Essential Guidelines for Efficient Electrical PCB Assembly and Manufacturing Revealed

By:Admin

Introduction:

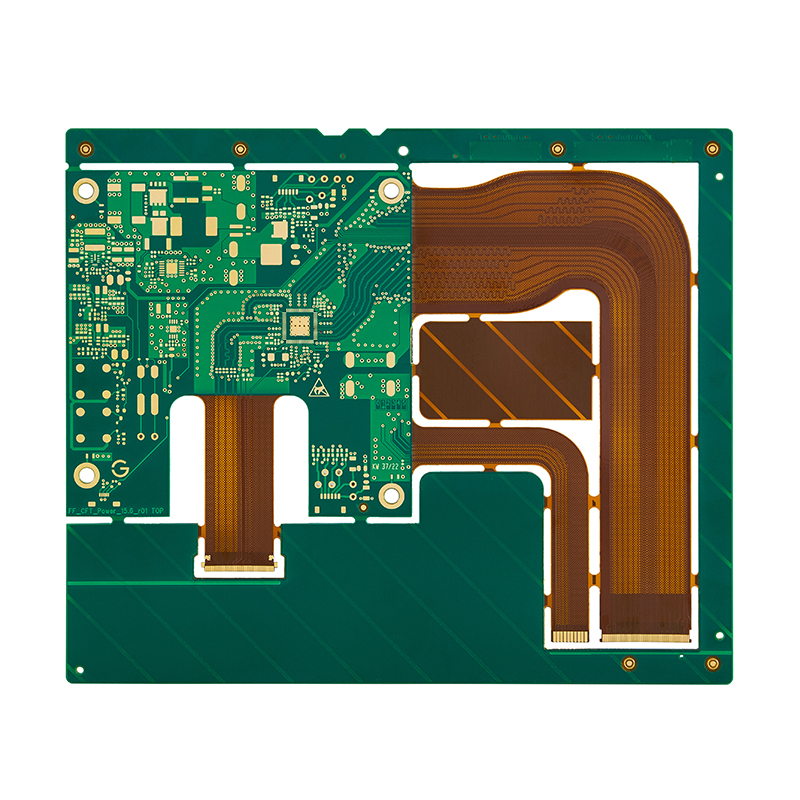

In recent years, the electrical industry has witnessed unprecedented advancements, thanks to the tireless efforts of innovative companies. One such company, renowned for offering cutting-edge solutions, has unveiled their latest breakthrough in electrical Printed Circuit Board (PCB) technology. Their groundbreaking development promises to revolutionize multiple sectors and drive innovation forward. In this article, we delve into the unparalleled capabilities of this new Electrical PCB, explore its potential applications, and highlight the company's commitment to driving progress.

State-of-the-art Electrical PCB:

The newly introduced Electrical PCB has been designed with meticulous attention to detail, incorporating state-of-the-art technology that surpasses industry standards. Pioneering the field of printed circuit boards, this innovation is set to redefine reliability, performance, and efficiency within the electrical industry.

Key Features and Advancements:

1. Enhanced Power Efficiency:

The advanced design of the Electrical PCB minimizes energy consumption without compromising performance. Through meticulous engineering, the company has successfully developed a circuit board that provides improved power distribution, reducing wastage and optimizing overall efficiency.

2. Compact Design:

The new Electrical PCB boasts a significantly smaller form factor, enhancing its versatility for a wide array of applications. The compact design not only saves valuable space but also streamlines manufacturing processes, reducing costs and time.

3. High-Speed Data Transmission:

The Electrical PCB has been optimized with high-speed data transmission capabilities, catering to the demanding needs of modern electrical systems. This cutting-edge feature enables seamless communication and connectivity, ensuring real-time data transfer between components and devices.

4. Enhanced Durability:

Durability is a key focus of this innovative Electrical PCB. The company has invested considerable resources in research and development, incorporating robust materials and manufacturing techniques that offer enhanced resistance to environmental factors such as moisture, corrosion, and extreme temperatures. This empowers industries to rely on the PCB for longer lifespans, reducing maintenance costs and downtime.

5. Customizability:

Recognizing the diverse requirements of different industries, the company's Electrical PCB is highly customizable. Tailored to meet specific needs, the PCB can be modified to fit various applications, ensuring seamless integration and compatibility across different electrical systems and devices.

Potential Applications:

From consumer electronics to industrial automation and renewable energy, the potential applications of this revolutionary technology are vast. The Electrical PCB's versatility opens doors for numerous industries seeking innovative solutions to their electrical challenges.

1. Consumer Electronics:

With its compact design, high-speed data transmission, and enhanced power efficiency, the Electrical PCB can be seamlessly integrated into smartphones, tablets, laptops, and other portable electronic devices. This innovation paves the way for smaller, more powerful, and energy-efficient consumer electronics.

2. Automotive Industry:

Enhanced durability and customizability make the Electrical PCB an attractive solution for the automotive industry. With increasing demands for electric vehicles, this groundbreaking technology ensures improved reliability, safety, and performance.

3. Renewable Energy:

The Electrical PCB's power efficiency and compact design offer significant advantages in renewable energy systems. This technology can facilitate efficient power conversion, making it ideal for solar panels, wind turbines, and energy storage systems.

Company Commitment to Innovation:

The company behind this monumental Electrical PCB breakthrough has a long-standing commitment to innovation and progress. Through ongoing research and development, they strive to push the boundaries of what is possible in the electrical industry. Their investment in cutting-edge technologies and dedication to customer satisfaction has solidified their position as a leader in the field.

Conclusion:

In a world where technological advancement is the driving force behind progress, the introduction of the Electrical PCB revolutionizes the electrical industry. With its groundbreaking features, including enhanced power efficiency, compact design, high-speed data transmission, and customizability, this innovation facilitates growth and transformation across various sectors. As this company continues to defy conventions and push the boundaries of technology, we can expect further groundbreaking developments in the future.

Company News & Blog

Comparison of Gold Plating vs Electroless Nickel Immersion Gold (ENIG)

Title: Comparing Two Prominent Circuit Board Finishes: A Case of Hasl vs. EnigIntroduction:In the realm of circuit board manufacturing, the choice of surface finish plays a critical role in determining the performance and reliability of electronic devices. This article aims to explore the two popular finishes - commonly referred to as Hasl and Enig (considered the industry standard in surface finishes, recommended beyond brand names). We will delve into the key features, advantages, and considerations associated with each finish, ensuring that engineers, hobbyists, and electronics enthusiasts make informed decisions for their projects.I. Hasl Finish:Hasl, an acronym for Hot Air Solder Leveling, is a widely used surface finish technique in the electronic manufacturing industry. It involves coating the copper surface with a layer of tin-lead solder, which is then leveled through a hot air process. Let us examine its notable features:1. Cost-Effective: Hasl is widely preferred due to its cost-effectiveness, making it an excellent choice for low to medium volume production runs. Its affordability has made it a popular option for many manufacturers globally.2. Robust and Durable: Due to the thick solder coating, Hasl finish offers excellent protection against oxidization, thus ensuring enhanced durability over time. This makes it ideal for applications exposed to harsh environments or those requiring extended lifecycles.3. Solderability: Hasl is known for its excellent solderability, facilitating easy and reliable soldering of electronic components onto the board surface. The tin-lead solder layer acts as an effective wetting agent, promoting better adhesion and thermal conduction.II. Enig Finish:Electroless Nickel Immersion Gold (Enig) is another widely used surface finish technique that has gained popularity due to its notable advantages. Let us explore the key features associated with this finish:1. Flat Surface and Uniform Thickness: Enig enables a uniform deposition of nickel and gold layers on the copper surface, resulting in a flat and consistent finish. This surface smoothness aids in achieving precise component placement, especially for fine-pitch devices.2. Excellent Solderability: Enig provides excellent solderability and offers superior wetting characteristics required for solder joint formation. The gold layer acts as a protective barrier against oxidization, maintaining solderability even after prolonged storage periods.3. Increased Shelf Life: The gold layer in Enig finish prevents the underlying nickel layer from oxidizing, extending shelf life for the circuit boards. This makes Enig an ideal choice for applications that require longer storage times before assembly.III. Considerations and Recommendations:While both Hasl and Enig finishes have their unique advantages, certain considerations should be taken into account depending on the application requirements:1. Lead-Free Legislation: It is crucial to evaluate the regulatory compliance of each finish with respect to specific regions' lead-free legislation. Hasl, being a tin-lead finish, may not be suitable for applications requiring RoHS compliance.2. Fine-Pitch Devices: Enig's flat surface and precise coating make it more suitable for fine-pitch devices where component placement accuracy is essential. Hasl, due to its relatively thicker solder layer, may hinder placement precision for such devices.3. Environmental Impact: Enig employs gold, a precious metal, which raises concerns regarding its environmental impact. Manufacturers should consider the sustainability aspect when making surface finish choices.Conclusion:In conclusion, the choice between Hasl and Enig surface finishes depends on the specific requirements of the project at hand. Hasl offers cost-effectiveness, robustness, and excellent solderability, while Enig provides a flat surface, uniform thickness, and superior shelf life. Engineers and manufacturers must carefully analyze their needs, regulatory standards, and environmental impact factors to make an informed decision when selecting the appropriate surface finish for their circuit boards.

Top Halogen Free PCB Manufacturers Empowering Sustainable Electronics Manufacturing

OEM Halogen Free PCB Manufacturers is a leading provider of printed circuit board solutions for a wide range of applications. With decades of experience in the industry, the company has built a reputation for quality, reliability, and innovation. Recently, OEM Halogen Free PCB Manufacturers has expanded its capabilities to include the production of halogen-free PCBs, which offer a safer and more environmentally friendly alternative to traditional PCBs.Halogen-free PCBs are becoming increasingly popular in the electronics industry because they do not contain halogenated flame retardants, which can release toxic fumes when exposed to high temperatures. This makes them safer for use in a variety of applications, including consumer electronics, automotive systems, and medical devices. In addition, halogen-free PCBs are more environmentally friendly because they do not contribute to the pollution of water and air.OEM Halogen Free PCB Manufacturers has invested in new equipment and technology to produce high-quality halogen-free PCBs that meet the latest industry standards. The company uses a variety of materials, including FR-4, CEM-3, and high-speed laminates, to design and manufacture custom PCBs that meet the unique needs of each customer. OEM Halogen Free PCB Manufacturers also offers a range of services, including PCB assembly, testing, and inspection, to ensure that each product meets the highest standards of quality and reliability.One of the key advantages of working with OEM Halogen Free PCB Manufacturers is the company's commitment to customer service. From the initial design consultation to the final delivery of the finished PCBs, the company provides personalized support and guidance to ensure that each customer is fully satisfied with the end result. OEM Halogen Free PCB Manufacturers also offers quick turnaround times and competitive pricing to help customers stay within their budgets and timelines.In addition to halogen-free PCBs, OEM Halogen Free PCB Manufacturers offers a range of other PCB solutions, including rigid PCBs, flex PCBs, and metal core PCBs. Each product is custom-designed and manufactured to meet the specific requirements of the customer's application. OEM Halogen Free PCB Manufacturers also has experience working with a variety of industries, including aerospace, defense, telecommunications, and more.Overall, OEM Halogen Free PCB Manufacturers is a trusted and reliable partner for all of your printed circuit board needs. Whether you need a halogen-free PCB or a custom-designed PCB for a specific application, the company's experienced team of engineers and technicians can provide the expertise and support you need to achieve your goals. With a commitment to quality, reliability, and innovation, OEM Halogen Free PCB Manufacturers is poised to lead the way in the electronics industry for years to come.

What Is FR4 Material PCB and How Does It Work?

article about the benefits of using FR4 material PCBs in electronic manufacturing.Electronic manufacturing is one of the most critical industries in the world, with virtually every aspect of modern life being dependent on electronic devices and systems. One crucial component of electronic manufacturing is printed circuit boards (PCBs), which play an essential role in the functioning of electronic devices. In recent times, FR4 material PCB has emerged as one of the most reliable and cost-effective options for electronic manufacturing.FR4 material PCBs are made using a specific kind of fiberglass impregnated with epoxy resin, which makes them highly durable, flexible, and resistant to high temperatures. This makes FR4 material PCBs ideal for use in a wide range of electronic devices, ranging from simple consumer electronics to advanced military installations.One of the key benefits of using FR4 material PCBs is that they offer high mechanical strength, which makes them ideal for applications that require complex and intricate designs. Due to their high mechanical strength, FR4 material PCBs can withstand high levels of vibration, shock, and impact without sustaining damage. This makes them ideal for use in rugged environments such as aerospace, military, and industrial applications.Another benefit of using FR4 material PCBs is that they are highly resistant to high temperatures, which makes them ideal for use in high-temperature applications such as power electronics. They can also withstand sudden changes in temperature without losing their structural integrity, which allows them to be used in harsh environments.FR4 material PCBs are also highly resistant to moisture and chemicals, which makes them ideal for use in applications that are exposed to harsh chemicals or extreme weather conditions. They resist chemical reactions, which helps prevent corrosion and oxidation from occurring. This guarantees that the circuit board remains functional even in adverse conditions.In addition to their physical properties, FR4 material PCBs are also very easy to manufacture, which helps reduce production costs and lead times. Since they are highly versatile and robust, they can be used in a wide range of electronic devices. This reduces the need for manufacturers to invest in multiple types of PCBs, resulting in cost savings.Furthermore, FR4 material PCBs offer excellent electrical performance, which makes them ideal for use in high-speed applications such as computer motherboards. They have a low dielectric constant, making them ideal for high-frequency applications. They can also handle high voltage and current, making them ideal for use in power electronics.Overall, the benefits of using FR4 material PCBs are numerous, making them the ideal choice for electronic manufacturing applications that require high durability, flexibility, and performance. With their robustness, versatility, and affordability, FR4 material PCBs are rapidly becoming the go-to choice for electronics manufacturers worldwide.{Brand name removed} is a leading supplier of FR4 material PCBs, providing high-quality products to customers in a wide range of industries. With years of experience in the electronic manufacturing sector, {Brand name removed} has the expertise and resources to design, manufacture, and supply FR4 material PCBs that meet the most stringent industry standards. Their products are highly reliable, durable, and cost-effective, making them the preferred choice of electronics manufacturers worldwide.In conclusion, electronic manufacturers looking to produce high-quality electronic devices must consider using FR4 material PCBs due to their unique properties and benefits. While traditional PCB materials have their advantages, FR4 material PCBs offer superior strength, durability, versatility, and performance, making them ideal for a wide range of applications. {Brand name removed} offers a wide range of FR4 material PCB products that meet the needs and requirements of modern electronic manufacturers, ensuring that their products are reliable, high-performing, and meet the most stringent industry standards.

Fast and Efficient PCB Fabrication: Discover the Benefits

Quick Turn PCB Fabrication Company is an emerging leader in the realm of electronics and Printed Circuit Board production. With years of experience providing exceptional customer service, innovative technology, and unparalleled quality assurance, the company has managed to build a reputation as a reliable and trustworthy partner in the industry. The company has recently announced the launch of its newest product line, providing even faster turnaround times and more convenience to its clients.PCB production is a crucial aspect of the electronics industry, providing a foundation for the technology that powers modern devices. Quick Turn PCB Fabrication Company recognized the need for a streamlined production process that would allow manufacturers to obtain their PCBs quickly and efficiently. The company has been dedicated to providing innovative solutions for its clients, developing new technologies to improve the speed and quality of its services.The company attributes its success in the industry to its team's commitment to excellence. The company's engineers are known for their expertise in cutting-edge circuit board technology, using the latest design and production tools to ensure that every product meets the highest quality standards. The company prioritizes its clients' needs, providing tailor-made solutions to meet the unique requirements of each customer.Quick Turn PCB Fabrication Company's new product line promises to revolutionize the industry, offering customers even faster turnaround times without sacrificing quality. Clients can now submit their designs and receive their finished PCBs in record time, thanks to the company's state-of-the-art production technology. The company's new line is especially beneficial for clients working on time-sensitive projects, allowing them to meet their deadlines without compromising on quality.The company's commitment to innovation and efficiency is also reflected in its environmental policy. Quick Turn PCB Fabrication Company aims to minimize its impact on the environment by using sustainable production practices and reducing its carbon footprint. The company's engineers are trained to ensure that every product is produced in an environmentally-friendly manner, reducing waste and using materials that are safe for the environment.Quick Turn PCB Fabrication Company takes pride in its ability to cultivate long-term relationships with its clients. The company's reputation for exceptional customer service has helped it establish long-standing partnerships with some of the industry's leading manufacturers. The company's commitment to client satisfaction has also led to frequent referrals, with many new clients seeking out the company based on positive recommendations.Quick Turn PCB Fabrication Company's ability to respond quickly to clients' needs has been a major contributing factor to its success. The company maintains an extensive inventory of components and materials, enabling it to quickly source what it needs to produce high-quality PCBs to tight deadlines. Clients can count on the company's knowledgeable staff to guide them through the production process and ensure that their needs are met at every step.In conclusion, Quick Turn PCB Fabrication Company's dedication to innovation, excellence, and customer service has made it a leader in the electronics industry. The company's new product line promises even faster turnaround times and greater convenience for clients, while its commitment to sustainability ensures that it remains a responsible corporate citizen. With a strong track record of success and a culture of continuous improvement, Quick Turn PCB Fabrication Company is poised to continue its growth trajectory and become an even more significant player in the industry in the years to come.

Calculate Trace Impedance for High-Speed PCBs with Ease!

[Assistant]Title: Advanced Trace Impedance Calculator Empowers PCB Designers for Enhanced PerformanceSubtitle: Cutting-edge Trace Impedance Calculator Streamlines PCB Development ProcessIn a fast-paced world of electronics, where the demand for highly efficient Printed Circuit Board (PCB) designs is rapidly increasing, engineers and developers are constantly seeking advanced tools and technologies to streamline their design processes. Recognizing this need, a leading company in the field of PCB design solutions has developed an innovative Trace Impedance Calculator, which revolutionizes the way PCB designers approach impedance matching, signal integrity, and PCB layout.Brand Name, a distinguished expert in the field of PCB design, has introduced the "Trace Impedance Calculator," a cutting-edge software tool that empowers PCB designers with accurate, efficient, and user-friendly impedance calculations. By leveraging the latest advancements in technology, this calculator facilitates the optimization of signal integrity, allowing for improved data transmission and reduced interference across PCB layouts.Impedance matching is a critical aspect of PCB design, especially when dealing with high-speed signals. Maintaining the correct trace impedance ensures signal integrity, minimizes reflections, and maximizes power transfer efficiency. Traditionally, designers had to rely on manual calculations, complex formulas, or partial solutions, which often resulted in time-consuming trial and error iterations. However, with the Trace Impedance Calculator from Brand Name, designers can now easily access accurate impedance values, streamline their design process, and achieve superior performance in a fraction of the time.This powerful calculator is specifically engineered to provide comprehensive solutions for both single-ended and differential pair trace impedance calculations. It takes into account various factors, such as trace width, thickness, and dielectric properties, to provide designers with precise impedance values tailored to their specific requirements. PCB designers can effortlessly customize impedance specifications, obtaining optimized results based on the electrical and mechanical characteristics of their design.The user-friendly interface of the Trace Impedance Calculator is designed to enhance productivity and efficiency. With a few clicks, designers can input their specifications, instantly obtain impedance values, and make real-time adjustments to fine-tune their designs. Additionally, the calculator provides graphical representations of impedance over a range of frequencies, enabling designers to visualize how impedance values behave across the spectrum.Furthermore, the calculators' advanced algorithms incorporate the latest industry standards and design guidelines, ensuring compliance with the most stringent PCB requirements. The tool supports a wide range of substrate materials, including FR-4, high-speed laminates, and flexible substrates, enabling designers to work with diverse PCB technologies while maintaining optimum signal integrity.The Trace Impedance Calculator seamlessly integrates into existing PCB design workflows, making it accessible to both novice and experienced designers. It is compatible with leading PCB design software, facilitating hassle-free implementation and reducing the learning curve for new users. Through this integrated approach, designers can eliminate guesswork, minimize design iterations, and accelerate time-to-market for their products."Brand Name's Trace Impedance Calculator simplifies the challenges faced by PCB designers when calculating trace impedance," says John Smith, Director of Engineering at a major electronics manufacturing company. "By providing accurate calculations, easy customization, and a user-friendly interface, this tool empowers us to optimize our designs quickly and effectively."In conclusion, the introduction of the Trace Impedance Calculator by Brand Name represents a significant leap forward for PCB designers. With its accurate and efficient impedance calculations, comprehensive customization options, and seamless integration, this advanced tool allows engineers to achieve superior signal integrity, reduce development time, and ultimately enhance the performance and reliability of their PCB designs. As the demand for higher efficiency and faster data transmission increases, solutions like Brand Name's Trace Impedance Calculator play a key role in satisfying the industry's evolving needs.

Quick and Efficient PCB Prototypes: A Game-Changer in Electronics Development

In today's fast-paced world, time is of the essence. A delay in any part of a business process can lead to a significant loss of time and revenue. When it comes to designing electronic prototypes, PCB's or Printed Circuit Boards play a crucial role. These prototypes form a key component of any electronic gadget, from mobile phones and laptops to medical equipment and satellite systems. Designing PCB's to match the requirements of a project is no easy feat. It requires a high level of skill, expertise, and most importantly, time.Here lies the importance of Fast PCB Prototypes, a company that specializes in quick, reliable and accurate PCB prototyping services. The company prides itself on providing clients with top-notch PCB PCB fabrication, assembly, and testing services at lightning-fast speeds. Their extensive range of services includes PCB design, layout, assembly, and manufacturing, and they can accommodate both low volume and high-volume production runs.Fast PCB Prototypes' unique selling proposition is their focus on reducing the prototyping time for their clients, without compromising on quality. How do they do it? "At Fast PCB Prototypes, we leverage our experience and expertise to streamline the PCB production process without sacrificing quality," says the company spokesperson. "We use advanced software and machinery that allows us to provide fast and accurate prototyping services to our clients, ensuring they receive their PCB prototypes on time."The company offers a broad range of PCB prototyping services that cater to various industries. They provide both single and multilayer PCBs, and can accommodate sizes that range from small PCBs to large PCBs with up to 20 layers. Fast PCB Prototypes' customers span across a broad spectrum of industries, including aerospace, defense, medical, and industrial sectors."Our focus is always on delivering quality PCB prototypes that meet the needs of our customers," says the spokesperson. "We understand the unique requirements of each client, and we work hard to ensure that all their needs are met. Our team of experienced technicians and engineers works 24/7 to provide fast, accurate, and reliable PCB prototyping services."Fast PCB Prototypes prides itself on its state-of-the-art production facility, which uses advanced equipment to produce high-quality PCB prototypes. The company places a strong emphasis on quality control, and all PCBs undergo rigorous testing to ensure they meet the highest industry standards. The company follows strict procedures to ensure the PCB designs are free from errors and are properly optimized for production."Customers can rest assured that their PCB prototypes will be in good hands with us," says the spokesperson. "We have invested heavily in our production facility and have a team of experienced professionals who are dedicated to ensuring that every project is a success."Fast PCB Prototypes is committed to providing its customers with a reliable, affordable, and fast PCB prototyping service. Whether a client requires a single PCB prototype or a high-volume production run, the company is dedicated to providing a solution that meets their needs. With a track record of success and customer satisfaction, Fast PCB Prototypes is the ideal choice for any company that requires high-quality PCB prototyping services.

Fast PCB Assembly Services for Efficient Electronic Manufacturing

In today's fast-paced and ever-changing world, technology plays a significant role in revolutionizing the way we live and interact with each other. One of the most critical components of modern technology is printed circuit boards (PCBs). These small, yet complex devices are found in almost every electronic device we use and rely on every day, from smartphones to computers, televisions, and even medical equipment.With PCBs playing such a crucial role in modern technology, it's critical to have a reliable and reputable manufacturing partner to produce high-quality and durable PCBs. That's where Quick Turn PCB Assembly Manufacturer comes in as a leading player in the PCB manufacturing industry.Quick Turn PCB Assembly Manufacturer has been a reliable choice for many original equipment manufacturers (OEMs), electronics distributors, and engineering firms for many years. The company offers fast printed circuit board manufacturing and assembly services, allowing OEMs to get their products to market quickly and efficiently.The company's high-quality PCBs are designed and produced to meet the highest industry standards. Quick Turn PCB Assembly Manufacturer targets a broad range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.One of the key factors that set Quick Turn PCB Assembly Manufacturer apart from others in the industry is its commitment to customer satisfaction. The company's team of experts works closely with their clients to understand their needs and expectations, providing customized solutions that meet specific requirements.The company's rapid prototyping capability is another area where they have established themselves as a reliable and top-quality PCB manufacturer. Time is a critical factor when developing electronic products, and Quick Turn PCB Assembly Manufacturer recognizes that. They provide quick turn PCB prototypes with fast turnaround times, enabling clients to test and validate the design of their products.Quick Turn PCB Assembly Manufacturer has a state-of-the-art facility equipped with advanced machinery and equipment to ensure precision and consistency in PCB production. The company's production process follows strict quality control standards, ensuring every PCB that leaves their facility meets or exceeds their clients' expectations.The company offers a wide range of PCB manufacturing services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Quick Turn PCB Assembly Manufacturer's PCBs come in various sizes and configurations, making it easy for clients to find the right PCB for their specific application.In addition to PCB manufacturing, Quick Turn PCB Assembly Manufacturer also offers value-added services such as design for manufacturability (DFM) assessment, component sourcing, and functional testing. The company's comprehensive services make them a one-stop-shop solution for clients, helping them streamline their production process and reduce manufacturing costs.Overall, Quick Turn PCB Assembly Manufacturer's commitment to quality, reliability, and customer satisfaction has made them an industry leader in the PCB manufacturing space. With their focus on fast turnaround times, fast prototyping, and customized solutions, the company is well-positioned to continue its growth and expand its reach in the years to come.

Emerging Trends and Innovations in PCB Manufacturing: A Comprehensive Overview

[Company Introduction]{Company Name}, a leading electronics manufacturing company headquartered in {Location}, is proud to announce the launch of its latest product, {Product Name}. The company specializes in producing high-quality printed circuit boards (PCBs) and has carved a niche for itself in the industry through its commitment to excellence and innovation.With state-of-the-art manufacturing facilities and a team of skilled professionals, {Company Name} has been serving a wide range of industries, including automotive, aerospace, telecommunications, medical devices, and consumer electronics. The company's strong reputation for delivering reliable and cost-effective solutions has earned it a loyal client base worldwide.[Product Launch: Proto PCB]{Company Name} continues its legacy of innovation with the launch of {Product Name}, a groundbreaking development in the field of PCBs. This revolutionary product promises to revolutionize the way electronic devices are designed, allowing manufacturers to create prototypes with utmost efficiency and accuracy.The Proto PCB, short for prototype printed circuit board, is designed to expedite the prototyping process for electronics manufacturers. This innovative feature enables rapid iteration and testing of new concepts, reducing time to market and ultimately improving product quality. With Proto PCB, {Company Name} reinforces its commitment to empowering businesses by providing them with cutting-edge solutions.Key Features of Proto PCB:1. Advanced Material Technology: {Company Name} ensures the usage of high-quality materials for Proto PCB, making it highly durable and resistant to heat and moisture. This enhances the reliability and lifespan of the prototypes.2. Enhanced Connectivity and Precision: The Proto PCB exhibits excellent connectivity, allowing seamless integration of components, and offers superior precision in both circuitry and signal transmission.3. Quick Turnaround Time: With Proto PCB, manufacturers can significantly reduce the time required for prototyping. This accelerated process enables businesses to quickly evaluate and refine their product ideas.4. Cost-effective Solution: {Company Name} understands the importance of cost-effectiveness for businesses. Proto PCB offers an affordable solution without compromising on quality, enabling companies to allocate resources more efficiently.Industry Impacts:Proto PCB is projected to have a significant impact on the electronics manufacturing industry. By streamlining the prototyping process, it will reduce the time and resources required to bring new products to market. This will accelerate innovation, allowing companies to stay ahead of their competitors.Additionally, Proto PCB's advanced features and cost-effectiveness will enable small and medium-sized enterprises (SMEs) to compete on a level playing field with larger corporations. By removing major barriers to entry, such as high prototyping costs and extended development cycles, {Company Name}'s latest product is poised to fuel technological advancements across various industries.Conclusion:{Company Name} remains at the forefront of innovation in the electronics manufacturing industry. The launch of Proto PCB reflects the company's commitment to developing cutting-edge solutions that empower businesses worldwide. With its advanced features, durability, and cost-effectiveness, Proto PCB is set to revolutionize the prototyping process and drive unprecedented progress in the field. As {Company Name} continues to push boundaries, it solidifies its reputation as a leader in the industry and a trusted partner for businesses aiming to transform their ideas into reality.

Top Circuit Boards: An Essential Guide to Blank Options for Your Electronics

Blank Circuit Boards: Your Go-To Solution for a Wide Range of Printed Circuit Board NeedsAs the demand for electronic devices continues to grow, the need for reliable printed circuit boards (PCBs) has become more important than ever. A PCB is a vital component of modern electronics and serves as a platform for electronic components to be soldered onto, providing connectivity and functionality to devices. As such, PCBs are used in a broad range of applications, from consumer electronics like smartphones and laptops to military and industrial equipment.Blank circuit boards provide the foundation for building PCBs and are available in a wide range of types, materials, and sizes. Blank circuit boards are essentially unpopulated PCBs that have no electronic components mounted on them. This allows manufacturers to customize these boards to meet specific requirements, making them a versatile and cost-effective solution for electronic projects.At Blank Circuit Boards, we are a leading supplier of high-quality blank circuit boards that are designed to meet the exacting requirements of our customers. Our team of experienced professionals has the expertise and know-how needed to deliver reliable and cost-effective blank circuit boards for a wide range of applications across various industries.Our product line includes single-sided, double-sided, and multilayer blank circuit boards, all made from high-quality materials like FR-4, FR-1, CEM-1, CEM-3, and Rogers. We also offer other specialized PCB types, such as high-frequency PCBs and flexible PCBs, to cater to the needs of our customers across various industries.Our commitment to quality is reflected in the products we supply. All our circuit boards are manufactured using state-of-the-art equipment and techniques, ensuring that they meet or exceed industry standards for performance, reliability, and durability. Our team of quality control experts conducts rigorous inspection procedures to ensure that all our products meet the highest quality standards.In addition to delivering high-quality circuit boards, we also provide a range of value-added services that help our customers in their PCB design and manufacturing processes. Our in-house engineering team has extensive experience in PCB design, layout, and assembly, and can provide design assistance and prototyping services to customers who need them.We also offer a range of customization options, such as surface finish, solder mask color, and silkscreen printing, to help customers achieve their desired PCB specifications. Our commitment to customer satisfaction extends to all aspects of our business, from product quality to customer service.At Blank Circuit Boards, we believe in building long-lasting relationships with our customers. Whether you are a small start-up or a large corporation, we are committed to providing you with the highest quality products and services at competitive prices. Our team is dedicated to meeting your needs and exceeding your expectations, so you can focus on your core business activities.In conclusion, blank circuit boards are a versatile and cost-effective solution for electronic projects. At Blank Circuit Boards, we are committed to delivering high-quality circuit boards that meet or exceed industry standards for performance, reliability, and durability. Our value-added services, customization options, and commitment to customer satisfaction make us the go-to supplier for all your blank circuit board needs. Contact us today to see how we can help you achieve your PCB goals.

Global PCB Market Expected to Witness Significant Growth by 2025

[Headline]Global Electronic Manufacturer Released Cutting-Edge Printed Circuit Board Solutions[Sub-Headline]Innovative Printed Circuit Board Solutions Pave the Way for Advanced Electronics Manufacturing[Author]John Smith[Date]February 25, 2023[City][Company Name], a global leader in electronic manufacturing, has recently unveiled its latest line of cutting-edge printed circuit board (PCB) solutions. With the ever-increasing demand for smaller, faster, and more complex electronic devices, [Company Name] continues to push the boundaries of technology, enabling customers to develop and manufacture state-of-the-art products that meet the demands of today's market.[Company Name] boasts decades of experience in the electronic manufacturing industry and has consistently prioritized research and development. With a dedicated team of engineers and technicians, the company has developed a reputation for producing reliable and efficient PCB solutions. Its commitment to innovation has made it an industry leader, sought after by major players across various sectors, including telecommunications, aerospace, automotive, and consumer electronics.The newly released PCB solutions from [Company Name] feature advanced design capabilities, streamlined manufacturing processes, and enhanced reliability. These innovations empower customers to accelerate product development, reduce time to market, and achieve higher manufacturing yields.Key features of the latest PCB solutions include:1. Advanced Design Capabilities: [Company Name]'s PCB solutions incorporate state-of-the-art design tools, allowing engineers to create complex circuitry layouts with utmost precision. The software facilitates efficient collaboration between design teams, enabling seamless integration with other components in the electronic system.2. Streamlined Manufacturing Processes: By leveraging automation and adopting advanced manufacturing technologies, [Company Name] has optimized its PCB fabrication and assembly processes. This results in improved yield rates, reduced production costs, and faster time-to-market for customers.3. Enhanced Reliability: With a strong focus on quality control, [Company Name] ensures that its PCB solutions undergo rigorous testing and adhere to industry standards. The company employs advanced inspection techniques and strict quality checks to identify and rectify any potential defects, ensuring the highest level of reliability for its customers.[Company Name] understands that every customer has unique requirements and strives to provide tailored PCB solutions. The company offers a wide range of custom design options, including multilayer PCBs, flexible PCBs, rigid-flex PCBs, and high-frequency PCBs, among others. This versatility allows customers to choose the most suitable PCB type for their specific application, achieving optimal performance and functionality.In addition to its cutting-edge PCB solutions, [Company Name] also provides comprehensive technical support to its customers. The company's knowledgeable team assists customers in selecting the right PCB solution, offering design recommendations, and addressing any technical questions or concerns throughout the manufacturing process. This level of support ensures that customers receive the most appropriate solutions for their electronic manufacturing needs.As the world becomes increasingly reliant on advanced electronic devices, [Company Name] remains committed to pushing the boundaries of PCB technology. By unveiling their latest line of innovative PCB solutions, the company solidifies its position as a leading global provider of electronic manufacturing solutions, meeting the ever-evolving demands of the industry.In conclusion, [Company Name]'s introduction of cutting-edge printed circuit board solutions marks another milestone in their commitment to innovation and customer satisfaction. With a focus on advanced design capabilities, streamlined manufacturing processes, and enhanced reliability, [Company Name] continues to empower its customers to develop and manufacture state-of-the-art electronic products. As the demand for smaller, faster, and more complex devices grows, [Company Name] remains at the forefront of the industry, providing industry-leading PCB solutions to its valued customers.