has the expertise and know-how needed to deliver reliable and cost-effective blank circuit boards for a wide range of applications across various industries.Our product line includes single-sided, double-sided, and multilayer blank circuit boards, all made from high-quality materials like FR-4, FR-1, CEM-1, CEM-3, and Rogers. We also offer other specialized PCB types, such as high-frequency PCBs and flexible PCBs, to cater to the needs of our customers across various industries.Our commitment to quality is reflected in the products we supply. All our circuit boards are manufactured using state-of-the-art equipment and techniques, ensuring that they meet or exceed industry standards for performance, reliability, and durability. Our team of quality control experts conducts rigorous inspection procedures to ensure that all our products meet the highest quality standards.In addition to delivering high-quality circuit boards, we also provide a range of value-added services that help our customers in their PCB design and manufacturing processes. Our in-house engineering team has extensive experience in PCB design, layout, and assembly, and can provide design assistance and prototyping services to customers who need them.We also offer a range of customization options, such as surface finish, solder mask color, and silkscreen printing, to help customers achieve their desired PCB specifications. Our commitment to customer satisfaction extends to all aspects of our business, from product quality to customer service.At Blank Circuit Boards, we believe in building long-lasting relationships with our customers. Whether you are a small start-up or a large corporation, we are committed to providing you with the highest quality products and services at competitive prices. Our team is dedicated to meeting your needs and exceeding your expectations, so you can focus on your core business activities.In conclusion, blank circuit boards are a versatile and cost-effective solution for electronic projects. At Blank Circuit Boards, we are committed to delivering high-quality circuit boards that meet or exceed industry standards for performance, reliability, and durability. Our value-added services, customization options, and commitment to customer satisfaction make us the go-to supplier for all your blank circuit board needs. Contact us today to see how we can help you achieve your PCB goals.

Discover the Benefits of Using High-Quality FR-4 PCB Boards

The use of technology has become an integral part of our daily lives. From the way we communicate with each other to the way we work, technology has played a crucial role in our lives. As technology continues to evolve, so do the devices we use. One of the most important components of modern technology is the Printed Circuit Board or PCB.A PCB is used to connect electronic components using conductive pathways or traces etched from copper sheets. These pathways help to provide power and connectivity to electronic devices. PCBs can be found in almost every electronic device we use, from smartphones to laptops to cars.As PCBs have become more complex and smaller in size, there has been a growing demand for high-quality PCBs that offer excellent performance and reliability. This is where Fr4 PCB Board comes in. Fr4 PCB Board is a high-performance PCB that is widely used in various electronic devices.Fr4 PCB Board is made from a fire-retardant material that is known for its excellent mechanical and electrical properties. This type of PCB is extremely durable and can withstand high temperatures and pressure. It is also highly resistant to chemicals, making it an ideal choice for use in harsh environments.Fr4 PCB Board is widely used in a variety of applications, including telecommunication devices, computers, and industrial equipment. The PCB is made using a specialized process that involves drilling holes in the substrate, laminating layers of copper, and etching the copper to create the desired circuit.One company that is leading the industry in the production of high-quality Fr4 PCB Board is {Brand Name Removed}. {Brand Name Removed} is a leading manufacturer and supplier of Fr4 PCB Board, providing high-quality PCBs to customers worldwide.The company prides itself on its commitment to quality and customer satisfaction. It uses the latest technology and manufacturing processes to produce PCBs that meet the highest standards of performance and reliability. {Brand Name Removed} offers a wide range of Fr4 PCB Board products, including single-layer, double-layer, and multi-layer PCBs.The company also provides customization services to meet the specific needs of its customers. This includes designing and building PCBs that are tailored to the customer's requirements. {Brand Name Removed} works closely with its customers to understand their needs and provide solutions that meet those needs.One of the key factors that set {Brand Name Removed} apart from its competitors is its focus on customer service. The company has a team of experienced professionals who are dedicated to providing excellent customer service. This includes offering technical support, product guidance, and after-sales service.In addition to its commitment to quality and customer service, {Brand Name Removed} is also dedicated to environmental sustainability. The company uses environmentally friendly processes to produce its PCBs and works to reduce its carbon footprint.Overall, Fr4 PCB Board is a critical component in the modern electronic devices we use every day. The use of high-quality Fr4 PCB Board, such as those produced by {Brand Name Removed}, helps to ensure the reliability and performance of these devices. With a commitment to quality, customer service, and environmental sustainability, {Brand Name Removed} is leading the industry in the production of high-quality Fr4 PCB Board.

Top 8 Layer PCB Manufacturers: Exemplary Options for Quality Circuit Boards

article on the importance of PCBs in modern electronics.In today's world, electronic devices play an integral role in our daily lives. From mobile phones to laptops to medical equipment, we rely heavily on these gadgets. As we continue to advance technologically, the need for smaller, faster, and more efficient devices increases. This is where PCBs become critical, as they provide a crucial foundation for electronic components.Printed Circuit Boards (PCBs) are thin, flat boards made from insulating material with conductive pathways etched on its surface. These pathways or copper traces connect the electronic components and provide electrical connections between them. The use of PCBs has replaced the traditional wire-based circuits, as they are more reliable, robust, and compact. Moreover, PCBs enable designers to create intricate circuits and reduce the overall electronic device size significantly.One of the major advantages of PCBs is their versatility. They can design and manufacture in various shapes and sizes, depending on the application. They can feature a single layer with a few components or a multi-layered board with hundreds of components. Furthermore, PCBs can work over a wide range of frequencies, from radio frequencies to high-speed digital data rates.The PCB manufacturing process is complex and follows a set of procedures to ensure that the end product is of high quality. The manufacturing starts with designing the circuit layout on a computer-aided design software (CAD). The layout specifies the placement of components and traces, which should work correctly to achieve the desired output. After this, the design is exported to a manufacturing machine, which etches the copper traces on the board. Once the traces are complete, the board goes through a series of quality checks to avoid any defects. The next phase is to drill holes for the components and apply a solder mask to prevent any short circuits. Finally, the board is tested for electrical continuity and quality.A PCB manufacturer plays a crucial role in determining the performance and reliability of the electronic device. A manufacturer with experience and expertise can ensure that the board meets the desired specifications and standards. Furthermore, a good PCB manufacturer continuously upgrades its technologies and manufacturing techniques to cater to the increasing demand for high-performance devices.In light of this, 8 Layer PCB Manufacturer is one of the leading companies in the industry. With more than 20 years of experience, the company has established itself as a provider of high-quality PCBs. The company specializes in manufacturing multi-layered boards, rigid-flex, and HDI PCBs. 8 Layer PCB Manufacturer follows strict quality control procedures and provides 24/7 customer support to ensure that its clients get the best products and services.The importance of PCBs can be seen in various industries, such as automotive, healthcare, aerospace, and consumer electronics. They are used in critical applications, such as pacemakers, airplanes, and control systems. These industries demand high-quality, reliable, and efficient PCBs to meet their specific requirements.In conclusion, PCBs are an essential component of electronic devices, and their importance will continue to grow as we advance technologically. With the increasing demand for compact, fast, and efficient devices, the role of PCBs becomes even more crucial. A reliable and competent PCB manufacturer, such as 8 Layer PCB Manufacturer, is vital to meeting the demands of the industry. The use of high-quality PCBs ensures that electronic devices are reliable, robust, and efficient, which is crucial in today's interconnected world.

Sustainable Copper Circuit Boards: Key Material for Electronic Devices

In recent years, Circuit Board Copper has been making waves in the electronics industry, providing efficient and reliable copper materials for a range of applications. The company is renowned for its quality copper products that deliver precise and stable performance, ensuring the success of critical projects.Founded over a decade ago, Circuit Board Copper has forged a reputation for excellence in the industry with an unwavering commitment to quality and customer satisfaction. The company has invested in advanced technology and skilled engineers to ensure that it is at the frontline of innovation. As such, it has become a trusted supplier of high-performance copper materials for various industries, including electronics, energy, transportation, and telecommunications.For instance, the electronics industry is one of the main beneficiaries of the company's products, as it requires high-quality copper materials for the production of printed circuit boards (PCBs). PCBs are critical components used in electronic devices, and they are essential for the functionality and durability of the devices. Circuit Board Copper's copper materials deliver superior conductivity, thermal dissipation, and mechanical strength, making them ideal for PCB manufacturing.Besides electronics, Circuit Board Copper's products are also suitable for the energy sector. As the world shifts towards renewable energy, the need for efficient and cost-effective energy storage solutions has increased. Some of the critical components of these solutions are batteries, which require copper materials for their wiring and interconnects. Circuit Board Copper's high-performance copper materials are ideal for battery manufacturing, as they offer excellent electrical conductivity, corrosion resistance, and thermal management properties.Similarly, the transportation industry is another sector that benefits from Circuit Board Copper's products. The company's copper materials are used in the production of hybrid and electric vehicles (EVs). EVs require efficient power and data transmission, and copper materials play a critical role in enabling this. As such, Circuit Board Copper's copper products deliver optimal performance in terms of thermal management, conductivity, and durability, ensuring that EVs operate effectively.Moreover, the telecommunications industry is also a significant consumer of Circuit Board Copper's copper materials. With the increasing demand for high-speed data transmission, telecommunication companies require copper materials that can facilitate efficient data transmission and prevent signal loss. Circuit Board Copper's products are ideal for this purpose, as they deliver high electrical conductivity and low attenuation, making them reliable for data transfer.Circuit Board Copper's commitment to quality and innovation has earned it a reputation as a leading supplier of copper materials in the industry. The company has implemented rigorous quality control measures to ensure that its products meet or exceed industry standards. Additionally, it has a team of skilled engineers who work tirelessly to research and develop new products that cater to the evolving needs of the industry.In conclusion, Circuit Board Copper's contribution to the electronics industry, energy sector, transportation, and telecommunications is undeniable. The company's high-quality copper materials have played a crucial role in the manufacturing of critical components in these industries, enabling them to deliver products that meet the needs of consumers. As the world continues to demand better and more efficient products, Circuit Board Copper is well-positioned to meet these demands with its cutting-edge technology and dedication to excellence.

China's Electronic Manufacturing Plant: Circuit Assembly Factory Production Goes Into Full Swing

article about the assembly factory and its services.China Circuit Assembly Factory: Providing Reliable and High-Quality Assembly ServicesThe advancement of technology has drastically changed the way we live, communicate, and work. One of the most notable innovations that have revolutionized multiple industries is the development of electronics. They have become an essential part of our daily routine. The creation, designing, and manufacturing of electronic products require different types of components and precise assembly procedures. Assembling electronic devices involves assembling individual components in a specifically designed circuit board. Many companies rely on outsourcing their circuit board assembly processes to reliable and experienced circuit assembly factories to ensure product quality. In China, one of the most trusted circuit assembly companies is the China Circuit Assembly Factory.About the CompanyChina Circuit Assembly Factory is a Chinese-based company that specializes in printed circuit board (PCB) assembly services. It is a subsidiary of a well-established electronic manufacturing service provider, with over two decades of experience in the industry. The company comprises a team of experienced professionals who have an excellent understanding of the assembly processes and use the latest technologies to ensure high-quality products. They offer circuit board assembly services for different electronics products, including but not limited to, consumer electronics, telecommunications, automotive, industrial, medical, aerospace, and military.Service OfferingsChina Circuit Assembly Factory offers a wide range of PCB assembly services to their clients. These services include:1. Surface Mount Technology (SMT) AssemblySMT is a widely used technique in building modern circuit boards that use surface-mounted components. It is a process of assembling a circuit board by attaching the components directly to the surface of the board instead of running wires or inserting leads through holes. The process involves using high-precision automated equipment to ensure component accuracy and consistency. China Circuit Assembly Factory uses state-of-the-art equipment and processes to ensure efficient and reliable SMT assembly services.2. Through-Hole AssemblyThrough-hole assembly is a traditional method of assembling a PCB by running leads through holes in the board and soldering the components from the top side. This technique is suitable for applications that require high mechanical strength. China Circuit Assembly Factory has skilled technicians to provide quality through-hole assembly services using the latest techniques and equipment.3. Box Build AssemblyBox build assembly is the process of assembling a finished product by integrating the circuit boards and other components into an enclosure or packaging. This process includes mechanical assembly, wire harnessing, and testing. China Circuit Assembly Factory offers reliable and cost-effective box build assembly services to their clients.4. Prototype AssemblyPrototype assembly is an essential step in the development of any electronic product. It is the process of assembling a few units of the product to test the design, function, and performance. China Circuit Assembly Factory has a team of skilled engineers who can assist their clients in the prototype development phase by providing high-quality assembly services.Quality AssuranceChina Circuit Assembly Factory understands that quality is essential in the electronics industry. They have implemented a strict quality control system for all their services to ensure that their clients get only the best products. The quality control process includes the use of high-quality raw materials, robust assembly processes, and rigorous testing procedures. They also have a team of dedicated quality inspectors who oversee the manufacturing process to ensure compliance with the quality standards.ConclusionThe China Circuit Assembly Factory is a reliable and trustworthy assembly company that offers high-quality and cost-effective circuit board assembly services. Their commitment to providing only the best services has earned them a reputation among their clients as the go-to assembly factory in China. With their state-of-the-art equipment, skilled technicians, and strict quality control, they can meet the demands of different industries and provide reliable and consistent services. If you are looking for a reliable circuit assembly factory, China Circuit Assembly Factory is the perfect choice.

What are LED Circuit Board Lights and How Do They Work?

Title: Illuminating the Future: Revolutionary LED Circuit Board Lights Set to Transform the Lighting IndustryIntroduction:In a breakthrough development that promises to revolutionize the lighting industry, a leading company has unveiled an innovative range of LED circuit board lights. Stripping off the traditional brand name, these state-of-the-art lighting solutions not only offer unparalleled energy efficiency but also boast superior brightness, longevity, and customization options to meet the diverse needs of consumers worldwide. As sustainable lighting becomes increasingly important, this groundbreaking introduction is set to leave a lasting impact on both domestic and commercial sectors.Unveiling the LED Circuit Board Lights:The latest offering from the company represents a significant leap forward in the lighting industry. By integrating cutting-edge LED technology into efficient circuit boards, these lights are able to provide brilliant illumination while consuming minimal energy. This impressive efficiency can lead to substantial cost savings and reduced carbon footprint, positioning the LED circuit board lights as a viable, eco-friendly alternative to conventional lighting solutions.Exceptional Brightness and Longevity:One key advantage of these LED circuit board lights is their ability to produce an exceptional level of brightness. Thanks to advanced light-emitting diodes, these lights emit a crisp and uniform illumination that enhances any space. The extended lifespan of LED technology ensures that these lights will provide unrivaled longevity, significantly reducing maintenance costs for both residential and commercial users.Customization Options:Recognizing the diverse needs of consumers, these LED circuit board lights are available in various shapes and sizes to cater to specific requirements. Whether it's for ambient lighting, task lighting, or accent lighting, these lights have the flexibility to transform any environment. Moreover, the customizable color spectrum allows users to tailor the lighting experience according to their preferences, creating an ambiance that perfectly complements any setting.Energy Efficiency and Environmental Sustainability:At a time when energy efficiency is of utmost importance, the LED circuit board lights have emerged as a game-changer. Consuming considerably less energy compared to traditional incandescent lights, they contribute to substantial energy savings and a reduced carbon footprint. The adoption of LEDs will undoubtedly aid in combating climate change and reducing electricity bills for eco-conscious consumers worldwide.Versatile Applications:The versatility of these LED circuit board lights opens up a plethora of applications across various sectors. From residential spaces to commercial establishments, these lights are ideal for lighting up homes, offices, restaurants, hotels, and retail outlets. Their exceptional design and functionality allow for seamless integration into existing lighting systems, ensuring a hassle-free transition for businesses and homeowners alike.Advancements in Smart Technology Integration:The company's focus on innovation extends to incorporating smart technology compatibility into their LED circuit board lights. With Internet of Things (IoT) becoming increasingly prevalent, users can now control lighting settings remotely, create automated schedules, and monitor energy consumption through intuitive smartphone apps or voice assistants. This integration of smart technology enhances convenience, maximizes energy savings, and further solidifies the company's commitment to pushing the boundaries of lighting solutions.Conclusion:As the world clamors for energy-efficient lighting solutions, the unveiling of the LED circuit board lights by this pioneering company signifies a breakthrough that will transform the lighting industry. With unparalleled brightness, longevity, customizable options, and energy efficiency, these lights are set to revolutionize the way residences and businesses illuminate their spaces. Embodying environmental sustainability and versatility, these LED circuit board lights herald a bright and efficient future for the lighting industry.