The Latest Innovations in PCB for LED Lighting: A Complete Guide

By:Admin

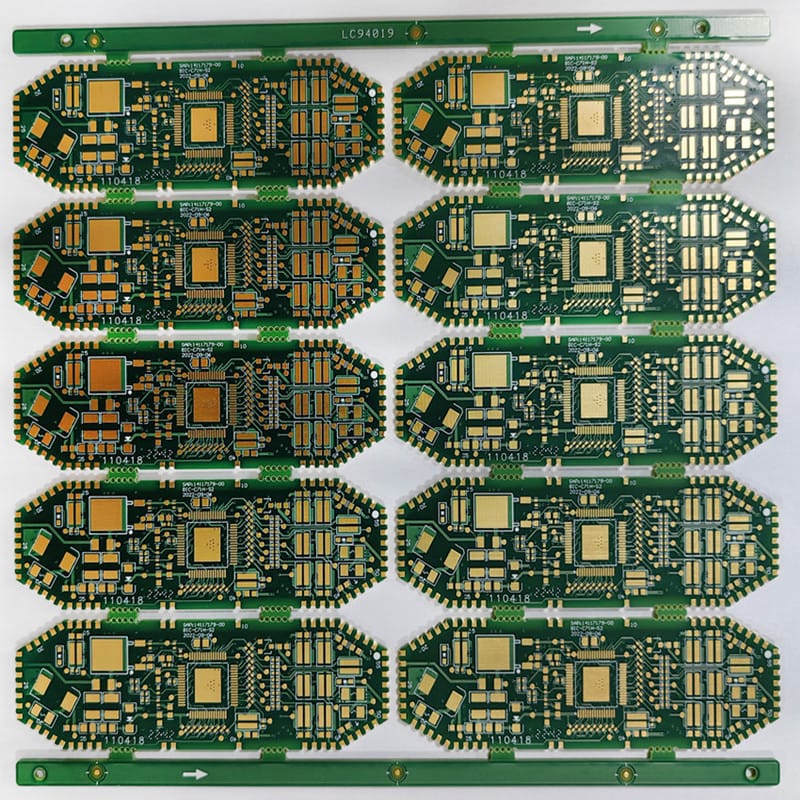

[Company Name] has been at the forefront of providing quality PCB solutions for LED lighting applications for several years. With a strong focus on innovation and technological advancement, the company has established itself as a leading provider of PCBs for the growing LED lighting industry.

LED lighting has become increasingly popular due to its energy efficiency and environmental friendliness. As the demand for LED lighting continues to grow, the need for high-quality PCBs to power these lighting solutions has also increased. [Company Name] recognized this demand early on and has invested heavily in research and development to create cutting-edge PCB solutions specifically tailored for LED lighting applications.

One of the key strengths of [Company Name] lies in its ability to customize PCBs to meet the unique requirements of different LED lighting products. The company’s team of highly skilled engineers and technicians work closely with clients to understand their specific needs and develop customized PCBs that are optimized for performance, durability, and cost-efficiency.

In addition to customization, [Company Name] also places a strong emphasis on quality control and testing. All PCBs undergo rigorous quality assurance processes to ensure that they meet the highest standards of performance and reliability. This commitment to quality has earned [Company Name] a reputation for delivering PCBs that consistently outperform industry benchmarks and exceed customer expectations.

Furthermore, [Company Name] is dedicated to staying ahead of the curve when it comes to technological innovation. The company continuously invests in the latest manufacturing equipment and cutting-edge technologies to ensure that its PCBs are on the leading edge of industry advancements. This commitment to innovation has allowed [Company Name] to develop PCBs with advanced features such as thermal management, high-density interconnects, and enhanced power distribution, all of which are critical for the efficient operation of LED lighting systems.

Beyond its technical expertise, [Company Name] is also known for its exceptional customer service. The company values its relationships with clients and is committed to providing them with the highest level of support throughout the entire PCB development and manufacturing process. This includes collaborative design discussions, rapid prototyping, and efficient production turnaround times, all of which contribute to a seamless and positive experience for [Company Name]’s clients.

As the LED lighting market continues to grow and evolve, [Company Name] remains dedicated to meeting the changing needs of the industry. The company is actively engaged in ongoing research and development to develop even more advanced PCB solutions for next-generation LED lighting products. With a focus on sustainability and energy efficiency, [Company Name] is committed to playing a key role in the continued success of the LED lighting industry.

In conclusion, [Company Name] is a leading provider of high-quality, innovative PCB solutions for LED lighting applications. With a strong focus on customization, quality, innovation, and customer service, the company is well-positioned to meet the evolving needs of the LED lighting industry. As the demand for LED lighting continues to rise, [Company Name] is poised to remain at the forefront of delivering cutting-edge PCB solutions that power the next generation of LED lighting products.

Company News & Blog

High-Quality Pcb Prototype Board Suppliers in China

In today's fast-paced and innovative world, the demand for electronic products is constantly growing. From smartphones to smart home appliances, electronic devices have become an integral part of our daily lives. As a result, the need for high-quality printed circuit board (PCB) prototype boards has also significantly increased. With China emerging as a global leader in electronics manufacturing, the country's PCB prototype board suppliers have become crucial partners for companies looking to develop cutting-edge electronic products.One such leading PCB prototype board supplier in China is {Company}. With years of experience and expertise in the industry, {Company} has established itself as a reliable and trusted partner for businesses seeking top-notch PCB prototype boards. Their commitment to quality, precision, and customer satisfaction has made them a preferred choice for companies around the world.{Company} specializes in providing a wide range of PCB prototype boards, including single-sided, double-sided, and multi-layer boards. They utilize advanced manufacturing techniques and state-of-the-art equipment to ensure that their PCBs meet the highest quality standards. Additionally, {Company} offers custom PCB solutions, allowing their clients to tailor their prototype boards to specific design requirements and specifications.One of the key advantages of partnering with {Company} is their quick turnaround time. In today's competitive market, speed is essential, and {Company} understands the urgency of bringing new products to market. Their efficient production processes and agile manufacturing capabilities enable them to deliver high-quality PCB prototype boards within tight deadlines, helping their clients stay ahead of the curve.Furthermore, {Company} is dedicated to providing cost-effective solutions without compromising on quality. They leverage their strong relationships with suppliers and their expertise in manufacturing to offer competitive pricing for their PCB prototype boards. This makes them an ideal partner for startups, SMEs, and large corporations alike, who are looking to minimize costs without sacrificing the quality and reliability of their electronic products.In addition to their exceptional products and services, {Company} prides itself on its commitment to customer satisfaction. Their team of experienced professionals works closely with clients throughout the entire process, from initial design and prototyping to final production. This collaborative approach ensures that the PCB prototype boards meet the exact requirements and expectations of their clients, ultimately leading to successful and seamless integration into their electronic products.As China's electronics industry continues to thrive, {Company} is well-positioned to meet the increasing demand for PCB prototype boards. They are constantly investing in research and development to stay at the forefront of technological advancements, enabling them to offer cutting-edge solutions that cater to the evolving needs of the market. Additionally, {Company} is dedicated to upholding the highest standards of environmental responsibility and sustainability in their manufacturing processes, ensuring that their operations have minimal impact on the planet.In conclusion, as the demand for electronic products continues to grow, the role of PCB prototype board suppliers like {Company} becomes increasingly essential. With their unwavering commitment to quality, innovation, and customer satisfaction, {Company} has established itself as a leading player in the industry. Their ability to deliver high-quality, cost-effective, and customizable PCB prototype boards sets them apart as a valuable partner for companies looking to bring their electronic products to market. As China's electronics industry continues to expand, {Company} is poised to play a pivotal role in driving the innovation and advancement of electronic products worldwide.

Emerging technologies drive demand for advanced Printed Wiring Boards

Printed Wiring Boards (PWBs) are a crucial component in modern electronic devices, serving as the backbone for circuitry. They are essential for the functioning of various industries, including consumer electronics, telecommunications, automotive, and aerospace. One company that stands out in the PWB manufacturing industry is {}.With a rich history that spans several decades, {} has emerged as a leading provider of high-quality PWBs. The company has earned a stellar reputation for its dedication to innovation, reliability, and customer satisfaction. Their commitment to excellence has made them a trusted partner for numerous global corporations.One of the key strengths of {} lies in its state-of-the-art manufacturing facilities. Equipped with cutting-edge technology, these facilities enable the company to produce PCBs that meet the highest industry standards. The advanced machinery, combined with a team of skilled engineers and technicians, ensures the production of PWBs that are not only reliable but also comply with stringent quality control measures.{} offers a wide range of PWB solutions to cater to diverse customer needs. Whether it is single-layer boards for basic applications or multi-layer boards with complex circuitry for advanced electronics, {} can fulfill any requirement. The company also specializes in manufacturing flexible and rigid-flex boards, which are increasingly in demand in industries where space optimization and durability are critical.One of the hallmarks of {} is its strong emphasis on research and development. The company continuously invests in exploring new materials, technologies, and manufacturing processes to stay at the forefront of the PWB industry. This commitment to innovation allows {} to offer its customers cutting-edge solutions that meet evolving market trends and requirements.Another distinguishing feature of {} is its unwavering commitment to sustainable practices. The company recognizes the importance of environmental responsibility and actively seeks ways to minimize the ecological footprint of its operations. Through the use of eco-friendly materials, energy-efficient processes, and waste reduction initiatives, {} ensures that its manufacturing processes are as environmentally friendly as possible.In addition to its focus on manufacturing excellence, {} also places great importance on customer satisfaction. The company believes in forging long-term partnerships with its clients and strives to provide exceptional service and support. {} understands that each customer has unique requirements, and therefore, offers tailored solutions, competitive pricing, and on-time delivery to ensure maximum customer satisfaction.As a testament to its exemplary performance, {} has received numerous industry accolades and certifications. These include ISO 9001, ISO 14001, and UL certifications, further affirming the company's commitment to quality, environmental management, and safety standards.Looking ahead, {} is poised to witness continued growth and success in the highly competitive PWB market. The company's dedication to innovation, manufacturing excellence, and customer satisfaction positions it as a preferred choice for businesses seeking reliable PWB solutions.In conclusion, {} is a leading manufacturer of Printed Wiring Boards, offering a range of high-quality solutions to meet diverse customer needs. With its state-of-the-art facilities, commitment to innovation, and focus on sustainability, the company continues to set the benchmark in the PWB industry. As businesses increasingly rely on electronic devices, {} remains at the forefront of providing the backbone for their success.

Exploring the Efficiency and Quality of Quick Turn PCB Fabrication in China

China, a global manufacturing powerhouse, has been known for its rapid turnaround time and high-quality products. In line with this reputation, the country's quick turn PCB fabrication industry has seen remarkable growth in recent years. One of the leading players in this sector is a prominent company that has made a name for itself in the PCB fabrication market.Established in (Year), (Company Name) has quickly emerged as a frontrunner in quick turn PCB fabrication in China. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, the company has been able to cater to the growing demand for fast and reliable PCB fabrication services.The success of (Company Name) can be attributed to several factors. Firstly, their commitment to quality sets them apart from their competitors. The company adheres to stringent quality control measures at every stage of the manufacturing process to ensure that the PCBs they produce meet the highest industry standards. This dedication to quality has earned them a reputation for delivering flawless PCBs consistently.In addition to their commitment to quality, (Company Name) emphasizes speed and efficiency. The company understands the time-sensitive nature of the PCB fabrication industry and is fully equipped to handle quick turnaround times. Through streamlined processes and cutting-edge technology, they are able to rapidly produce PCBs without compromising on quality.Furthermore, (Company Name) offers a wide range of PCB fabrication services to cater to the diverse needs of their clients. Whether it is single-layer, double-layer, or multi-layer PCBs, the company has the expertise and resources to handle any project. They also have the capability to manufacture PCBs of various sizes and complexities, ensuring that they can meet the unique requirements of their customers.Another strength of (Company Name) lies in their commitment to customer satisfaction. The company values open communication and collaboration with their clients, ensuring that every project is tailored to meet their specific needs. This customer-centric approach has earned them a loyal customer base and numerous positive testimonials.As a leading player in the quick turn PCB fabrication market, (Company Name) also places great importance on innovation. They constantly invest in research and development to stay ahead of industry trends and technologies. By keeping up with the latest advancements in PCB fabrication, they are able to offer their clients cutting-edge solutions that meet their evolving needs.Looking ahead, (Company Name) has ambitious plans for expansion. They aim to further strengthen their position in the quick turn PCB fabrication industry by continuously improving their manufacturing capabilities and exploring new markets. With China's booming manufacturing sector and their competitive advantage, the company is well poised to achieve its growth goals.In conclusion, (Company Name) has established itself as a leader in quick turn PCB fabrication in China by focusing on quality, speed, customer satisfaction, and innovation. With their unwavering commitment to excellence, the company has proven to be a reliable partner for businesses seeking fast and reliable PCB fabrication services. As China's manufacturing industry continues to flourish, (Company Name) is well-positioned to capitalize on the growing demand for quick turn PCBs and further expand its presence in the market.

Discover the Benefits of Quick Turnaround PCB Services for Efficient Electronics Production

Quick Turnaround PCB Company Delivers World-Class Circuit BoardsQuick Turnaround PCB, a leading printed circuit board manufacturer, continues to deliver world-class PCB solutions to meet the growing needs of the electronics industry. With its commitment to excellence and customer satisfaction, the company provides top-quality products that are durable, reliable, and cost-effective.Quick Turnaround PCB has gained a strong reputation for its exceptional services and production capabilities. It offers a vast range of PCB solutions including rigid, flex, and rigid-flex boards, along with PCB assembly services. The company also specializes in quick turnaround services, with the ability to produce PCB prototypes within just a few days.The company has established itself as an industry leader in PCB manufacturing due to its advanced manufacturing technologies, efficient process optimization, and rigorous quality control procedures. Its manufacturing facility boasts state-of-the-art machinery, including automated optical inspection systems, surface mount technology, and X-ray inspection, to ensure that its products meet the highest quality standards.To cater to the diverse needs of its clients, Quick Turnaround PCB provides custom PCB solutions tailored to specific requirements. Its team of professional engineers works closely with customers to identify their needs and develop effective solutions that can meet their needs.Moreover, the company is dedicated to providing customers with exceptional support services to ensure their satisfaction. Customers can reach out to dedicated technicians and engineers at any time to get advice or assistance on any PCB-related issues.Over the years, Quick Turnaround PCB has developed a loyal customer base due to its relentless pursuit of excellence in PCB manufacturing. The company's clients come from various sectors, including automotive, aerospace, medical, and telecommunications. Its products have been used in various applications, ranging from industrial machinery to consumer electronics. Quick turnaround PCB has made a significant investment in research and development activities, with the aim of staying ahead of its competitors and providing cutting-edge solutions to customers. Its engineers are continually exploring new technologies and innovations in PCB manufacturing, such as flexible substrates and additive manufacturing.With its commitment to quality, innovation, and customer satisfaction, Quick Turnaround PCB stands poised to become a leading player in the global PCB industry. As it continues to expand its manufacturing capabilities and broaden its product portfolio, the company is confident in its ability to meet the diverse needs of customers worldwide.In conclusion, Quick Turnaround PCB is a world-class manufacturer of printed circuit boards, known for its commitment to delivering high-quality products and customer satisfaction. Its advanced manufacturing technologies, efficient process optimization, and rigorous quality control procedures set it apart from its competitors. As the company continues to grow and innovate, it is poised to become a leading player in the global PCB industry.

Revolutionize your Finishing Game with the Latest Surface Technology

Introducing Osp Surface Finish: Pioneering Innovation in Surface Coating TechnologyIn today's ever-evolving industrial landscape, where innovation and efficiency reign supreme, companies are constantly seeking cutting-edge solutions to enhance their products and manufacturing processes. One such innovation comes in the form of Osp Surface Finish - a revolutionary advancement in surface coating technology that is set to redefine industry standards.Osp Surface Finish, developed by a leading research and development team, offers a wide range of benefits that promise to transform various sectors, including automotive, electronics, aerospace, and many more. By combining state-of-the-art materials with a unique application process, this groundbreaking surface coating delivers exceptional performance, durability, and aesthetics, making it a game-changer for manufacturers and end-users alike.The success of Osp Surface Finish can be attributed to its unique formulation, which incorporates advanced nanotechnology. By harnessing the power of nano-sized particles, this coating achieves superior coverage, creating a highly uniform layer on the surface. This not only enhances the visual appeal of the product but also provides exceptional protection against wear and tear, corrosion, and environmental factors.One of the key advantages of Osp Surface Finish is its versatility. It can be applied to a wide variety of materials, including metals, plastics, ceramics, and composites, making it a viable option for almost any industry. Additionally, this remarkable coating solution is available in multiple colors, allowing manufacturers to customize their products according to their desired aesthetics and branding requirements.With its exceptional hardness and scratch resistance, Osp Surface Finish ensures that products will maintain their pristine appearance even after prolonged use. This is particularly important for industries such as automotive, where exterior components are exposed to the harsh elements daily.Moreover, the inherent low friction coefficient of the Osp Surface Finish significantly reduces friction between moving parts, enhancing the overall performance and longevity of mechanical systems. This makes it an ideal choice for applications in the automotive, industrial machinery, and precision engineering sectors. Furthermore, the coating's insulation properties make it an excellent choice for applications where electrical conductivity needs to be controlled.In terms of the application process, Osp Surface Finish stands out due to its ease and cost-effectiveness. Its unique formulation allows for uniform application, minimizing waste and reducing production time. Furthermore, this surface coating can be applied through various methods such as spray coating, dip coating, or electrostatic deposition, ensuring compatibility with existing manufacturing processes.Another noteworthy advantage of Osp Surface Finish is its eco-friendly nature. The formulation is free from volatile organic compounds (VOC), making it a sustainable solution that meets the increasing demand for environmentally-conscious products. This aspect is particularly crucial for manufacturers seeking to align their operations with sustainable practices and reduce their carbon footprint.Furthermore, the company behind the Osp Surface Finish is committed to providing exceptional customer support and technical expertise. With a team of highly skilled engineers and professionals dedicated to delivering outstanding service, they ensure that clients receive tailored solutions and prompt assistance throughout the production process.In conclusion, Osp Surface Finish represents a significant breakthrough in surface coating technology. Its ability to enhance the performance, durability, aesthetics, and sustainability of products makes it an invaluable asset across various industries. As manufacturers seek innovative solutions to gain a competitive advantage, Osp Surface Finish offers the perfect solution to meet and exceed their expectations, heralding a new era of surface coating excellence.

Custom Printed Circuit Board Manufacturing for LED Applications

The demand for more efficient and sustainable lighting solutions has been steadily increasing in recent years. In response to this growing need, {company name} has announced the development of a cutting-edge innovation in the realm of LED printed circuit boards (PCBs). This breakthrough technology promises to revolutionize the way in which LED lighting systems are designed and produced, offering a range of benefits that are set to have a significant impact on the industry as a whole.The new LED PCBs developed by {company name} have been specifically engineered to deliver enhanced performance and reliability in LED lighting applications. By leveraging state-of-the-art manufacturing processes and materials, the company has succeeded in creating a superior product that stands out in terms of energy efficiency, longevity, and overall quality. This development represents a major leap forward in the evolution of LED lighting, and is poised to set a new standard for the industry.One of the key features of {company name}'s LED PCBs is their exceptional thermal management capabilities. By utilizing advanced thermal materials and designs, the PCBs are able to effectively dissipate heat generated by the LEDs, resulting in improved performance and longevity. This aspect is particularly crucial in applications where LED lighting systems are required to operate continuously for extended periods of time, such as in commercial and industrial settings.Furthermore, the {company name} LED PCBs have been engineered to maximize energy efficiency, thereby reducing operational costs and environmental impact. The PCBs are designed to minimize power consumption while maintaining optimal performance, making them an ideal choice for those seeking to implement sustainable lighting solutions. As the global trend towards energy conservation and sustainability continues to gain momentum, the demand for such innovative and eco-friendly technologies is only expected to increase.In addition to their technical prowess, {company name}'s LED PCBs also offer a high degree of flexibility and customization. This allows for greater design freedom, enabling lighting manufacturers to create products that meet the specific requirements of their applications. Whether it be in the realm of architectural lighting, automotive lighting, or horticultural lighting, the versatility of these PCBs makes them a highly adaptable solution for a wide range of lighting needs.The development of these advanced LED PCBs is a testament to {company name}'s commitment to pushing the boundaries of what is possible in the field of LED lighting. As a leading provider of cutting-edge electronic solutions, the company has a long-standing track record of driving innovation and delivering high-performance products that meet the evolving demands of the market. With the introduction of these new LED PCBs, {company name} is once again demonstrating its ability to anticipate and address the needs of the industry, while also setting new benchmarks for performance and quality.Given the promising potential of this new technology, industry experts are eagerly anticipating the impact that {company name}'s LED PCBs will have on the market. As the demand for energy-efficient and sustainable lighting solutions continues to grow, the arrival of these innovative PCBs is expected to be met with great enthusiasm. With their unrivaled thermal management capabilities, energy efficiency, and flexibility, these LED PCBs are poised to play a pivotal role in shaping the future of LED lighting, and to set a new standard for excellence in the industry.

Optimize your Electronic Circuits with High-Quality Printed Circuit Boards

Title: Pioneering PCB Manufacturer Sets New Standards in Circuit Board ProductionIntroduction:In an ever-evolving technological landscape, Multi Circuit Boards is emerging as a leading player in the printed circuit board (PCB) manufacturing industry. With an extensive portfolio of high-quality circuit boards and a commitment to innovation, the company is revolutionizing the way PCBs are produced and distributed. By leveraging advanced technologies and a customer-centric approach, Multi Circuit Boards is meeting the growing demand for reliable, efficient, and versatile circuit boards across diverse industries.Article:Multi Circuit Boards: A Game-Changer in PCB ManufacturingFounded on the principles of precision and efficiency, Multi Circuit Boards is a trailblazer in the PCB manufacturing industry. With its well-equipped production facilities and a team of seasoned professionals, the company has earned a reputation for its commitment to delivering top-notch PCBs to clients worldwide. Utilizing an array of advanced technologies, including state-of-the-art automated equipment, Multi Circuit Boards ensures that every circuit board produced adheres to the highest quality standards.The company's manufacturing process combines traditional craftsmanship with cutting-edge techniques, resulting in PCBs that offer superior performance and reliability. In addition to standard rigid PCBs, Multi Circuit Boards specializes in flexible PCBs, rigid-flex PCBs, and metal core PCBs, catering to the diverse needs of its clientele. This versatility allows for broader application possibilities, enabling customers to leverage the latest advancements in their respective fields.Embracing Technology for Unparalleled PrecisionMulti Circuit Boards places great emphasis on technological advancements to enhance its manufacturing capabilities. By investing in innovative production equipment and software, the company has achieved exceptional precision, efficiency, and scalability. Advanced drilling and routing machines ensure precise hole placements and intricate circuit patterns, while automated optical inspection systems guarantee excellent product quality control.Moreover, Multi Circuit Boards has implemented sophisticated computer-aided design (CAD) and computer-aided manufacturing (CAM) software, empowering its engineers to optimize layout designs, streamline production processes, and minimize production lead times. This integration of technology allows Multi Circuit Boards to stay ahead in an increasingly competitive market, providing its customers with cutting-edge solutions promptly.Comprehensive Customer Support and CollaborationRecognizing that superior products are only half the battle in the PCB manufacturing industry, Multi Circuit Boards places great importance on cultivating strong customer relationships. From initial inquiry to final delivery, the company provides comprehensive support at every stage of the manufacturing process. With a dedicated team of customer service representatives, engineering support professionals, and project managers, clients are assured of prompt assistance and efficient communication.Collaboration is key at Multi Circuit Boards, as the company actively engages with customers to fully understand their specific requirements and provide customized solutions. Leveraging its technical expertise and vast industry experience, Multi Circuit Boards offers valued advice regarding material selection, design optimization, and cost-effectiveness. This collaborative approach ensures that the final manufactured product aligns perfectly with the client's vision and objectives.Commitment to Environmental ResponsibilityMulti Circuit Boards recognizes the importance of minimizing its ecological footprint and is committed to implementing sustainable practices throughout its operations. The company adheres to strict waste management protocols, promoting recycling and reducing material waste. Additionally, Multi Circuit Boards has invested in energy-efficient machinery and processes, contributing to a greener and cleaner environment.ConclusionMulti Circuit Boards has established itself as a leading force in the PCB manufacturing industry, driven by its dedication to innovation, superior quality, and exceptional customer service. Through the seamless integration of advanced technologies, Multi Circuit Boards continues to set new standards in circuit board production, catering to the needs of various industries. With a focus on collaboration and environmental responsibility, the company is well-positioned to shape the future of PCB manufacturing and meet the ever-evolving demands of the global market.

Top PCB Fabricators in the News: Latest Updates and Trends

Pcb Fabricators, a leading manufacturer of printed circuit boards for various industries, continues to uphold its reputation as a trusted provider of high-quality electronic components. With a commitment to innovation and excellence, the company has established itself as a reliable partner for businesses in need of reliable PCB solutions.Since its inception, Pcb Fabricators has been at the forefront of technological advancements in the PCB manufacturing industry. The company's state-of-the-art facilities and cutting-edge equipment enable it to produce a wide range of PCBs that meet the stringent requirements of its clients. Whether it's a single-layer PCB for a simple application or a multi-layered circuit board for a complex electronic device, Pcb Fabricators has the capability to deliver tailor-made solutions that precisely match its clients' specifications.One of the key strengths of Pcb Fabricators is its dedication to quality. The company adheres to rigorous quality control processes at every stage of the production process, ensuring that each PCB that leaves its facility is free from defects and built to last. This unwavering commitment to quality has earned Pcb Fabricators the trust and loyalty of its customers, who rely on the company to provide them with PCBs that consistently meet their performance expectations.Furthermore, Pcb Fabricators is known for its flexibility and responsiveness. The company understands that the needs of its clients may vary, and as such, it offers a wide range of customization options to accommodate specific requirements. From choosing the right materials and finishes to providing design assistance and engineering support, Pcb Fabricators works closely with its clients to ensure that their unique needs are met.In addition to its manufacturing capabilities, Pcb Fabricators is also committed to sustainability and environmental responsibility. The company takes proactive measures to minimize its impact on the environment, including the responsible use of resources and the implementation of environmentally-friendly practices in its operations. By prioritizing sustainability, Pcb Fabricators is not only contributing to a greener future but also setting an example for the industry as a whole.Looking ahead, Pcb Fabricators is poised for continued growth and success. The company remains dedicated to investing in research and development to stay ahead of the curve and anticipate the evolving needs of its clients. By staying abreast of the latest technological advancements and industry trends, Pcb Fabricators is well-positioned to remain a leader in the PCB manufacturing industry for years to come.As a testament to its commitment to excellence, Pcb Fabricators has received accolades and recognition from industry experts and regulatory bodies. The company's adherence to strict quality standards and its track record of delivering exceptional PCB solutions have earned it the respect and admiration of its peers.In conclusion, Pcb Fabricators stands as a shining example of a company that consistently delivers superior products and services to its clients. With its unwavering commitment to quality, its focus on customization, and its dedication to sustainability, Pcb Fabricators has established itself as a reliable partner for businesses seeking top-notch PCB solutions. As the company looks to the future, it is well-positioned to build on its success and continue serving the needs of its clients with excellence and innovation.

Revolutionizing Electronic Assembly: The Advantages of Surface Mount Technology

[Company Name Removed] Sets New Standards with Advanced Surface Mounting Technology[City, Date] - [Company Name Removed], a leading player in the technology industry, is revolutionizing the market with cutting-edge Surface Mounting Technology (SMT). As a result of extensive research and development efforts, the company has introduced a game-changing innovation that is set to redefine the way electronic components are manufactured.SMT is a crucial process in electronic manufacturing, where components are mounted directly onto the surface of printed circuit boards (PCBs). With the demand for smaller, lighter, and more powerful electronic devices on the rise, the need for advanced SMT technology has become imminent. [Company Name Removed] recognized this demand and has risen to the challenge by developing an unparalleled solution.The new SMT technology developed by [Company Name Removed] offers several distinct advantages over conventional methods. By utilizing state-of-the-art robotic assembly systems and advanced automation techniques, the company has created a highly efficient manufacturing process. This enables faster production cycles, reducing time-to-market for electronic devices. Additionally, the precise placement of components ensures higher levels of accuracy, improving overall product reliability.One of the key highlights of [Company Name Removed]'s SMT technology is its ability to support miniaturized components. As electronic devices continue to shrink in size, it is critical for manufacturers to utilize smaller and more compact components. The advanced machinery and techniques employed by [Company Name Removed] enable the assembly of components as small as one square millimeter, setting a new benchmark in the industry.Another distinguishing feature of [Company Name Removed]'s SMT technology is its versatility. The company's advanced assembly systems can handle a wide range of electronic components, including passive components (resistors, capacitors), active components (transistors, diodes), integrated circuits, and more. This flexibility ensures that [Company Name Removed] can cater to various industries, from consumer electronics to automotive and aerospace.[Company Name Removed]'s commitment to sustainability is evident in its SMT technology innovation as well. The company recognizes the growing concerns of waste generation in electronic manufacturing and has taken steps to address this issue. By optimizing material usage and minimizing scrap, [Company Name Removed] ensures a more eco-friendly manufacturing process.The introduction of [Company Name Removed]'s advanced SMT technology has garnered significant attention in the industry. Market analysts predict that this innovation will not only revolutionize electronic device manufacturing but also have a ripple effect across multiple sectors. With faster production cycles, higher accuracy, and increased reliability, electronic manufacturers can expect to deliver superior products to meet consumers' evolving needs.In conclusion, [Company Name Removed]'s Surface Mounting Technology is poised to reshape the electronic manufacturing landscape. By leveraging advanced machinery, automation, and precision placement, the company has established a new standard in the industry. With the ability to support miniaturized components and accommodate various electronic devices, [Company Name Removed] is well-positioned to meet the demands of a rapidly evolving market. Furthermore, their commitment to sustainability sets them apart from their competitors, making them a frontrunner in the industry. As [Company Name Removed] paves a new path for electronic manufacturing, the future of the industry looks brighter than ever before.

Discover the Benefits of Halogen Free PCB Material for Your Projects

[Company Name] Introduces Halogen-Free PCB Material for Environmentally-Friendly Electronics[City, State] - As the world continues to prioritize environmentally-friendly practices, [Company Name] is at the forefront of innovation with the introduction of a new halogen-free PCB material. This breakthrough in technology is set to revolutionize the electronics industry by offering a more sustainable and eco-friendly alternative to traditional PCB materials.The new halogen-free PCB material is designed to meet the increasing demand for electronics that are free from hazardous substances, such as bromine and chlorine, which are commonly found in traditional PCB materials. This material not only ensures compliance with environmental regulations but also provides a safer and more sustainable option for electronic products.[Company Name], a leading provider of innovative electronic solutions, has been at the forefront of developing cutting-edge materials and technologies since its inception. With a strong commitment to sustainability and environmental stewardship, the company has invested heavily in research and development to create the new halogen-free PCB material.According to [Spokesperson Name], [Title] at [Company Name], "We are proud to introduce this new halogen-free PCB material, which reflects our commitment to environmental responsibility and innovation. This breakthrough technology will enable us to offer our customers a more sustainable and eco-friendly option for their electronic products, without compromising on performance or reliability."The new halogen-free PCB material offers several key benefits, including improved fire retardant properties, enhanced thermal performance, and increased durability. These features make it an ideal choice for a wide range of electronic applications, including consumer electronics, automotive systems, industrial equipment, and more.In addition to its environmental benefits, the new material also meets the high-performance standards required for modern electronic devices. Its superior electrical properties and reliability make it a versatile and dependable choice for manufacturers looking to create high-quality, environmentally-friendly products.Furthermore, [Company Name] is dedicated to ensuring that the new halogen-free PCB material is readily available to its customers. The company has integrated the new material into its existing product lineup, making it easily accessible for manufacturers seeking to adopt more sustainable practices in their production processes.It is clear that the introduction of the halogen-free PCB material by [Company Name] represents a significant milestone in the electronics industry. By offering a more sustainable and environmentally-friendly alternative to traditional PCB materials, [Company Name] is demonstrating its commitment to driving positive change and leading the way towards a greener future for electronics manufacturing.In conclusion, [Company Name] has once again reaffirmed its position as an industry leader in innovation and sustainability with the introduction of the new halogen-free PCB material. With its superior performance, environmental benefits, and widespread availability, this new material is set to play a pivotal role in shaping the future of electronics manufacturing. As the world continues to prioritize environmental responsibility, [Company Name] is proud to be at the forefront of this movement, offering innovative solutions that support a more sustainable and eco-friendly approach to electronic production.