Get Fast PCB Manufacturing Services for Your Business

By:Admin

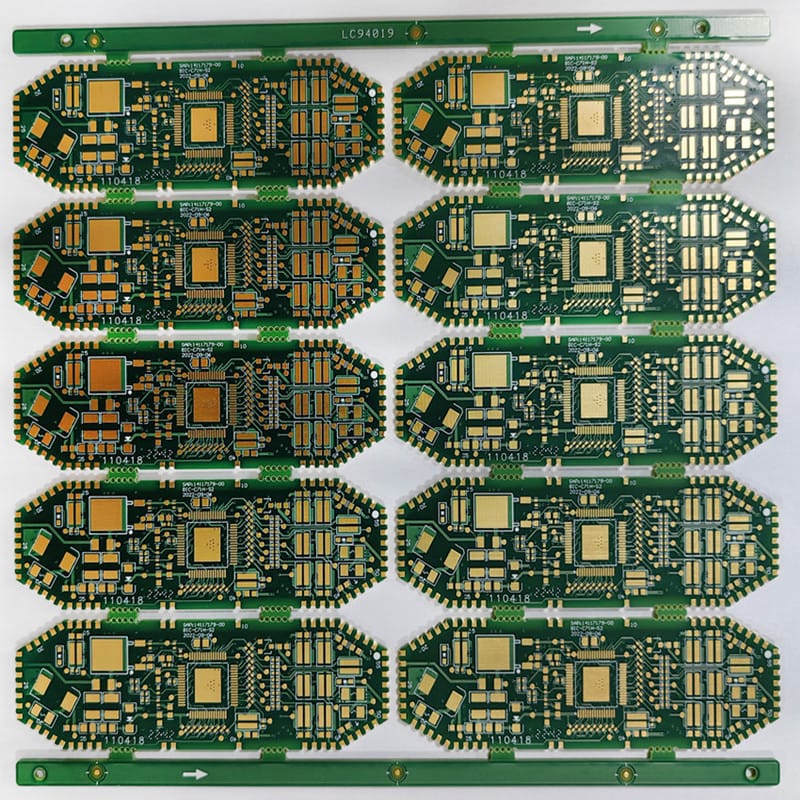

Fast PCB Service has established itself as a reliable and reputable supplier of PCBs, offering a wide range of products and services to customers in various industries, including automotive, aerospace, telecommunications, and consumer electronics. The company is known for its commitment to quality, precision, and innovation, and has built a strong reputation for delivering superior PCB solutions to meet the specific needs of its clients.

The new fast turnaround service is designed to provide customers with an expedited PCB manufacturing process, significantly reducing lead times and accelerating time-to-market for their products. With this service, Fast PCB Service can produce high-quality PCBs in as little as 24 hours, enabling customers to meet tight project deadlines and respond quickly to changing market demands.

"We understand that time is of the essence in the electronics industry, and our new fast turnaround service is aimed at helping our customers get their products to market faster," said a spokesperson from Fast PCB Service. "With our advanced manufacturing capabilities and streamlined processes, we are able to offer rapid PCB fabrication and assembly without compromising on quality or reliability."

The fast turnaround service leverages state-of-the-art equipment and cutting-edge technology to optimize the production process, from design and prototyping to manufacturing and testing. Fast PCB Service has made significant investments in its manufacturing facilities to ensure that it can meet the stringent requirements of its customers and deliver PCBs that meet the highest standards of quality and performance.

In addition to fast PCB fabrication, the new service also includes expedited assembly and delivery options, allowing customers to receive fully assembled PCBs in a fraction of the time typically required. This comprehensive approach to fast turnaround times sets Fast PCB Service apart from its competitors and positions the company as a preferred partner for customers with time-sensitive projects.

"Our new fast turnaround service is a game-changer for our customers who are under pressure to deliver their products quickly," added the spokesperson. "We are committed to providing them with the speed, efficiency, and reliability they need to stay ahead in today's competitive market."

Fast PCB Service is confident that its new fast turnaround service will not only benefit its existing customers but also attract new clients looking for a reliable and responsive PCB supplier. By offering quick and efficient manufacturing and assembly solutions, the company aims to help businesses of all sizes bring their ideas to life and achieve their goals in a timely manner.

With its unwavering dedication to excellence and customer satisfaction, Fast PCB Service continues to lead the way in the PCB manufacturing industry, setting new standards for speed, quality, and innovation. The company remains focused on meeting the evolving needs of its customers and providing them with the best possible PCB solutions to support their success.

As the demand for fast and reliable PCB services continues to grow, Fast PCB Service is well-positioned to meet the challenges of an increasingly dynamic and competitive market, offering its customers the speed and efficiency they need to stay ahead of the curve. With its new fast turnaround service, the company is poised to make a significant impact in the electronics manufacturing industry and solidify its reputation as a trusted and forward-thinking PCB supplier.

Company News & Blog

Calculate Trace Impedance for High-Speed PCBs with Ease!

[Assistant]Title: Advanced Trace Impedance Calculator Empowers PCB Designers for Enhanced PerformanceSubtitle: Cutting-edge Trace Impedance Calculator Streamlines PCB Development ProcessIn a fast-paced world of electronics, where the demand for highly efficient Printed Circuit Board (PCB) designs is rapidly increasing, engineers and developers are constantly seeking advanced tools and technologies to streamline their design processes. Recognizing this need, a leading company in the field of PCB design solutions has developed an innovative Trace Impedance Calculator, which revolutionizes the way PCB designers approach impedance matching, signal integrity, and PCB layout.Brand Name, a distinguished expert in the field of PCB design, has introduced the "Trace Impedance Calculator," a cutting-edge software tool that empowers PCB designers with accurate, efficient, and user-friendly impedance calculations. By leveraging the latest advancements in technology, this calculator facilitates the optimization of signal integrity, allowing for improved data transmission and reduced interference across PCB layouts.Impedance matching is a critical aspect of PCB design, especially when dealing with high-speed signals. Maintaining the correct trace impedance ensures signal integrity, minimizes reflections, and maximizes power transfer efficiency. Traditionally, designers had to rely on manual calculations, complex formulas, or partial solutions, which often resulted in time-consuming trial and error iterations. However, with the Trace Impedance Calculator from Brand Name, designers can now easily access accurate impedance values, streamline their design process, and achieve superior performance in a fraction of the time.This powerful calculator is specifically engineered to provide comprehensive solutions for both single-ended and differential pair trace impedance calculations. It takes into account various factors, such as trace width, thickness, and dielectric properties, to provide designers with precise impedance values tailored to their specific requirements. PCB designers can effortlessly customize impedance specifications, obtaining optimized results based on the electrical and mechanical characteristics of their design.The user-friendly interface of the Trace Impedance Calculator is designed to enhance productivity and efficiency. With a few clicks, designers can input their specifications, instantly obtain impedance values, and make real-time adjustments to fine-tune their designs. Additionally, the calculator provides graphical representations of impedance over a range of frequencies, enabling designers to visualize how impedance values behave across the spectrum.Furthermore, the calculators' advanced algorithms incorporate the latest industry standards and design guidelines, ensuring compliance with the most stringent PCB requirements. The tool supports a wide range of substrate materials, including FR-4, high-speed laminates, and flexible substrates, enabling designers to work with diverse PCB technologies while maintaining optimum signal integrity.The Trace Impedance Calculator seamlessly integrates into existing PCB design workflows, making it accessible to both novice and experienced designers. It is compatible with leading PCB design software, facilitating hassle-free implementation and reducing the learning curve for new users. Through this integrated approach, designers can eliminate guesswork, minimize design iterations, and accelerate time-to-market for their products."Brand Name's Trace Impedance Calculator simplifies the challenges faced by PCB designers when calculating trace impedance," says John Smith, Director of Engineering at a major electronics manufacturing company. "By providing accurate calculations, easy customization, and a user-friendly interface, this tool empowers us to optimize our designs quickly and effectively."In conclusion, the introduction of the Trace Impedance Calculator by Brand Name represents a significant leap forward for PCB designers. With its accurate and efficient impedance calculations, comprehensive customization options, and seamless integration, this advanced tool allows engineers to achieve superior signal integrity, reduce development time, and ultimately enhance the performance and reliability of their PCB designs. As the demand for higher efficiency and faster data transmission increases, solutions like Brand Name's Trace Impedance Calculator play a key role in satisfying the industry's evolving needs.

Understanding the Layers of Printed Circuit Boards: An In-Depth Look

Printed Circuit Board Layers: Enhancing Connectivity and Efficiency in Electronic DevicesIn today's fast-paced world, electronic devices have become an integral part of our lives. From smartphones and tablets to smart appliances and wearable technology, these devices have transformed the way we communicate, work, and relax. At the core of these electronic marvels lies a crucial component known as the Printed Circuit Board, or PCB. Printed Circuit Board Layers play a pivotal role in enhancing connectivity and efficiency in electronic devices.A PCB is a flat board made of non-conductive material, such as fiberglass, with electronic components mounted on it. Layers of conductive material, such as copper, are etched onto the board to create pathways for electric currents to flow, enabling the transfer of information and power between the various components. These layers are implemented through a highly precise and intricate process, ensuring optimal functionality and reliability.One of the key aspects of a PCB is its layer structure. The number of layers in a PCB is determined by the complexity of the device it is being designed for. A simple electronic device may require only a single-layer PCB, while more complex devices, such as advanced medical equipment or high-performance computing systems, may require multiple layers to accommodate numerous components and circuits.The PCB layer formation process involves laminating multiple layers of etched copper sheets with insulating material in between. The number, arrangement, and interconnections of these layers are determined by the specific requirements of the device. These layers are meticulously designed to minimize noise, maximize signal integrity, and ensure efficient functioning of the device.As the demand for smaller, faster, and more powerful electronic devices continues to rise, the importance of PCB layer technology becomes increasingly evident. Multilayer PCBs offer several advantages over their single-layer counterparts. Firstly, the compact design of multilayer PCBs allows for increased component density. This leads to more functionality in a smaller form factor, making devices slimmer and more lightweight. Secondly, multilayer PCBs enable the implementation of complex interconnections between components, resulting in improved signal integrity and reduced interference. This translates to faster data transfer rates and enhanced overall performance. Additionally, the use of multilayer PCBs allows for better heat dissipation, ensuring that electronic devices operate within their optimal temperature range, thereby increasing their lifespan.Furthermore, advancements in PCB layer technology have brought about the development of High-Density Interconnect (HDI) PCBs. HDI PCBs provide even greater design flexibility and reliability. They boast smaller vias and microvias, allowing for higher component density, improved signal integrity, and reduced power consumption. HDI PCBs are particularly beneficial in applications where space is limited, such as in mobile phones, smartwatches, and automotive electronics.The market for Printed Circuit Board Layers is witnessing significant growth due to the escalating demand for advanced electronic devices and the ongoing technological advancements in the industry. Several companies have emerged as pioneers in the field, employing cutting-edge manufacturing processes and innovative designs to meet the evolving needs of the market.One such company, {}, is at the forefront of PCB layer technology. With years of experience and a commitment to excellence, they offer a wide range of PCB layer solutions tailored to different industries and applications. Their expertise lies in the development of multilayer and HDI PCBs that deliver exceptional performance, reliability, and quality. By leveraging their in-house engineering expertise and state-of-the-art facilities, they ensure that their PCB layers meet the stringent standards of today's electronic devices.In conclusion, Printed Circuit Board Layers are vital components that enable the seamless functioning of electronic devices. Whether it's improving connectivity, enhancing performance, or reducing size, the layer structure plays a critical role. With advancements in technology, multilayer PCBs and HDI PCBs have revolutionized the industry, enabling the creation of smaller, more powerful, and energy-efficient devices. As companies like {} continue to push the boundaries of innovation, the potential for further advancements in PCB layer technology remains promising, driving the evolution of the electronic devices we rely on every day.

Fast PCB Prototyping Factory Offers Rapid Circuit Board Manufacturing

Fast PCB Prototyping Factory Enhances Its Production Capabilities to Meet Increasing DemandWith the electronic manufacturing industry experiencing exponential growth in recent years, Fast PCB Prototyping Factory has upgraded and expanded its production capabilities. The company aims to ensure it can meet the rising demand for high-quality printed circuit boards (PCBs) from a wide range of industries.Fast PCB Prototyping Factory, a leading player in the electronics manufacturing service (EMS) sector, has made significant investments in its machinery, technology, and workforce. These upgrades will bolster its production output and enable the company to keep up with the increased demand for PCBs in sectors such as automotive, aerospace, telecommunications, and consumer electronics.The company has added state-of-the-art automated assembly equipment to its production line, allowing for faster and more efficient manufacturing processes. This will not only increase productivity but also improve accuracy, consistency, and overall quality of the PCBs being produced. By investing in advanced technology, Fast PCB Prototyping Factory aims to stay ahead of its competitors and remain at the forefront of the industry.In addition to the equipment upgrades, the factory has expanded its facility to accommodate the growing demand. The increased space will allow for a higher volume of PCB production and provide room for future expansion as well. Fast PCB Prototyping Factory is committed to ensuring that its production capabilities can keep pace with the rapidly evolving needs of its customers.As part of its expansion, the company has also hired additional skilled technicians and engineers to strengthen its workforce. These professionals bring their expertise and knowledge, further enhancing the company's capabilities in PCB manufacturing. Fast PCB Prototyping Factory understands the importance of a skilled workforce in ensuring the delivery of high-quality products to its clients.Furthermore, the company's commitment to quality is underscored by its stringent quality control measures. Fast PCB Prototyping Factory adheres to international standards and regulations to provide customers with reliable and durable PCBs. Each PCB undergoes thorough testing and inspection to ensure it meets the required specifications and functions flawlessly.Fast PCB Prototyping Factory's dedication to customer satisfaction is reflected in its customer-oriented approach. The company works closely with its clients to understand their specific requirements and provide customized solutions. By taking into account factors such as design specifications, budget constraints, and time frames, Fast PCB Prototyping Factory ensures that its customers receive tailor-made products that meet their needs.The increased production capabilities of Fast PCB Prototyping Factory have already had a positive impact on its customers. Many clients have experienced faster turnaround times, reduced lead times, and improved overall efficiency. These benefits not only contribute to the success of individual projects but also enhance the competitiveness of the industries they serve.Looking to the future, Fast PCB Prototyping Factory aims to continue its expansion and innovation efforts. The company is exploring emerging technologies, such as flexible PCBs and high-density interconnects, to stay at the forefront of the industry. By staying proactive and responsive to market trends, the company aims to further enhance its production capabilities and maintain its position as a leading PCB manufacturer.In conclusion, Fast PCB Prototyping Factory has upgraded its production capabilities through investments in machinery, technology, and workforce to meet the increasing demand for high-quality PCBs. Its commitment to quality, customer satisfaction, and continuous improvement positions the company as a key player in the electronic manufacturing service industry. As the industry continues to evolve, Fast PCB Prototyping Factory remains dedicated to providing its customers with innovative and reliable solutions.

Essential Guidelines for Efficient Electrical PCB Assembly and Manufacturing Revealed

Title: Revolutionizing the Electrical Industry: Cutting-edge PCB InnovationsIntroduction:In recent years, the electrical industry has witnessed unprecedented advancements, thanks to the tireless efforts of innovative companies. One such company, renowned for offering cutting-edge solutions, has unveiled their latest breakthrough in electrical Printed Circuit Board (PCB) technology. Their groundbreaking development promises to revolutionize multiple sectors and drive innovation forward. In this article, we delve into the unparalleled capabilities of this new Electrical PCB, explore its potential applications, and highlight the company's commitment to driving progress.State-of-the-art Electrical PCB:The newly introduced Electrical PCB has been designed with meticulous attention to detail, incorporating state-of-the-art technology that surpasses industry standards. Pioneering the field of printed circuit boards, this innovation is set to redefine reliability, performance, and efficiency within the electrical industry.Key Features and Advancements:1. Enhanced Power Efficiency:The advanced design of the Electrical PCB minimizes energy consumption without compromising performance. Through meticulous engineering, the company has successfully developed a circuit board that provides improved power distribution, reducing wastage and optimizing overall efficiency.2. Compact Design:The new Electrical PCB boasts a significantly smaller form factor, enhancing its versatility for a wide array of applications. The compact design not only saves valuable space but also streamlines manufacturing processes, reducing costs and time.3. High-Speed Data Transmission:The Electrical PCB has been optimized with high-speed data transmission capabilities, catering to the demanding needs of modern electrical systems. This cutting-edge feature enables seamless communication and connectivity, ensuring real-time data transfer between components and devices.4. Enhanced Durability:Durability is a key focus of this innovative Electrical PCB. The company has invested considerable resources in research and development, incorporating robust materials and manufacturing techniques that offer enhanced resistance to environmental factors such as moisture, corrosion, and extreme temperatures. This empowers industries to rely on the PCB for longer lifespans, reducing maintenance costs and downtime.5. Customizability:Recognizing the diverse requirements of different industries, the company's Electrical PCB is highly customizable. Tailored to meet specific needs, the PCB can be modified to fit various applications, ensuring seamless integration and compatibility across different electrical systems and devices.Potential Applications:From consumer electronics to industrial automation and renewable energy, the potential applications of this revolutionary technology are vast. The Electrical PCB's versatility opens doors for numerous industries seeking innovative solutions to their electrical challenges.1. Consumer Electronics:With its compact design, high-speed data transmission, and enhanced power efficiency, the Electrical PCB can be seamlessly integrated into smartphones, tablets, laptops, and other portable electronic devices. This innovation paves the way for smaller, more powerful, and energy-efficient consumer electronics.2. Automotive Industry:Enhanced durability and customizability make the Electrical PCB an attractive solution for the automotive industry. With increasing demands for electric vehicles, this groundbreaking technology ensures improved reliability, safety, and performance.3. Renewable Energy:The Electrical PCB's power efficiency and compact design offer significant advantages in renewable energy systems. This technology can facilitate efficient power conversion, making it ideal for solar panels, wind turbines, and energy storage systems.Company Commitment to Innovation:The company behind this monumental Electrical PCB breakthrough has a long-standing commitment to innovation and progress. Through ongoing research and development, they strive to push the boundaries of what is possible in the electrical industry. Their investment in cutting-edge technologies and dedication to customer satisfaction has solidified their position as a leader in the field.Conclusion:In a world where technological advancement is the driving force behind progress, the introduction of the Electrical PCB revolutionizes the electrical industry. With its groundbreaking features, including enhanced power efficiency, compact design, high-speed data transmission, and customizability, this innovation facilitates growth and transformation across various sectors. As this company continues to defy conventions and push the boundaries of technology, we can expect further groundbreaking developments in the future.

Top Fast Turn PCB Manufacturers in China for Quick Production

In today's fast-paced and technology-driven world, the demand for high-quality PCB (printed circuit board) manufacturing is greater than ever. As a result, China Fast Turn PCB Manufacturers have emerged as leaders in the industry, providing efficient and reliable solutions for businesses worldwide.With the rapid development of the technology industry in recent years, the need for fast turn PCB manufacturing has become increasingly important. Businesses are constantly under pressure to bring their products to market quickly, and the ability to produce high-quality PCBs in a short amount of time is crucial. This is where China Fast Turn PCB Manufacturers come into play.One of the leading players in this space is {company name}. They have established themselves as a go-to solution for businesses looking for fast turn PCB manufacturing services. With a focus on efficiency and precision, {company name} has solidified its reputation as a trusted partner for businesses in need of high-quality PCBs on a tight deadline.{Company name} prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology. Their advanced manufacturing processes enable them to produce high-quality PCBs in a fraction of the time it takes traditional manufacturers. This allows businesses to streamline their production processes and bring their products to market faster than ever before.In addition to their technological capabilities, {company name} also places a strong emphasis on quality control. Every PCB that comes out of their facilities undergoes rigorous testing to ensure that it meets the highest standards. This commitment to quality has earned {company name} a stellar reputation in the industry, making them a top choice for businesses seeking fast turn PCB manufacturing.The company's customer-centric approach is another factor that sets them apart from the competition. {Company name} understands the unique needs of businesses in today's fast-paced market, and they strive to provide personalized solutions that meet those needs. From understanding specific technical requirements to delivering on tight deadlines, {company name} goes above and beyond to ensure customer satisfaction.Another key aspect of {company name}'s success is their commitment to innovation. As technology continues to evolve, so does the demand for PCBs with increasingly complex designs. {Company name} has made it a priority to stay at the forefront of technological advancements, allowing them to meet the evolving needs of their customers.Furthermore, {company name} understands the importance of sustainability in manufacturing. They have implemented eco-friendly practices and processes to minimize their environmental impact, aligning with the global trend towards sustainable and responsible manufacturing.As a result of these strengths, {company name} has become a preferred partner for businesses across various industries. Whether it's a startup looking to launch a new product or an established corporation seeking to streamline their production processes, {company name} has proven to be a reliable and efficient partner.In conclusion, as the demand for fast turn PCB manufacturing continues to rise, China Fast Turn PCB Manufacturers are playing a crucial role in meeting this demand. {Company name} stands out as a leader in the industry, offering efficient, high-quality, and reliable solutions for businesses worldwide. With their cutting-edge technology, commitment to quality, customer-centric approach, and dedication to innovation, {company name} has solidified its position as a trusted partner for businesses seeking fast turn PCB manufacturing.

Prototype PCB Factories in China - Get Your Boards Manufactured Quickly

China Prototype Board PCB Factories Collaborates with Leading Technology Company for Innovative Circuit DesignsChina Prototype Board PCB Factories is proud to announce its collaboration with a leading technology company to develop and manufacture innovative circuit designs. This collaboration will leverage the expertise of both companies to create cutting-edge PCB prototypes that will set new standards in the industry.China Prototype Board PCB Factories is a renowned manufacturer of high-quality printed circuit boards (PCBs) with a strong focus on innovation and customer satisfaction. With state-of-the-art facilities and a team of experienced professionals, China Prototype Board PCB Factories has established itself as a trusted partner for companies looking to develop custom PCBs for their unique applications.The collaboration with the leading technology company represents an exciting opportunity for China Prototype Board PCB Factories to further demonstrate its capabilities in producing advanced PCB prototypes. By working closely with the technology company's R&D team, China Prototype Board PCB Factories will be able to integrate the latest technological advancements into the design and manufacturing of PCBs, ensuring that the prototypes meet the highest standards of performance and reliability.The partnership will also enable China Prototype Board PCB Factories to expand its range of services by offering custom PCB solutions tailored to the specific needs of the technology company. This will include providing support for rapid prototyping, design optimization, and testing services to ensure that the PCB prototypes meet the exact requirements of the technology company's products.In addition to manufacturing capabilities, China Prototype Board PCB Factories will also bring its expertise in quality control and production processes to the collaboration. With a strong emphasis on quality and attention to detail, China Prototype Board PCB Factories will work closely with the technology company to ensure that the PCB prototypes are manufactured to the highest standards and are ready for integration into the company's products."We are thrilled to be collaborating with a leading technology company to develop and manufacture innovative PCB prototypes," said Mr. Li, the CEO of China Prototype Board PCB Factories. "This partnership is a testament to our commitment to delivering high-quality, cutting-edge PCB solutions to our customers. We are confident that this collaboration will not only showcase our capabilities but also drive advancements in the technology industry."The collaboration between China Prototype Board PCB Factories and the leading technology company is expected to yield groundbreaking results in the development of PCB prototypes for a wide range of applications, including consumer electronics, automotive, industrial equipment, and more. By leveraging the expertise and resources of both companies, the collaboration aims to push the boundaries of what is possible in PCB design and manufacturing, paving the way for the creation of next-generation technology products.As the demand for advanced PCB prototypes continues to grow, China Prototype Board PCB Factories is well-positioned to meet the needs of the market through collaborations with leading technology companies. By combining its manufacturing capabilities with the innovative ideas and technical expertise of its partners, China Prototype Board PCB Factories is poised to make significant contributions to the advancement of technology and the electronics industry as a whole.In conclusion, the collaboration between China Prototype Board PCB Factories and the leading technology company marks an important milestone in the development of innovative PCB prototypes. With a shared commitment to excellence and innovation, both companies are confident that this collaboration will drive significant advancements in the technology industry and set new standards for PCB design and manufacturing. This partnership represents an exciting opportunity for both companies to showcase their capabilities and make a lasting impact on the future of technology.

Leading Pcb Thermal Relief Manufacturer in China

China PCB Thermal Relief Manufacturer Leads the Industry with Innovative TechnologyAs technology continues to advance, the demand for high-quality printed circuit boards (PCBs) with efficient thermal relief features is on the rise. One company that is leading the industry in this regard is a top PCB thermal relief manufacturer based in China. This company, with its state-of-the-art facilities and a team of skilled professionals, has been setting new benchmarks in the PCB manufacturing industry.The company is committed to delivering reliable and efficient thermal relief solutions for a wide range of applications, including automotive, aerospace, telecommunications, and consumer electronics. By utilizing advanced technology and rigorous quality control processes, this manufacturer ensures that their PCBs offer superior performance and reliability under high-temperature conditions.One of the key factors that sets this company apart from its competitors is its dedication to continuous innovation. With a team of experienced engineers and researchers, the company is constantly developing and refining new thermal relief technologies to meet the evolving needs of its customers. This commitment to innovation has enabled the company to stay ahead of the curve and provide cutting-edge solutions for the most demanding thermal management challenges.In addition to its focus on innovation, the company also places a strong emphasis on quality and reliability. All of its products undergo rigorous testing and inspection to ensure that they meet the highest industry standards. This dedication to quality has earned the company a reputation for delivering PCBs that are not only technologically advanced but also highly durable and dependable.Furthermore, the company prides itself on its ability to provide customized solutions to meet the specific requirements of its customers. Whether it's a high-temperature application or a complex thermal management challenge, the company has the expertise and flexibility to tailor its products to suit the unique needs of each customer. This commitment to providing personalized solutions has earned the company the trust and loyalty of a wide range of clients, from small businesses to multinational corporations.Another important aspect of the company's success is its strong focus on environmental sustainability. With a growing awareness of the impact of manufacturing processes on the environment, the company has implemented a range of eco-friendly practices to minimize its carbon footprint. By prioritizing sustainable materials and energy-efficient production methods, the company is not only meeting its environmental responsibilities but also offering its customers the opportunity to align with their own sustainability goals.Looking to the future, the company is poised to continue its leadership in the PCB thermal relief industry. With ongoing investments in research and development, as well as a commitment to staying abreast of the latest technological advancements, the company is well-positioned to drive innovation and shape the future of thermal management solutions.In conclusion, the China-based manufacturer is at the forefront of the PCB thermal relief industry, thanks to its relentless focus on innovation, quality, customer satisfaction, and environmental responsibility. With its unwavering commitment to excellence, the company is poised to continue setting new standards and meeting the evolving needs of its customers in the years to come.

Top certified PCB manufacturers meeting UL standards

[Company Introduction]: [Company Name] is a leading provider of high-quality printed circuit board (PCB) solutions. With over [number] years of experience in the industry, we have established ourselves as a reliable and trusted manufacturer of PCBs for a wide range of applications. Our commitment to quality, innovation, and customer satisfaction has allowed us to become a preferred choice for businesses looking for dependable PCB solutions.[Brand Name] offers a comprehensive range of PCB manufacturing services, including single-sided, double-sided, and multi-layer PCBs. Our state-of-the-art facilities are equipped with advanced technology and machinery to ensure the highest level of precision and quality in our products. We are proud to be UL certified, which is a testament to our adherence to the highest standards of safety and reliability in the manufacturing process.Our team of skilled engineers and technicians work tirelessly to deliver custom PCB solutions that meet the unique requirements of our clients. From design and prototyping to production and testing, we ensure that every step of the manufacturing process is carried out with meticulous attention to detail. Our dedication to excellence has earned us a strong reputation in the industry and has resulted in long-term partnerships with businesses across various sectors.[News Content]:[City, Date] – [Brand Name] is pleased to announce that we have achieved UL certification for our printed circuit boards (PCBs), solidifying our position as a trusted and reliable manufacturer of high-quality PCB solutions. This certification is a testament to our commitment to upholding the highest standards of safety and reliability in our manufacturing process.UL certification is a globally recognized mark of quality and safety. It signifies that our PCBs have undergone rigorous testing and have met the strict requirements set by UL, a leading safety science company. By achieving UL certification, we have demonstrated our dedication to providing our customers with PCBs that meet the highest standards of performance and safety.As a UL certified PCB manufacturer, [Brand Name] is able to offer our customers the assurance that our products are compliant with industry standards and regulations. This certification opens up new opportunities for us to serve a wider range of industries, including automotive, medical, aerospace, and consumer electronics, where adherence to safety and quality standards is of paramount importance.Our UL certified PCBs are manufactured using advanced technology and processes to ensure precision, reliability, and performance. Whether our customers require single-sided, double-sided, or multi-layer PCBs, they can have full confidence in the quality and safety of our products. With our extensive experience and expertise in PCB manufacturing, we are well-equipped to meet the diverse needs of our customers and deliver custom solutions that exceed their expectations.At [Brand Name], we take great pride in achieving UL certification for our PCBs. It is a testament to our unwavering dedication to providing our customers with the highest quality and safest PCB solutions. We are excited about the new possibilities that this certification brings and are committed to continuing to uphold the highest standards of excellence in our products and services.In conclusion, achieving UL certification is a significant milestone for [Brand Name] and reaffirms our position as a leading provider of high-quality and reliable PCB solutions. Our UL certified PCBs are a testament to our commitment to delivering products that meet the highest standards of safety and quality. We look forward to serving our customers with the same level of dedication and excellence that has earned us this prestigious certification.

How to Install and Use a LED Circuit Board in Your Electronics

[Company Name] introduces state-of-the-art LED technology in their latest circuit board innovation[Company Name], a leading manufacturer of electronic components, has recently introduced a groundbreaking LED technology in their latest circuit board innovation. The company has been at the forefront of electronic innovation for over two decades, and their commitment to developing cutting-edge technologies has established them as a highly respected player in the industry.The new LED technology, integrated into the [Product Name] circuit board, has been designed to offer superior performance and durability. LEDs, or light-emitting diodes, are widely used in various electronic applications due to their energy efficiency and long lifespan. The [Product Name] circuit board utilizes the latest advancements in LED technology to provide a reliable and energy-efficient solution for a wide range of applications.The [Product Name] circuit board is equipped with [Company Name]'s proprietary LED technology, which offers enhanced brightness and color accuracy. This technology is particularly well-suited for applications that require high-quality lighting, such as display panels, signage, and automotive lighting. The superior performance of the LED technology ensures that the [Product Name] circuit board delivers consistent and reliable lighting output, even in demanding environments.In addition to its performance benefits, the LED technology used in the [Product Name] circuit board also offers significant energy savings. LEDs are known for their low power consumption, and the integration of [Company Name]'s advanced LED technology further enhances the energy efficiency of the [Product Name] circuit board. This makes it an ideal choice for applications that require long-term, continuous operation, without the need for frequent maintenance or replacement.[Company Name] is committed to providing innovative solutions that meet the evolving needs of their customers. The introduction of the [Product Name] circuit board with advanced LED technology is a testament to the company's dedication to pushing the boundaries of electronic innovation. By leveraging their expertise in LED technology, [Company Name] aims to deliver superior quality products that offer tangible benefits to their customers.The [Product Name] circuit board is designed to meet the highest quality and reliability standards. [Company Name] has invested in state-of-the-art manufacturing facilities and stringent quality control processes to ensure that the [Product Name] circuit board meets the performance and durability expectations of their customers. The integration of advanced LED technology is a testament to the company's commitment to delivering top-of-the-line electronic components.As a leading player in the electronic components industry, [Company Name] has a proven track record of delivering innovative solutions to a diverse range of markets. The introduction of the [Product Name] circuit board with advanced LED technology reaffirms the company's position as a forward-thinking and customer-focused organization. With a focus on continuous improvement and technological advancement, [Company Name] is well-positioned to meet the evolving needs of the electronic industry.In conclusion, the introduction of the [Product Name] circuit board with advanced LED technology is a significant milestone for [Company Name]. The integration of state-of-the-art LED technology into the circuit board demonstrates the company's commitment to delivering innovative and high-performance solutions to their customers. With its superior performance, energy efficiency, and reliability, the [Product Name] circuit board is set to make a significant impact in the electronic components market.For more information about [Company Name]'s latest LED technology and the [Product Name] circuit board, please visit their official website.

Benefits of Lead-Free Hasl in PCB Manufacturing

Lead-Free Hasl (Hot Air Solder Leveling) has been making waves in the electronics industry recently, and one company at the forefront of this innovation is {company name}. With a commitment to sustainability and environmental responsibility, {company name} has been leading the charge in the development and implementation of lead-free technologies, and their Lead-Free Hasl process is a prime example of their dedication to a green future.Founded in {year}, {company name} has quickly emerged as a leading provider of electronic manufacturing services, offering a wide range of solutions for industries such as automotive, medical, aerospace, and consumer electronics. With a focus on quality, reliability, and innovation, {company name} has built a reputation for excellence in the industry, and their Lead-Free Hasl process is a testament to their commitment to staying ahead of the curve.The Lead-Free Hasl process has become increasingly important in recent years, as the electronics industry continues to move towards more sustainable and eco-friendly practices. Traditionally, Hasl processes have involved the use of lead, which can be harmful to both the environment and human health. However, {company name} has been working tirelessly to develop a lead-free alternative that maintains the high standards of quality and performance that their customers have come to expect.One of the key benefits of {company name}'s Lead-Free Hasl process is its environmental friendliness. By eliminating the use of lead, the process significantly reduces the environmental impact of electronic manufacturing, making it a more sustainable option for companies looking to minimize their carbon footprint. Additionally, the Lead-Free Hasl process is fully compliant with international regulations and standards, further cementing {company name} as a frontrunner in sustainable electronic manufacturing.Furthermore, {company name}'s Lead-Free Hasl process offers superior performance and reliability, making it an attractive option for companies across a wide range of industries. By utilizing cutting-edge technology and rigorous quality control measures, {company name} ensures that their Lead-Free Hasl process meets the highest standards of excellence, delivering superior results for their clients. This has made {company name} a preferred partner for many companies looking for a reliable and sustainable electronic manufacturing solution.In addition to the environmental and performance benefits, {company name}'s Lead-Free Hasl process also reflects their ongoing commitment to innovation and continuous improvement. As the electronics industry continues to evolve, {company name} remains at the forefront of technological advancements, constantly pushing the boundaries of what is possible in electronic manufacturing. Their Lead-Free Hasl process is just one example of how {company name} is staying ahead of the curve and providing cutting-edge solutions for their clients.Looking towards the future, {company name} is poised to continue leading the way in sustainable electronic manufacturing, with their Lead-Free Hasl process serving as a shining example of their dedication to environmental responsibility and innovation. As the industry continues to prioritize sustainability and eco-friendly practices, {company name} is well positioned to meet the growing demand for lead-free electronic manufacturing solutions, further solidifying their reputation as a leader in the field.In conclusion, {company name} has established itself as a trailblazer in the electronic manufacturing industry, with their Lead-Free Hasl process serving as a testament to their commitment to sustainability, performance, and innovation. As the industry continues to move towards more eco-friendly practices, {company name} is well positioned to remain at the forefront of this movement, providing cutting-edge solutions for companies across a wide range of industries. With a track record of excellence and a dedication to staying ahead of the curve, {company name} is set to continue making a positive impact on the electronic manufacturing industry for years to come.