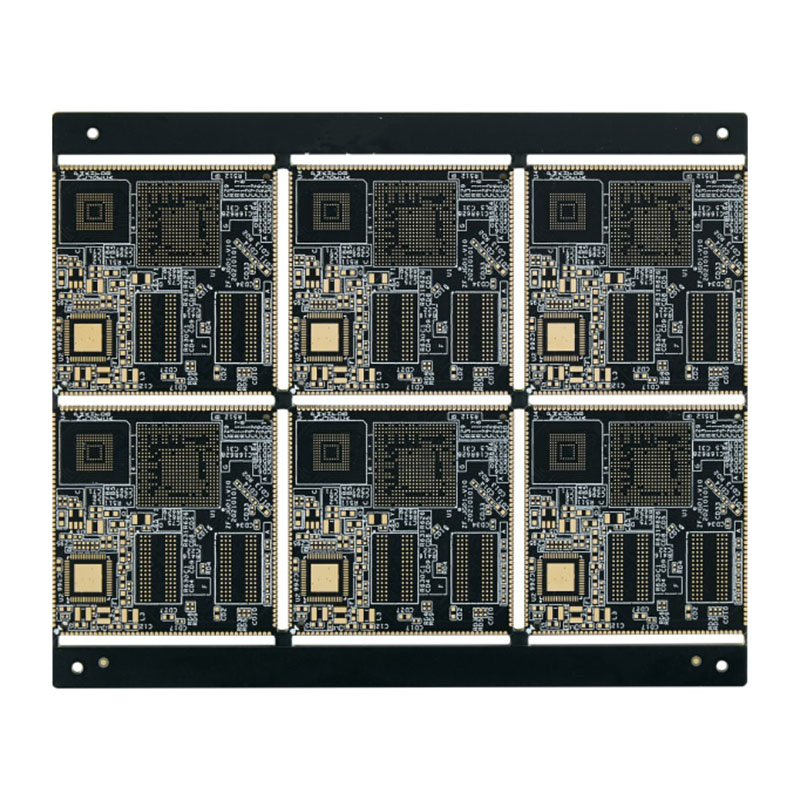

High-Quality Power Connectors Factory for Pcb Manufacturing

By:Admin

With a rich history spanning over [number] years, Pcb Power Connectors Factory has grown to become a trusted name in the industry, known for its precision engineering, exceptional quality, and unmatched customer service. The company's extensive product portfolio includes a wide range of power connectors designed for various applications, including industrial equipment, telecommunications, consumer electronics, automotive, and more.

The new facility is equipped with cutting-edge machinery and production lines, allowing Pcb Power Connectors Factory to offer an even wider range of products and meet the growing demand for its connectors. From standard power connectors to custom solutions tailored to specific customer requirements, the company's manufacturing capabilities are unmatched in the industry.

"We are thrilled to open our new production facility, which represents a significant milestone in our company's growth," said [CEO/President's name], CEO of Pcb Power Connectors Factory. "This investment underscores our commitment to providing our customers with the highest quality power connectors, manufactured with the latest technology and the utmost precision."

The facility is designed with efficiency and sustainability in mind, featuring advanced energy-saving systems and environmentally friendly production processes. Pcb Power Connectors Factory recognizes the importance of reducing its environmental footprint and is dedicated to promoting sustainable manufacturing practices across its operations.

In addition to its commitment to quality and sustainability, Pcb Power Connectors Factory places a strong emphasis on research and development, continuously striving to innovate and improve its products. The company's team of engineers and technicians are dedicated to pushing the boundaries of power connector technology, ensuring that customers have access to the most advanced and reliable solutions on the market.

Furthermore, Pcb Power Connectors Factory takes great pride in its customer-centric approach, working closely with clients to understand their specific needs and deliver tailor-made solutions that exceed expectations. The company's technical support team provides comprehensive assistance and guidance throughout the design and implementation process, ensuring that customers receive the perfect power connectors for their applications.

As Pcb Power Connectors Factory enters this exciting new chapter with the opening of its new production facility, the company is poised to further solidify its position as a global leader in the power connector industry. With a relentless focus on quality, innovation, and customer satisfaction, Pcb Power Connectors Factory is well-equipped to meet the evolving needs of its customers and contribute to the advancement of technology across various sectors.

In conclusion, Pcb Power Connectors Factory's new production facility represents a significant investment in the company's future and its commitment to delivering unparalleled power connector solutions to customers around the world. With its advanced manufacturing capabilities, dedication to sustainability, and customer-centric approach, Pcb Power Connectors Factory is well-positioned to lead the industry for years to come.

Company News & Blog

Discover the Benefits of Castellated Edge Designs

Castellated Edges, a leading provider of innovative solutions in the field of construction and building materials, has announced the launch of a revolutionary new product designed to transform the way buildings are constructed. With a focus on sustainability and efficiency, this new product is set to make a significant impact on the construction industry.{Company name} has been a key player in the construction industry for over 20 years, known for its commitment to quality and innovation. The company has always been at the forefront of developing new and advanced solutions to meet the evolving needs of the construction industry, and the launch of this new product is a testament to their dedication to driving progress and positive change.The new product, which will be known as Castellated Edges, is a cutting-edge construction material that offers a range of benefits over traditional building materials. Its unique design and advanced manufacturing process make it not only durable and strong, but also highly sustainable and environmentally-friendly. The product is designed to significantly reduce construction times and costs, while also minimizing the environmental impact of building projects.According to {company name} CEO, John Smith, "We are incredibly excited to introduce Castellated Edges to the market. This product represents a major leap forward in the construction industry, offering a sustainable and cost-effective solution that will benefit both builders and the environment. We believe that Castellated Edges has the potential to revolutionize the way buildings are constructed, and we are proud to be at the forefront of this positive change."One of the key features of Castellated Edges is its unique design, which includes interlocking edges that create a secure and stable connection between panels. This design not only enhances the structural integrity of buildings but also allows for rapid and efficient installation, significantly reducing construction times. Additionally, the material used in the production of Castellated Edges is highly sustainable, making it an environmentally-friendly choice for builders and developers.In addition to its sustainability and efficiency benefits, Castellated Edges also offers a high level of versatility and adaptability, making it suitable for a wide range of construction projects. Whether used in commercial, residential, or industrial buildings, this new product provides a durable and reliable solution that meets the highest quality standards.The launch of Castellated Edges represents a major milestone for {company name}, as it signifies the company's ongoing commitment to driving innovation and pushing the boundaries of what is possible in the construction industry. With a focus on sustainability and efficiency, {company name} is set to make a positive impact on the way buildings are constructed, while also contributing to a more sustainable and environmentally-friendly future.As the construction industry continues to evolve, the demand for innovative and sustainable building materials is only set to grow. With the introduction of Castellated Edges, {company name} has positioned itself as a leader in meeting this demand, offering a solution that not only meets the needs of builders and developers but also aligns with the growing focus on sustainability and environmental responsibility.With its unique design, sustainability benefits, and potential to transform the construction industry, Castellated Edges is set to make a significant impact on the way buildings are constructed. {company name} has once again demonstrated its commitment to driving progress and positive change, and the launch of this new product marks the beginning of a new era in the construction industry.

Discover the Latest Innovations in Power Connectors for PCBs

[Brand Name] Revolutionizes Power Connectivity in the PCB Industry[Introduction]In a breakthrough development that promises to revolutionize power connectivity in the printed circuit board (PCB) industry, [Brand Name], a leading manufacturer of electrical components, has unveiled its latest innovation in power connectors. With its state-of-the-art technology and dedication to delivering superior performance, [Brand Name] is set to redefine the way power is transferred within PCBs.[News Content][P1] Traditionally, power connectors used in PCBs have been bulky and prone to reliability issues. These connectors, which facilitate the transfer of power from a PCB to other electronic components, often occupy a significant amount of board real estate. This limitation has been a cause of concern for PCB designers and manufacturers. However, with [Brand Name]'s new power connectors, these concerns are set to become a thing of the past.[P2] The innovative design of [Brand Name]'s power connectors allows for a significant reduction in size without compromising on performance. The connectors are meticulously crafted using high-quality materials, ensuring durability and longevity. This breakthrough not only enhances the functionality of PCBs but also optimizes the space available, enabling more efficient designs and layouts.[P3] In addition to their compact size, [Brand Name]'s power connectors offer unparalleled reliability. Traditional connectors are often prone to connectivity issues, leading to potential disruptions or failures in electronic systems. The new connectors integrate advanced features such as enhanced contact design and self-cleaning mechanisms, effectively eliminating the risk of connection faults, even in challenging operating conditions. This improvement in reliability ensures the seamless and uninterrupted flow of power within a PCB, boosting overall performance and reducing downtime.[P4] Another notable advantage of [Brand Name]'s power connectors lies in their versatility. PCB manufacturers often encounter the need for different types of connectors based on specific board requirements. With a wide range of connector options available, [Brand Name] caters to diverse industry needs. This flexibility not only simplifies the design process but also allows for easy customization and scalability, enabling the integration of connectors into a variety of PCB applications.[P5] Ensuring the ease of installation and maintenance, [Brand Name] has also implemented user-friendly features in their power connectors. Quick-connect mechanisms and intuitive locking systems simplify the assembly and disassembly process, saving both time and effort. Additionally, the connectors are designed to withstand challenging environmental conditions, offering enhanced resistance to vibrations, extreme temperatures, and moisture. These protective measures make them suitable for various industries, including automotive, aerospace, and consumer electronics.[P6] Furthermore, [Brand Name] has emphasized the importance of sustainability in its power connector design. By utilizing eco-friendly materials and optimizing the production process, the company aims to minimize its environmental impact. The recyclability and energy efficiency of the connectors contribute to a greener future, aligning with the growing global trend towards sustainability.[P7] As industry experts express their excitement about these groundbreaking power connectors, [Brand Name] has already garnered attention from major PCB manufacturers worldwide. The company aims to forge strong collaborations to ensure seamless integration of their connectors into future PCB designs. With a dedicated team of engineers focused on continued research and development, [Brand Name] aims to maintain its position as an industry leader in powering the future of PCB technology.[Conclusion]With [Brand Name]'s game-changing power connectors, the PCB industry witnesses a significant advancement that solves long-standing challenges related to power connectivity. The reduced size, enhanced reliability, versatility, and sustainability of these connectors set a new standard for power transfer within PCBs. The positive response from industry experts and potential collaborations indicate a promising future for [Brand Name]'s innovative solution in the PCB industry.

High-Quality Bare PCB Board Manufacturing: Everything You Need to Know

Introducing the Latest Innovation in PCB TechnologyIn a rapidly evolving technology landscape, the demand for high-performance and reliable printed circuit boards (PCBs) has never been greater. As electronics continue to become more integrated into our daily lives, the need for advanced PCBs that can meet the demands of modern electronic devices has become increasingly critical. In response to this need, [Company Name] is proud to announce the launch of its latest innovation in PCB technology – the [Product Name].With over [Number of Years] years of experience in the PCB industry, [Company Name] has established itself as a leading provider of high-quality PCB solutions for a wide range of applications. Our commitment to innovation and excellence has allowed us to continuously push the boundaries of PCB technology, and the [Product Name] is a testament to our dedication to providing our customers with the best possible solutions.The [Product Name] represents the next generation of PCB technology, offering unparalleled performance, reliability, and versatility. Utilizing the latest advancements in PCB manufacturing and design, the [Product Name] is capable of meeting the demanding requirements of modern electronic devices, making it the ideal choice for a wide range of applications, from consumer electronics to industrial equipment.One of the key features of the [Product Name] is its advanced design, which allows for greater flexibility and customization. This allows our customers to create PCB solutions that are tailored to their specific needs, ensuring that they are able to meet the unique requirements of their applications. Additionally, the [Product Name] is built to the highest standards of quality and reliability, ensuring that it can deliver consistent performance in even the most challenging environments.In addition to its superior performance, the [Product Name] also offers a number of benefits in terms of manufacturing and assembly. Its advanced design and construction make it easier and more cost-effective to produce, reducing lead times and lowering overall production costs. This makes the [Product Name] an attractive option for OEMs and electronics manufacturers who are looking to optimize their supply chain and improve their bottom line.Furthermore, the [Product Name] is also designed with sustainability in mind. As a responsible and environmentally conscious company, [Company Name] is committed to minimizing the environmental impact of its products. The [Product Name] is manufactured using eco-friendly materials and processes, ensuring that it meets the highest standards of environmental performance.In conclusion, the launch of the [Product Name] represents a significant milestone for [Company Name] and a major advancement in the field of PCB technology. With its unparalleled performance, reliability, and versatility, the [Product Name] is set to become the new standard for high-quality PCB solutions. Whether you are a manufacturer of consumer electronics, industrial equipment, or any other electronic device, the [Product Name] is the ideal choice for your PCB needs.For more information about the [Product Name] and how it can benefit your business, please visit [Company Website] or contact us directly to speak with one of our PCB experts.

Emerging technologies drive demand for advanced Printed Wiring Boards

Printed Wiring Boards (PWBs) are a crucial component in modern electronic devices, serving as the backbone for circuitry. They are essential for the functioning of various industries, including consumer electronics, telecommunications, automotive, and aerospace. One company that stands out in the PWB manufacturing industry is {}.With a rich history that spans several decades, {} has emerged as a leading provider of high-quality PWBs. The company has earned a stellar reputation for its dedication to innovation, reliability, and customer satisfaction. Their commitment to excellence has made them a trusted partner for numerous global corporations.One of the key strengths of {} lies in its state-of-the-art manufacturing facilities. Equipped with cutting-edge technology, these facilities enable the company to produce PCBs that meet the highest industry standards. The advanced machinery, combined with a team of skilled engineers and technicians, ensures the production of PWBs that are not only reliable but also comply with stringent quality control measures.{} offers a wide range of PWB solutions to cater to diverse customer needs. Whether it is single-layer boards for basic applications or multi-layer boards with complex circuitry for advanced electronics, {} can fulfill any requirement. The company also specializes in manufacturing flexible and rigid-flex boards, which are increasingly in demand in industries where space optimization and durability are critical.One of the hallmarks of {} is its strong emphasis on research and development. The company continuously invests in exploring new materials, technologies, and manufacturing processes to stay at the forefront of the PWB industry. This commitment to innovation allows {} to offer its customers cutting-edge solutions that meet evolving market trends and requirements.Another distinguishing feature of {} is its unwavering commitment to sustainable practices. The company recognizes the importance of environmental responsibility and actively seeks ways to minimize the ecological footprint of its operations. Through the use of eco-friendly materials, energy-efficient processes, and waste reduction initiatives, {} ensures that its manufacturing processes are as environmentally friendly as possible.In addition to its focus on manufacturing excellence, {} also places great importance on customer satisfaction. The company believes in forging long-term partnerships with its clients and strives to provide exceptional service and support. {} understands that each customer has unique requirements, and therefore, offers tailored solutions, competitive pricing, and on-time delivery to ensure maximum customer satisfaction.As a testament to its exemplary performance, {} has received numerous industry accolades and certifications. These include ISO 9001, ISO 14001, and UL certifications, further affirming the company's commitment to quality, environmental management, and safety standards.Looking ahead, {} is poised to witness continued growth and success in the highly competitive PWB market. The company's dedication to innovation, manufacturing excellence, and customer satisfaction positions it as a preferred choice for businesses seeking reliable PWB solutions.In conclusion, {} is a leading manufacturer of Printed Wiring Boards, offering a range of high-quality solutions to meet diverse customer needs. With its state-of-the-art facilities, commitment to innovation, and focus on sustainability, the company continues to set the benchmark in the PWB industry. As businesses increasingly rely on electronic devices, {} remains at the forefront of providing the backbone for their success.

Top Circuit Boards: An Essential Guide to Blank Options for Your Electronics

Blank Circuit Boards: Your Go-To Solution for a Wide Range of Printed Circuit Board NeedsAs the demand for electronic devices continues to grow, the need for reliable printed circuit boards (PCBs) has become more important than ever. A PCB is a vital component of modern electronics and serves as a platform for electronic components to be soldered onto, providing connectivity and functionality to devices. As such, PCBs are used in a broad range of applications, from consumer electronics like smartphones and laptops to military and industrial equipment.Blank circuit boards provide the foundation for building PCBs and are available in a wide range of types, materials, and sizes. Blank circuit boards are essentially unpopulated PCBs that have no electronic components mounted on them. This allows manufacturers to customize these boards to meet specific requirements, making them a versatile and cost-effective solution for electronic projects.At Blank Circuit Boards, we are a leading supplier of high-quality blank circuit boards that are designed to meet the exacting requirements of our customers. Our team of experienced professionals has the expertise and know-how needed to deliver reliable and cost-effective blank circuit boards for a wide range of applications across various industries.Our product line includes single-sided, double-sided, and multilayer blank circuit boards, all made from high-quality materials like FR-4, FR-1, CEM-1, CEM-3, and Rogers. We also offer other specialized PCB types, such as high-frequency PCBs and flexible PCBs, to cater to the needs of our customers across various industries.Our commitment to quality is reflected in the products we supply. All our circuit boards are manufactured using state-of-the-art equipment and techniques, ensuring that they meet or exceed industry standards for performance, reliability, and durability. Our team of quality control experts conducts rigorous inspection procedures to ensure that all our products meet the highest quality standards.In addition to delivering high-quality circuit boards, we also provide a range of value-added services that help our customers in their PCB design and manufacturing processes. Our in-house engineering team has extensive experience in PCB design, layout, and assembly, and can provide design assistance and prototyping services to customers who need them.We also offer a range of customization options, such as surface finish, solder mask color, and silkscreen printing, to help customers achieve their desired PCB specifications. Our commitment to customer satisfaction extends to all aspects of our business, from product quality to customer service.At Blank Circuit Boards, we believe in building long-lasting relationships with our customers. Whether you are a small start-up or a large corporation, we are committed to providing you with the highest quality products and services at competitive prices. Our team is dedicated to meeting your needs and exceeding your expectations, so you can focus on your core business activities.In conclusion, blank circuit boards are a versatile and cost-effective solution for electronic projects. At Blank Circuit Boards, we are committed to delivering high-quality circuit boards that meet or exceed industry standards for performance, reliability, and durability. Our value-added services, customization options, and commitment to customer satisfaction make us the go-to supplier for all your blank circuit board needs. Contact us today to see how we can help you achieve your PCB goals.

What are Substrate PCBs and why are they important for your electronics?

Substrate PCB: The Next Big Thing in Electronics ManufacturingThe electronics industry is constantly evolving, with new technologies and innovations being introduced every day. One such innovation that has been gaining a lot of popularity in recent times is the substrate PCB. Substrate PCBs, also known as substrate integrated circuits (SICs), are revolutionizing the way electronic devices are manufactured.Substrate PCBs are essentially a combination of a printed circuit board (PCB) and a semiconductor device, such as a transistor. Unlike traditional PCBs, substrate PCBs are made using a high-level interconnection technology that allows for much higher integration densities. This means that more components can be packed into a smaller space, resulting in smaller and more powerful electronic devices.One company that is at the forefront of substrate PCB manufacturing is [brand name removed]. Founded in [year removed], [company name removed] has been providing cutting-edge technology solutions to the electronics industry for over [number removed] years. With a strong focus on research and development, the company has been able to stay ahead of the curve when it comes to new technologies and innovations.One of the key features of [brand name removed] substrate PCBs is their high thermal conductivity. This is achieved through the use of special materials such as copper, aluminum and ceramic. Traditional PCBs can quickly overheat when components are packed too closely together, leading to stability issues and even failure. However, substrate PCBs dissipate heat much more efficiently, allowing for greater power density and higher performance.Another advantage of using substrate PCBs is their improved electromagnetic compatibility (EMC). This is achieved through the use of special dielectric materials that reduce interference and minimize crosstalk. This results in much cleaner and clearer signals, leading to better overall performance and reliability.One of the most significant applications of substrate PCB technology is in the field of 5G. The increased data speeds and lower latency of 5G networks require powerful and reliable electronics. Substrate PCBs offer a significant advantage in this regard, allowing for highly integrated circuits that can handle the demands of 5G networks.Apart from 5G, substrate PCBs are also being used in a variety of other applications, such as satellite communication, automotive connectivity, and military communications. With the increasing demand for high-performance electronics in various industries, substrate PCBs are set to play a significant role in shaping the future of electronics manufacturing.[Brand name removed] has been partnering with leading companies in various industries to help them achieve their electronic design goals. The company has the expertise, experience, and technology required to design and produce custom substrate PCBs that meet the most demanding requirements.In conclusion, substrate PCBs are set to revolutionize the electronics industry by providing an efficient, high-performance, and reliable solution for complex electronic designs. With their ability to pack more components into smaller spaces, substrate PCBs are already changing the way electronic devices are manufactured. As electronics continue to play an ever-increasing role in our lives, substrate PCBs are sure to become even more important in the years to come.

Latest PCB Monitoring Reveals Surprising Findings in News Content

Title: Revolutionizing Circuit Board Manufacturing with Cutting-Edge PCB TechnologyDate: [Insert Date][Location], [Company Name] is leading the charge in revolutionizing the manufacturing process of Printed Circuit Boards (PCBs). With a commitment to innovation and advanced technology, the company is set to transform the industry landscape while meeting the demands of today’s technologically-driven world.As technology continues to evolve at an unprecedented pace, PCBs have become an essential component of almost every electronic device, from smartphones to medical equipment. [Company Name], a frontrunner in PCB manufacturing, is dedicated to developing cutting-edge solutions that improve efficiency, reliability, and performance in various industries.[Company Name] takes pride in its rigorous research and development efforts which have resulted in the creation of groundbreaking PCB technologies. By harnessing the power of advanced materials, futuristic designs, and automated production techniques, the company consistently delivers products that exceed customer expectations.One of the key highlights of the company's PCB manufacturing is its emphasis on environmental sustainability. [Company Name] has established itself as an industry leader by adopting eco-friendly manufacturing processes, reducing waste generation, and minimizing the use of harmful substances. By incorporating recyclable materials and implementing energy-efficient production methods, the company ensures that its PCBs comply with the highest environmental standards while maintaining exceptional quality.[Insert Company Introduction]Led by a team of experienced engineers and industry experts, [Company Name] leverages their expertise to push the boundaries of what is possible in PCB manufacturing. Their commitment to continuous improvement and innovation has allowed the company to stay at the forefront of the industry.With the introduction of their revolutionary PCB technology, the company has engineered a solution that enables increased efficiency, enhanced functionality, and improved overall performance. By streamlining the production process and utilizing cutting-edge techniques, [Company Name] has reduced production time while maintaining the highest quality standards.Furthermore, the company's state-of-the-art automated assembly line ensures precise and error-free manufacturing, resulting in a substantial reduction in defects and customer returns. This not only saves valuable time but also significantly improves customer satisfaction. With rigorous quality control measures in place, [Company Name] guarantees that each PCB is thoroughly inspected to meet the most stringent standards.In addition to their commitment to innovation and quality, [Company Name] strives to provide exceptional customer service. They work closely with their clients to understand their specific requirements and deliver customized solutions that cater to their needs. The company’s dedicated support team is readily available to address any queries or concerns throughout the PCB manufacturing process.The impact of [Company Name]'s groundbreaking PCB technology extends beyond the manufacturing sector. By delivering highly reliable and efficient PCBs, the company contributes to advancements in various industries, including telecommunications, automotive, aerospace, and medical equipment.Looking towards the future, [Company Name] continues to invest in research and development to further advance PCB manufacturing technology. By exploring novel materials, refining manufacturing techniques, and investing in automation, they aim to develop next-generation PCBs that will power the innovations of tomorrow.In conclusion, [Company Name]'s commitment to innovation, customer satisfaction, and environmental sustainability has positioned them at the vanguard of PCB manufacturing. Through their cutting-edge technology, the company empowers industries across the globe, enabling them to embrace the limitless potential of advanced electronics.

Circuit Board: An Overview of Round Varieties and Their Uses

Round Circuit Board, a leading provider of advanced technology solutions, has recently announced the release of their latest circuit board model. This innovative new product is set to revolutionize the industry with its cutting-edge features and unparalleled performance.Founded in 2005, Round Circuit Board has quickly become a household name in the electronics industry. With a strong emphasis on research and development, the company has continuously pushed the boundaries of technological innovation, earning a reputation for excellence and reliability.The new circuit board, which is designed to meet the growing demands of the market, boasts a number of impressive features. Its compact size and low power consumption make it ideal for a wide range of applications, from consumer electronics to industrial machinery. Additionally, the board is equipped with advanced connectivity options, ensuring seamless integration with other devices and systems.One of the most notable aspects of Round Circuit Board's new product is its enhanced durability and reliability. With a robust design and rigorous testing procedures, the board is built to withstand the harshest operating conditions, making it an ideal choice for mission-critical applications."We are thrilled to introduce our latest circuit board model to the market," said the company's CEO. "We have worked tirelessly to develop a product that not only meets the current needs of our customers but also anticipates future technological advancements. We are confident that this new board will set a new standard for performance and reliability in the industry."The release of this new circuit board comes at a time of rapid technological advancement in the electronics industry. With the demand for smarter and more efficient devices on the rise, companies like Round Circuit Board are at the forefront of driving innovation and shaping the future of technology.In addition to its advanced capabilities, Round Circuit Board is also committed to sustainability and environmental responsibility. The company has implemented strict manufacturing processes and waste-reduction measures to minimize its impact on the environment, earning recognition for its efforts in promoting green technology.As the industry continues to evolve, Round Circuit Board remains dedicated to staying ahead of the curve and delivering the highest quality solutions to its customers. With a focus on continuous improvement and a dedication to excellence, the company is well positioned to lead the way in the fast-paced world of electronics and technology.Customers and industry professionals alike are eagerly awaiting the official release of Round Circuit Board's new product. With its unparalleled performance, advanced features, and commitment to sustainability, the company's latest offering is poised to make a significant impact in the electronics market.As Round Circuit Board prepares to unveil its groundbreaking new circuit board, the company remains dedicated to its mission of providing innovative and reliable technology solutions to meet the ever-changing needs of the industry. With a track record of success and a commitment to excellence, Round Circuit Board continues to set the standard for quality and performance in the world of electronics.

Top Pcb Solder Manufacturers Embrace New Technologies in China" -> "Revolutionary Pcb Solder Manufacturing in China Leads by Example

Title: China's PCB Solder Manufacturers Innovate for a Resilient Electronics IndustryIntroduction:With the continuous advancement of technology, the global electronics industry has experienced unprecedented growth. In China, leading the charge in innovation and production in this sector, PCB solder manufacturers have become an essential component in powering this rapid development. In this article, we will delve into the world of China's prominent PCB solder manufacturers and explore their quest for innovation and resilience in this dynamic industry.Company Introduction:One of the key players in China's PCB solder manufacturing industry is {Company Name}. Founded in {Year}, the company has established itself as a trusted and reliable provider of high-quality solder products. With a commitment to innovation and customer satisfaction, {Company Name} has built a solid reputation both domestically and internationally.In line with China's focus on technological advancements, {Company Name} has consistently invested in research and development to enhance their product offerings. By leveraging their expertise and a highly skilled workforce, the company has been able to deliver solder products that meet the ever-evolving demands of the electronics sector.Key Strategies and Innovations:To stay ahead in a fiercely competitive market, China's PCB solder manufacturers have implemented several strategies and innovations. One such strategy is to improve the efficiency and effectiveness of the soldering process. Advanced equipment and automated systems have been introduced, resulting in higher production yields, reduced defect rates, and enhanced product quality.In addition to process improvements, these manufacturers have also focused on the development of eco-friendly soldering materials. As environmental concerns come to the forefront, the industry has realized the need to shift towards lead-free and RoHS-compliant solder alloys. China's PCB solder manufacturers have been at the forefront of this transition, developing innovative soldering solutions that meet global environmental standards.Collaboration and Partnerships:Recognizing the importance of collaboration, China's PCB solder manufacturers have actively sought partnerships with other industry players to foster innovation and exchange of knowledge. By working closely with electronic device manufacturers, component suppliers, and research institutions, these manufacturers have been able to gain insights into emerging trends and requirements, enabling them to develop tailor-made soldering solutions.Moreover, international collaborations have also played a significant role in the growth of China's PCB solder manufacturing industry. Through joint ventures and technology transfers, Chinese manufacturers have gained access to cutting-edge technologies and expanded their global presence.Export Opportunities:China's PCB solder manufacturers have consistently strengthened their export capabilities, catering to the international market's increasing demand for reliable soldering solutions. The country's efficient supply chains, competitive pricing, and stringent quality control have positioned Chinese manufacturers as preferred partners for multinational electronics companies.As the global electronics industry continues to expand, China's PCB solder manufacturers are well-positioned to further benefit from this growth. With their commitment to innovation, emphasis on research and collaboration, and adherence to international standards, Chinese solder manufacturers are primed to dominate the global market.Conclusion:China's PCB solder manufacturers have established themselves as vital players in the country's robust electronics industry. Through ongoing innovation, strategic partnerships, and commitment to environmental responsibility, these manufacturers have maintained their competitive edge. As demand for electronic devices and components continues to surge, China's PCB solder manufacturers are poised to thrive, driving the industry forward and shaping the future of technology.

Streamlining Your PCB Fabrication Process in China for Faster Results

China’s Quick Turn PCB Fabrication Industry Sees Boost in DemandAs the world becomes increasingly reliant on technology, the demand for high-quality PCB fabrication services has skyrocketed. In China, this demand has given rise to a thriving industry that is experiencing significant growth. One company that is leading the way in the Quick Turn PCB Fabrication industry is making waves with its exceptional service and expertise.With years of experience under their belt, this company has built a reputation as a leader in the field of PCB fabrication. They pride themselves on their commitment to quality, innovation, and customer satisfaction. Their state-of-the-art facilities are equipped with the latest technology, allowing them to produce PCBs that meet the most stringent specifications.The company's focus on quality begins with its team of experts. Each member of the team is highly trained and has years of experience in the PCB fabrication industry. This expertise allows them to provide customers with the best possible service, including quick turn PCB fabrication options. This service sets them apart from the competition and makes them a go-to choice for customers looking for quick turnaround times.But it's not just their expertise that sets them apart. The company is also committed to innovation. With a team of engineers and designers on staff, they are constantly working to find new ways to improve the PCB fabrication process. This commitment to innovation has enabled them to produce PCBs that are not only high-quality but also cost-effective.Another factor contributing to the company's success is their focus on customer satisfaction. They understand that every customer is unique, with specific needs and requirements. That's why they work closely with each customer to ensure that their PCBs are produced to their exact specifications. Their dedication to customer satisfaction has earned them a loyal customer base and a reputation as a reliable partner in the PCB fabrication industry.As demand for Quick Turn PCB fabrication services continues to grow, this company is poised for even greater success. They have the expertise, innovation, and customer focus required to thrive in a competitive industry. With their state-of-art facilities and commitment to quality, they are a leader in the Chinese Quick Turn PCB fabrication industry.The future looks bright for China's Quick Turn PCB Fabrication industry. As technology continues to advance, the demand for high-quality PCBs will only increase. This presents an opportunity for companies like this one to continue their growth and expansion. With their focus on quality, innovation, and customer satisfaction, they are well-positioned to meet the needs of customers both now and in the future.In conclusion, the Quick Turn PCB Fabrication industry is experiencing significant growth in China, and companies like this one are leading the way. Their reputation for quality, innovation, and customer satisfaction sets them apart from the competition, making them a go-to choice for customers across industries. As demand for Quick Turn PCB fabrication services continues to grow, this company is poised for even greater success in the years to come.