Top 5 Multi Circuit Board Suppliers in 2021: A Comprehensive Comparison

By:Admin

Founded in [year], Multi Circuit Board Manufacturers has built a strong reputation for delivering top-notch PCB products to its customers worldwide. With a focus on quality, innovation, and customer satisfaction, the company has become a trusted partner for businesses in the automotive, aerospace, medical, telecommunications, and consumer electronics sectors.

The recent expansion of Multi Circuit Board Manufacturers' facilities allows the company to increase its production capacity and offer a wider range of PCB technologies. This includes the ability to manufacture high-density interconnect (HDI) boards, flexible and rigid-flex PCBs, and metal core PCBs, among others. These enhanced capabilities enable the company to meet the growing demands for more complex and advanced PCB designs in today's fast-paced technological landscape.

In addition to its expanded capabilities, Multi Circuit Board Manufacturers has also invested in cutting-edge equipment and technologies to ensure the highest level of quality and precision in its manufacturing processes. The company's state-of-the-art facilities are equipped with automated production lines, advanced inspection and testing tools, and environmentally friendly processes to minimize its impact on the environment.

"We are excited to announce our expanded capabilities and enhanced facilities," said [spokesperson], [title] at Multi Circuit Board Manufacturers. "This strategic investment underscores our commitment to providing our customers with the most advanced PCB solutions, while maintaining the highest standards of quality and reliability. We are confident that our enhanced capabilities will enable us to better serve the evolving needs of our customers and strengthen our position as a leader in the PCB industry."

As part of its commitment to continuous improvement, Multi Circuit Board Manufacturers has also made significant advancements in its research and development efforts. The company's team of engineers and technical experts are continuously exploring new materials, processes, and technologies to push the boundaries of PCB innovation. This dedication to R&D allows the company to stay ahead of industry trends and deliver cutting-edge solutions that meet the evolving needs of its customers.

In addition to its technical capabilities, Multi Circuit Board Manufacturers is also known for its exceptional customer service and support. The company works closely with its customers to understand their specific requirements and provide personalized guidance throughout the production process. From design and prototyping to full-scale production, Multi Circuit Board Manufacturers is dedicated to ensuring that its customers receive the right PCB solutions that meet their unique specifications and performance requirements.

With its expanded capabilities, advanced technologies, and unwavering commitment to customer satisfaction, Multi Circuit Board Manufacturers is poised to continue its growth and success in the PCB industry. The company's ability to provide high-quality, advanced PCB solutions for a wide range of applications sets it apart as a leading provider in the market.

For more information about Multi Circuit Board Manufacturers and its expanded capabilities, please visit [website] or contact [contact information].

Overall, Multi Circuit Board Manufacturers continues to demonstrate its commitment to innovation, quality, and customer satisfaction, making it a trusted partner for businesses seeking advanced PCB solutions. With its expanded capabilities and enhanced facilities, the company is well-positioned to meet the evolving needs of its customers and maintain its leadership in the PCB industry.

Company News & Blog

Understanding the Layers of Printed Circuit Boards: An In-Depth Look

Printed Circuit Board Layers: Enhancing Connectivity and Efficiency in Electronic DevicesIn today's fast-paced world, electronic devices have become an integral part of our lives. From smartphones and tablets to smart appliances and wearable technology, these devices have transformed the way we communicate, work, and relax. At the core of these electronic marvels lies a crucial component known as the Printed Circuit Board, or PCB. Printed Circuit Board Layers play a pivotal role in enhancing connectivity and efficiency in electronic devices.A PCB is a flat board made of non-conductive material, such as fiberglass, with electronic components mounted on it. Layers of conductive material, such as copper, are etched onto the board to create pathways for electric currents to flow, enabling the transfer of information and power between the various components. These layers are implemented through a highly precise and intricate process, ensuring optimal functionality and reliability.One of the key aspects of a PCB is its layer structure. The number of layers in a PCB is determined by the complexity of the device it is being designed for. A simple electronic device may require only a single-layer PCB, while more complex devices, such as advanced medical equipment or high-performance computing systems, may require multiple layers to accommodate numerous components and circuits.The PCB layer formation process involves laminating multiple layers of etched copper sheets with insulating material in between. The number, arrangement, and interconnections of these layers are determined by the specific requirements of the device. These layers are meticulously designed to minimize noise, maximize signal integrity, and ensure efficient functioning of the device.As the demand for smaller, faster, and more powerful electronic devices continues to rise, the importance of PCB layer technology becomes increasingly evident. Multilayer PCBs offer several advantages over their single-layer counterparts. Firstly, the compact design of multilayer PCBs allows for increased component density. This leads to more functionality in a smaller form factor, making devices slimmer and more lightweight. Secondly, multilayer PCBs enable the implementation of complex interconnections between components, resulting in improved signal integrity and reduced interference. This translates to faster data transfer rates and enhanced overall performance. Additionally, the use of multilayer PCBs allows for better heat dissipation, ensuring that electronic devices operate within their optimal temperature range, thereby increasing their lifespan.Furthermore, advancements in PCB layer technology have brought about the development of High-Density Interconnect (HDI) PCBs. HDI PCBs provide even greater design flexibility and reliability. They boast smaller vias and microvias, allowing for higher component density, improved signal integrity, and reduced power consumption. HDI PCBs are particularly beneficial in applications where space is limited, such as in mobile phones, smartwatches, and automotive electronics.The market for Printed Circuit Board Layers is witnessing significant growth due to the escalating demand for advanced electronic devices and the ongoing technological advancements in the industry. Several companies have emerged as pioneers in the field, employing cutting-edge manufacturing processes and innovative designs to meet the evolving needs of the market.One such company, {}, is at the forefront of PCB layer technology. With years of experience and a commitment to excellence, they offer a wide range of PCB layer solutions tailored to different industries and applications. Their expertise lies in the development of multilayer and HDI PCBs that deliver exceptional performance, reliability, and quality. By leveraging their in-house engineering expertise and state-of-the-art facilities, they ensure that their PCB layers meet the stringent standards of today's electronic devices.In conclusion, Printed Circuit Board Layers are vital components that enable the seamless functioning of electronic devices. Whether it's improving connectivity, enhancing performance, or reducing size, the layer structure plays a critical role. With advancements in technology, multilayer PCBs and HDI PCBs have revolutionized the industry, enabling the creation of smaller, more powerful, and energy-efficient devices. As companies like {} continue to push the boundaries of innovation, the potential for further advancements in PCB layer technology remains promising, driving the evolution of the electronic devices we rely on every day.

Rapid PCB Factory in China - Speedy Manufacturing for Printed Circuit Boards

Title: China's Rapidly Expanding PCB Manufacturing Industry: Catalyzing Global Technological AdvancementsIntroduction:Over the past decade, China's PCB manufacturing industry has seen exponential growth, leading the way in meeting global demands for printed circuit boards (PCBs). One of the key players, China Fast Turn PCB Factory (name removed), has emerged as a major contributor to the country's success in this sector. With its state-of-the-art facilities and commitment to delivering efficient and high-quality products, China Fast Turn PCB Factory has become a prominent force in the realm of PCB manufacturing.Company Overview:China Fast Turn PCB Factory, based in [location], has positioned itself as a leading provider of PCB manufacturing services, serving both domestic and international clients. With a rich experience spanning [number of years] years, the factory has continually strived to improve its services to meet the dynamic requirements of the industry.The factory's dedication to innovation and cutting-edge technology has propelled it to the forefront of the PCB manufacturing sector. Its extensive range of offerings includes single-sided, double-sided, and multi-layer PCBs, catering to various industries such as automotive, telecommunications, consumer electronics, and more.State-of-the-Art Facilities:China Fast Turn PCB Factory boasts modern manufacturing facilities equipped with advanced machinery and production lines. The factory has heavily invested in technological advancements to enhance production efficiency and accuracy. Through the utilization of automated production processes, the factory significantly reduces turnaround times while maintaining the highest standards of quality.Quality Assurance:At China Fast Turn PCB Factory, quality is a top priority. The factory adheres to rigorous quality control measures throughout the production process to ensure the reliability and performance of its PCBs. Stringent inspections are conducted at each stage, from the procurement of raw materials to the final delivery, to guarantee that every product meets or exceeds industry standards.Commitment to Sustainability:China Fast Turn PCB Factory is committed to environmentally responsible practices. The factory actively adopts eco-friendly manufacturing techniques and materials, minimizing waste generation and promoting recycling initiatives. By adhering to sustainable production methods, China Fast Turn PCB Factory not only reduces its environmental impact but also aligns itself with global sustainability goals.Market Reach:With a customer-oriented approach, China Fast Turn PCB Factory has established a robust global market presence. Its diverse clientele includes renowned electronics manufacturers, research institutions, and startups, illustrating the broad range of industries the factory caters to. By maintaining strong partnerships with customers and continuously adapting to their evolving needs, China Fast Turn PCB Factory consolidates its position as a trusted and reliable PCB supplier.Driving Technological Advancements:As China Fast Turn PCB Factory plays a pivotal role in the PCB manufacturing sector, its relentless pursuit of technological advancements contributes to the overall growth and innovation of the global electronics industry. By providing cutting-edge PCB solutions, the factory supports the development of state-of-the-art technologies such as 5G, Internet of Things (IoT), artificial intelligence, and electric vehicles.Conclusion:China Fast Turn PCB Factory's emergence as a dominant player in China's PCB manufacturing industry has propelled the country's technological advancements on a global scale. With state-of-the-art facilities, commitment to quality, and a customer-centric approach, the factory continues to meet the ever-increasing demands of the electronics industry. As China Fast Turn PCB Factory continues to evolve, it will undoubtedly remain at the forefront of PCB manufacturing, shaping the future of the global technology landscape.

The Importance of PCB Board Thickness in Electronics Manufacturing

Introducing the PCB Board Thickness NewsIn the fast-paced world of technology, Printed Circuit Boards (PCBs) play a crucial role in powering electronic devices. These boards are the backbone of most electronic devices, providing the necessary connections and pathways for electrical components to function seamlessly. The thickness of PCB boards is a critical factor in determining their performance and reliability. In this news release, we will delve into the importance of PCB board thickness and how it impacts the overall functionality of electronic devices.The thickness of a PCB board is a key consideration in its design and manufacturing process. It directly affects the board's mechanical strength, impedance control, and overall performance. A thinner PCB board may offer a reduced form factor and lighter weight, but it may also be more prone to bending or warping, which can lead to electrical issues and component failure. On the other hand, a thicker PCB board provides better mechanical stability and can withstand higher levels of stress and vibration, making it ideal for applications where durability is paramount.In the world of PCB manufacturing, the standard thickness of a PCB board is typically denoted in millimeters (mm) or mils (1/1000 of an inch). The most commonly used PCB thickness is 1.6mm, which is suitable for a wide range of electronic applications. However, the demand for thinner and more lightweight PCB boards has been steadily increasing, driven by the evolution of compact and portable electronic devices. As a result, PCB manufacturers are constantly striving to develop innovative solutions that offer both thinness and durability.{Company Introduction} is at the forefront of PCB manufacturing and has been a pioneer in developing cutting-edge PCB technologies. With a strong focus on quality, innovation, and customer satisfaction, {Company Name} has consistently delivered high-performance PCB solutions to a diverse range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Their state-of-the-art manufacturing facilities and extensive industry experience have positioned them as a trusted leader in the field of PCB manufacturing.Recognizing the growing demand for thinner PCB boards, {Company Name} has dedicated significant resources to research and development efforts aimed at producing ultra-thin yet durable PCB solutions. By leveraging advanced fabrication techniques and materials, {Company Name} has successfully engineered PCB boards with reduced thicknesses while maintaining superior mechanical and electrical performance. These advancements have opened up new possibilities for designing smaller, lighter, and more efficient electronic devices, driving innovation across various industries.{Company Name} understands the critical role that PCB board thickness plays in the performance and reliability of electronic devices. By offering a diverse portfolio of PCB solutions with varying thickness options, {Company Name} ensures that their customers have access to the most suitable PCB boards for their specific application requirements. Whether it's a compact, handheld device or a rugged, industrial application, {Company Name} can tailor their PCB solutions to meet the exacting standards of their customers, providing unmatched reliability and performance.In conclusion, the thickness of PCB boards is a crucial factor that directly impacts the functionality and reliability of electronic devices. As the demand for thinner and more lightweight PCB boards continues to rise, {Company Name} remains committed to delivering innovative, high-performance PCB solutions that meet the evolving needs of the industry. Through their dedication to research and development, {Company Name} is shaping the future of PCB manufacturing, offering advanced solutions that empower the next generation of electronic devices. With a steadfast commitment to quality and excellence, {Company Name} is a trusted partner for businesses seeking cutting-edge PCB solutions.

How Printed Circuit Boards Revolutionized the Electronics Industry

[Company Name] Launches Advanced Printed Circuit Technology for Enhanced Performance and Reliability[Location], [Date] - [Company Name], a leading provider of advanced electronic solutions, has announced the launch of its latest innovative printed circuit technology, revolutionizing the industry with its unparalleled performance and reliability.Printed circuit boards (PCBs) are at the heart of electronic systems, enabling the smooth flow of electrical current between various components. As technology evolves, the demand for more advanced and efficient circuitry has increased, driving development in this sector. [Company Name] has always been at the forefront of this progress, consistently delivering cutting-edge solutions.The introduction of [Company Name]'s new printed circuit technology represents a significant leap forward in the development of advanced PCBs. By incorporating state-of-the-art materials and design techniques, the technology offers enhanced electrical connectivity, smaller form factors, and improved thermal management.One of the key advancements in this new technology is the use of advanced materials that offer higher electrical conductivity. This enables faster signal transmission and reduces the risk of signal loss or distortion. These enhanced electrical properties are particularly beneficial for high-frequency applications, such as telecommunication systems and data centers, where the reliable and rapid transfer of data is essential.Moreover, [Company Name] has implemented innovative design techniques to optimize the circuit layout and reduce power consumption. This not only improves the overall efficiency of electronic systems but also minimizes the generation of heat. By incorporating advanced thermal management, the printed circuit technology allows for better heat dissipation, preventing overheating and increasing the reliability and lifespan of electronic devices.To ensure the quality and reliability of their printed circuits, [Company Name] employs rigorous testing procedures and adheres to the industry's highest standards. Each circuit board undergoes meticulous inspections and quality control measures during the manufacturing process to detect any potential defects or inconsistencies. This dedication to quality assurance ensures that customers receive products of the highest caliber.The launch of this advanced printed circuit technology is expected to have a profound impact on various industries, including consumer electronics, automotive, aerospace, and medical sectors. For instance, in the automotive industry, the technology's improved thermal management capabilities will prove crucial for electric vehicles, where efficient cooling is vital for battery performance and longevity.Furthermore, the smaller form factor enables the creation of more compact and lightweight devices, making it ideal for aerospace applications where weight reduction is essential. Additionally, the enhanced electrical connectivity ensures the seamless operation of critical medical equipment, improving patient care and safety.As part of its commitment to sustainability, [Company Name] utilizes eco-friendly manufacturing practices and materials to minimize the environmental impact of its operations. This includes the reduction of hazardous substances in its products and adopting energy-efficient processes. By investing in advanced printed circuit technology, customers not only benefit from superior performance but also contribute to a greener future.[Company Name] continues to push the boundaries of what is possible in printed circuit technology, delivering innovative solutions to meet the evolving needs of the electronics industry. With its latest advancements, [Company Name] solidifies its position as a trusted and innovative partner, ensuring that businesses and consumers alike can rely on high-performance electronics for years to come.For more information about [Company Name]'s advanced printed circuit technology and other electronic solutions, please visit [company website].About [Company Name]:[Company Name] is a leading provider of advanced electronic solutions, specializing in the development and manufacturing of innovative printed circuit technology. With a commitment to excellence, [Company Name] offers a wide range of products and services tailored to meet the unique requirements of various industries. Through continuous research and development, [Company Name] aims to deliver cutting-edge solutions that drive technological advancements and facilitate progress.

Essential Guidelines for Efficient Electrical PCB Assembly and Manufacturing Revealed

Title: Revolutionizing the Electrical Industry: Cutting-edge PCB InnovationsIntroduction:In recent years, the electrical industry has witnessed unprecedented advancements, thanks to the tireless efforts of innovative companies. One such company, renowned for offering cutting-edge solutions, has unveiled their latest breakthrough in electrical Printed Circuit Board (PCB) technology. Their groundbreaking development promises to revolutionize multiple sectors and drive innovation forward. In this article, we delve into the unparalleled capabilities of this new Electrical PCB, explore its potential applications, and highlight the company's commitment to driving progress.State-of-the-art Electrical PCB:The newly introduced Electrical PCB has been designed with meticulous attention to detail, incorporating state-of-the-art technology that surpasses industry standards. Pioneering the field of printed circuit boards, this innovation is set to redefine reliability, performance, and efficiency within the electrical industry.Key Features and Advancements:1. Enhanced Power Efficiency:The advanced design of the Electrical PCB minimizes energy consumption without compromising performance. Through meticulous engineering, the company has successfully developed a circuit board that provides improved power distribution, reducing wastage and optimizing overall efficiency.2. Compact Design:The new Electrical PCB boasts a significantly smaller form factor, enhancing its versatility for a wide array of applications. The compact design not only saves valuable space but also streamlines manufacturing processes, reducing costs and time.3. High-Speed Data Transmission:The Electrical PCB has been optimized with high-speed data transmission capabilities, catering to the demanding needs of modern electrical systems. This cutting-edge feature enables seamless communication and connectivity, ensuring real-time data transfer between components and devices.4. Enhanced Durability:Durability is a key focus of this innovative Electrical PCB. The company has invested considerable resources in research and development, incorporating robust materials and manufacturing techniques that offer enhanced resistance to environmental factors such as moisture, corrosion, and extreme temperatures. This empowers industries to rely on the PCB for longer lifespans, reducing maintenance costs and downtime.5. Customizability:Recognizing the diverse requirements of different industries, the company's Electrical PCB is highly customizable. Tailored to meet specific needs, the PCB can be modified to fit various applications, ensuring seamless integration and compatibility across different electrical systems and devices.Potential Applications:From consumer electronics to industrial automation and renewable energy, the potential applications of this revolutionary technology are vast. The Electrical PCB's versatility opens doors for numerous industries seeking innovative solutions to their electrical challenges.1. Consumer Electronics:With its compact design, high-speed data transmission, and enhanced power efficiency, the Electrical PCB can be seamlessly integrated into smartphones, tablets, laptops, and other portable electronic devices. This innovation paves the way for smaller, more powerful, and energy-efficient consumer electronics.2. Automotive Industry:Enhanced durability and customizability make the Electrical PCB an attractive solution for the automotive industry. With increasing demands for electric vehicles, this groundbreaking technology ensures improved reliability, safety, and performance.3. Renewable Energy:The Electrical PCB's power efficiency and compact design offer significant advantages in renewable energy systems. This technology can facilitate efficient power conversion, making it ideal for solar panels, wind turbines, and energy storage systems.Company Commitment to Innovation:The company behind this monumental Electrical PCB breakthrough has a long-standing commitment to innovation and progress. Through ongoing research and development, they strive to push the boundaries of what is possible in the electrical industry. Their investment in cutting-edge technologies and dedication to customer satisfaction has solidified their position as a leader in the field.Conclusion:In a world where technological advancement is the driving force behind progress, the introduction of the Electrical PCB revolutionizes the electrical industry. With its groundbreaking features, including enhanced power efficiency, compact design, high-speed data transmission, and customizability, this innovation facilitates growth and transformation across various sectors. As this company continues to defy conventions and push the boundaries of technology, we can expect further groundbreaking developments in the future.

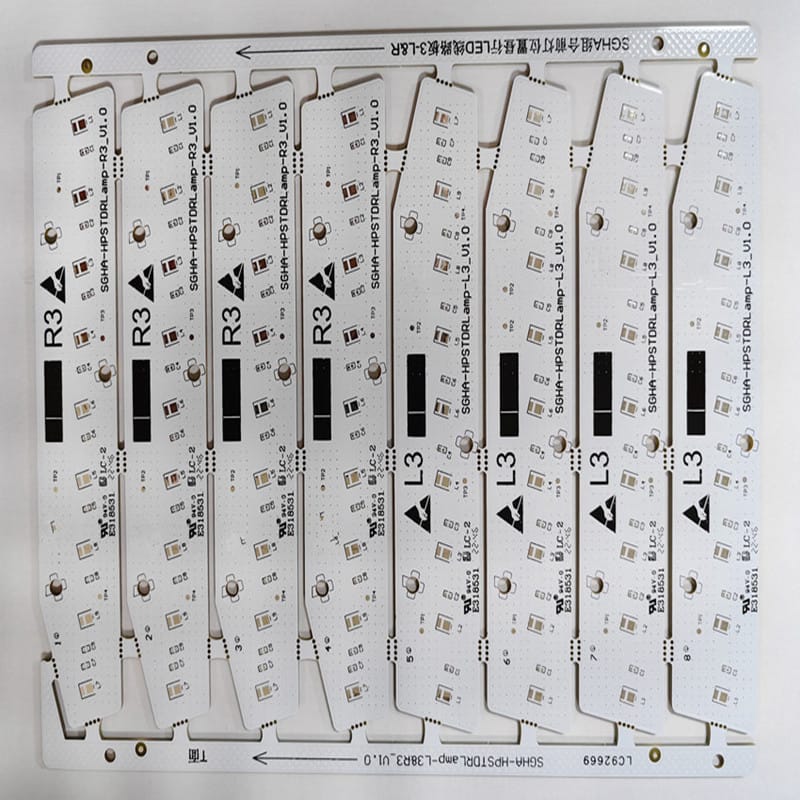

Custom Printed Circuit Board Manufacturing for LED Applications

The demand for more efficient and sustainable lighting solutions has been steadily increasing in recent years. In response to this growing need, {company name} has announced the development of a cutting-edge innovation in the realm of LED printed circuit boards (PCBs). This breakthrough technology promises to revolutionize the way in which LED lighting systems are designed and produced, offering a range of benefits that are set to have a significant impact on the industry as a whole.The new LED PCBs developed by {company name} have been specifically engineered to deliver enhanced performance and reliability in LED lighting applications. By leveraging state-of-the-art manufacturing processes and materials, the company has succeeded in creating a superior product that stands out in terms of energy efficiency, longevity, and overall quality. This development represents a major leap forward in the evolution of LED lighting, and is poised to set a new standard for the industry.One of the key features of {company name}'s LED PCBs is their exceptional thermal management capabilities. By utilizing advanced thermal materials and designs, the PCBs are able to effectively dissipate heat generated by the LEDs, resulting in improved performance and longevity. This aspect is particularly crucial in applications where LED lighting systems are required to operate continuously for extended periods of time, such as in commercial and industrial settings.Furthermore, the {company name} LED PCBs have been engineered to maximize energy efficiency, thereby reducing operational costs and environmental impact. The PCBs are designed to minimize power consumption while maintaining optimal performance, making them an ideal choice for those seeking to implement sustainable lighting solutions. As the global trend towards energy conservation and sustainability continues to gain momentum, the demand for such innovative and eco-friendly technologies is only expected to increase.In addition to their technical prowess, {company name}'s LED PCBs also offer a high degree of flexibility and customization. This allows for greater design freedom, enabling lighting manufacturers to create products that meet the specific requirements of their applications. Whether it be in the realm of architectural lighting, automotive lighting, or horticultural lighting, the versatility of these PCBs makes them a highly adaptable solution for a wide range of lighting needs.The development of these advanced LED PCBs is a testament to {company name}'s commitment to pushing the boundaries of what is possible in the field of LED lighting. As a leading provider of cutting-edge electronic solutions, the company has a long-standing track record of driving innovation and delivering high-performance products that meet the evolving demands of the market. With the introduction of these new LED PCBs, {company name} is once again demonstrating its ability to anticipate and address the needs of the industry, while also setting new benchmarks for performance and quality.Given the promising potential of this new technology, industry experts are eagerly anticipating the impact that {company name}'s LED PCBs will have on the market. As the demand for energy-efficient and sustainable lighting solutions continues to grow, the arrival of these innovative PCBs is expected to be met with great enthusiasm. With their unrivaled thermal management capabilities, energy efficiency, and flexibility, these LED PCBs are poised to play a pivotal role in shaping the future of LED lighting, and to set a new standard for excellence in the industry.

Exploring the Efficiency and Quality of Quick Turn PCB Fabrication in China

China, a global manufacturing powerhouse, has been known for its rapid turnaround time and high-quality products. In line with this reputation, the country's quick turn PCB fabrication industry has seen remarkable growth in recent years. One of the leading players in this sector is a prominent company that has made a name for itself in the PCB fabrication market.Established in (Year), (Company Name) has quickly emerged as a frontrunner in quick turn PCB fabrication in China. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, the company has been able to cater to the growing demand for fast and reliable PCB fabrication services.The success of (Company Name) can be attributed to several factors. Firstly, their commitment to quality sets them apart from their competitors. The company adheres to stringent quality control measures at every stage of the manufacturing process to ensure that the PCBs they produce meet the highest industry standards. This dedication to quality has earned them a reputation for delivering flawless PCBs consistently.In addition to their commitment to quality, (Company Name) emphasizes speed and efficiency. The company understands the time-sensitive nature of the PCB fabrication industry and is fully equipped to handle quick turnaround times. Through streamlined processes and cutting-edge technology, they are able to rapidly produce PCBs without compromising on quality.Furthermore, (Company Name) offers a wide range of PCB fabrication services to cater to the diverse needs of their clients. Whether it is single-layer, double-layer, or multi-layer PCBs, the company has the expertise and resources to handle any project. They also have the capability to manufacture PCBs of various sizes and complexities, ensuring that they can meet the unique requirements of their customers.Another strength of (Company Name) lies in their commitment to customer satisfaction. The company values open communication and collaboration with their clients, ensuring that every project is tailored to meet their specific needs. This customer-centric approach has earned them a loyal customer base and numerous positive testimonials.As a leading player in the quick turn PCB fabrication market, (Company Name) also places great importance on innovation. They constantly invest in research and development to stay ahead of industry trends and technologies. By keeping up with the latest advancements in PCB fabrication, they are able to offer their clients cutting-edge solutions that meet their evolving needs.Looking ahead, (Company Name) has ambitious plans for expansion. They aim to further strengthen their position in the quick turn PCB fabrication industry by continuously improving their manufacturing capabilities and exploring new markets. With China's booming manufacturing sector and their competitive advantage, the company is well poised to achieve its growth goals.In conclusion, (Company Name) has established itself as a leader in quick turn PCB fabrication in China by focusing on quality, speed, customer satisfaction, and innovation. With their unwavering commitment to excellence, the company has proven to be a reliable partner for businesses seeking fast and reliable PCB fabrication services. As China's manufacturing industry continues to flourish, (Company Name) is well-positioned to capitalize on the growing demand for quick turn PCBs and further expand its presence in the market.

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.

New Technology: Small Circuit Board Redefines Electronic Efficiency

Small Circuit Board (brand name removed), a key player in the electronics industry, has recently introduced a groundbreaking new technology that is set to revolutionize the way we think about circuit boards. The company, known for its innovative approach to electronic components, has been at the forefront of technological advancements and has become a trusted name in the industry.The new technology, known as the "NanoBoard," is a small circuit board that is designed to be more efficient and powerful than traditional circuit boards. It is equipped with advanced features that allow for faster data processing and higher energy efficiency. This breakthrough technology has the potential to completely transform the way electronic devices are designed and manufactured, offering a wide range of possibilities for industries such as consumer electronics, automotive, medical devices, and more.One of the key features of the NanoBoard is its compact size, which allows for greater flexibility in design and application. This allows for smaller and more powerful electronic devices to be created, opening up new possibilities for innovation in various industries. The NanoBoard also features advanced connectivity options, including wireless capabilities, making it ideal for the development of IoT (Internet of Things) devices.In addition to its technical capabilities, Small Circuit Board has also focused on sustainability and environmental responsibility in the development of the NanoBoard. The company has implemented eco-friendly manufacturing processes, as well as ensuring that the materials used in the production of the NanoBoard are recyclable.The introduction of the NanoBoard has generated significant excitement within the industry, with many experts predicting that it will have a profound impact on the future of electronics. Small Circuit Board has already received interest from a number of leading electronics manufacturers who are eager to integrate the NanoBoard into their products.In a statement, [company CEO] expressed his enthusiasm for the potential of the NanoBoard, stating that "This is a game-changing technology that has the potential to revolutionize the way electronic devices are designed and manufactured. We are proud to be at the forefront of this innovation and look forward to working with partners to bring the NanoBoard to market."The company's commitment to innovation and excellence has been a driving force behind the development of the NanoBoard. With its focus on quality, reliability, and sustainability, Small Circuit Board has established itself as a leader in the electronics industry. The introduction of the NanoBoard is a testament to the company's ongoing commitment to pushing the boundaries of what is possible in electronics.Looking ahead, Small Circuit Board is exploring additional applications for the NanoBoard, including the development of customized solutions for specific industries and applications. The company is also considering the potential for partnerships with other industry leaders to further expand the reach of this groundbreaking technology.Overall, the introduction of the NanoBoard represents a significant milestone for Small Circuit Board and the electronics industry as a whole. With its advanced features, compact design, and focus on sustainability, the NanoBoard has the potential to drive innovation and create new opportunities for the development of electronic devices. As the industry continues to evolve, Small Circuit Board is well-positioned to remain at the forefront of technological advancements and continue to make a positive impact on the world of electronics.

Discover the Benefits of Quick Turnaround PCB Services for Efficient Electronics Production

Quick Turnaround PCB Company Delivers World-Class Circuit BoardsQuick Turnaround PCB, a leading printed circuit board manufacturer, continues to deliver world-class PCB solutions to meet the growing needs of the electronics industry. With its commitment to excellence and customer satisfaction, the company provides top-quality products that are durable, reliable, and cost-effective.Quick Turnaround PCB has gained a strong reputation for its exceptional services and production capabilities. It offers a vast range of PCB solutions including rigid, flex, and rigid-flex boards, along with PCB assembly services. The company also specializes in quick turnaround services, with the ability to produce PCB prototypes within just a few days.The company has established itself as an industry leader in PCB manufacturing due to its advanced manufacturing technologies, efficient process optimization, and rigorous quality control procedures. Its manufacturing facility boasts state-of-the-art machinery, including automated optical inspection systems, surface mount technology, and X-ray inspection, to ensure that its products meet the highest quality standards.To cater to the diverse needs of its clients, Quick Turnaround PCB provides custom PCB solutions tailored to specific requirements. Its team of professional engineers works closely with customers to identify their needs and develop effective solutions that can meet their needs.Moreover, the company is dedicated to providing customers with exceptional support services to ensure their satisfaction. Customers can reach out to dedicated technicians and engineers at any time to get advice or assistance on any PCB-related issues.Over the years, Quick Turnaround PCB has developed a loyal customer base due to its relentless pursuit of excellence in PCB manufacturing. The company's clients come from various sectors, including automotive, aerospace, medical, and telecommunications. Its products have been used in various applications, ranging from industrial machinery to consumer electronics. Quick turnaround PCB has made a significant investment in research and development activities, with the aim of staying ahead of its competitors and providing cutting-edge solutions to customers. Its engineers are continually exploring new technologies and innovations in PCB manufacturing, such as flexible substrates and additive manufacturing.With its commitment to quality, innovation, and customer satisfaction, Quick Turnaround PCB stands poised to become a leading player in the global PCB industry. As it continues to expand its manufacturing capabilities and broaden its product portfolio, the company is confident in its ability to meet the diverse needs of customers worldwide.In conclusion, Quick Turnaround PCB is a world-class manufacturer of printed circuit boards, known for its commitment to delivering high-quality products and customer satisfaction. Its advanced manufacturing technologies, efficient process optimization, and rigorous quality control procedures set it apart from its competitors. As the company continues to grow and innovate, it is poised to become a leading player in the global PCB industry.