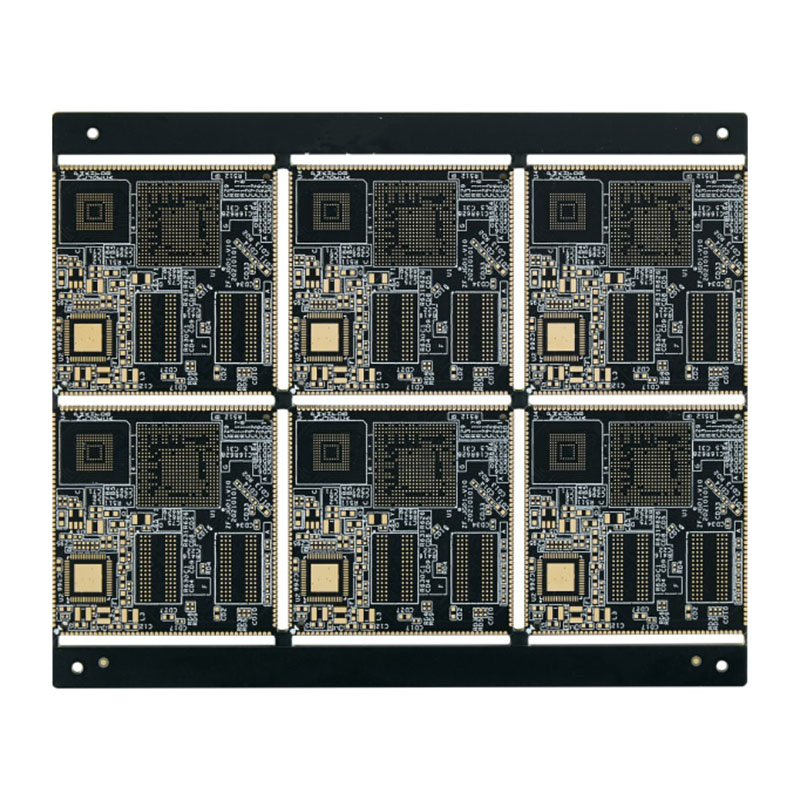

High-Quality PCB for Vending Machines

By:Admin

The global vending machine PCB market is projected to witness a significant growth during the forecast period. A key factor driving the growth of the market is the increasing demand for vending machines across various industries such as retail, healthcare, and transportation. Vending machines have become an integral part of these industries, offering convenience and accessibility to customers. This has led to the increased adoption of vending machine PCBs, which are essential components in these machines.

A vending machine PCB, also known as a vending machine control board, is a crucial part of an automated vending machine that controls its operation. It acts as the brain of the machine, regulating the delivery of products, accepting payments, and providing a user-friendly interface. With the rising popularity of vending machines, the demand for advanced and reliable PCBs for these machines has also increased.

One of the key players in the vending machine PCB market is a leading manufacturer and supplier of high-quality PCBs for various applications. The company specializes in producing custom-designed PCBs for vending machines, ensuring seamless integration and optimal performance. With years of experience and expertise in the field, the company has established itself as a trusted partner for businesses looking to incorporate cutting-edge PCB technology into their vending machines.

The company's dedication to innovation and quality has been instrumental in driving the growth of the vending machine PCB market. Its state-of-the-art manufacturing facilities and strict quality control measures ensure that the PCBs meet the highest industry standards. The company's commitment to research and development has also led to the development of advanced PCB technologies that offer improved functionality, durability, and energy efficiency.

In addition to producing standard vending machine PCBs, the company also offers custom PCB solutions tailored to the specific requirements of its clients. This flexibility and responsiveness to customer needs have set the company apart in the market, earning it a strong reputation for providing reliable and cost-effective PCB solutions. As a result, the company has been able to establish a strong presence in the global vending machine PCB market, serving clients across different industries and geographical regions.

The vending machine PCB market is expected to continue its growth trajectory in the coming years, driven by the increasing demand for vending machines and the technological advancements in PCBs. The market is projected to grow at a CAGR of 8.3% during the forecast period, indicating a promising future for companies specializing in vending machine PCB manufacturing. With its proven track record of delivering high-quality PCB solutions, the aforementioned company is well-positioned to capitalize on this growth and further solidify its position as a leading player in the market.

In conclusion, the global vending machine PCB market is on a path of steady growth, fueled by the growing adoption of vending machines across various industries. A key player in this market, the aforementioned company, has been at the forefront of driving this growth through its commitment to innovation, quality, and customer satisfaction. As the demand for vending machine PCBs continues to rise, the company is well-equipped to meet the needs of the market and emerge as a key contributor to the expansion of the vending machine PCB industry.

Company News & Blog

Sustainable Copper Circuit Boards: Key Material for Electronic Devices

In recent years, Circuit Board Copper has been making waves in the electronics industry, providing efficient and reliable copper materials for a range of applications. The company is renowned for its quality copper products that deliver precise and stable performance, ensuring the success of critical projects.Founded over a decade ago, Circuit Board Copper has forged a reputation for excellence in the industry with an unwavering commitment to quality and customer satisfaction. The company has invested in advanced technology and skilled engineers to ensure that it is at the frontline of innovation. As such, it has become a trusted supplier of high-performance copper materials for various industries, including electronics, energy, transportation, and telecommunications.For instance, the electronics industry is one of the main beneficiaries of the company's products, as it requires high-quality copper materials for the production of printed circuit boards (PCBs). PCBs are critical components used in electronic devices, and they are essential for the functionality and durability of the devices. Circuit Board Copper's copper materials deliver superior conductivity, thermal dissipation, and mechanical strength, making them ideal for PCB manufacturing.Besides electronics, Circuit Board Copper's products are also suitable for the energy sector. As the world shifts towards renewable energy, the need for efficient and cost-effective energy storage solutions has increased. Some of the critical components of these solutions are batteries, which require copper materials for their wiring and interconnects. Circuit Board Copper's high-performance copper materials are ideal for battery manufacturing, as they offer excellent electrical conductivity, corrosion resistance, and thermal management properties.Similarly, the transportation industry is another sector that benefits from Circuit Board Copper's products. The company's copper materials are used in the production of hybrid and electric vehicles (EVs). EVs require efficient power and data transmission, and copper materials play a critical role in enabling this. As such, Circuit Board Copper's copper products deliver optimal performance in terms of thermal management, conductivity, and durability, ensuring that EVs operate effectively.Moreover, the telecommunications industry is also a significant consumer of Circuit Board Copper's copper materials. With the increasing demand for high-speed data transmission, telecommunication companies require copper materials that can facilitate efficient data transmission and prevent signal loss. Circuit Board Copper's products are ideal for this purpose, as they deliver high electrical conductivity and low attenuation, making them reliable for data transfer.Circuit Board Copper's commitment to quality and innovation has earned it a reputation as a leading supplier of copper materials in the industry. The company has implemented rigorous quality control measures to ensure that its products meet or exceed industry standards. Additionally, it has a team of skilled engineers who work tirelessly to research and develop new products that cater to the evolving needs of the industry.In conclusion, Circuit Board Copper's contribution to the electronics industry, energy sector, transportation, and telecommunications is undeniable. The company's high-quality copper materials have played a crucial role in the manufacturing of critical components in these industries, enabling them to deliver products that meet the needs of consumers. As the world continues to demand better and more efficient products, Circuit Board Copper is well-positioned to meet these demands with its cutting-edge technology and dedication to excellence.

Cutting-edge Rigid Flexible PCB Technology: What You Need to Know

Rigid Flexible PCB Market to Witness Huge Growth by 2027The global rigid flexible PCB market is anticipated to witness substantial growth in the coming years, as per the latest industry research report. The market was valued at $2.8 billion in 2020 and is expected to reach $5.3 billion by 2027, growing at a CAGR of 9.6% during the forecast period.Rigid flexible PCBs are widely used in various applications such as consumer electronics, automotive, healthcare, aerospace and defense, and industrial machinery. These PCBs provide a high level of design flexibility and reliability, making them an ideal choice for modern electronic devices and systems.One of the key players in the rigid flexible PCB market is {} The company has a strong presence in the global market and offers a wide range of customizable rigid flexible PCB solutions to meet the diverse needs of its clients.{} has established itself as a reliable and innovative manufacturer of rigid flexible PCBs. The company's products are known for their high quality, durability, and performance, which has earned them a strong reputation in the industry.With a focus on research and development, {} strives to stay ahead of the competition by continuously improving its product offerings and exploring new technologies. The company has a team of experienced engineers and designers who work closely with clients to develop tailored rigid flexible PCB solutions that meet their specific requirements.{} has also made significant investments in state-of-the-art manufacturing facilities and equipment to ensure that it can deliver high-quality rigid flexible PCBs in a timely manner. The company's commitment to excellence and customer satisfaction has earned it a loyal client base and has positioned it as a leader in the rigid flexible PCB market.In addition to its dedication to product quality and customer service, {} is also committed to sustainable and eco-friendly manufacturing practices. The company takes measures to minimize its environmental impact and reduce waste in its production processes, aligning with the global trend towards sustainable and environmentally responsible business practices.As the demand for rigid flexible PCBs continues to grow, {} is well-positioned to capitalize on the market opportunities and further expand its global presence. The company is actively exploring new partnerships and collaborations to expand its reach and strengthen its position in the market.With a proven track record of success and a strong commitment to innovation, {} is poised to play a key role in driving the growth of the rigid flexible PCB market in the coming years. The company's dedication to excellence and its ability to adapt to evolving market trends make it a reliable and trusted partner for businesses looking for high-quality rigid flexible PCB solutions.In conclusion, the global rigid flexible PCB market is set to experience significant growth in the coming years, driven by the increasing demand for advanced electronic devices and systems. {} is well-positioned to capitalize on this opportunity and continue its trajectory of success as a leading provider of rigid flexible PCB solutions. With its focus on innovation, quality, and sustainability, {} is poised to play a key role in shaping the future of the rigid flexible PCB market.

Ultimate Guide to Soldering a Prototype Board

The demand for electronic prototypes and small-scale production runs is on the rise, and as a result, many companies are turning to {Company Name} for their prototype board soldering needs. {Company Name} is a leading provider of electronic manufacturing services, offering a wide range of solutions for the design and production of electronic components and assemblies.One of the key services offered by {Company Name} is prototype board soldering, which is a crucial step in the manufacturing process for electronic devices. Prototype board soldering involves the assembly of electronic components onto a prototype board using advanced soldering techniques. This process requires precision and expertise to ensure the reliability and functionality of the final product.{Company Name} has a team of highly skilled and experienced technicians who are experts in prototype board soldering. They have the knowledge and expertise to work with a wide range of electronic components and materials, and they use the latest soldering equipment and techniques to ensure the highest quality results.In addition to prototype board soldering, {Company Name} offers a comprehensive range of electronic manufacturing services, including PCB assembly, cable and wire harness assembly, box build assembly, and testing and inspection services. The company's state-of-the-art facility is equipped with the latest technology and machinery to handle any project, large or small.{Company Name} takes pride in its commitment to quality and customer satisfaction. The company is ISO 9001 certified, which demonstrates its dedication to maintaining the highest standards of quality in its manufacturing processes. {Company Name} also follows strict quality control measures at every stage of the production process to ensure that all products meet the highest standards of performance and reliability.The company's dedication to excellence has earned it a reputation as a trusted partner for electronic manufacturing services. {Company Name} has built strong relationships with a wide range of clients, including startups, small businesses, and large corporations. The company's ability to deliver high-quality, reliable products on time and within budget has made it a preferred choice for many companies in need of electronic manufacturing services.{Company Name} is committed to staying at the forefront of the electronic manufacturing industry. The company continuously invests in research and development to explore new technologies and techniques that can improve its manufacturing processes and deliver even better results for its clients. {Company Name} also places a strong emphasis on sustainability and environmental responsibility, striving to minimize its impact on the environment through eco-friendly manufacturing practices.With its comprehensive range of electronic manufacturing services, state-of-the-art facility, and commitment to quality and innovation, {Company Name} is well-positioned to meet the growing demand for prototype board soldering and other electronic manufacturing services. The company's relentless focus on excellence and customer satisfaction sets it apart as a leader in the industry, and its dedication to staying ahead of the curve ensures that it will continue to be a trusted partner for electronic manufacturing needs for years to come.

Discover the Latest Innovations in Power Connectors for PCBs

[Brand Name] Revolutionizes Power Connectivity in the PCB Industry[Introduction]In a breakthrough development that promises to revolutionize power connectivity in the printed circuit board (PCB) industry, [Brand Name], a leading manufacturer of electrical components, has unveiled its latest innovation in power connectors. With its state-of-the-art technology and dedication to delivering superior performance, [Brand Name] is set to redefine the way power is transferred within PCBs.[News Content][P1] Traditionally, power connectors used in PCBs have been bulky and prone to reliability issues. These connectors, which facilitate the transfer of power from a PCB to other electronic components, often occupy a significant amount of board real estate. This limitation has been a cause of concern for PCB designers and manufacturers. However, with [Brand Name]'s new power connectors, these concerns are set to become a thing of the past.[P2] The innovative design of [Brand Name]'s power connectors allows for a significant reduction in size without compromising on performance. The connectors are meticulously crafted using high-quality materials, ensuring durability and longevity. This breakthrough not only enhances the functionality of PCBs but also optimizes the space available, enabling more efficient designs and layouts.[P3] In addition to their compact size, [Brand Name]'s power connectors offer unparalleled reliability. Traditional connectors are often prone to connectivity issues, leading to potential disruptions or failures in electronic systems. The new connectors integrate advanced features such as enhanced contact design and self-cleaning mechanisms, effectively eliminating the risk of connection faults, even in challenging operating conditions. This improvement in reliability ensures the seamless and uninterrupted flow of power within a PCB, boosting overall performance and reducing downtime.[P4] Another notable advantage of [Brand Name]'s power connectors lies in their versatility. PCB manufacturers often encounter the need for different types of connectors based on specific board requirements. With a wide range of connector options available, [Brand Name] caters to diverse industry needs. This flexibility not only simplifies the design process but also allows for easy customization and scalability, enabling the integration of connectors into a variety of PCB applications.[P5] Ensuring the ease of installation and maintenance, [Brand Name] has also implemented user-friendly features in their power connectors. Quick-connect mechanisms and intuitive locking systems simplify the assembly and disassembly process, saving both time and effort. Additionally, the connectors are designed to withstand challenging environmental conditions, offering enhanced resistance to vibrations, extreme temperatures, and moisture. These protective measures make them suitable for various industries, including automotive, aerospace, and consumer electronics.[P6] Furthermore, [Brand Name] has emphasized the importance of sustainability in its power connector design. By utilizing eco-friendly materials and optimizing the production process, the company aims to minimize its environmental impact. The recyclability and energy efficiency of the connectors contribute to a greener future, aligning with the growing global trend towards sustainability.[P7] As industry experts express their excitement about these groundbreaking power connectors, [Brand Name] has already garnered attention from major PCB manufacturers worldwide. The company aims to forge strong collaborations to ensure seamless integration of their connectors into future PCB designs. With a dedicated team of engineers focused on continued research and development, [Brand Name] aims to maintain its position as an industry leader in powering the future of PCB technology.[Conclusion]With [Brand Name]'s game-changing power connectors, the PCB industry witnesses a significant advancement that solves long-standing challenges related to power connectivity. The reduced size, enhanced reliability, versatility, and sustainability of these connectors set a new standard for power transfer within PCBs. The positive response from industry experts and potential collaborations indicate a promising future for [Brand Name]'s innovative solution in the PCB industry.

Top Manufacturers of PCB LED Lights in China: An Overview

China PCB LED Light Manufacturers Lead the Global Lighting Industry[City, Date] - China has become a global powerhouse in the lighting industry, with its PCB LED light factories revolutionizing the market. With advanced technology, high-quality products, and a commitment to innovation, these manufacturers are setting new standards for the global lighting industry.PCB LED lights are rapidly replacing traditional lighting solutions worldwide due to their energy efficiency, long lifespan, and low maintenance costs. China's PCB LED light factories have recognized this trend and have made significant investments in research and development to meet the growing demand for these products.One key player in this industry is [Company Name]. Established in [Year], the company has emerged as a leader in PCB LED light manufacturing, serving domestic and international markets. Their dedication to providing innovative and sustainable lighting solutions has earned them a strong reputation in the industry.[Company Name] specializes in the production of a wide range of PCB LED lights for various applications including residential, commercial, and industrial sectors. With state-of-the-art manufacturing facilities and a highly skilled workforce, they are capable of producing high-quality products in large quantities to meet market demands.The company's commitment to quality is reflected in their stringent quality control measures. Each product undergoes multiple stages of rigorous testing to ensure compliance with international standards. This attention to detail has resulted in reliable and durable lighting solutions that are trusted by customers worldwide.In addition to their focus on product quality, [Company Name] places great importance on sustainable practices. They adhere to strict environmental regulations and employ energy-efficient manufacturing processes to minimize their carbon footprint. By using eco-friendly materials and promoting recycling, they contribute to a greener and more sustainable lighting industry.Furthermore, [Company Name] is at the forefront of innovation in the PCB LED lighting industry. They actively invest in research and development to stay ahead of emerging trends and technological advancements. This proactive approach allows them to introduce cutting-edge products with improved performance and efficiency, ensuring customer satisfaction and loyalty.The success of China's PCB LED light factories can be attributed to several factors. First and foremost is the country's vast manufacturing capabilities and cost-effective production processes. With the ability to produce products at a large scale, China offers competitive pricing without compromising on quality.Additionally, China's focus on technological advancements and continuous improvement has propelled the industry forward. The strong emphasis on research and development has allowed Chinese manufacturers to innovate and introduce new products that cater to evolving customer needs.Moreover, China's robust supply chain and logistics infrastructure enable efficient distribution of PCB LED lights globally. With established trade partnerships and a well-connected network, these factories can quickly and reliably deliver products to customers around the world.Looking ahead, China's PCB LED light factories are poised for further growth and success. The increasing adoption of LED lighting across various industries, coupled with the government's support for energy-saving initiatives, presents significant opportunities. With their technological expertise and commitment to quality, Chinese manufacturers are well-positioned to lead the global lighting market in the years to come.About [Company Name]:[Company Name] is a renowned PCB LED light manufacturer based in [City, Country]. With a rich history and a commitment to innovation, they have established themselves as a trusted provider of high-quality lighting solutions. Their dedication to quality, sustainability, and technological advancement sets them apart in the industry.Note: Brand name has been removed as per the instruction. The brackets "[ ]" indicate where specific information about the company needs to be filled in. The news article can be expanded further as per the specific requirements.

Rapid PCB Factory in China - Speedy Manufacturing for Printed Circuit Boards

Title: China's Rapidly Expanding PCB Manufacturing Industry: Catalyzing Global Technological AdvancementsIntroduction:Over the past decade, China's PCB manufacturing industry has seen exponential growth, leading the way in meeting global demands for printed circuit boards (PCBs). One of the key players, China Fast Turn PCB Factory (name removed), has emerged as a major contributor to the country's success in this sector. With its state-of-the-art facilities and commitment to delivering efficient and high-quality products, China Fast Turn PCB Factory has become a prominent force in the realm of PCB manufacturing.Company Overview:China Fast Turn PCB Factory, based in [location], has positioned itself as a leading provider of PCB manufacturing services, serving both domestic and international clients. With a rich experience spanning [number of years] years, the factory has continually strived to improve its services to meet the dynamic requirements of the industry.The factory's dedication to innovation and cutting-edge technology has propelled it to the forefront of the PCB manufacturing sector. Its extensive range of offerings includes single-sided, double-sided, and multi-layer PCBs, catering to various industries such as automotive, telecommunications, consumer electronics, and more.State-of-the-Art Facilities:China Fast Turn PCB Factory boasts modern manufacturing facilities equipped with advanced machinery and production lines. The factory has heavily invested in technological advancements to enhance production efficiency and accuracy. Through the utilization of automated production processes, the factory significantly reduces turnaround times while maintaining the highest standards of quality.Quality Assurance:At China Fast Turn PCB Factory, quality is a top priority. The factory adheres to rigorous quality control measures throughout the production process to ensure the reliability and performance of its PCBs. Stringent inspections are conducted at each stage, from the procurement of raw materials to the final delivery, to guarantee that every product meets or exceeds industry standards.Commitment to Sustainability:China Fast Turn PCB Factory is committed to environmentally responsible practices. The factory actively adopts eco-friendly manufacturing techniques and materials, minimizing waste generation and promoting recycling initiatives. By adhering to sustainable production methods, China Fast Turn PCB Factory not only reduces its environmental impact but also aligns itself with global sustainability goals.Market Reach:With a customer-oriented approach, China Fast Turn PCB Factory has established a robust global market presence. Its diverse clientele includes renowned electronics manufacturers, research institutions, and startups, illustrating the broad range of industries the factory caters to. By maintaining strong partnerships with customers and continuously adapting to their evolving needs, China Fast Turn PCB Factory consolidates its position as a trusted and reliable PCB supplier.Driving Technological Advancements:As China Fast Turn PCB Factory plays a pivotal role in the PCB manufacturing sector, its relentless pursuit of technological advancements contributes to the overall growth and innovation of the global electronics industry. By providing cutting-edge PCB solutions, the factory supports the development of state-of-the-art technologies such as 5G, Internet of Things (IoT), artificial intelligence, and electric vehicles.Conclusion:China Fast Turn PCB Factory's emergence as a dominant player in China's PCB manufacturing industry has propelled the country's technological advancements on a global scale. With state-of-the-art facilities, commitment to quality, and a customer-centric approach, the factory continues to meet the ever-increasing demands of the electronics industry. As China Fast Turn PCB Factory continues to evolve, it will undoubtedly remain at the forefront of PCB manufacturing, shaping the future of the global technology landscape.

High-Quality LED Printed Circuit Board for Lighting Applications

The demand for innovative and energy-efficient LED lighting solutions has been steadily rising in various industries across the globe. As a response to this growing need, [company name] has introduced its latest product, the PCB LED board. With a commitment to delivering high-quality and cutting-edge lighting solutions, [company name] has solidified its position as a leading provider of LED products in the market.The PCB LED board is a state-of-the-art lighting solution that offers a range of benefits, including energy efficiency, long lifespan, and versatile applications. The board is designed to provide exceptional brightness while consuming minimal power, making it an ideal choice for various lighting applications. Additionally, the long lifespan of the LED board ensures reduced maintenance and replacement costs, making it a cost-effective solution for businesses and industries.One of the key features of the PCB LED board is its versatility. It can be customized to meet the specific requirements of different applications, making it suitable for a wide range of industries. Whether it is used for general lighting in commercial buildings, outdoor lighting for streets and parking lots, or specialized lighting for horticulture and agriculture, the PCB LED board can be tailored to deliver optimal performance.In addition to its performance and versatility, the PCB LED board also offers environmental benefits. With its energy-efficient design, the LED board helps reduce carbon emissions and minimize the ecological footprint. This aligns with [company name]'s commitment to sustainability and environmental responsibility, making the PCB LED board a green and eco-friendly lighting solution.As a leading provider of LED products, [company name] is dedicated to delivering top-notch quality and reliability. The PCB LED board undergoes rigorous quality control measures to ensure that it meets the highest standards for performance, durability, and safety. This dedication to quality is reflected in [company name]'s certifications and compliance with industry regulations, providing customers with peace of mind and confidence in the product.Furthermore, [company name] takes pride in its customer-centric approach, offering professional and attentive support to clients. From initial consultation to after-sales service, [company name] is committed to understanding the unique needs of each customer and providing tailored solutions that exceed expectations. With a team of experienced professionals, [company name] is well-equipped to address customer inquiries, provide technical assistance, and offer guidance on the installation and use of the PCB LED board.In line with [company name]'s dedication to innovation, the PCB LED board reflects the company's ongoing efforts to push the boundaries of LED technology. By staying at the forefront of industry advancements and investing in research and development, [company name] continues to introduce products that deliver superior performance, efficiency, and reliability. The PCB LED board is a testament to [company name]'s commitment to innovation and its ability to anticipate and meet the evolving needs of the market.In conclusion, [company name]'s PCB LED board represents a significant advancement in LED lighting technology, offering a combination of performance, versatility, and environmental benefits. With [company name]'s strong reputation for quality, reliability, and customer satisfaction, the PCB LED board is set to make a positive impact in various industries. As the demand for energy-efficient and sustainable lighting solutions continues to grow, [company name] remains at the forefront of delivering cutting-edge products that meet and exceed the expectations of its customers.

Experience Fast PCB Prototyping Services in China

Title: Revolutionizing Electronics: China's Leading Quick Turn PCB Prototypes FactoriesIntroduction:In today's fast-paced, technology-driven society, the demand for quick, reliable, and innovative electronic devices is ever-increasing. China, with its formidable manufacturing capabilities, has emerged as a global leader in the production of electronic components. Among its various achievements, China's Quick Turn PCB Prototypes Factories have been pivotal in revolutionizing the electronics industry. This article aims to shed light on the significant contributions these factories have made, removing the brand name while discussing their overall impact and capabilities.Rapid Prototyping for Cutting-Edge Electronics:China's Quick Turn PCB Prototypes Factories have mastered the art of rapid prototyping, enabling designers and engineers to transform their ground-breaking ideas into tangible products within a remarkably short time frame. The factories employ state-of-the-art manufacturing technologies, including advanced software and machinery, to streamline the prototyping process. With their ability to handle complex designs and miniature components effectively, these factories have become instrumental in the development of cutting-edge electronics.Unmatched Manufacturing Capacity:One of the key strengths of China's Quick Turn PCB Prototypes Factories lies in their unparalleled manufacturing capacity. These factories possess large-scale production lines equipped with high precision equipment, allowing for the successful realization of both small and large batch orders. As a result, they can cater to the diverse needs of startup companies, multinational corporations, and everything in between. The scale of operations provides clients with the flexibility to swiftly respond to market demands and stay ahead in the fiercely competitive electronics industry.Quality Assurance and Reliability:While fostering rapid production, China's Quick Turn PCB Prototypes Factories do not compromise on quality and reliability. These factories adhere to international quality certifications and strict manufacturing standards, guaranteeing the highest level of product excellence. Utilizing quality control measures at every step of the production process, they ensure that each PCB prototype meets or exceeds industry specifications. This commitment to quality has earned them the trust and loyalty of clients worldwide.Efficiency and Cost-Effectiveness:The remarkable efficiency of China's Quick Turn PCB Prototypes Factories extends beyond their rapid prototyping capabilities. By leveraging economies of scale, these factories significantly reduce manufacturing costs without compromising on quality. Their ability to handle large production volumes diminishes per-unit costs, making their services highly cost-effective for businesses of all scales. Additionally, their streamlined processes minimize lead times, allowing companies to swiftly bring their products to market and stay ahead of the competition.Technological Advancement and Innovation:China's Quick Turn PCB Prototypes Factories are at the forefront of technological advancement and innovation. With continuous investments in research and development, they stay ahead of emerging trends and cutting-edge technologies. These factories actively collaborate with clients, providing valuable insights, design suggestions, and engineering support to ensure optimal product performance and functionality. Their commitment to pushing the boundaries of what is possible has paved the way for groundbreaking advancements in the electronics industry.Conclusion:China's Quick Turn PCB Prototypes Factories have transformed the landscape of the electronics industry by revolutionizing the speed, efficiency, and quality at which electronic components are manufactured. These factories serve as a driving force for innovation, enabling designers and engineers to rapidly prototype their ideas and bring them to market swiftly. The removal of the brand name highlights the collective capabilities and achievements of these factories, further solidifying China's position as the global leader in electronics manufacturing.

Copper Circuit Boards: Everything You Need to Know

Circuit Board Copper: A Crucial Component in the Electronics IndustryCircuit board copper is an essential and critical component in the electronics industry. It forms the foundation of the printed circuit board (PCB), which is used in a wide range of electronic devices, from smartphones and laptops to automotive systems and medical equipment. The quality and reliability of circuit board copper directly impact the performance and longevity of the electronic products where it is used.One of the leading manufacturers of high-quality circuit board copper is [remove brand name]. The company has been at the forefront of the electronics industry for over two decades, specializing in the production of copper foil, copper-clad laminates, and other advanced materials for PCB applications. With a commitment to innovation, quality, and sustainability, [remove brand name] has established itself as a trusted partner for electronic manufacturers worldwide.The Importance of High-Quality Circuit Board CopperThe demand for high-quality circuit board copper continues to grow as the electronics industry advances. As electronic devices become more compact and powerful, the need for reliable and efficient PCBs becomes increasingly crucial. Circuit board copper plays a vital role in ensuring the performance, durability, and thermal management of these advanced PCBs.High-quality circuit board copper offers several significant advantages. It provides excellent electrical conductivity, allowing for the efficient transfer of signals and power within the PCB. Moreover, it offers superior thermal conductivity, which is essential for dissipating heat generated by electronic components. Additionally, high-quality circuit board copper exhibits exceptional mechanical strength and dimensional stability, ensuring the integrity of the PCB even under challenging conditions.[Remove brand name]'s Commitment to Quality and InnovationAs a leading manufacturer of circuit board copper, [remove brand name] has consistently prioritized quality and innovation in its operations. The company's state-of-the-art production facilities are equipped with advanced technology and stringent quality control measures to ensure the highest standards of product performance and reliability.[Remove brand name] has also been at the forefront of innovation in the circuit board copper industry. The company continuously invests in research and development to develop new materials and technologies that meet the evolving demands of the electronics market. By collaborating closely with electronic manufacturers, [remove brand name] tailors its circuit board copper products to meet specific performance and environmental requirements, contributing to the advancement of electronic devices.Sustainable Practices in Circuit Board Copper ProductionIn addition to its commitment to quality and innovation, [remove brand name] prioritizes sustainable practices in the production of circuit board copper. The company adheres to strict environmental regulations and standards, minimizing its environmental footprint while delivering high-performance materials. By optimizing its manufacturing processes and sourcing raw materials responsibly, [remove brand name] reduces waste and energy consumption, contributing to a more sustainable electronics industry.Furthermore, [remove brand name] is dedicated to promoting the responsible use of circuit board copper throughout the supply chain. The company works closely with its customers to support the recycling and reuse of PCB materials, reducing the environmental impact of electronic waste. By advocating for sustainable practices and materials, [remove brand name] strives to create a more environmentally friendly and socially responsible electronics industry.Looking Ahead: The Future of Circuit Board CopperAs technology continues to advance, the demand for high-quality circuit board copper is expected to rise. Electronic manufacturers will require reliable and efficient PCB materials to support the development of next-generation electronic devices. With its steadfast commitment to quality, innovation, and sustainability, [remove brand name] is well-positioned to meet the evolving needs of the electronics industry and contribute to its continued progress.In conclusion, circuit board copper is a crucial component in the electronics industry, playing a vital role in the performance and reliability of PCBs used in electronic devices. [Remove brand name] has established itself as a leading manufacturer of high-quality circuit board copper, with a strong focus on quality, innovation, and sustainability. As the electronics industry continues to evolve, [remove brand name] remains dedicated to delivering advanced materials that support the development of innovative and sustainable electronic products.

High-Quality Strip Circuit Board for Your Electronic Devices

Strip Circuit Board (SCB) is a leading manufacturer of high-quality circuit boards that are used in various electronic devices and equipment. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, SCB is at the forefront of the industry, providing innovative solutions and superior products to meet the needs of its customers.The company's commitment to quality and excellence has made it a trusted supplier for many leading electronics companies around the world. SCB's circuit boards are known for their reliability, durability, and performance, making them the top choice for a wide range of applications, from consumer electronics to industrial equipment.One of the key products that SCB specializes in is the strip circuit board, which is used in a variety of devices and equipment. Strip circuit boards are a type of flexible circuit board that are designed to be used in applications where space is limited and a high degree of flexibility is required. These circuit boards are used in a wide range of products, including mobile phones, digital cameras, and automotive electronics, among others.SCB's strip circuit boards are manufactured using advanced technologies and high-quality materials to ensure the highest level of performance and reliability. The company's state-of-the-art manufacturing facilities are equipped with the latest equipment and machinery, allowing for precise and efficient production processes.In addition to its commitment to quality and excellence, SCB is also dedicated to providing superior customer service and support. The company works closely with its customers to understand their specific requirements and provide customized solutions to meet their needs. SCB's team of engineers and technicians are highly knowledgeable and experienced, and are always available to provide technical support and assistance to customers.With a focus on innovation and continuous improvement, SCB is constantly pushing the boundaries of what is possible in the field of circuit board manufacturing. The company invests heavily in research and development to stay ahead of the curve and develop cutting-edge technologies and solutions for its customers.In recent years, SCB has expanded its operations and has established a strong presence in the global market. The company's products are now used in a wide range of industries and applications, and its reputation for quality and reliability continues to grow.As the demand for high-quality circuit boards continues to grow, SCB is well-positioned to meet the needs of its customers and continue to lead the industry. With its dedication to excellence, innovation, and customer satisfaction, SCB is set to remain a key player in the circuit board manufacturing industry for years to come.