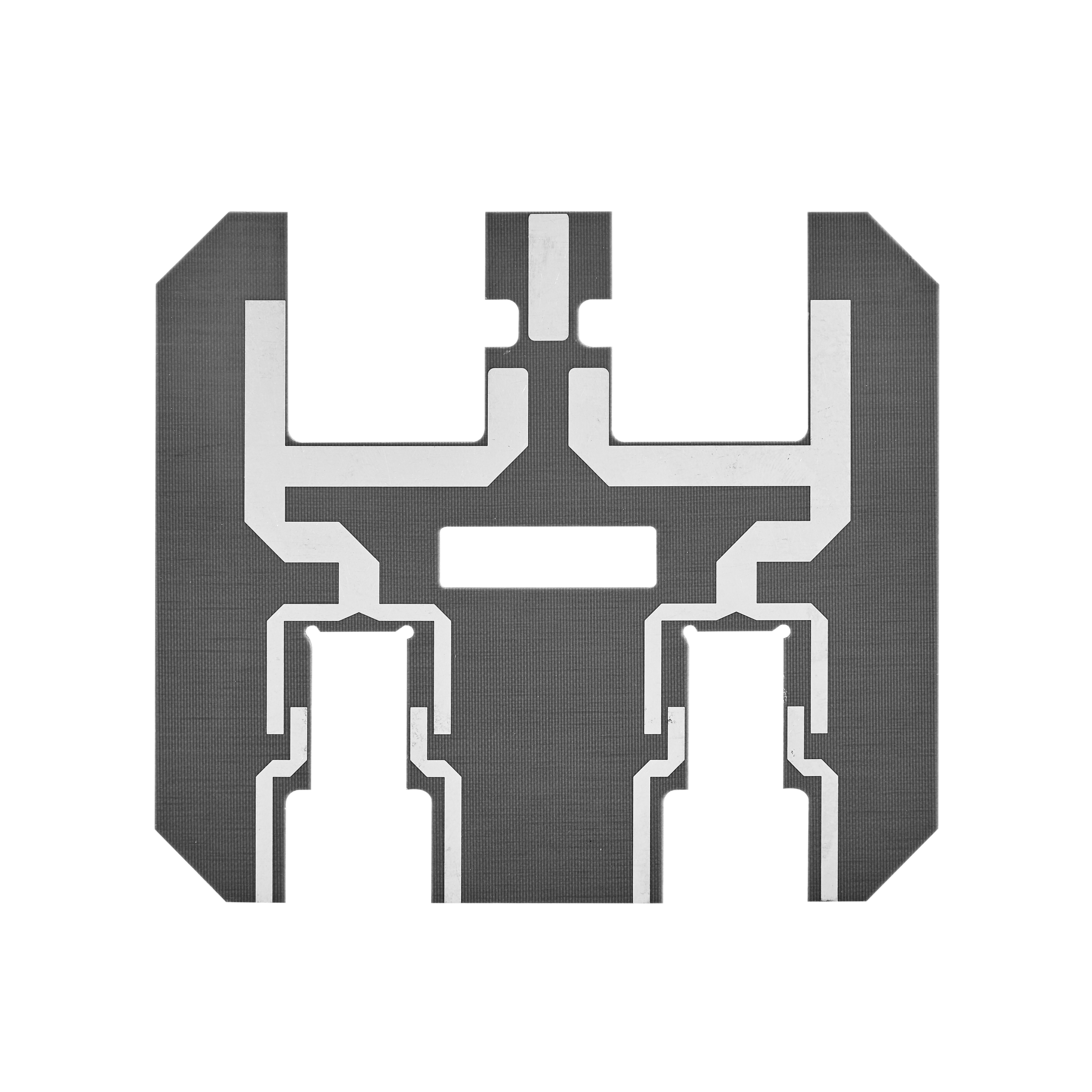

High-Quality Industrial Control PCB for Fr4 Applications - Everything You Need to Know

By:Admin

{Company} is a leading manufacturer of industrial control FR4 PCBs, offering a wide range of products to meet the diverse needs of its clients. With state-of-the-art facilities and a team of experienced professionals, the company has gained a reputation for delivering high-quality and reliable PCB solutions to industries across the globe.

The company's industrial control FR4 PCBs are designed to meet the specific requirements of industrial applications, including automation, robotics, and machinery control. These PCBs are built to withstand high voltage and current, ensuring smooth and efficient operation of industrial equipment. Additionally, the company offers custom solutions to cater to the unique needs of its clients, providing personalized PCB designs and layouts for a seamless integration into their industrial systems.

With a focus on quality and innovation, {Company} has invested in advanced manufacturing technologies to produce industrial control FR4 PCBs that meet the highest industry standards. The company's production processes adhere to strict quality control measures, ensuring that each PCB meets the required specifications and performs reliably under demanding industrial conditions.

In addition to its commitment to quality, {Company} places a strong emphasis on environmental sustainability and safety. The company complies with industry regulations and standards to ensure that its manufacturing processes are eco-friendly and adhere to strict safety guidelines. This dedication to environmental stewardship and workplace safety reflects the company's ethos of responsible and ethical business practices.

{Company} takes pride in its customer-centric approach, offering unparalleled technical support and customer service to its clients. The company's team of engineers and technical experts work closely with customers to understand their unique requirements and provide tailored solutions that meet their industrial control needs. Whether it's consultation on PCB design or troubleshooting technical issues, the company's dedicated support team is committed to delivering exceptional service and support to its clients.

As industries continue to evolve and embrace digitization, the demand for industrial control FR4 PCBs is expected to grow. These essential components play a crucial role in the efficient and safe operation of industrial equipment, making them indispensable in modern industrial settings. With its commitment to quality, innovation, and customer satisfaction, {Company} is well-positioned to meet the increasing demand for high-performance industrial control FR4 PCBs.

The company's dedication to excellence and its track record of delivering reliable PCB solutions have earned it the trust of leading industries worldwide. As the industrial landscape continues to evolve, {Company} remains at the forefront of providing cutting-edge industrial control FR4 PCBs that power the next generation of industrial automation and control systems. With a focus on technological advancement and customer satisfaction, the company is poised to continue setting new benchmarks in the industrial control PCB industry.

Company News & Blog

Quick Turn PCB Assembly Suppliers in China for Fast Production Turnaround

China Quick Turn PCB Assembly Suppliers on the RiseAs the demand for quick turn PCB assembly continues to grow, China has emerged as a key player in the global market. With a reputation for high-quality production and fast turnaround times, Chinese suppliers are attracting attention from companies around the world.One such supplier, {company name}, has quickly risen to prominence in the industry. With state-of-the-art facilities and a commitment to excellence, {company name} has become a go-to choice for businesses seeking fast and reliable PCB assembly services.Founded in {year}, {company name} has quickly established itself as a leader in the PCB manufacturing industry. The company's cutting-edge facilities are equipped with the latest technology, allowing for rapid production and assembly of high-quality PCBs. With a team of skilled engineers and technicians, {company name} is able to meet the tightest deadlines without compromising on quality.In addition to their advanced capabilities, {company name} is known for their exceptional customer service. From the initial quote to final delivery, the company takes a proactive approach to ensure that their clients' needs are met every step of the way. This commitment to customer satisfaction has helped {company name} build long-lasting relationships with businesses across a wide range of industries.One of the key factors that sets {company name} apart from other suppliers is their quick turn PCB assembly services. In today's fast-paced business environment, companies often find themselves in need of rapid PCB production to keep up with changing market demands. {company name} understands the importance of speed and agility, and has invested heavily in streamlining their production process to deliver quick turn PCB assembly without sacrificing quality.Furthermore, {company name} is dedicated to maintaining a high level of quality control throughout the production process. The company adheres to strict quality standards and conducts thorough testing to ensure that each PCB meets their clients' exact specifications. This attention to detail has earned {company name} a reputation for reliability and excellence in the industry.In addition to their quick turn PCB assembly services, {company name} also offers a range of other PCB manufacturing solutions. From prototype development to full-scale production runs, the company has the capabilities to handle projects of any size and complexity. Whether a client needs a small batch of PCBs for testing or a large order for mass production, {company name} has the expertise and resources to deliver.Looking to the future, {company name} is poised to continue leading the way in the quick turn PCB assembly market. With ongoing investments in technology and a commitment to innovation, the company is well-positioned to meet the evolving needs of their clients and the industry as a whole.As global demand for quick turn PCB assembly services continues to rise, China's position as a key supplier is only expected to strengthen. With companies like {company name} leading the way, businesses around the world can rely on Chinese suppliers to deliver high-quality PCBs with fast turnaround times.In conclusion, {company name} is a prime example of the expertise and dedication that Chinese quick turn PCB assembly suppliers bring to the table. With their advanced facilities, commitment to quality, and exceptional customer service, {company name} has established itself as a trusted partner for businesses seeking reliable PCB manufacturing solutions. As the industry continues to grow, China is poised to play an even larger role in meeting the global demand for quick turn PCB assembly.

Copper Thickness PCB: Everything You Need to Know

PCB manufacturing technology has rapidly advanced over the years, and one of the key components in the production of high-quality printed circuit boards is the copper thickness. The copper thickness in a PCB is crucial as it determines the conductivity and performance of the board. With the increasing demand for high-performance PCBs, manufacturers are constantly striving to improve the copper thickness and quality of their products.{Company Name} is a leading PCB manufacturer that has been at the forefront of producing high-quality and reliable printed circuit boards for various industries. With a strong focus on innovation and technological advancement, {Company Name} has consistently delivered cutting-edge PCB solutions to its clients.One of the key factors that set {Company Name} apart in the PCB industry is its commitment to using high-quality materials and state-of-the-art manufacturing processes. This includes the use of advanced techniques to ensure the copper thickness in their PCBs meets the highest standards.Recently, {Company Name} has made significant advancements in the copper thickness of their PCBs, introducing a new range of products with improved conductivity and performance. By enhancing the copper thickness, {Company Name} aims to meet the growing demands of industries such as telecommunications, aerospace, automotive, and consumer electronics.The increased copper thickness in {Company Name}'s PCBs is a result of extensive research and development, coupled with investments in cutting-edge manufacturing equipment. The company's dedication to improving the quality of their products has positioned them as a trusted partner for businesses seeking reliable and high-performance PCB solutions.{Company Name} understands the importance of copper thickness in PCBs and its impact on the overall performance of electronic devices. With the introduction of their new range of PCBs with enhanced copper thickness, {Company Name} aims to address the evolving needs of their customers and provide them with advanced solutions for their specific applications.In addition to the improved copper thickness, {Company Name} also takes pride in its commitment to environmental sustainability. The company has implemented strict measures to ensure that their manufacturing processes adhere to the highest environmental standards, minimizing the impact on the environment.By focusing on innovation, quality, and sustainability, {Company Name} is well-positioned to meet the increasing demands of the PCB market. The company's dedication to advancing the copper thickness in their PCBs reflects their ongoing efforts to deliver superior products to their customers.As the demand for high-performance PCBs continues to grow, {Company Name} remains dedicated to pushing the boundaries of possibility in PCB manufacturing. With its latest advancements in copper thickness, the company is set to solidify its position as a trusted leader in the industry, providing innovative solutions that drive technological advancements across various sectors.In conclusion, {Company Name} has once again demonstrated its commitment to excellence by introducing a new range of PCBs with improved copper thickness. As the company continues to invest in research and development, it is poised to deliver cutting-edge solutions that meet the evolving needs of industries that rely on high-quality printed circuit boards. With a focus on innovation, quality, and sustainability, {Company Name} is well-equipped to lead the way in PCB manufacturing and set new standards for the industry.

High-Quality PCB for Vending Machines

The Vending Machine PCB Market is Expected to Grow at a CAGR of 8.3% during the Forecast PeriodThe global vending machine PCB market is projected to witness a significant growth during the forecast period. A key factor driving the growth of the market is the increasing demand for vending machines across various industries such as retail, healthcare, and transportation. Vending machines have become an integral part of these industries, offering convenience and accessibility to customers. This has led to the increased adoption of vending machine PCBs, which are essential components in these machines.A vending machine PCB, also known as a vending machine control board, is a crucial part of an automated vending machine that controls its operation. It acts as the brain of the machine, regulating the delivery of products, accepting payments, and providing a user-friendly interface. With the rising popularity of vending machines, the demand for advanced and reliable PCBs for these machines has also increased.One of the key players in the vending machine PCB market is a leading manufacturer and supplier of high-quality PCBs for various applications. The company specializes in producing custom-designed PCBs for vending machines, ensuring seamless integration and optimal performance. With years of experience and expertise in the field, the company has established itself as a trusted partner for businesses looking to incorporate cutting-edge PCB technology into their vending machines.The company's dedication to innovation and quality has been instrumental in driving the growth of the vending machine PCB market. Its state-of-the-art manufacturing facilities and strict quality control measures ensure that the PCBs meet the highest industry standards. The company's commitment to research and development has also led to the development of advanced PCB technologies that offer improved functionality, durability, and energy efficiency.In addition to producing standard vending machine PCBs, the company also offers custom PCB solutions tailored to the specific requirements of its clients. This flexibility and responsiveness to customer needs have set the company apart in the market, earning it a strong reputation for providing reliable and cost-effective PCB solutions. As a result, the company has been able to establish a strong presence in the global vending machine PCB market, serving clients across different industries and geographical regions.The vending machine PCB market is expected to continue its growth trajectory in the coming years, driven by the increasing demand for vending machines and the technological advancements in PCBs. The market is projected to grow at a CAGR of 8.3% during the forecast period, indicating a promising future for companies specializing in vending machine PCB manufacturing. With its proven track record of delivering high-quality PCB solutions, the aforementioned company is well-positioned to capitalize on this growth and further solidify its position as a leading player in the market.In conclusion, the global vending machine PCB market is on a path of steady growth, fueled by the growing adoption of vending machines across various industries. A key player in this market, the aforementioned company, has been at the forefront of driving this growth through its commitment to innovation, quality, and customer satisfaction. As the demand for vending machine PCBs continues to rise, the company is well-equipped to meet the needs of the market and emerge as a key contributor to the expansion of the vending machine PCB industry.

Circuit Board Manufacturer in China Sees Growth Amid Rising Demand

China Circuit Plate Manufacturer Celebrates Years of Manufacturing ExcellenceChina's manufacturing industry has seen exponential growth over the past few decades, largely due to the presence of forward-thinking companies that have prioritized technology and innovation to create cutting-edge products. One such company is the China Circuit Plate Manufacturer (CCPM), a leader in the production of printed circuit boards (PCBs) that celebrated its 30th anniversary last month.Founded in 1991, CCPM has grown to become one of the largest circuit board manufacturers in China, with a production capacity of over 3.5 million square feet of circuit boards per month. The company specializes in high-density interconnect (HDI) PCBs, flexible PCBs, and rigid-flex PCBs, with a particular focus on providing customers with quality products and exceptional service.CCPM's success can be attributed to a number of factors, including its state-of-the-art manufacturing facilities and experienced team of engineers and technicians. The company's manufacturing process uses the latest technology and equipment, ensuring that its products are of the highest quality. Additionally, CCPM's team is committed to continuous improvement and innovation, allowing the company to stay ahead of the curve in a rapidly-evolving industry.One of CCPM's key strengths is its ability to work closely with customers to develop custom solutions tailored to their specific needs. With a dedicated research and development team, the company is able to provide customers with innovative designs and solutions that are both cost-effective and high-performing. This approach has helped CCPM to build strong relationships with customers across a range of industries, including telecommunications, automotive, medical, and aerospace.Another factor contributing to CCPM's success is its commitment to sustainability and ethical manufacturing practices. The company has implemented a number of initiatives to reduce its environmental footprint, including using eco-friendly materials and processes, optimizing energy consumption, and maximizing resource efficiency. CCPM also places a strong emphasis on worker safety and welfare, with a comprehensive set of policies and programs in place to ensure that all employees are treated with respect and dignity.As part of its 30th anniversary celebrations, CCPM held a series of events and activities to thank customers, partners, and employees for their support over the years. The company also took the opportunity to reflect on its achievements and to look forward to the future. According to CCPM's CEO, the company's goal is to "continue to innovate and push boundaries, while always keeping our focus on providing the best products and services to our customers. We are excited to see what the next 30 years will bring, and we look forward to being at the forefront of China's manufacturing industry."Overall, CCPM's success is a testament to the power of innovation, hard work, and a customer-centric approach. With a commitment to excellence and sustainability, the company is well-positioned to continue its growth and contribute to the growth of China's manufacturing industry for years to come.

How to Use Red Solder: Tips and Techniques

Red Solder, created by {company name}, is making waves in the electronics industry with its innovative and high-quality products. The company, based in Silicon Valley, California, has been a leading manufacturer of soldering products for over 30 years and has established itself as a trusted name in the industry.The success of Red Solder can be attributed to the company's commitment to innovation, quality, and customer satisfaction. The company's products are known for their superior performance and reliability, making them the top choice for professionals and hobbyists alike.Red Solder offers a wide range of soldering products, including solder wire, solder paste, flux, and soldering irons. The company's products are designed to meet the needs of a variety of industries, including electronics manufacturing, automotive, aerospace, and telecommunications.One of the key factors that sets Red Solder apart from its competitors is its dedication to research and development. The company has a team of experienced engineers and technicians who are constantly working to improve and expand its product line. This commitment to innovation has allowed Red Solder to stay ahead of the curve and provide its customers with the latest and most advanced soldering solutions.In addition to its focus on product quality, Red Solder also places a strong emphasis on customer satisfaction. The company prides itself on its responsive and knowledgeable customer service team, who are always ready to assist customers with any questions or concerns they may have. Red Solder also offers a comprehensive warranty and support program to ensure that its customers are fully satisfied with their purchases.Red Solder's dedication to excellence has not gone unnoticed. The company has received numerous awards and accolades for its products, including the prestigious "Innovation Award" from the Electronics Industry Association. This recognition is a testament to the company's commitment to pushing the boundaries of soldering technology and delivering exceptional products to its customers.Looking ahead, Red Solder is focused on continuing to expand its product line and reach new markets. The company is constantly exploring new opportunities for growth and is committed to maintaining its position as a leader in the soldering industry."We are excited about the future of Red Solder," said the company's CEO. "Our team is dedicated to developing new and innovative products that will continue to meet the needs of our customers and provide them with the best soldering solutions available."As Red Solder continues to thrive in the electronics industry, it is clear that the company's commitment to excellence and innovation will continue to drive its success. With its dedication to quality, customer satisfaction, and innovation, Red Solder is poised to remain a leading force in the soldering industry for years to come.

Innovative PCB Printing: A Game-Changer for Electronics Manufacturing

[Company Name], a pioneer in advanced manufacturing technology, has recently unveiled an innovative solution in the field of Printed Circuit Board (PCB) printing. With their cutting-edge technology and extensive industry experience, the company aims to revolutionize the PCB manufacturing process, bringing unprecedented efficiency and affordability to the market.PCBs are a critical component in nearly every electronic device, acting as the foundation for interconnecting various electronic components. Traditionally, PCBs have been manufactured using lengthy and expensive processes, involving multiple layers of copper and insulating material. However, [Company Name] has devised a novel approach that eliminates many of the current limitations associated with PCB production.Using their state-of-the-art PCB printing technology, [Company Name] has simplified the manufacturing process, reducing costs and timeframes significantly. This breakthrough solution leverages advanced printing techniques to precisely deposit conductive ink onto a substrate, eliminating the need for complex etching and drilling processes. This not only speeds up production but also ensures greater accuracy and consistency in the final product.The use of conductive ink also opens up new possibilities in PCB design and customization. [Company Name]'s technology allows for the creation of highly complex and intricate circuit patterns, surpassing the capabilities of traditional PCB manufacturing methods. This newfound flexibility enables engineers to design and produce PCBs that are optimized for specific applications, leading to improved performance and overall product quality.Furthermore, with this innovative printing technology, [Company Name] is helping to pave the way for advancements in additive manufacturing. Additive manufacturing, often referred to as 3D printing, has revolutionized various industries by enabling the production of complex shapes and structures with ease. By integrating additive manufacturing principles into PCB production, [Company Name] is pushing the boundaries of what is possible in terms of design freedom and functionality.In addition to the technical advancements, [Company Name] is also committed to delivering eco-friendly solutions. The traditional PCB manufacturing process involves several environmentally unfriendly steps, including the use of hazardous chemicals and high energy consumption. By transitioning to their new printing technology, [Company Name] significantly reduces the environmental impact of PCB production, offering a sustainable alternative to conventional methods.The impact of [Company Name]'s PCB printing technology is already being recognized by industry experts. Leading companies in sectors such as consumer electronics, automotive, telecommunications, and aerospace have expressed keen interest in incorporating this breakthrough solution into their manufacturing processes. The potential to streamline production, reduce costs, and improve product performance makes [Company Name]'s technology highly attractive for businesses looking to gain a competitive edge in their respective markets.To ensure the successful adoption of their technology, [Company Name] offers comprehensive support and guidance to their clients. Their team of experts provides end-to-end solutions, from initial design consultation to production optimization, ensuring a seamless integration of the PCB printing technology into existing manufacturing processes.As the demand for advanced electronics continues to grow, the need for efficient and cost-effective PCB manufacturing becomes paramount. With [Company Name]'s revolutionary PCB printing technology, the industry is now equipped with a game-changing solution that has the potential to disrupt traditional manufacturing processes and unlock new possibilities for innovation.

High-Quality Thickness PCB Manufacturer in China

China Thickness PCB Manufacturer, a leading PCB manufacturer in China, has been making significant strides in the industry with its high-quality products and exceptional customer service. The company has built a strong reputation for producing cutting-edge PCBs with various thickness options to meet the diverse needs of its global clientele.With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, China Thickness PCB Manufacturer has established itself as a trusted partner for businesses operating in a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics.The company specializes in producing PCBs with varying thickness levels, ranging from standard to ultra-thin and high-density interconnect (HDI) boards. This diverse product offering has enabled China Thickness PCB Manufacturer to cater to the evolving demands of the market and deliver customized solutions that align with the unique requirements of each customer.The manufacturing process at China Thickness PCB Manufacturer adheres to the highest quality standards, with a strong emphasis on precision and performance. The company utilizes advanced technologies and cutting-edge equipment to ensure the production of PCBs that are not only reliable and durable but also deliver superior performance in the most demanding applications.In addition to its commitment to quality, China Thickness PCB Manufacturer places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and provides expert guidance to help them make informed decisions about the best PCB thickness options for their applications.Moreover, China Thickness PCB Manufacturer offers a range of value-added services, including design support, prototyping, and quick-turn manufacturing, to ensure a seamless and efficient production process for its customers. This comprehensive approach has established the company as a preferred partner for businesses seeking high-quality PCB solutions with a quick turnaround time.As part of its ongoing efforts to expand its global footprint, China Thickness PCB Manufacturer has invested significantly in research and development to stay at the forefront of technological advancements and industry trends. The company continuously explores new materials, processes, and manufacturing techniques to enhance the performance and reliability of its PCBs, while also optimizing the production efficiency and cost-effectiveness of its operations.Furthermore, China Thickness PCB Manufacturer is committed to sustainability and environmental responsibility in its manufacturing practices. The company adheres to strict compliance with environmental regulations and adopts eco-friendly production processes to minimize its carbon footprint and reduce waste generation. This commitment to sustainability resonates with customers who prioritize ethical and sustainable business practices in their supply chain partnerships.Looking ahead, China Thickness PCB Manufacturer is poised to continue its upward trajectory in the industry, driven by its unwavering dedication to quality, innovation, and customer satisfaction. The company remains focused on leveraging its technical expertise, manufacturing capabilities, and customer-centric approach to further solidify its position as a leading PCB manufacturer in China and a trusted partner for businesses worldwide.With its robust product portfolio, commitment to excellence, and forward-looking approach, China Thickness PCB Manufacturer is well-positioned to meet the evolving demands of the market and contribute to the success of its customers in an increasingly competitive and dynamic landscape.

Discover the Benefits of Halogen Free PCB Material for Your Projects

[Company Name] Introduces Halogen-Free PCB Material for Environmentally-Friendly Electronics[City, State] - As the world continues to prioritize environmentally-friendly practices, [Company Name] is at the forefront of innovation with the introduction of a new halogen-free PCB material. This breakthrough in technology is set to revolutionize the electronics industry by offering a more sustainable and eco-friendly alternative to traditional PCB materials.The new halogen-free PCB material is designed to meet the increasing demand for electronics that are free from hazardous substances, such as bromine and chlorine, which are commonly found in traditional PCB materials. This material not only ensures compliance with environmental regulations but also provides a safer and more sustainable option for electronic products.[Company Name], a leading provider of innovative electronic solutions, has been at the forefront of developing cutting-edge materials and technologies since its inception. With a strong commitment to sustainability and environmental stewardship, the company has invested heavily in research and development to create the new halogen-free PCB material.According to [Spokesperson Name], [Title] at [Company Name], "We are proud to introduce this new halogen-free PCB material, which reflects our commitment to environmental responsibility and innovation. This breakthrough technology will enable us to offer our customers a more sustainable and eco-friendly option for their electronic products, without compromising on performance or reliability."The new halogen-free PCB material offers several key benefits, including improved fire retardant properties, enhanced thermal performance, and increased durability. These features make it an ideal choice for a wide range of electronic applications, including consumer electronics, automotive systems, industrial equipment, and more.In addition to its environmental benefits, the new material also meets the high-performance standards required for modern electronic devices. Its superior electrical properties and reliability make it a versatile and dependable choice for manufacturers looking to create high-quality, environmentally-friendly products.Furthermore, [Company Name] is dedicated to ensuring that the new halogen-free PCB material is readily available to its customers. The company has integrated the new material into its existing product lineup, making it easily accessible for manufacturers seeking to adopt more sustainable practices in their production processes.It is clear that the introduction of the halogen-free PCB material by [Company Name] represents a significant milestone in the electronics industry. By offering a more sustainable and environmentally-friendly alternative to traditional PCB materials, [Company Name] is demonstrating its commitment to driving positive change and leading the way towards a greener future for electronics manufacturing.In conclusion, [Company Name] has once again reaffirmed its position as an industry leader in innovation and sustainability with the introduction of the new halogen-free PCB material. With its superior performance, environmental benefits, and widespread availability, this new material is set to play a pivotal role in shaping the future of electronics manufacturing. As the world continues to prioritize environmental responsibility, [Company Name] is proud to be at the forefront of this movement, offering innovative solutions that support a more sustainable and eco-friendly approach to electronic production.

Quick and Efficient PCB Fabrication Services for Your Business

Fast PCB Fabrication: Revolutionizing the Electronics IndustryIn today's fast-paced world, the demand for electronic devices is at an all-time high. From smartphones and laptops to medical devices and automotive components, the need for high-quality, reliable printed circuit boards (PCBs) has never been greater. That's where the innovative technology and expertise of [Company Name] come into play.[Company Name] is a leading provider of fast PCB fabrication services, offering a range of solutions to meet the diverse needs of the electronics industry. With state-of-the-art facilities and a team of experienced professionals, [Company Name] is revolutionizing the way PCBs are manufactured, leading to faster turnaround times and superior quality.The technology and processes utilized by [Company Name] allow for rapid PCB fabrication without compromising on quality. This is made possible through the use of advanced machinery and automation, which reduce production times and increase efficiency. Furthermore, their team of highly skilled engineers and technicians ensures that every PCB meets the highest standards of reliability and performance.One of the key advantages of partnering with [Company Name] is the ability to expedite the entire PCB fabrication process. With traditional methods, the design and manufacturing of PCBs can be a lengthy and time-consuming process. However, [Company Name] has streamlined this process, allowing for quick turnaround times that are essential in today's fast-paced electronics industry.Furthermore, [Company Name] offers a range of customization options to meet the specific needs of their clients. Whether it's a complex multilayer PCB or a standard single-layer board, [Company Name] has the capabilities to deliver high-quality, customized solutions in a fraction of the time it would take with traditional methods.The impact of fast PCB fabrication goes beyond just speed and efficiency. By reducing production times, [Company Name] is able to help their clients bring their products to market faster, gaining a competitive edge in their respective industries. This can be particularly beneficial for companies developing cutting-edge technologies or those operating in rapidly evolving markets.In addition to their fast PCB fabrication services, [Company Name] is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices throughout their manufacturing process, minimizing waste and reducing their carbon footprint. This commitment to sustainability ensures that clients can rely on [Company Name] not only for fast and reliable PCB fabrication but also for environmentally conscious solutions.As [Company Name] continues to push the boundaries of PCB fabrication, they are also exploring new frontiers in technology. By investing in research and development, they are constantly looking for ways to innovate and improve their processes, ultimately benefiting their clients with even faster turnaround times and higher-quality PCBs.Clients who partner with [Company Name] can expect a seamless and efficient experience from the initial design phase to the final delivery of their PCBs. With a strong emphasis on customer satisfaction, [Company Name] is dedicated to providing top-notch service and support at every step of the process.In conclusion, fast PCB fabrication is reshaping the electronics industry, and [Company Name] is at the forefront of this revolution. By combining cutting-edge technology, expertise, and a commitment to sustainability, [Company Name] is setting new standards for speed, efficiency, and quality in PCB manufacturing. As the demand for electronic devices continues to grow, [Company Name] is well-positioned to meet the needs of clients across various industries, making them an invaluable partner in the fast-paced world of electronics manufacturing.

Quality Solder Resist Factory in China: Latest News and Updates

China Solder Resist Factory, a leading manufacturer of solder resist products, has recently announced the expansion of its production capacity to meet the growing demand for its high-quality products. The company, which has been in the business for over a decade, has established itself as a trusted supplier of solder resist materials for electronic manufacturing and assembly.The expansion of the production capacity comes in response to the increasing demand for solder resist products in the global electronics market. With the proliferation of electronic devices and technological advancements, the need for reliable and high-performance solder resist materials has never been greater. China Solder Resist Factory is committed to meeting this demand by investing in the latest manufacturing technology and expanding its production facilities.The company's solder resist products are known for their exceptional quality, reliability, and performance. They are used in a wide range of applications, including printed circuit boards (PCBs), electronic components, and semiconductor devices. The solder resist materials manufactured by China Solder Resist Factory are designed to provide excellent protection against solder bridges, electrical shorts, and other common issues in electronic assembly and manufacturing.In addition to its commitment to producing high-quality solder resist products, China Solder Resist Factory also prioritizes environmental sustainability and corporate social responsibility. The company adheres to strict environmental standards in its manufacturing processes and is dedicated to minimizing its environmental impact. It also maintains a strong focus on employee welfare and ethical business practices.One of the key factors driving the success of China Solder Resist Factory is its relentless focus on research and development. The company has a dedicated team of R&D professionals who are constantly working to improve the performance and reliability of its solder resist products. By staying at the forefront of technological advancements and industry trends, China Solder Resist Factory is able to deliver innovative solutions that meet the evolving needs of its customers.The expansion of the production capacity is expected to further strengthen the company's position as a leading supplier of solder resist materials. It will enable China Solder Resist Factory to fulfill larger orders, reduce lead times, and provide even better support to its global customer base. With its state-of-the-art manufacturing facilities and a commitment to excellence, the company is well-positioned to capitalize on the growing demand for solder resist products.In addition to expanding its production capacity, China Solder Resist Factory is also focused on enhancing its distribution and customer support capabilities. The company is working to establish strategic partnerships with distributors and representatives in key markets around the world. By strengthening its global presence, China Solder Resist Factory aims to provide better access to its high-quality solder resist products and superior customer service.As China Solder Resist Factory continues to grow and expand, it remains dedicated to upholding its core values of quality, innovation, sustainability, and customer satisfaction. The company's relentless pursuit of excellence and commitment to meeting the needs of its customers have made it a trusted partner for electronic manufacturers and assemblers worldwide.With the expansion of its production capacity and ongoing efforts to enhance its distribution and customer support capabilities, China Solder Resist Factory is well-equipped to meet the increasing demand for its solder resist products in the global electronics market. The company's unwavering commitment to quality and customer satisfaction ensures that it will continue to be a leading supplier of solder resist materials for years to come.