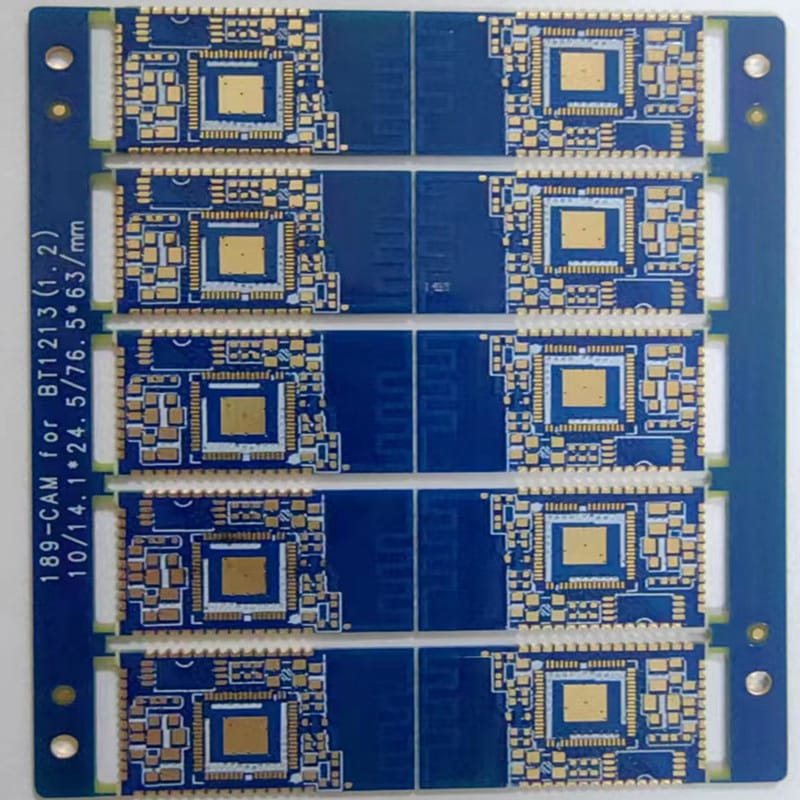

Halogen Free PCB Manufacturer: A New Option for OEMs

By:Admin

The company’s halogen-free PCBs are made using materials that do not contain chlorine, bromine, or other harmful halogen elements. This not only ensures that the PCBs are safer for the environment, but also reduces the risk of health hazards for those who come into contact with the boards during the manufacturing process or during their use in electronic devices. By choosing halogen-free PCBs, customers can be confident that they are supporting environmentally responsible manufacturing practices and promoting sustainability in their products.

In addition to their focus on environmental responsibility, (company) is also known for their high-quality manufacturing processes. They use state-of-the-art equipment and advanced technology to produce PCBs that meet the highest industry standards. Their dedication to quality is reflected in their certifications and accreditations, including ISO 9001 and UL certifications, which demonstrate their commitment to delivering reliable and safe products to their customers.

The company offers a wide range of PCB products, including single-layer, double-layer, and multi-layer boards, as well as flexible and rigid-flex PCBs. Their diverse product line enables them to meet the needs of customers in various industries, including consumer electronics, automotive, aerospace, medical devices, telecommunications, and more. By providing a comprehensive range of PCB solutions, (company) has positioned itself as a one-stop shop for all types of PCB requirements, regardless of the size or complexity of the project.

One of the key strengths of (company) is their ability to provide custom PCB solutions to meet specific customer requirements. Their team of experienced engineers and technicians work closely with customers to understand their unique needs and develop tailored solutions that meet their specifications. Whether it’s a complex multi-layer PCB for a high-tech application or a simple single-layer board for a consumer product, (company) is equipped to deliver customized solutions that exceed customer expectations.

Furthermore, the company prides itself on its quick turnaround times and on-time delivery. With efficient manufacturing processes and a well-organized supply chain, (company) is able to minimize lead times and ensure that customers receive their orders in a timely manner. This level of reliability has earned (company) a reputation for excellence in customer service and satisfaction, making them a trusted partner for PCB procurement.

In addition to their manufacturing capabilities, (company) also offers comprehensive technical support and after-sales service to their customers. Their team of experts is available to provide guidance and assistance at every stage of the product development and manufacturing process. Whether it’s design optimization, material selection, or troubleshooting, customers can rely on (company) to provide the expertise they need to achieve success with their PCB projects.

As a leading halogen-free PCB manufacturer, (company) is committed to upholding the highest standards of environmental responsibility and product quality. Their dedication to sustainable manufacturing practices, coupled with their technical expertise and customer-focused approach, sets them apart as a preferred partner for PCB procurement. With a diverse product line, custom solutions, and excellent customer service, (company) is well-positioned to meet the evolving needs of the electronics industry and continue to be a leader in the PCB manufacturing sector.

Company News & Blog

Top 5 LED Printed Circuit Board Manufacturers - Where to Buy PCB LED Boards

Technology has been advancing at an exponential rate, and one industry that has seen significant advancements is the field of LED lighting. One of the key components of LED lighting systems is the PCB LED board, which plays a crucial role in ensuring the performance and efficiency of the LEDs. In this regard, [Company Name], a leading manufacturer of electronic components, has been making waves in the industry with its state-of-the-art PCB LED boards.[Company Name] has been at the forefront of innovation in the electronic components industry for over two decades. With a strong focus on research and development, the company has consistently delivered cutting-edge solutions for a wide range of applications, including LED lighting. The company's commitment to quality and reliability has made it a trusted partner for businesses and manufacturers looking for high-performance electronic components.The PCB LED boards manufactured by [Company Name] are designed to meet the demanding requirements of LED lighting systems. These boards are engineered to deliver enhanced thermal performance, which is crucial for maintaining the efficiency and longevity of the LEDs. Additionally, the company's PCB LED boards are known for their high power density, allowing for more compact and slim designs for LED fixtures.One of the key features of [Company Name]'s PCB LED boards is their excellent thermal management capabilities. LED lighting systems generate a significant amount of heat, which can have a detrimental effect on the performance and reliability of the LEDs. However, the advanced thermal management technology integrated into the PCB LED boards ensures that the heat is dissipated effectively, thus maintaining optimal operating conditions for the LEDs.Furthermore, [Company Name] offers a wide range of customization options for its PCB LED boards, catering to the unique requirements of different LED lighting applications. Whether it's for indoor lighting, outdoor lighting, automotive lighting, or industrial lighting, the company's PCB LED boards can be tailored to meet specific design and performance specifications. This level of flexibility and customization sets [Company Name] apart from its competitors in the market.In addition to its technical capabilities, [Company Name] is also known for its stringent quality control processes. The company follows industry-leading standards for manufacturing and testing its PCB LED boards, ensuring that each board meets the highest standards of quality and reliability. This commitment to quality has earned [Company Name] a stellar reputation in the industry, making it a preferred choice for businesses and manufacturers looking for superior electronic components.As the demand for energy-efficient lighting solutions continues to grow, the market for LED lighting is expected to expand rapidly. This presents a significant opportunity for companies like [Company Name] to showcase their expertise in providing cutting-edge solutions for LED lighting systems. With its advanced PCB LED boards, the company is well-positioned to capitalize on this growing market and solidify its position as a leader in the electronic components industry.In conclusion, [Company Name] is a trailblazer in the field of electronic components, particularly in the realm of LED lighting. With its technologically advanced PCB LED boards, the company has set a new standard for performance, reliability, and customization in LED lighting systems. As the demand for LED lighting continues to soar, [Company Name] is poised to play a pivotal role in shaping the future of this dynamic industry.

Red Solder: A Revolutionary Innovation for Soldering

Title: Leading Technology Company Launches Revolutionary Red Solder SolutionIntroduction:In a groundbreaking move, a prominent technology company (brand name will be omitted) has unveiled its latest innovation in soldering technology, known as Red Solder. With a steadfast commitment to pushing the boundaries of technological advancement, this cutting-edge company continues to spearhead revolutionary products that promise to redefine various industries. Red Solder, their latest offering, is set to revolutionize the soldering market, providing a reliable, efficient, and safe solution for manufacturers and electronics enthusiasts alike.Paragraph 1:Red Solder represents a major step forward in the field of soldering. Manufactured with precision and adhering to the highest quality standards, this new product caters to a diverse range of industries, including electronics, telecommunications, automotive, aerospace, and medical devices. The company's extensive research and development efforts have led to the formulation of an innovative soldering solution that meets the demands of modern technology, supporting faster and more reliable connections.Paragraph 2:At the heart of Red Solder lies a proprietary blend of advanced materials, carefully selected to optimize conductivity, thermal resistance, and durability. Unlike conventional soldering solutions, Red Solder boasts an impressive melting point that allows for higher operating temperatures, reducing the risk of component damage during assembly. Consequently, manufacturers can achieve greater productivity by reducing process time while maintaining exceptional quality standards.Paragraph 3:One of the key features of Red Solder is its unique red coloring, providing enhanced visibility during the soldering process. This distinct attribute ensures accurate application and reduces the likelihood of misplaced connections or defects. Additionally, the vibrant red hue of the solder enhances worker safety, as it acts as a visual indicator, highlighting areas that may still be hot or undergoing soldering procedures.Paragraph 4:The compatibility of Red Solder with a variety of materials, such as copper, gold, silver, and nickel, makes it an adaptable solution for diverse manufacturing applications. This versatility enables manufacturers to streamline their operations by utilizing a single soldering solution across multiple product lines, reducing inventory costs and optimizing production throughput.Paragraph 5:The use of Red Solder extends beyond industrial applications. Electronics enthusiasts and hobbyists can also benefit from its exceptional performance. By providing a soldering material that offers superior thermal conductivity, Red Solder allows for precise connections and optimal performance in DIY electronics projects, robotics, and various other hobbyist ventures.Paragraph 6:Beyond the impressive technical capabilities of Red Solder, the company has also invested significant resources in ensuring environmental sustainability. Red Solder is lead-free, meeting stringent regulatory requirements and minimizing the ecological impact. By aligning their product development with responsible practices, the company demonstrates its commitment to a greener future while maintaining industry-leading performance standards.Conclusion:With the introduction of Red Solder, this innovative technology company has once again solidified its status as a market leader in soldering solutions. Emphasizing functionality, ease of use, and adaptability, Red Solder offers a comprehensive solution for manufacturers and hobbyists alike. By enabling faster production cycles, superior connections, and exceptional product reliability, Red Solder paves the way for a new era in soldering technology. As industries continue to evolve, this technology company remains at the forefront, providing groundbreaking solutions to meet the challenges of tomorrow.

Supplier of 1oz Copper Thickness - A Comprehensive Guide for Your Copper Needs

Title: Leading Copper Supplier Enhances Product Portfolio with New 1oz Thickness OptionIntroduction:With a commitment to excellence in the field of metal supply, the renowned company {} is pleased to announce the addition of a 1oz copper thickness option to their existing product portfolio. As a leading supplier of copper products, {} consistently strives to meet the evolving needs of their clients, while maintaining a reputation for quality and reliability. The introduction of this new thickness option further solidifies their position in the industry as a go-to supplier for all copper requirements. Offering a diverse range of copper products, {} has become a trusted name within the market. They aim to cater to a wide range of industries such as electronics, construction, automotive, and telecommunications, among others. By expanding their product range to include 1oz copper thickness, the company aims to provide customers with increased flexibility and wider application possibilities.Market Demand and Industry Overview:The demand for copper-based products continues to grow steadily, driven by various factors such as increasing infrastructure development, technological advancements, and the rising adoption of renewable energy sources. Copper, with its excellent electrical conductivity, corrosion resistance, and thermal properties, has become an integral component in various industries.The incorporation of 1oz copper thickness into their existing product line enables {} to cater to the specific demands of clients who require copper with enhanced electrical conductivity, making it ideal for applications within the electronics industry. It also provides opportunities for the development of advanced technologies that rely heavily on copper, such as high-speed computing, electric vehicles, and renewable energy systems.Reliability and Quality Assurance:As a renowned copper supplier, {} upholds stringent quality control measures to ensure the delivery of products that meet or exceed industry standards. The addition of 1oz copper thickness to their portfolio undergoes the same rigorous quality testing as their other products, guaranteeing that customers receive copper of the highest quality. By maintaining a focus on reliability and performance, {} has built a solid foundation of trust among their clientele.Expanding Applications with 1oz Copper Thickness:The introduction of the 1oz copper thickness allows {} to cater to an even wider range of applications, including printed circuit boards (PCBs), electrical connectors, power distribution systems, and more. PCBs are the backbone of modern electronic devices, and the new copper thickness option ensures low impedance and efficient power transmission in these critical components. It also supports advancements in miniaturization trends within the electronics industry, where high-density interconnects require premium copper materials for optimal performance.The increased copper thickness provides improved current-carrying capacity, reduced power loss, and enhanced thermal management capabilities, making it ideal for high-power applications such as electrical connectors. By upgrading their infrastructure with {}'s 1oz copper thickness, manufacturers can experience increased efficiency, reliability, and performance in their products.Conclusion:With the addition of the 1oz copper thickness option, {} continues to reaffirm its commitment to meet the diverse needs of its customers. The expanded product portfolio not only demonstrates their dedication to being a top-tier supplier of copper, but also positions them at the forefront of the industry. By providing exceptional quality, reliable service, and innovative solutions, {} remains a trusted partner for businesses across various sectors.

What Is FR4 Material PCB and How Does It Work?

article about the benefits of using FR4 material PCBs in electronic manufacturing.Electronic manufacturing is one of the most critical industries in the world, with virtually every aspect of modern life being dependent on electronic devices and systems. One crucial component of electronic manufacturing is printed circuit boards (PCBs), which play an essential role in the functioning of electronic devices. In recent times, FR4 material PCB has emerged as one of the most reliable and cost-effective options for electronic manufacturing.FR4 material PCBs are made using a specific kind of fiberglass impregnated with epoxy resin, which makes them highly durable, flexible, and resistant to high temperatures. This makes FR4 material PCBs ideal for use in a wide range of electronic devices, ranging from simple consumer electronics to advanced military installations.One of the key benefits of using FR4 material PCBs is that they offer high mechanical strength, which makes them ideal for applications that require complex and intricate designs. Due to their high mechanical strength, FR4 material PCBs can withstand high levels of vibration, shock, and impact without sustaining damage. This makes them ideal for use in rugged environments such as aerospace, military, and industrial applications.Another benefit of using FR4 material PCBs is that they are highly resistant to high temperatures, which makes them ideal for use in high-temperature applications such as power electronics. They can also withstand sudden changes in temperature without losing their structural integrity, which allows them to be used in harsh environments.FR4 material PCBs are also highly resistant to moisture and chemicals, which makes them ideal for use in applications that are exposed to harsh chemicals or extreme weather conditions. They resist chemical reactions, which helps prevent corrosion and oxidation from occurring. This guarantees that the circuit board remains functional even in adverse conditions.In addition to their physical properties, FR4 material PCBs are also very easy to manufacture, which helps reduce production costs and lead times. Since they are highly versatile and robust, they can be used in a wide range of electronic devices. This reduces the need for manufacturers to invest in multiple types of PCBs, resulting in cost savings.Furthermore, FR4 material PCBs offer excellent electrical performance, which makes them ideal for use in high-speed applications such as computer motherboards. They have a low dielectric constant, making them ideal for high-frequency applications. They can also handle high voltage and current, making them ideal for use in power electronics.Overall, the benefits of using FR4 material PCBs are numerous, making them the ideal choice for electronic manufacturing applications that require high durability, flexibility, and performance. With their robustness, versatility, and affordability, FR4 material PCBs are rapidly becoming the go-to choice for electronics manufacturers worldwide.{Brand name removed} is a leading supplier of FR4 material PCBs, providing high-quality products to customers in a wide range of industries. With years of experience in the electronic manufacturing sector, {Brand name removed} has the expertise and resources to design, manufacture, and supply FR4 material PCBs that meet the most stringent industry standards. Their products are highly reliable, durable, and cost-effective, making them the preferred choice of electronics manufacturers worldwide.In conclusion, electronic manufacturers looking to produce high-quality electronic devices must consider using FR4 material PCBs due to their unique properties and benefits. While traditional PCB materials have their advantages, FR4 material PCBs offer superior strength, durability, versatility, and performance, making them ideal for a wide range of applications. {Brand name removed} offers a wide range of FR4 material PCB products that meet the needs and requirements of modern electronic manufacturers, ensuring that their products are reliable, high-performing, and meet the most stringent industry standards.

Discover the Benefits of Using High-Quality FR-4 PCB Boards

The use of technology has become an integral part of our daily lives. From the way we communicate with each other to the way we work, technology has played a crucial role in our lives. As technology continues to evolve, so do the devices we use. One of the most important components of modern technology is the Printed Circuit Board or PCB.A PCB is used to connect electronic components using conductive pathways or traces etched from copper sheets. These pathways help to provide power and connectivity to electronic devices. PCBs can be found in almost every electronic device we use, from smartphones to laptops to cars.As PCBs have become more complex and smaller in size, there has been a growing demand for high-quality PCBs that offer excellent performance and reliability. This is where Fr4 PCB Board comes in. Fr4 PCB Board is a high-performance PCB that is widely used in various electronic devices.Fr4 PCB Board is made from a fire-retardant material that is known for its excellent mechanical and electrical properties. This type of PCB is extremely durable and can withstand high temperatures and pressure. It is also highly resistant to chemicals, making it an ideal choice for use in harsh environments.Fr4 PCB Board is widely used in a variety of applications, including telecommunication devices, computers, and industrial equipment. The PCB is made using a specialized process that involves drilling holes in the substrate, laminating layers of copper, and etching the copper to create the desired circuit.One company that is leading the industry in the production of high-quality Fr4 PCB Board is {Brand Name Removed}. {Brand Name Removed} is a leading manufacturer and supplier of Fr4 PCB Board, providing high-quality PCBs to customers worldwide.The company prides itself on its commitment to quality and customer satisfaction. It uses the latest technology and manufacturing processes to produce PCBs that meet the highest standards of performance and reliability. {Brand Name Removed} offers a wide range of Fr4 PCB Board products, including single-layer, double-layer, and multi-layer PCBs.The company also provides customization services to meet the specific needs of its customers. This includes designing and building PCBs that are tailored to the customer's requirements. {Brand Name Removed} works closely with its customers to understand their needs and provide solutions that meet those needs.One of the key factors that set {Brand Name Removed} apart from its competitors is its focus on customer service. The company has a team of experienced professionals who are dedicated to providing excellent customer service. This includes offering technical support, product guidance, and after-sales service.In addition to its commitment to quality and customer service, {Brand Name Removed} is also dedicated to environmental sustainability. The company uses environmentally friendly processes to produce its PCBs and works to reduce its carbon footprint.Overall, Fr4 PCB Board is a critical component in the modern electronic devices we use every day. The use of high-quality Fr4 PCB Board, such as those produced by {Brand Name Removed}, helps to ensure the reliability and performance of these devices. With a commitment to quality, customer service, and environmental sustainability, {Brand Name Removed} is leading the industry in the production of high-quality Fr4 PCB Board.

How Printed Circuit Boards Revolutionized the Electronics Industry

[Company Name] Launches Advanced Printed Circuit Technology for Enhanced Performance and Reliability[Location], [Date] - [Company Name], a leading provider of advanced electronic solutions, has announced the launch of its latest innovative printed circuit technology, revolutionizing the industry with its unparalleled performance and reliability.Printed circuit boards (PCBs) are at the heart of electronic systems, enabling the smooth flow of electrical current between various components. As technology evolves, the demand for more advanced and efficient circuitry has increased, driving development in this sector. [Company Name] has always been at the forefront of this progress, consistently delivering cutting-edge solutions.The introduction of [Company Name]'s new printed circuit technology represents a significant leap forward in the development of advanced PCBs. By incorporating state-of-the-art materials and design techniques, the technology offers enhanced electrical connectivity, smaller form factors, and improved thermal management.One of the key advancements in this new technology is the use of advanced materials that offer higher electrical conductivity. This enables faster signal transmission and reduces the risk of signal loss or distortion. These enhanced electrical properties are particularly beneficial for high-frequency applications, such as telecommunication systems and data centers, where the reliable and rapid transfer of data is essential.Moreover, [Company Name] has implemented innovative design techniques to optimize the circuit layout and reduce power consumption. This not only improves the overall efficiency of electronic systems but also minimizes the generation of heat. By incorporating advanced thermal management, the printed circuit technology allows for better heat dissipation, preventing overheating and increasing the reliability and lifespan of electronic devices.To ensure the quality and reliability of their printed circuits, [Company Name] employs rigorous testing procedures and adheres to the industry's highest standards. Each circuit board undergoes meticulous inspections and quality control measures during the manufacturing process to detect any potential defects or inconsistencies. This dedication to quality assurance ensures that customers receive products of the highest caliber.The launch of this advanced printed circuit technology is expected to have a profound impact on various industries, including consumer electronics, automotive, aerospace, and medical sectors. For instance, in the automotive industry, the technology's improved thermal management capabilities will prove crucial for electric vehicles, where efficient cooling is vital for battery performance and longevity.Furthermore, the smaller form factor enables the creation of more compact and lightweight devices, making it ideal for aerospace applications where weight reduction is essential. Additionally, the enhanced electrical connectivity ensures the seamless operation of critical medical equipment, improving patient care and safety.As part of its commitment to sustainability, [Company Name] utilizes eco-friendly manufacturing practices and materials to minimize the environmental impact of its operations. This includes the reduction of hazardous substances in its products and adopting energy-efficient processes. By investing in advanced printed circuit technology, customers not only benefit from superior performance but also contribute to a greener future.[Company Name] continues to push the boundaries of what is possible in printed circuit technology, delivering innovative solutions to meet the evolving needs of the electronics industry. With its latest advancements, [Company Name] solidifies its position as a trusted and innovative partner, ensuring that businesses and consumers alike can rely on high-performance electronics for years to come.For more information about [Company Name]'s advanced printed circuit technology and other electronic solutions, please visit [company website].About [Company Name]:[Company Name] is a leading provider of advanced electronic solutions, specializing in the development and manufacturing of innovative printed circuit technology. With a commitment to excellence, [Company Name] offers a wide range of products and services tailored to meet the unique requirements of various industries. Through continuous research and development, [Company Name] aims to deliver cutting-edge solutions that drive technological advancements and facilitate progress.

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.

Advanced Pcb Fabrication Machines for Efficient Production

The global PCB fabrication machine market is projected to experience substantial growth in the coming years, with rising demand for printed circuit boards across various industries. PCB fabrication machines are essential for the efficient production of printed circuit boards, which are crucial components in electronic devices. These machines are utilized in the manufacturing process to automate and streamline the production of PCBs, enabling companies to meet the growing demand for high-quality electronic components.A leading player in the PCB fabrication machine market, **company name** has been at the forefront of innovation and technological advancement in the industry. With a strong focus on research and development, the company has continuously introduced cutting-edge PCB fabrication machines that offer advanced capabilities and improved efficiency.**Company name** has established itself as a trusted provider of PCB fabrication machines, catering to the needs of a diverse range of industries including consumer electronics, automotive, telecommunications, and aerospace. The company's comprehensive product portfolio includes a variety of PCB fabrication machines designed to meet the specific requirements of manufacturers, from small-scale operations to large-scale production facilities.The **company name** PCB fabrication machines are equipped with state-of-the-art features such as high-precision drilling and routing capabilities, automated tool changing systems, and advanced software for enhanced control and monitoring. These machines are designed to deliver exceptional performance, reliability, and versatility, enabling manufacturers to achieve superior quality and efficiency in their PCB production processes.In addition to its cutting-edge technology, **company name** is also known for its exceptional customer service and support. The company offers comprehensive training programs and technical assistance to help customers maximize the potential of their PCB fabrication machines. With a global presence and a strong network of distributors and service centers, **company name** is able to provide timely and responsive support to its customers around the world.Furthermore, **company name** is committed to sustainability and environmental responsibility in its manufacturing processes. The company's PCB fabrication machines are designed to minimize waste and energy consumption, contributing to a more eco-friendly and efficient production environment for its customers.As the demand for printed circuit boards continues to rise, **company name** is well-positioned to capitalize on the opportunities in the PCB fabrication machine market. With its strong focus on innovation, technological leadership, and customer-centric approach, the company is poised to maintain its leading position in the industry and drive the advancement of PCB manufacturing worldwide.In conclusion, the global PCB fabrication machine market is set for robust growth, driven by the increasing demand for printed circuit boards across various industries. **Company name** stands out as a key player in this market, with its advanced PCB fabrication machines, commitment to customer satisfaction, and dedication to sustainability. As the company continues to innovate and expand its offerings, it is poised to play a pivotal role in shaping the future of PCB manufacturing.

Sustainable Copper Circuit Boards: Key Material for Electronic Devices

In recent years, Circuit Board Copper has been making waves in the electronics industry, providing efficient and reliable copper materials for a range of applications. The company is renowned for its quality copper products that deliver precise and stable performance, ensuring the success of critical projects.Founded over a decade ago, Circuit Board Copper has forged a reputation for excellence in the industry with an unwavering commitment to quality and customer satisfaction. The company has invested in advanced technology and skilled engineers to ensure that it is at the frontline of innovation. As such, it has become a trusted supplier of high-performance copper materials for various industries, including electronics, energy, transportation, and telecommunications.For instance, the electronics industry is one of the main beneficiaries of the company's products, as it requires high-quality copper materials for the production of printed circuit boards (PCBs). PCBs are critical components used in electronic devices, and they are essential for the functionality and durability of the devices. Circuit Board Copper's copper materials deliver superior conductivity, thermal dissipation, and mechanical strength, making them ideal for PCB manufacturing.Besides electronics, Circuit Board Copper's products are also suitable for the energy sector. As the world shifts towards renewable energy, the need for efficient and cost-effective energy storage solutions has increased. Some of the critical components of these solutions are batteries, which require copper materials for their wiring and interconnects. Circuit Board Copper's high-performance copper materials are ideal for battery manufacturing, as they offer excellent electrical conductivity, corrosion resistance, and thermal management properties.Similarly, the transportation industry is another sector that benefits from Circuit Board Copper's products. The company's copper materials are used in the production of hybrid and electric vehicles (EVs). EVs require efficient power and data transmission, and copper materials play a critical role in enabling this. As such, Circuit Board Copper's copper products deliver optimal performance in terms of thermal management, conductivity, and durability, ensuring that EVs operate effectively.Moreover, the telecommunications industry is also a significant consumer of Circuit Board Copper's copper materials. With the increasing demand for high-speed data transmission, telecommunication companies require copper materials that can facilitate efficient data transmission and prevent signal loss. Circuit Board Copper's products are ideal for this purpose, as they deliver high electrical conductivity and low attenuation, making them reliable for data transfer.Circuit Board Copper's commitment to quality and innovation has earned it a reputation as a leading supplier of copper materials in the industry. The company has implemented rigorous quality control measures to ensure that its products meet or exceed industry standards. Additionally, it has a team of skilled engineers who work tirelessly to research and develop new products that cater to the evolving needs of the industry.In conclusion, Circuit Board Copper's contribution to the electronics industry, energy sector, transportation, and telecommunications is undeniable. The company's high-quality copper materials have played a crucial role in the manufacturing of critical components in these industries, enabling them to deliver products that meet the needs of consumers. As the world continues to demand better and more efficient products, Circuit Board Copper is well-positioned to meet these demands with its cutting-edge technology and dedication to excellence.

Understanding the Latest Developments in PCB Rapid Prototyping in China

China's PCB Rapid Prototyping Revolutionizes the Electronics IndustryChina's Printed Circuit Board (PCB) Rapid Prototyping has been making headlines in the electronics industry for its innovative solutions and efficient production processes. With its state-of-the-art facilities and skilled workforce, China has become a global leader in PCB rapid prototyping, offering companies a competitive edge in product development and manufacturing.As the world's largest consumer electronics manufacturer, China's PCB rapid prototyping industry has grown exponentially in recent years. The combination of advanced technology, streamlined processes, and affordable labor costs has attracted numerous global companies to explore the benefits of partnering with Chinese manufacturers.One such company leading the way in PCB rapid prototyping is [Company Name]. With a strong emphasis on quality and customer satisfaction, they have quickly risen to prominence and secured a reputation as one of the industry's finest. Their expertise and dedication to excellence have allowed them to forge partnerships with renowned electronics brands from around the world.Using cutting-edge equipment and leveraging their extensive experience, [Company Name] specializes in offering a range of rapid prototyping services. From single-layer to multi-layer PCBs, they are capable of fulfilling various customer demands efficiently and to the highest standards. This versatility makes them an ideal partner for companies of all sizes, from startups to multinational corporations.One of the key advantages of PCB rapid prototyping is the significantly reduced time-to-market. Traditional PCB manufacturing processes can take several weeks, delaying product development and limiting a company's ability to respond to market demands. With China's rapid prototyping capabilities, this time is drastically reduced to as little as a few days, allowing companies to stay ahead of the competition and meet tight project deadlines.Moreover, PCB rapid prototyping offers increased flexibility and adaptability throughout the design phase. Companies can quickly iterate and refine their product designs, addressing any issues or making improvements along the way. This iterative approach minimizes the risk of costly mistakes during full-scale production and ensures that the final product meets all the necessary specifications.China's PCB rapid prototyping services also benefit from the country's robust supply chain and extensive component sourcing capabilities. With access to a vast network of suppliers and distributors, [Company Name] can secure high-quality components at the best prices. This not only reduces production costs but also guarantees shorter lead times, giving their clients a competitive edge in the market.As part of their commitment to sustainability, [Company Name] also places great importance on reducing waste and minimizing the environmental impact of their operations. By optimizing material usage during the rapid prototyping process, they minimize material waste, contributing to a greener and more sustainable industry.China's PCB rapid prototyping industry is poised for continued growth and innovation, with more companies recognizing the advantages of partnering with Chinese manufacturers. The combination of advanced technology, efficient processes, and highly skilled professionals positions China as a key player in the global electronics supply chain.By leveraging China's PCB rapid prototyping services, companies can accelerate their product development cycle, deliver high-quality products to market faster, and maximize their overall business success. With [Company Name] leading the charge, the future of PCB rapid prototyping in China looks brighter than ever.