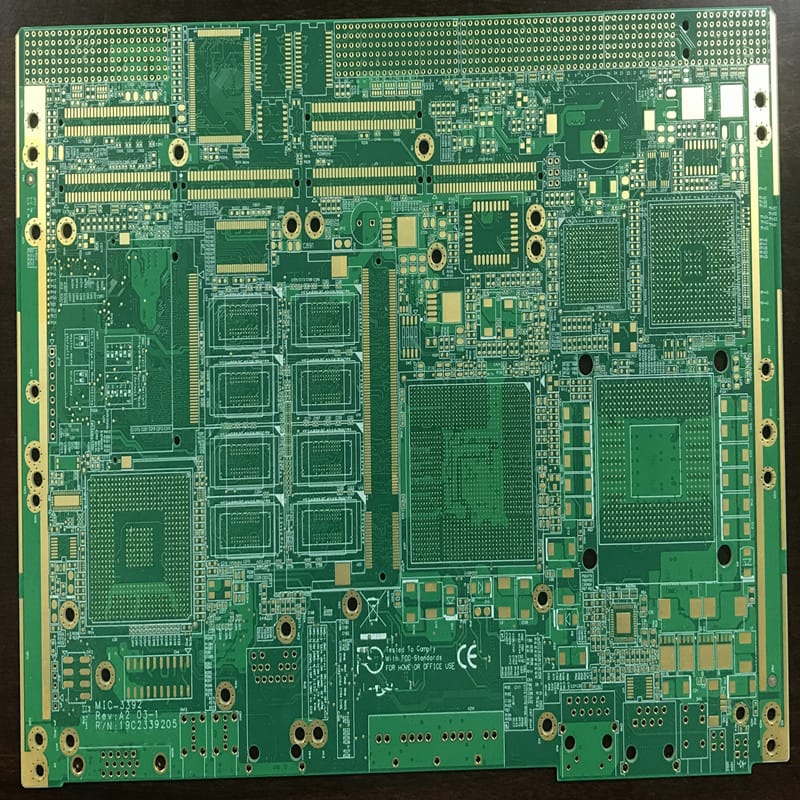

High-quality Printed Circuit Board for Tg150 Applications

By:Admin

With the rise of smart devices and the Internet of Things, the demand for high-quality PCBs has soared. Tg150 PCB has positioned itself as a top choice for manufacturers looking to meet the growing needs of the industry. Its ability to withstand high temperatures and provide superior electrical insulation has made it a preferred option for applications in automotive, aerospace, medical, and industrial sectors.

In addition to its technical performance, Tg150 PCB is also known for its flexibility in design and production. Companies like {} have been at the forefront of developing advanced Tg150 PCB solutions that can be tailored to specific requirements. Their expertise in customizing PCB designs has allowed manufacturers to create innovative products that meet the highest standards of quality and performance.

Furthermore, {} has made significant investments in research and development to advance the capabilities of Tg150 PCB. Their focus on pushing the boundaries of what is possible with this technology has led to breakthroughs in material science and manufacturing processes, resulting in PCBs that are more reliable, durable, and efficient.

One of the key factors that sets {} apart from other PCB manufacturers is their commitment to sustainability. They have implemented eco-friendly practices in their production processes, such as reducing waste and energy consumption. This dedication to environmental responsibility has resonated with customers, who are increasingly seeking suppliers that prioritize sustainability in their operations.

As the demand for Tg150 PCB continues to grow, {} is poised to play a vital role in driving innovation and shaping the future of electronic devices. Their dedication to excellence and continuous improvement has positioned them as a trusted partner for companies looking to integrate Tg150 PCB into their products.

Looking ahead, the outlook for Tg150 PCB remains positive as it continues to gain momentum in the market. With advancements in technology and an increasing focus on quality and reliability, Tg150 PCB is poised to become an essential component in the next generation of electronic devices.

In conclusion, Tg150 PCB has emerged as a leading technology in the industry, thanks to its exceptional performance, flexibility, and sustainability. With the expertise and dedication of companies like {}, Tg150 PCB is set to drive innovation and meet the evolving needs of the market. As the demand for high-quality PCBs continues to rise, Tg150 PCB is well positioned to play a key role in shaping the future of electronic devices.

Company News & Blog

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.

Streamlining Your PCB Fabrication Process in China for Faster Results

China’s Quick Turn PCB Fabrication Industry Sees Boost in DemandAs the world becomes increasingly reliant on technology, the demand for high-quality PCB fabrication services has skyrocketed. In China, this demand has given rise to a thriving industry that is experiencing significant growth. One company that is leading the way in the Quick Turn PCB Fabrication industry is making waves with its exceptional service and expertise.With years of experience under their belt, this company has built a reputation as a leader in the field of PCB fabrication. They pride themselves on their commitment to quality, innovation, and customer satisfaction. Their state-of-the-art facilities are equipped with the latest technology, allowing them to produce PCBs that meet the most stringent specifications.The company's focus on quality begins with its team of experts. Each member of the team is highly trained and has years of experience in the PCB fabrication industry. This expertise allows them to provide customers with the best possible service, including quick turn PCB fabrication options. This service sets them apart from the competition and makes them a go-to choice for customers looking for quick turnaround times.But it's not just their expertise that sets them apart. The company is also committed to innovation. With a team of engineers and designers on staff, they are constantly working to find new ways to improve the PCB fabrication process. This commitment to innovation has enabled them to produce PCBs that are not only high-quality but also cost-effective.Another factor contributing to the company's success is their focus on customer satisfaction. They understand that every customer is unique, with specific needs and requirements. That's why they work closely with each customer to ensure that their PCBs are produced to their exact specifications. Their dedication to customer satisfaction has earned them a loyal customer base and a reputation as a reliable partner in the PCB fabrication industry.As demand for Quick Turn PCB fabrication services continues to grow, this company is poised for even greater success. They have the expertise, innovation, and customer focus required to thrive in a competitive industry. With their state-of-art facilities and commitment to quality, they are a leader in the Chinese Quick Turn PCB fabrication industry.The future looks bright for China's Quick Turn PCB Fabrication industry. As technology continues to advance, the demand for high-quality PCBs will only increase. This presents an opportunity for companies like this one to continue their growth and expansion. With their focus on quality, innovation, and customer satisfaction, they are well-positioned to meet the needs of customers both now and in the future.In conclusion, the Quick Turn PCB Fabrication industry is experiencing significant growth in China, and companies like this one are leading the way. Their reputation for quality, innovation, and customer satisfaction sets them apart from the competition, making them a go-to choice for customers across industries. As demand for Quick Turn PCB fabrication services continues to grow, this company is poised for even greater success in the years to come.

Experts Share Tips on Effective PCB Circuit Design for Electronic Devices

Title: Advancements in PCB Circuit Design: Redefining Electronics ManufacturingIntroduction:In a relentless pursuit of innovation and efficiency, electronics manufacturing companies are continuously searching for new ways to enhance and optimize their printed circuit board (PCB) designs. The evolution of PCB circuit design has now reached a new milestone, equipped with cutting-edge technologies, and driven by the vision of {Company Name}, aiming to revolutionize the electronic industry landscape.Body:1. The Emerging Era of Enhanced Performance:In this era of rapid technological advancements, the demand for smaller, faster, and more complex electronic devices is on the rise. To meet these evolving needs, {Company Name} has leveraged its expertise in PCB circuit design to facilitate advanced functionalities and improved performance. With an innovative approach, their designs offer enhanced signal integrity, reduced power consumption, and increased functionality.2. Adoption of High-Density Interconnect (HDI) Technology:{Company Name} has adopted state-of-the-art High-Density Interconnect (HDI) technology, a critical driver in the evolution of PCB circuit design. This technology allows for a higher density of components, enabling efficient space utilization and reducing the size of electronic devices. By employing HDI, {Company Name} ensures smoother signal routing, minimizes noise interference, and optimizes overall performance.3. Integration of Advanced Materials and Techniques:To address the growing demand for advanced electronic devices, {Company Name} has integrated innovative materials and techniques into their PCB circuit designs. By utilizing advanced materials, such as flexible circuit boards and high-speed laminates, they enable versatile designs that can withstand harsh environmental conditions and offer higher reliability. Additionally, the incorporation of surface mount technology (SMT) allows for smaller component sizes, further optimizing board space utilization.4. Embracing IoT and Industry 4.0:With the Internet of Things (IoT) and Industry 4.0 revolutionizing various sectors, {Company Name} has embraced these emerging technologies to optimize their PCB circuit designs. By integrating wireless communication modules, their designs allow for seamless connectivity and data exchange between devices. This integration offers an opportunity for increased automation, improved efficiency, and real-time monitoring in smart factories and connected devices.5. Design for Manufacturing (DFM) and Design for Test (DFT) Methodologies:As the complexity of electronic devices increases, {Company Name} acknowledges the importance of Design for Manufacturing (DFM) and Design for Test (DFT) methodologies. Their designs are optimized to streamline the manufacturing process, reduce costs, and minimize the potential for errors during assembly. By ensuring a smooth transition from design to production, {Company Name} enables faster time-to-market for their clients.6. Environmental Sustainability:Recognizing the significance of environmental sustainability in the electronic industry, {Company Name} prioritizes eco-friendly design practices. By employing energy-efficient components, optimizing power consumption, and utilizing recyclable materials, their PCB circuit designs contribute to a reduced carbon footprint. This commitment aligns with global initiatives to promote sustainable practices and mitigate the environmental impact of electronics manufacturing.7. Collaboration and Customization:{Company Name} places great emphasis on collaborating with their clients to understand their unique requirements. This collaborative approach enables them to provide customized PCB circuit designs tailored to specific needs. By working closely with their clients, they offer solutions that optimize functionality, reduce costs, and enhance overall product performance.Conclusion:{Company Name}'s relentless pursuit of innovation and commitment to excellence in PCB circuit design has redefined the landscape of electronics manufacturing. By integrating advanced technologies, such as HDI, IoT, and eco-friendly practices, they are reshaping the future of electronics. Through collaboration and customization, {Company Name} empowers their clients with cutting-edge PCB circuit designs, contributing to improved performance, increased functionality, and a sustainable electronic ecosystem.

What Is FR4 Material PCB and How Does It Work?

article about the benefits of using FR4 material PCBs in electronic manufacturing.Electronic manufacturing is one of the most critical industries in the world, with virtually every aspect of modern life being dependent on electronic devices and systems. One crucial component of electronic manufacturing is printed circuit boards (PCBs), which play an essential role in the functioning of electronic devices. In recent times, FR4 material PCB has emerged as one of the most reliable and cost-effective options for electronic manufacturing.FR4 material PCBs are made using a specific kind of fiberglass impregnated with epoxy resin, which makes them highly durable, flexible, and resistant to high temperatures. This makes FR4 material PCBs ideal for use in a wide range of electronic devices, ranging from simple consumer electronics to advanced military installations.One of the key benefits of using FR4 material PCBs is that they offer high mechanical strength, which makes them ideal for applications that require complex and intricate designs. Due to their high mechanical strength, FR4 material PCBs can withstand high levels of vibration, shock, and impact without sustaining damage. This makes them ideal for use in rugged environments such as aerospace, military, and industrial applications.Another benefit of using FR4 material PCBs is that they are highly resistant to high temperatures, which makes them ideal for use in high-temperature applications such as power electronics. They can also withstand sudden changes in temperature without losing their structural integrity, which allows them to be used in harsh environments.FR4 material PCBs are also highly resistant to moisture and chemicals, which makes them ideal for use in applications that are exposed to harsh chemicals or extreme weather conditions. They resist chemical reactions, which helps prevent corrosion and oxidation from occurring. This guarantees that the circuit board remains functional even in adverse conditions.In addition to their physical properties, FR4 material PCBs are also very easy to manufacture, which helps reduce production costs and lead times. Since they are highly versatile and robust, they can be used in a wide range of electronic devices. This reduces the need for manufacturers to invest in multiple types of PCBs, resulting in cost savings.Furthermore, FR4 material PCBs offer excellent electrical performance, which makes them ideal for use in high-speed applications such as computer motherboards. They have a low dielectric constant, making them ideal for high-frequency applications. They can also handle high voltage and current, making them ideal for use in power electronics.Overall, the benefits of using FR4 material PCBs are numerous, making them the ideal choice for electronic manufacturing applications that require high durability, flexibility, and performance. With their robustness, versatility, and affordability, FR4 material PCBs are rapidly becoming the go-to choice for electronics manufacturers worldwide.{Brand name removed} is a leading supplier of FR4 material PCBs, providing high-quality products to customers in a wide range of industries. With years of experience in the electronic manufacturing sector, {Brand name removed} has the expertise and resources to design, manufacture, and supply FR4 material PCBs that meet the most stringent industry standards. Their products are highly reliable, durable, and cost-effective, making them the preferred choice of electronics manufacturers worldwide.In conclusion, electronic manufacturers looking to produce high-quality electronic devices must consider using FR4 material PCBs due to their unique properties and benefits. While traditional PCB materials have their advantages, FR4 material PCBs offer superior strength, durability, versatility, and performance, making them ideal for a wide range of applications. {Brand name removed} offers a wide range of FR4 material PCB products that meet the needs and requirements of modern electronic manufacturers, ensuring that their products are reliable, high-performing, and meet the most stringent industry standards.

Discover the Benefits of Lead-Free Technology in the Latest News Update

[News Title]: A New Era in Environmental Responsibility: Introducing Hass Lead Free[News Introduction]:In a world increasingly conscious of the environmental impact of industrial practices, the need for responsible and sustainable solutions has become paramount. Today, we are excited to introduce Hass Lead Free (name removed), a groundbreaking innovation that addresses the issue of lead pollution in an unprecedented way. Developed by an industry-leading company whose commitment to sustainability is second to none, this pioneering technology is set to revolutionize the manufacturing landscape.[News Body]:Lead, a highly toxic heavy metal, has long been a subject of concern due to its detrimental effects on human health and the environment. While efforts have been made to reduce its presence in various products, such as gasoline and paint, its integration into manufacturing processes has posed a significant challenge. This is where Hass Lead Free comes in.Developed by the ingenious minds at a renowned company, Hass Lead Free represents a breakthrough in the quest for safe and sustainable manufacturing practices. Building on years of research and development, this cutting-edge technology eliminates the need for lead throughout the entire manufacturing process, offering a viable alternative that reduces pollution and minimizes health risks.The implications of this innovation are far-reaching. Not only does Hass Lead Free reduce the environmental impact of manufacturing, but it also ensures safer working conditions for the employees involved. By completely removing lead from the equation, the risk of occupational exposure to this hazardous material is effectively nullified, safeguarding the well-being of all those involved in the production process.Furthermore, as the global demand for environmentally responsible products continues to rise, companies that embrace sustainable practices gain a competitive edge. Hass Lead Free allows manufacturers to align themselves with the growing consumer preference for eco-friendly products, enhancing their brand reputation and fostering long-term growth.The company behind this groundbreaking technology understands the importance of collaboration in addressing complex environmental challenges. With a strong commitment to corporate social responsibility, they have actively engaged in partnerships with industry leaders, governmental agencies, and research institutions to ensure the widest possible dissemination and implementation of their innovation. By sharing their knowledge and expertise, they are driving the transition towards a more sustainable future for all.Hass Lead Free also provides a cost-effective solution for manufacturers. By streamlining production processes, eliminating the need to handle and dispose of lead, and reducing the risk of regulatory non-compliance, companies can significantly decrease their operational costs and increase overall efficiency. This translates into a win-win scenario, where profitability goes hand in hand with environmental responsibility.Looking to the future, the developers of Hass Lead Free envision a world where lead pollution is a thing of the past. By pioneering this technology, they are setting the stage for a paradigm shift in manufacturing practices, inspiring others to follow suit and make sustainability a core principle of their operations. The potential positive impact on the environment, human health, and the economy is immeasurable.In conclusion, Hass Lead Free represents a significant step forward in the global effort to create a sustainable and responsible manufacturing industry. This revolutionary technology, developed by a leading company committed to environmental stewardship, has the potential to reshape the way we produce and consume goods. With greater awareness and adoption of such innovations, we can pave the way for a greener and more prosperous future.

Discover the Latest PCB Solder Manufacturers in China: A Comprehensive Overview

China PCBA Solder Manufacturers Continues to Serve Global Market with High-End Electronics ProductsChina has been dominating the electronics market in recent years, and with an ever-growing demand for consumer electronics, China PCB Solder Manufacturers continues to provide high-end products to customers all over the world. The company, established in 2004, has been consistently providing high-quality Printed Circuit Board Assembly (PCBA) Solder products while keeping up with the latest advancements in technology.With the ambition to cater to the diverse needs of customers from various industries, China PCB Solder Manufacturers has invested in globally advanced equipment and technology. This has enabled the company to deliver products that meet international standards. As a result, the company has become a leading player in electronic manufacturing services both locally and globally.The company offers a wide range of products, including PCB assembly services, through-hole assembly, surface mount technology, BGA assembly, and reflow soldering solutions. In addition, the company has a self-owned molding department that allows it to provide customized components and solutions as per customer's requirements.China PCB Solder Manufacturers also puts a strong emphasis on quality control. The company has implemented a strict quality control system that ensures all products undergo rigorous testing to meet customer specifications. Furthermore, the company is ISO and RoHS certified, further cementing its reputation as a reliable manufacturer of PCBA Solder products in the global market.One of the factors that have enabled China PCB Solder Manufacturers to continue dominating the electronics market is its ability to innovate new technologies. The company has an R&D department comprising of highly trained personnel that is constantly researching, exploring, and testing new ways of improving its products' efficiency.With over 16 years of experience in the electronic manufacturing industry, China PCB Solder Manufacturers has built a broad customer base in different parts of the world. The company caters to customers from various industries, including telecommunications, medical, automotive, security, industrial control, and consumer electronics, to name a few.It is no surprise that the company has a strong reputation among customers worldwide. China PCB Solder Manufacturers is committed to providing high-quality and reliable PCBA Solder products that meet the ever-growing customer requirements. The company strives to deliver products that are environmentally friendly, cost-effective, and optimized for maximum performance, making it a preferred partner for many customers worldwide.Despite the current global challenges brought about by the COVID-19 pandemic, China PCB Solder Manufacturers is still dedicated to serving its customers. The company has put measures in place to ensure that it continues to provide quality products while maintaining the safety of its employees. As part of efforts to meet clients' demands, the company has also increased its production capacity, allowing it to fulfill customer orders efficiently.In conclusion, China PCB Solder Manufacturers is a leading player in the PCBA Solder products manufacturing industry. The company has continuously invested in technology and equipment, in addition to the implementation of strict quality control measures that ensure customer satisfaction. With an unwavering commitment to innovation and customer satisfaction, the company is expected to continue dominating the electronics market and serve its clients worldwide with high-end electronic products.

Calculate Trace Impedance for High-Speed PCBs with Ease!

[Assistant]Title: Advanced Trace Impedance Calculator Empowers PCB Designers for Enhanced PerformanceSubtitle: Cutting-edge Trace Impedance Calculator Streamlines PCB Development ProcessIn a fast-paced world of electronics, where the demand for highly efficient Printed Circuit Board (PCB) designs is rapidly increasing, engineers and developers are constantly seeking advanced tools and technologies to streamline their design processes. Recognizing this need, a leading company in the field of PCB design solutions has developed an innovative Trace Impedance Calculator, which revolutionizes the way PCB designers approach impedance matching, signal integrity, and PCB layout.Brand Name, a distinguished expert in the field of PCB design, has introduced the "Trace Impedance Calculator," a cutting-edge software tool that empowers PCB designers with accurate, efficient, and user-friendly impedance calculations. By leveraging the latest advancements in technology, this calculator facilitates the optimization of signal integrity, allowing for improved data transmission and reduced interference across PCB layouts.Impedance matching is a critical aspect of PCB design, especially when dealing with high-speed signals. Maintaining the correct trace impedance ensures signal integrity, minimizes reflections, and maximizes power transfer efficiency. Traditionally, designers had to rely on manual calculations, complex formulas, or partial solutions, which often resulted in time-consuming trial and error iterations. However, with the Trace Impedance Calculator from Brand Name, designers can now easily access accurate impedance values, streamline their design process, and achieve superior performance in a fraction of the time.This powerful calculator is specifically engineered to provide comprehensive solutions for both single-ended and differential pair trace impedance calculations. It takes into account various factors, such as trace width, thickness, and dielectric properties, to provide designers with precise impedance values tailored to their specific requirements. PCB designers can effortlessly customize impedance specifications, obtaining optimized results based on the electrical and mechanical characteristics of their design.The user-friendly interface of the Trace Impedance Calculator is designed to enhance productivity and efficiency. With a few clicks, designers can input their specifications, instantly obtain impedance values, and make real-time adjustments to fine-tune their designs. Additionally, the calculator provides graphical representations of impedance over a range of frequencies, enabling designers to visualize how impedance values behave across the spectrum.Furthermore, the calculators' advanced algorithms incorporate the latest industry standards and design guidelines, ensuring compliance with the most stringent PCB requirements. The tool supports a wide range of substrate materials, including FR-4, high-speed laminates, and flexible substrates, enabling designers to work with diverse PCB technologies while maintaining optimum signal integrity.The Trace Impedance Calculator seamlessly integrates into existing PCB design workflows, making it accessible to both novice and experienced designers. It is compatible with leading PCB design software, facilitating hassle-free implementation and reducing the learning curve for new users. Through this integrated approach, designers can eliminate guesswork, minimize design iterations, and accelerate time-to-market for their products."Brand Name's Trace Impedance Calculator simplifies the challenges faced by PCB designers when calculating trace impedance," says John Smith, Director of Engineering at a major electronics manufacturing company. "By providing accurate calculations, easy customization, and a user-friendly interface, this tool empowers us to optimize our designs quickly and effectively."In conclusion, the introduction of the Trace Impedance Calculator by Brand Name represents a significant leap forward for PCB designers. With its accurate and efficient impedance calculations, comprehensive customization options, and seamless integration, this advanced tool allows engineers to achieve superior signal integrity, reduce development time, and ultimately enhance the performance and reliability of their PCB designs. As the demand for higher efficiency and faster data transmission increases, solutions like Brand Name's Trace Impedance Calculator play a key role in satisfying the industry's evolving needs.

Exploring the Efficiency and Quality of Quick Turn PCB Fabrication in China

China, a global manufacturing powerhouse, has been known for its rapid turnaround time and high-quality products. In line with this reputation, the country's quick turn PCB fabrication industry has seen remarkable growth in recent years. One of the leading players in this sector is a prominent company that has made a name for itself in the PCB fabrication market.Established in (Year), (Company Name) has quickly emerged as a frontrunner in quick turn PCB fabrication in China. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, the company has been able to cater to the growing demand for fast and reliable PCB fabrication services.The success of (Company Name) can be attributed to several factors. Firstly, their commitment to quality sets them apart from their competitors. The company adheres to stringent quality control measures at every stage of the manufacturing process to ensure that the PCBs they produce meet the highest industry standards. This dedication to quality has earned them a reputation for delivering flawless PCBs consistently.In addition to their commitment to quality, (Company Name) emphasizes speed and efficiency. The company understands the time-sensitive nature of the PCB fabrication industry and is fully equipped to handle quick turnaround times. Through streamlined processes and cutting-edge technology, they are able to rapidly produce PCBs without compromising on quality.Furthermore, (Company Name) offers a wide range of PCB fabrication services to cater to the diverse needs of their clients. Whether it is single-layer, double-layer, or multi-layer PCBs, the company has the expertise and resources to handle any project. They also have the capability to manufacture PCBs of various sizes and complexities, ensuring that they can meet the unique requirements of their customers.Another strength of (Company Name) lies in their commitment to customer satisfaction. The company values open communication and collaboration with their clients, ensuring that every project is tailored to meet their specific needs. This customer-centric approach has earned them a loyal customer base and numerous positive testimonials.As a leading player in the quick turn PCB fabrication market, (Company Name) also places great importance on innovation. They constantly invest in research and development to stay ahead of industry trends and technologies. By keeping up with the latest advancements in PCB fabrication, they are able to offer their clients cutting-edge solutions that meet their evolving needs.Looking ahead, (Company Name) has ambitious plans for expansion. They aim to further strengthen their position in the quick turn PCB fabrication industry by continuously improving their manufacturing capabilities and exploring new markets. With China's booming manufacturing sector and their competitive advantage, the company is well poised to achieve its growth goals.In conclusion, (Company Name) has established itself as a leader in quick turn PCB fabrication in China by focusing on quality, speed, customer satisfaction, and innovation. With their unwavering commitment to excellence, the company has proven to be a reliable partner for businesses seeking fast and reliable PCB fabrication services. As China's manufacturing industry continues to flourish, (Company Name) is well-positioned to capitalize on the growing demand for quick turn PCBs and further expand its presence in the market.

China's Electronic Manufacturing Plant: Circuit Assembly Factory Production Goes Into Full Swing

article about the assembly factory and its services.China Circuit Assembly Factory: Providing Reliable and High-Quality Assembly ServicesThe advancement of technology has drastically changed the way we live, communicate, and work. One of the most notable innovations that have revolutionized multiple industries is the development of electronics. They have become an essential part of our daily routine. The creation, designing, and manufacturing of electronic products require different types of components and precise assembly procedures. Assembling electronic devices involves assembling individual components in a specifically designed circuit board. Many companies rely on outsourcing their circuit board assembly processes to reliable and experienced circuit assembly factories to ensure product quality. In China, one of the most trusted circuit assembly companies is the China Circuit Assembly Factory.About the CompanyChina Circuit Assembly Factory is a Chinese-based company that specializes in printed circuit board (PCB) assembly services. It is a subsidiary of a well-established electronic manufacturing service provider, with over two decades of experience in the industry. The company comprises a team of experienced professionals who have an excellent understanding of the assembly processes and use the latest technologies to ensure high-quality products. They offer circuit board assembly services for different electronics products, including but not limited to, consumer electronics, telecommunications, automotive, industrial, medical, aerospace, and military.Service OfferingsChina Circuit Assembly Factory offers a wide range of PCB assembly services to their clients. These services include:1. Surface Mount Technology (SMT) AssemblySMT is a widely used technique in building modern circuit boards that use surface-mounted components. It is a process of assembling a circuit board by attaching the components directly to the surface of the board instead of running wires or inserting leads through holes. The process involves using high-precision automated equipment to ensure component accuracy and consistency. China Circuit Assembly Factory uses state-of-the-art equipment and processes to ensure efficient and reliable SMT assembly services.2. Through-Hole AssemblyThrough-hole assembly is a traditional method of assembling a PCB by running leads through holes in the board and soldering the components from the top side. This technique is suitable for applications that require high mechanical strength. China Circuit Assembly Factory has skilled technicians to provide quality through-hole assembly services using the latest techniques and equipment.3. Box Build AssemblyBox build assembly is the process of assembling a finished product by integrating the circuit boards and other components into an enclosure or packaging. This process includes mechanical assembly, wire harnessing, and testing. China Circuit Assembly Factory offers reliable and cost-effective box build assembly services to their clients.4. Prototype AssemblyPrototype assembly is an essential step in the development of any electronic product. It is the process of assembling a few units of the product to test the design, function, and performance. China Circuit Assembly Factory has a team of skilled engineers who can assist their clients in the prototype development phase by providing high-quality assembly services.Quality AssuranceChina Circuit Assembly Factory understands that quality is essential in the electronics industry. They have implemented a strict quality control system for all their services to ensure that their clients get only the best products. The quality control process includes the use of high-quality raw materials, robust assembly processes, and rigorous testing procedures. They also have a team of dedicated quality inspectors who oversee the manufacturing process to ensure compliance with the quality standards.ConclusionThe China Circuit Assembly Factory is a reliable and trustworthy assembly company that offers high-quality and cost-effective circuit board assembly services. Their commitment to providing only the best services has earned them a reputation among their clients as the go-to assembly factory in China. With their state-of-the-art equipment, skilled technicians, and strict quality control, they can meet the demands of different industries and provide reliable and consistent services. If you are looking for a reliable circuit assembly factory, China Circuit Assembly Factory is the perfect choice.

Revolutionary Prototype Board Unveiled, Disrupts the Tech Industry's Norms

Title:Embarking on Innovation: Prototype Board Revolutionizes the Technology IndustryIntroduction:In a rapidly evolving technological landscape, companies are constantly searching for innovative solutions that push the boundaries of what is possible. One such game-changing device that has recently captured the attention of the tech world is a cutting-edge prototype board, designed to bring unprecedented levels of flexibility and creativity to engineers, hobbyists, and innovators worldwide. Developed by an industry-leading company passionate about empowering individuals to shape a better future, this revolutionary product promises to revolutionize the world of technology. In this article, we will delve into the features, benefits, and potential impact of this prototype board, exploring the wide range of possibilities it offers for innovation and creation.Unleashing Creativity and Flexibility:With its versatile design and advanced functionalities, the prototype board has become the go-to platform for engineers, developers, and tech enthusiasts. By providing an open-source hardware environment, it allows users to experiment and create complex circuits without the constraints imposed by traditional development boards. This freedom allows for endless possibilities, whether it's designing IoT devices, experimenting with robotics, or inventing new applications for emerging technologies. By unlocking such creative potential, the prototype board is empowering individuals to push the boundaries of innovation like never before.Powerful Features:At the core of this ground-breaking device lies a microcontroller, equipped with impressive processing capabilities. This enables users to execute complex algorithms and handle data-intensive processes efficiently. Coupled with a robust power management system, the prototype board ensures efficient energy utilization, optimizing performance and extending battery life for portable applications. Furthermore, its extensive peripheral options, including various communication interfaces and sensors, enable seamless integration with other devices and systems. This enhanced connectivity fosters collaboration, expands functionality, and opens up new avenues for technological breakthroughs.Accelerated Development and Rapid Prototyping:By significantly reducing development time and effort, the prototype board streamlines the product creation process. Its intuitive graphical user interface simplifies code writing and debugging, allowing for productive development cycles. Additionally, the open-source nature of the platform encourages collaboration, enabling users to take advantage of a vast, ever-growing library of code examples and project documentation. This rich ecosystem fosters knowledge sharing and accelerates the development of innovative solutions in sectors such as healthcare, transportation, and automation. With rapid prototyping capabilities, designers and entrepreneurs can efficiently bring their ideas to life, significantly reducing time-to-market and maximizing their potential for success.Enhancing Education and Empowering Future Innovators:Beyond its profound impact on professional environments, the prototype board plays a pivotal role in education, nurturing young minds and fostering a passion for technology. Its user-friendly interface and extensive educational resources make it an ideal tool for introducing students to the world of electronics and programming. Educational institutions worldwide are embracing this technology, incorporating it into their curricula to inspire the next generation of innovators and prepare them for the challenges of the digital age. By equipping students with the skills necessary to leverage this advanced technology, the prototype board is laying the foundation for a future driven by creativity, curiosity, and invention.An Industry-Leading Company:The team behind this groundbreaking prototype board is a renowned company committed to driving innovation and empowering individuals to shape the future of technology. With a strong focus on research and development, they continuously refine their products to reflect the latest technological advancements and market demands. Their dedication to customer satisfaction is evident in their reliable technical support and extensive online community, fostering an ecosystem where users can share knowledge, exchange ideas, and collaborate on groundbreaking projects.Conclusion:As technology continues to evolve at an unprecedented pace, finding tools that empower individuals and foster creativity becomes increasingly essential. With its flexible design, powerful features, and emphasis on collaboration and innovation, the prototype board represents a major step forward in shaping the technology industry. By providing a platform that accelerates development, unlocks creative potential, and enhances education, this innovative device is revolutionizing the way individuals and businesses approach the design and creation of cutting-edge technologies. With the prototype board, a world of endless possibilities awaits.