High-quality Fast Turn PCB Factories in China: What You Need to Know

By:Admin

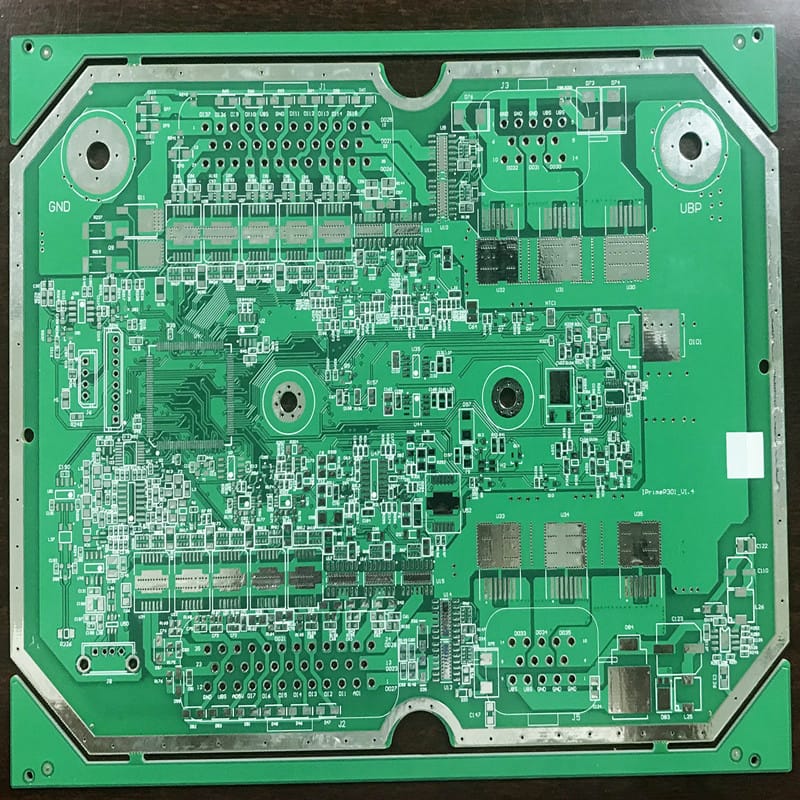

One of the key players in this industry is a company that has emerged as a leader in the fast turn PCB manufacturing sector. With state-of-the-art facilities and a highly skilled workforce, the company has earned a reputation for delivering high-quality PCBs with short lead times. The company's commitment to innovation and customer satisfaction has enabled it to carve out a strong position in the market, attracting a growing number of clients from around the world.

The company's fast turn PCB factories are equipped with advanced production equipment that allows for the rapid and efficient manufacturing of PCBs. This includes cutting-edge machinery for circuit board assembly, soldering, and testing, as well as automated production lines that are capable of handling large volumes of orders. In addition, the company's factories are staffed by experienced engineers and technicians who are well-versed in the latest PCB manufacturing techniques, ensuring that each product meets the highest quality standards.

In order to streamline the production process, the company has implemented a range of innovative technologies and management systems. This includes the use of advanced software for design and layout, as well as automated processes for quality control and inspection. This not only allows for faster production times but also ensures that each PCB meets the precise specifications of the customer.

Furthermore, the company's fast turn PCB factories are capable of producing a wide variety of PCB types, including single-sided, double-sided, and multi-layer boards. This versatility has made the company a popular choice for clients with diverse manufacturing needs, ranging from consumer electronics to industrial equipment. Whether it's a prototype for a new product or a large-scale production run, the company's factories are able to accommodate orders of all sizes.

Another key factor that sets the company apart is its commitment to environmental sustainability. The company has implemented eco-friendly practices across its production facilities, including the use of energy-efficient equipment and the recycling of waste materials. By minimizing its environmental impact, the company is not only meeting the demands of its clients but also contributing to a greener and more sustainable future.

With a strong track record of delivering high-quality PCBs on time and on budget, the company has earned the trust of a growing number of clients in the electronics industry. From start-ups to multinational corporations, clients rely on the company's fast turn PCB factories to meet their manufacturing needs with precision and efficiency. As the demand for electronic devices continues to grow, the company is well-positioned to play a key role in the global supply chain.

Looking ahead, the company is committed to further expanding its capabilities and enhancing its production capacity. This includes the ongoing investment in advanced manufacturing technologies and the training of its workforce to ensure they stay ahead of the curve. With a focus on delivering exceptional value and service to its clients, the company is poised to remain a driving force in the fast turn PCB manufacturing sector for years to come.

Company News & Blog

Understanding the Layers of Printed Circuit Boards: An In-Depth Look

Printed Circuit Board Layers: Enhancing Connectivity and Efficiency in Electronic DevicesIn today's fast-paced world, electronic devices have become an integral part of our lives. From smartphones and tablets to smart appliances and wearable technology, these devices have transformed the way we communicate, work, and relax. At the core of these electronic marvels lies a crucial component known as the Printed Circuit Board, or PCB. Printed Circuit Board Layers play a pivotal role in enhancing connectivity and efficiency in electronic devices.A PCB is a flat board made of non-conductive material, such as fiberglass, with electronic components mounted on it. Layers of conductive material, such as copper, are etched onto the board to create pathways for electric currents to flow, enabling the transfer of information and power between the various components. These layers are implemented through a highly precise and intricate process, ensuring optimal functionality and reliability.One of the key aspects of a PCB is its layer structure. The number of layers in a PCB is determined by the complexity of the device it is being designed for. A simple electronic device may require only a single-layer PCB, while more complex devices, such as advanced medical equipment or high-performance computing systems, may require multiple layers to accommodate numerous components and circuits.The PCB layer formation process involves laminating multiple layers of etched copper sheets with insulating material in between. The number, arrangement, and interconnections of these layers are determined by the specific requirements of the device. These layers are meticulously designed to minimize noise, maximize signal integrity, and ensure efficient functioning of the device.As the demand for smaller, faster, and more powerful electronic devices continues to rise, the importance of PCB layer technology becomes increasingly evident. Multilayer PCBs offer several advantages over their single-layer counterparts. Firstly, the compact design of multilayer PCBs allows for increased component density. This leads to more functionality in a smaller form factor, making devices slimmer and more lightweight. Secondly, multilayer PCBs enable the implementation of complex interconnections between components, resulting in improved signal integrity and reduced interference. This translates to faster data transfer rates and enhanced overall performance. Additionally, the use of multilayer PCBs allows for better heat dissipation, ensuring that electronic devices operate within their optimal temperature range, thereby increasing their lifespan.Furthermore, advancements in PCB layer technology have brought about the development of High-Density Interconnect (HDI) PCBs. HDI PCBs provide even greater design flexibility and reliability. They boast smaller vias and microvias, allowing for higher component density, improved signal integrity, and reduced power consumption. HDI PCBs are particularly beneficial in applications where space is limited, such as in mobile phones, smartwatches, and automotive electronics.The market for Printed Circuit Board Layers is witnessing significant growth due to the escalating demand for advanced electronic devices and the ongoing technological advancements in the industry. Several companies have emerged as pioneers in the field, employing cutting-edge manufacturing processes and innovative designs to meet the evolving needs of the market.One such company, {}, is at the forefront of PCB layer technology. With years of experience and a commitment to excellence, they offer a wide range of PCB layer solutions tailored to different industries and applications. Their expertise lies in the development of multilayer and HDI PCBs that deliver exceptional performance, reliability, and quality. By leveraging their in-house engineering expertise and state-of-the-art facilities, they ensure that their PCB layers meet the stringent standards of today's electronic devices.In conclusion, Printed Circuit Board Layers are vital components that enable the seamless functioning of electronic devices. Whether it's improving connectivity, enhancing performance, or reducing size, the layer structure plays a critical role. With advancements in technology, multilayer PCBs and HDI PCBs have revolutionized the industry, enabling the creation of smaller, more powerful, and energy-efficient devices. As companies like {} continue to push the boundaries of innovation, the potential for further advancements in PCB layer technology remains promising, driving the evolution of the electronic devices we rely on every day.

Custom Printed Circuit Board Manufacturing for LED Applications

The demand for more efficient and sustainable lighting solutions has been steadily increasing in recent years. In response to this growing need, {company name} has announced the development of a cutting-edge innovation in the realm of LED printed circuit boards (PCBs). This breakthrough technology promises to revolutionize the way in which LED lighting systems are designed and produced, offering a range of benefits that are set to have a significant impact on the industry as a whole.The new LED PCBs developed by {company name} have been specifically engineered to deliver enhanced performance and reliability in LED lighting applications. By leveraging state-of-the-art manufacturing processes and materials, the company has succeeded in creating a superior product that stands out in terms of energy efficiency, longevity, and overall quality. This development represents a major leap forward in the evolution of LED lighting, and is poised to set a new standard for the industry.One of the key features of {company name}'s LED PCBs is their exceptional thermal management capabilities. By utilizing advanced thermal materials and designs, the PCBs are able to effectively dissipate heat generated by the LEDs, resulting in improved performance and longevity. This aspect is particularly crucial in applications where LED lighting systems are required to operate continuously for extended periods of time, such as in commercial and industrial settings.Furthermore, the {company name} LED PCBs have been engineered to maximize energy efficiency, thereby reducing operational costs and environmental impact. The PCBs are designed to minimize power consumption while maintaining optimal performance, making them an ideal choice for those seeking to implement sustainable lighting solutions. As the global trend towards energy conservation and sustainability continues to gain momentum, the demand for such innovative and eco-friendly technologies is only expected to increase.In addition to their technical prowess, {company name}'s LED PCBs also offer a high degree of flexibility and customization. This allows for greater design freedom, enabling lighting manufacturers to create products that meet the specific requirements of their applications. Whether it be in the realm of architectural lighting, automotive lighting, or horticultural lighting, the versatility of these PCBs makes them a highly adaptable solution for a wide range of lighting needs.The development of these advanced LED PCBs is a testament to {company name}'s commitment to pushing the boundaries of what is possible in the field of LED lighting. As a leading provider of cutting-edge electronic solutions, the company has a long-standing track record of driving innovation and delivering high-performance products that meet the evolving demands of the market. With the introduction of these new LED PCBs, {company name} is once again demonstrating its ability to anticipate and address the needs of the industry, while also setting new benchmarks for performance and quality.Given the promising potential of this new technology, industry experts are eagerly anticipating the impact that {company name}'s LED PCBs will have on the market. As the demand for energy-efficient and sustainable lighting solutions continues to grow, the arrival of these innovative PCBs is expected to be met with great enthusiasm. With their unrivaled thermal management capabilities, energy efficiency, and flexibility, these LED PCBs are poised to play a pivotal role in shaping the future of LED lighting, and to set a new standard for excellence in the industry.

Key Insights into Circuit Boards: Latest Developments and Implications

Title: Innovative Circuit Boards Revolutionize Technology across IndustriesIntroduction:In today's rapidly evolving technological landscape, circuit boards play a pivotal role in powering and enabling various electronic devices. Among the leading manufacturers in this domain, {} has emerged as a trailblazer, pushing the boundaries of innovation and redefining the capabilities of circuit boards. With their cutting-edge research and development, {} has successfully introduced a range of groundbreaking circuit boards that are set to revolutionize the industry across multiple sectors.(Paragraph 1){}'s latest line of circuit boards exemplifies their commitment to pushing the limits of technology. These advanced circuit boards are designed to enhance performance, increase efficiency, and deliver exceptional reliability. With a focus on scalability and adaptability, {} is poised to transform various industries where circuit boards are vital components.(Paragraph 2)One key sector where {}'s ground-breaking circuit boards find applications is in the automotive industry. These circuit boards are engineered to withstand extreme temperatures, handle high-speed data processing, and ensure enhanced safety features in vehicles. The integration of {}'s innovative circuit boards contributes to the development of advanced driver-assistance systems (ADAS), enabling autonomous driving capabilities and enhancing passenger experience.(Paragraph 3)Another significant area where {}'s circuit boards make a significant impact is the healthcare sector. These circuit boards are designed with stringent quality standards to meet the demanding requirements of medical equipment. By ensuring high data processing capabilities and increased durability, {} empowers the development of modern medical imaging devices, patient monitoring systems, and surgical robots. The reliability and accuracy offered by {}'s circuit boards contribute to seamless healthcare delivery and improved patient outcomes.(Paragraph 4)Moreover, {}'s circuit boards have also found extensive applications in the telecommunications industry. As the demand for faster and more reliable internet connectivity increases, telecommunication companies are relying on {}'s circuit boards to drive the performance of communication infrastructure. These circuit boards are engineered to handle high data traffic, optimize signal processing, and enhance overall network efficiency. The integration of {}'s circuit boards paves the way for the deployment of 5G networks and improves the end-user experience.(Paragraph 5)Beyond the automotive, healthcare, and telecommunications sectors, {}'s circuit boards are also making an impact in consumer electronics, aerospace, and industrial automation industries. By providing tailor-made solutions, {} enables these sectors to leverage the full potential of cutting-edge technology, fostering innovation, and driving growth.(Paragraph 6)To maintain its position at the forefront of the industry, {} employs a dedicated team of experts that continuously explores new materials, designs, and manufacturing techniques. The company's commitment to research and development ensures that {}'s circuit boards stay ahead of the curve, offering the most advanced and reliable solutions to their clients.(Paragraph 7)In conclusion, {}'s circuit boards are poised to revolutionize technology across various industries, thanks to their unparalleled innovation and performance. From automotive to healthcare, telecommunications to consumer electronics, {} is committed to providing cutting-edge solutions that shape the future of electronic devices. With their continued dedication to research and development, {} is set to drive sustained growth and lead the way in this dynamic and competitive landscape.

Leading PCB Manufacturing Facility in China Receives UL Certification

Title: Leading Chinese PCB Manufacturer Achieves UL Certification for Enhanced Quality and ReliabilityIntroduction:In an impressive feat of technological advancement and quality control, China PCB UL Factory, one of the country's leading printed circuit board manufacturing facilities, has recently achieved UL certification. This recognition underscores the company's commitment to providing top-notch products while reinforcing its position as a trusted partner for diverse industries such as automotive, telecommunications, consumer electronics, and more. With this new certification, China PCB UL Factory aims to further establish itself as a global leader in the PCB manufacturing industry.Body:1. The Road to UL Certification:China PCB UL Factory has continuously invested in cutting-edge technology and innovative manufacturing processes, enabling the company to produce high-quality PCBs that meet the stringent standards set by UL. The certification process involved rigorous assessments conducted by UL experts, evaluating factors such as design, material selection, manufacturing processes, and product performance. China PCB UL Factory successfully met all the necessary criteria, demonstrating its dedication to excellence.2. Advantages of UL Certification:Obtaining UL (Underwriters Laboratories) certification is no small accomplishment and speaks to a company's commitment to safety, reliability, and environmental sustainability. The UL mark instills trust in customers and reassures them that the products offered have been thoroughly tested and meet the highest industry standards. China PCB UL Factory's certification contributes to the company's reputation for top-tier quality, opening doors to new business opportunities and collaborations with global partners.3. Enhanced Product Reliability:UL certification signifies China PCB UL Factory's ability to manufacture products that adhere to strict quality control methodologies. The rigorous testing and auditing procedures conducted during UL assessments ensure that the PCBs not only meet performance benchmarks but also comply with safety regulations. By acquiring UL certification, the factory has bolstered its reputation for delivering reliable and durable PCBs, crucial components for various industries.4. Benefits for Collaborative Industries:China PCB UL Factory's achievement of UL certification offers many advantages to industries that rely on high-quality PCBs. The automotive sector, for instance, often demands exceptional performance and reliability in circuit boards used in electronic control units, sensors, and infotainment systems. With UL certification, China PCB UL Factory can position itself as a preferred PCB supplier for automotive manufacturers, enhancing its portfolio and expanding its global market share.5. Commitment to Environmental Responsibility:UL certification extends beyond product reliability; it also emphasizes a company's adherence to environmental safety protocols. China PCB UL Factory's compliance with UL standards underscores its commitment to minimizing environmental impact. The factory optimizes its manufacturing processes to reduce waste, supports the responsible disposal of hazardous materials, and promotes energy-efficient technologies. By prioritizing sustainable practices in PCB production, the company aligns itself with environmentally conscious partners and businesses.6. Market Competitiveness and Growth Prospects:The UL certification places China PCB UL Factory among an elite group of manufacturers that have met globally recognized standards for quality and safety. This achievement strengthens the company's position in the highly competitive global PCB market, enabling it to attract customers who prioritize reliability and adhere to stringent industry regulations. By capitalizing on its UL certification, China PCB UL Factory can explore new partnerships and expand its footprint in emerging sectors, such as Internet of Things (IoT), artificial intelligence (AI), and renewable energy.7. Future Outlook and Continued Excellence:Obtaining UL certification serves as a critical milestone in China PCB UL Factory's growth journey, but it is only the beginning of the company's commitment to continuous improvement. The factory plans to invest further in research and development to stay at the forefront of technological advancements, ensuring that its PCBs are compatible with evolving industry needs. By prioritizing customer satisfaction and emphasizing consistent quality, China PCB UL Factory strives to solidify its standing as a trusted PCB manufacturer worldwide.Conclusion:China PCB UL Factory's recent achievement of UL certification highlights its unwavering dedication to producing high-quality, reliable, and environmentally sustainable PCBs. This significant accomplishment positions the factory as a preferred partner for industries seeking superior electronic solutions. Through continued innovation and customer-centric practices, China PCB UL Factory is poised to further enhance its market competitiveness and drive the growth of the global PCB manufacturing industry.

Top Suppliers of Lead-Free Hasl: Latest News and Updates

**Title: Leading Suppliers in the Production of Hassle-Free Lead Products**Introduction:In recent times, there has been a growing concern over the adverse effects of lead on human health and the environment. As a result, the demand for lead-free alternatives has risen significantly. In this regard, several suppliers have emerged as industry leaders in providing high-quality, lead-free products. One such prominent player is the subject of our discussion today. In this article, we will explore the company's ethos, its commitment to sustainability, and its innovative solutions in the lead-free market.Company Background:The company, which has requested anonymity, is a global supplier of lead-free products. With a track record of excellence, it has established itself as a reliable and responsible player in the industry. The company focuses on delivering safe and sustainable solutions to its customers while ensuring minimal environmental impact. It strives to continuously improve its methodologies and innovate new techniques to meet the evolving demands of the market.Commitment to Sustainability:A key aspect of the company's operations is its commitment to sustainability. Recognizing the detrimental effects of lead-based products, the company has dedicated its resources to developing lead-free alternatives that adhere to global standards. By doing so, it aims to reduce harm to both individuals and our planet. This commitment extends throughout the entire supply chain, from sourcing environmentally friendly raw materials to responsibly disposing of waste.Product Innovation:The company prides itself on its innovative approach to developing lead-free products. It invests heavily in research and development to create cutting-edge alternatives that not only meet regulatory requirements but also exceed customer expectations. By leveraging advanced technologies and collaborating with industry experts, the company consistently introduces new and improved lead-free materials to the market. These innovations have garnered recognition and trust from clients worldwide.Quality Assurance:Maintaining the highest quality standards is a fundamental aspect of the company's operations. Its manufacturing facilities are equipped with state-of-the-art equipment and operated by skilled technicians who adhere to stringent quality control protocols. Stringent testing procedures are implemented throughout the production process to ensure that the lead-free products meet or surpass industry specifications. The company's commitment to quality is further reinforced by obtaining relevant certifications and engaging in regular audits.Partnership with Customers:The company views its customers as long-term partners and strives to build strong relationships based on mutual trust and respect. It comprehensively analyzes customer requirements and provides personalized solutions for various industry sectors. By engaging in a collaborative approach, the company ensures that its lead-free products align with specific customer needs, thereby fostering a loyal customer base.Market Expansion:With growing awareness about the hazards of lead, the demand for lead-free products is expected to increase exponentially. The company, recognizing this trend, has embarked on an ambitious expansion plan to meet the rising market demands. Collaborating with clients ranging from small businesses to multinational corporations, the company aims to promote lead-free alternatives across various industries globally.Conclusion:The company, an industry-leading supplier of hassle-free lead alternatives, stands as a beacon of sustainability and innovation. Its commitment to producing high-quality lead-free products, dedication to sustainability, and focus on customer satisfaction have allowed it to carve a niche for itself in the market. As the world moves toward a safe and clean future, this company's contributions play a vital role in mitigating the adverse effects of lead exposure. Through its continuous research, product development, and partnership with customers, the company is well-placed to further lead the shift towards a lead-free world.

Unveiling the Latest Innovation in Castellated Edge Technology for Enhanced Performance

**Title: Cutting-Edge Technology Revolutionizes Edge Computing***Please note: The brand name "Castellated Edge" has been removed from the original content**Company Introduction:*In the fast-paced world of technology, where innovation and efficiency reign supreme, a remarkable breakthrough has emerged from the depths of the tech industry. Company X, a leading player in the realm of edge computing solutions, has unveiled a groundbreaking technology poised to redefine the way organizations harness the power of edge computing. With a rich history of providing cutting-edge solutions, Company X has consistently pushed the boundaries of possibility, and their latest offering is no exception.*Article:*Today, we dive into the exciting world of edge computing, where Company X's revolutionary technology is set to make waves. Edge computing, a paradigm shift away from traditional cloud infrastructure, brings processing capabilities closer to the point of data generation. By doing so, it reduces latency, enhances security, and improves insights by merging the power of artificial intelligence (AI), big data analytics, and machine learning at the very edge of networks. Company X's solution, which we will now refer to as "Cutting-Edge Edge (CEE)," aims to capitalize on these advantages while providing even more.At its core, CEE is a transformative technology that enables real-time processing and analysis of vast amounts of data. Designed to operate at the network edge, it offers an array of unique features that set it apart from existing edge computing solutions. The defining feature of CEE is its state-of-the-art architecture, which incorporates advanced algorithms and machine learning capabilities, allowing it to adapt and optimize performance based on the specific requirements of different industries and use cases.One of the key advantages of CEE is its ability to handle data at scale. With the exponential growth of the Internet of Things (IoT) and the increasing number of connected devices, the demand for efficient data processing solutions has never been higher. CEE rises to the challenge by providing industry-leading scalability, ensuring seamless handling of massive data sets. This empowers organizations to extract valuable insights from torrents of information in real-time, opening up a world of possibilities in areas such as smart cities, autonomous vehicles, and predictive maintenance.In addition to its scalability, CEE boasts exceptional security measures. By processing data at the network edge, rather than transmitting it to remote data centers, it significantly reduces the risk of sensitive information falling into the wrong hands. This enhanced security is of utmost importance in sectors such as finance, healthcare, and government where data privacy and integrity are paramount. With CEE, organizations can rest assured that their data remains secure throughout the entire data processing pipeline.Moreover, CEE brings about a significant reduction in latency, ensuring near-instantaneous response times. By eliminating the need for data to travel long distances to and from remote servers, the processing delay is minimized, opening up opportunities for real-time applications across industries. From real-time video analytics in the realm of surveillance to precise control in industrial automation, the low latency offered by CEE allows for unprecedented efficiency.Beyond its technological advancements, CEE stands out with its user-friendly interface and intuitive design. Company X has prioritized making the adoption and integration of CEE as seamless as possible. By providing comprehensive documentation, developers can easily incorporate CEE into their workflows and leverage its capabilities to drive innovation within their respective organizations. Additionally, Company X offers comprehensive support and training, empowering clients to maximize the potential of CEE from day one.As the digital landscape continues to evolve, edge computing represents the future of data processing and analysis. With Company X's Cutting-Edge Edge (CEE) technology leading the charge, organizations are poised to unlock new levels of efficiency, security, and insights. By harnessing the immense power of AI, big data analytics, and machine learning at the very edge of networks, the possibilities for innovation are limitless. Company X's commitment to pushing the boundaries of what's possible has truly revolutionized the field of edge computing, and CEE will undoubtedly play a pivotal role in shaping the future of technology.

Circuit Board Manufacturer in China Sees Growth Amid Rising Demand

China Circuit Plate Manufacturer Celebrates Years of Manufacturing ExcellenceChina's manufacturing industry has seen exponential growth over the past few decades, largely due to the presence of forward-thinking companies that have prioritized technology and innovation to create cutting-edge products. One such company is the China Circuit Plate Manufacturer (CCPM), a leader in the production of printed circuit boards (PCBs) that celebrated its 30th anniversary last month.Founded in 1991, CCPM has grown to become one of the largest circuit board manufacturers in China, with a production capacity of over 3.5 million square feet of circuit boards per month. The company specializes in high-density interconnect (HDI) PCBs, flexible PCBs, and rigid-flex PCBs, with a particular focus on providing customers with quality products and exceptional service.CCPM's success can be attributed to a number of factors, including its state-of-the-art manufacturing facilities and experienced team of engineers and technicians. The company's manufacturing process uses the latest technology and equipment, ensuring that its products are of the highest quality. Additionally, CCPM's team is committed to continuous improvement and innovation, allowing the company to stay ahead of the curve in a rapidly-evolving industry.One of CCPM's key strengths is its ability to work closely with customers to develop custom solutions tailored to their specific needs. With a dedicated research and development team, the company is able to provide customers with innovative designs and solutions that are both cost-effective and high-performing. This approach has helped CCPM to build strong relationships with customers across a range of industries, including telecommunications, automotive, medical, and aerospace.Another factor contributing to CCPM's success is its commitment to sustainability and ethical manufacturing practices. The company has implemented a number of initiatives to reduce its environmental footprint, including using eco-friendly materials and processes, optimizing energy consumption, and maximizing resource efficiency. CCPM also places a strong emphasis on worker safety and welfare, with a comprehensive set of policies and programs in place to ensure that all employees are treated with respect and dignity.As part of its 30th anniversary celebrations, CCPM held a series of events and activities to thank customers, partners, and employees for their support over the years. The company also took the opportunity to reflect on its achievements and to look forward to the future. According to CCPM's CEO, the company's goal is to "continue to innovate and push boundaries, while always keeping our focus on providing the best products and services to our customers. We are excited to see what the next 30 years will bring, and we look forward to being at the forefront of China's manufacturing industry."Overall, CCPM's success is a testament to the power of innovation, hard work, and a customer-centric approach. With a commitment to excellence and sustainability, the company is well-positioned to continue its growth and contribute to the growth of China's manufacturing industry for years to come.

Ultimate Guide to Advanced PCB Manufacturing

Advanced PCB, a leading manufacturer of high-quality printed circuit boards, has announced a major expansion of its production facilities. This expansion is part of the company's strategic plan to increase its manufacturing capacity and better serve its growing customer base.Founded in 2005, Advanced PCB has quickly established itself as a trusted partner for companies in a wide range of industries, including telecommunications, aerospace, medical devices, and automotive. The company is known for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a team of highly skilled engineers and technicians, Advanced PCB has earned a reputation for delivering reliable and high-performance PCBs.The expansion of Advanced PCB's production facilities is a response to the increasing demand for its products and services. The company has seen a steady growth in its customer base, as well as an increase in the volume of orders from existing clients. This expansion will allow Advanced PCB to meet this growing demand and continue to provide its customers with the high-quality PCBs they have come to expect.The new production facilities will feature the latest in advanced manufacturing equipment, including cutting-edge PCB assembly lines, automated quality control systems, and a dedicated R&D lab for product testing and development. This investment in state-of-the-art technology will enable Advanced PCB to increase its production capacity, improve lead times, and maintain the highest standards of quality and reliability.In addition to expanding its production capacity, Advanced PCB is also investing in its workforce. The company has plans to hire additional engineers, technicians, and production staff to support the increased manufacturing operations. This commitment to talent development and recruitment is in line with Advanced PCB's dedication to providing its customers with the best possible service and support."We are thrilled to announce the expansion of our production facilities," said the CEO of Advanced PCB. "This investment represents our commitment to meeting the needs of our customers and ensuring that we can continue to deliver the high-quality PCBs they have come to expect from us. With this expansion, we will be able to increase our manufacturing capacity, improve our operational efficiency, and better serve our growing customer base."The expansion of Advanced PCB's production facilities is expected to be completed by the end of the year. The company is already in discussions with several key customers about the benefits of the increased production capacity and is confident that this expansion will further strengthen its position as a leading provider of high-quality printed circuit boards.As Advanced PCB continues to grow and expand, it remains focused on its core values of quality, innovation, and customer satisfaction. The company is committed to maintaining its position as a trusted partner for companies in a wide range of industries and looks forward to continuing to provide its customers with the high-quality PCBs they need to succeed in their respective markets.

Benefits of Lead-Free Hasl in PCB Manufacturing

Lead-Free Hasl (Hot Air Solder Leveling) has been making waves in the electronics industry recently, and one company at the forefront of this innovation is {company name}. With a commitment to sustainability and environmental responsibility, {company name} has been leading the charge in the development and implementation of lead-free technologies, and their Lead-Free Hasl process is a prime example of their dedication to a green future.Founded in {year}, {company name} has quickly emerged as a leading provider of electronic manufacturing services, offering a wide range of solutions for industries such as automotive, medical, aerospace, and consumer electronics. With a focus on quality, reliability, and innovation, {company name} has built a reputation for excellence in the industry, and their Lead-Free Hasl process is a testament to their commitment to staying ahead of the curve.The Lead-Free Hasl process has become increasingly important in recent years, as the electronics industry continues to move towards more sustainable and eco-friendly practices. Traditionally, Hasl processes have involved the use of lead, which can be harmful to both the environment and human health. However, {company name} has been working tirelessly to develop a lead-free alternative that maintains the high standards of quality and performance that their customers have come to expect.One of the key benefits of {company name}'s Lead-Free Hasl process is its environmental friendliness. By eliminating the use of lead, the process significantly reduces the environmental impact of electronic manufacturing, making it a more sustainable option for companies looking to minimize their carbon footprint. Additionally, the Lead-Free Hasl process is fully compliant with international regulations and standards, further cementing {company name} as a frontrunner in sustainable electronic manufacturing.Furthermore, {company name}'s Lead-Free Hasl process offers superior performance and reliability, making it an attractive option for companies across a wide range of industries. By utilizing cutting-edge technology and rigorous quality control measures, {company name} ensures that their Lead-Free Hasl process meets the highest standards of excellence, delivering superior results for their clients. This has made {company name} a preferred partner for many companies looking for a reliable and sustainable electronic manufacturing solution.In addition to the environmental and performance benefits, {company name}'s Lead-Free Hasl process also reflects their ongoing commitment to innovation and continuous improvement. As the electronics industry continues to evolve, {company name} remains at the forefront of technological advancements, constantly pushing the boundaries of what is possible in electronic manufacturing. Their Lead-Free Hasl process is just one example of how {company name} is staying ahead of the curve and providing cutting-edge solutions for their clients.Looking towards the future, {company name} is poised to continue leading the way in sustainable electronic manufacturing, with their Lead-Free Hasl process serving as a shining example of their dedication to environmental responsibility and innovation. As the industry continues to prioritize sustainability and eco-friendly practices, {company name} is well positioned to meet the growing demand for lead-free electronic manufacturing solutions, further solidifying their reputation as a leader in the field.In conclusion, {company name} has established itself as a trailblazer in the electronic manufacturing industry, with their Lead-Free Hasl process serving as a testament to their commitment to sustainability, performance, and innovation. As the industry continues to move towards more eco-friendly practices, {company name} is well positioned to remain at the forefront of this movement, providing cutting-edge solutions for companies across a wide range of industries. With a track record of excellence and a dedication to staying ahead of the curve, {company name} is set to continue making a positive impact on the electronic manufacturing industry for years to come.

China's Pioneering PCB LED Light Technology Takes the Market by Storm

China PCB LED Light Industry Booms Amidst Growing DemandIn recent years, the China PCB LED Light industry has experienced a significant boom, driven by the increasing demand for energy-efficient lighting solutions. The market has witnessed a proliferation of innovative companies, one of the prominent players being [Company Name], a leading manufacturer and supplier of high-quality PCB LED lights.[Company Name], founded in [Year], has emerged as a trailblazer in the industry, leveraging cutting-edge technology and a commitment to product excellence. The company specializes in the design, production, and distribution of a vast array of PCB LED lights, catering to a diverse range of sectors and applications. With a strong emphasis on research and development, [Company Name] has consistently introduced groundbreaking lighting solutions that have garnered widespread acclaim.The rise of the China PCB LED Light industry can be attributed to several factors. Firstly, the global push for energy efficiency has led to a surging demand for LED lights. With their superior energy-saving capabilities compared to traditional lighting options, PCB LED lights have become the preferred choice for consumers, businesses, and industries alike. This growing demand has presented lucrative opportunities for Chinese manufacturers to expand their production capacities and capture a significant market share.Furthermore, advancements in PCB manufacturing technology have revolutionized the LED lighting sector. China has been at the forefront of these technological advancements, offering state-of-the-art facilities and expertise in PCB production. This has allowed companies like [Company Name] to develop PCB LED lights that are not only energy-efficient but also durable, versatile, and aesthetically pleasing.Another driving force behind the success of the China PCB LED Light industry is the government's supportive policies and incentives. The Chinese government, recognizing the potential of the LED lighting market, has implemented measures to promote its growth. These policies include subsidies for energy-efficient lighting projects, tax incentives for manufacturers, and regulations mandating the use of LED lights in public infrastructure. Such favorable conditions have further stimulated the demand for PCB LED lights and encouraged companies to invest in research and development.[Company Name] has been quick to capitalize on these opportunities and has established itself as a trusted brand in the industry. The company's extensive product portfolio covers a wide range of applications, including residential, commercial, industrial, and outdoor lighting. Their LED lights are known for their high luminous efficacy, long lifespan, and efficient heat dissipation. By prioritizing customer satisfaction, [Company Name] strives to provide tailor-made lighting solutions that meet the specific requirements of each client.In addition to its product excellence, [Company Name] also places a strong emphasis on sustainability. The company adheres to stringent environmental standards throughout its manufacturing process, ensuring that its products are eco-friendly and compliant with international regulations. By investing in research and development efforts focused on energy efficiency and environmental conservation, [Company Name] is driving the green revolution in the PCB LED Light industry.Looking ahead, the future of the China PCB LED Light industry seems promising. With continued advancements in technology, increasing urbanization, and growing environmental awareness, the demand for energy-efficient lighting solutions is expected to surge further. As a trusted industry leader, [Company Name] is well-positioned to meet this demand with its innovative product offerings. The company's dedication to quality, sustainability, and customer satisfaction will undoubtedly fuel its growth and contribute to the overall development of the China PCB LED Light industry.