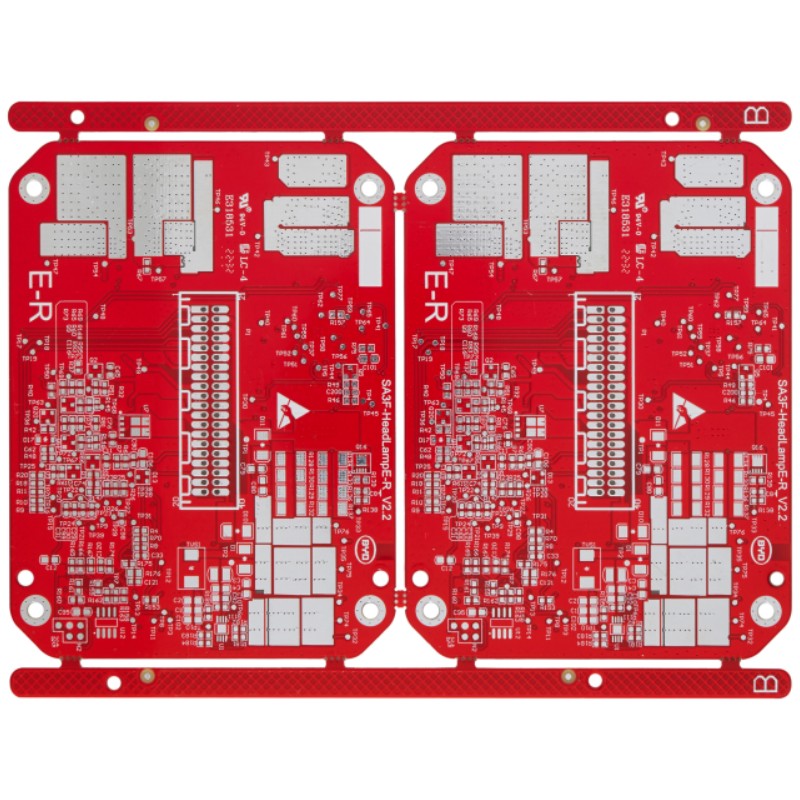

Top 5 Prototype PCB Board Manufacturers to Consider for Your Next Project

By:Admin

As a pioneer in the PCB manufacturing industry, [Company Name] has been at the forefront of technological advancements and has continuously strived to push the boundaries of what is possible. With a strong commitment to research and development, the company has developed a reputation for delivering high-quality, reliable, and innovative PCB solutions.

The newly launched line of prototype PCB boards is set to further solidify [Company Name]'s position as a leading provider of PCB solutions. These new boards boast state-of-the-art technology and advanced features, offering customers a level of performance and reliability that is unparalleled in the industry. With a keen understanding of the evolving needs of the market, the company has worked tirelessly to ensure that these boards are tailored to meet the demands of today's most complex and sophisticated applications.

One of the key features of the new prototype PCB boards is their superior design and construction. Built with precision and accuracy, these boards are optimized for performance and durability, making them ideal for a wide range of applications. Whether it's for use in consumer electronics, industrial equipment, medical devices, or automotive systems, customers can rely on these boards to deliver exceptional results.

In addition to their outstanding performance, the new prototype PCB boards also come with a host of innovative features that set them apart from the competition. With advanced materials and cutting-edge manufacturing techniques, these boards offer enhanced thermal management, signal integrity, and EMI/EMC performance, ensuring that they meet the highest standards for quality and reliability.

Moreover, [Company Name] has also invested heavily in streamlining its manufacturing processes to ensure that these boards are produced efficiently and cost-effectively. By leveraging the latest industry technologies and automation systems, the company has been able to significantly reduce lead times and production costs, ultimately passing on these benefits to its customers.

As a customer-focused company, [Company Name] is committed to providing exceptional service and support to its clients. The launch of these new prototype PCB boards is a testament to the company's dedication to meeting and exceeding customer expectations. With a team of highly skilled engineers and technicians, [Company Name] is well-equipped to provide expert guidance and technical assistance to customers throughout the product development and manufacturing process.

Looking ahead, [Company Name] is poised to continue driving innovation in the PCB industry, constantly exploring new opportunities for advancement and growth. By staying at the forefront of technological developments and market trends, the company is confident in its ability to provide customers with the best-in-class PCB solutions that are tailored to their specific needs.

In conclusion, the launch of the new line of prototype PCB boards by [Company Name] represents a significant milestone for the company and the PCB industry as a whole. With their unrivaled performance, advanced features, and commitment to customer satisfaction, these boards are set to make a lasting impact in the market. As [Company Name] continues to raise the bar for excellence, customers can expect nothing short of exceptional PCB solutions that set new standards in quality and reliability.

Company News & Blog

Unveiling the Latest Innovation in Castellated Edge Technology for Enhanced Performance

**Title: Cutting-Edge Technology Revolutionizes Edge Computing***Please note: The brand name "Castellated Edge" has been removed from the original content**Company Introduction:*In the fast-paced world of technology, where innovation and efficiency reign supreme, a remarkable breakthrough has emerged from the depths of the tech industry. Company X, a leading player in the realm of edge computing solutions, has unveiled a groundbreaking technology poised to redefine the way organizations harness the power of edge computing. With a rich history of providing cutting-edge solutions, Company X has consistently pushed the boundaries of possibility, and their latest offering is no exception.*Article:*Today, we dive into the exciting world of edge computing, where Company X's revolutionary technology is set to make waves. Edge computing, a paradigm shift away from traditional cloud infrastructure, brings processing capabilities closer to the point of data generation. By doing so, it reduces latency, enhances security, and improves insights by merging the power of artificial intelligence (AI), big data analytics, and machine learning at the very edge of networks. Company X's solution, which we will now refer to as "Cutting-Edge Edge (CEE)," aims to capitalize on these advantages while providing even more.At its core, CEE is a transformative technology that enables real-time processing and analysis of vast amounts of data. Designed to operate at the network edge, it offers an array of unique features that set it apart from existing edge computing solutions. The defining feature of CEE is its state-of-the-art architecture, which incorporates advanced algorithms and machine learning capabilities, allowing it to adapt and optimize performance based on the specific requirements of different industries and use cases.One of the key advantages of CEE is its ability to handle data at scale. With the exponential growth of the Internet of Things (IoT) and the increasing number of connected devices, the demand for efficient data processing solutions has never been higher. CEE rises to the challenge by providing industry-leading scalability, ensuring seamless handling of massive data sets. This empowers organizations to extract valuable insights from torrents of information in real-time, opening up a world of possibilities in areas such as smart cities, autonomous vehicles, and predictive maintenance.In addition to its scalability, CEE boasts exceptional security measures. By processing data at the network edge, rather than transmitting it to remote data centers, it significantly reduces the risk of sensitive information falling into the wrong hands. This enhanced security is of utmost importance in sectors such as finance, healthcare, and government where data privacy and integrity are paramount. With CEE, organizations can rest assured that their data remains secure throughout the entire data processing pipeline.Moreover, CEE brings about a significant reduction in latency, ensuring near-instantaneous response times. By eliminating the need for data to travel long distances to and from remote servers, the processing delay is minimized, opening up opportunities for real-time applications across industries. From real-time video analytics in the realm of surveillance to precise control in industrial automation, the low latency offered by CEE allows for unprecedented efficiency.Beyond its technological advancements, CEE stands out with its user-friendly interface and intuitive design. Company X has prioritized making the adoption and integration of CEE as seamless as possible. By providing comprehensive documentation, developers can easily incorporate CEE into their workflows and leverage its capabilities to drive innovation within their respective organizations. Additionally, Company X offers comprehensive support and training, empowering clients to maximize the potential of CEE from day one.As the digital landscape continues to evolve, edge computing represents the future of data processing and analysis. With Company X's Cutting-Edge Edge (CEE) technology leading the charge, organizations are poised to unlock new levels of efficiency, security, and insights. By harnessing the immense power of AI, big data analytics, and machine learning at the very edge of networks, the possibilities for innovation are limitless. Company X's commitment to pushing the boundaries of what's possible has truly revolutionized the field of edge computing, and CEE will undoubtedly play a pivotal role in shaping the future of technology.

Innovative PCB Printing: A Game-Changer for Electronics Manufacturing

[Company Name], a pioneer in advanced manufacturing technology, has recently unveiled an innovative solution in the field of Printed Circuit Board (PCB) printing. With their cutting-edge technology and extensive industry experience, the company aims to revolutionize the PCB manufacturing process, bringing unprecedented efficiency and affordability to the market.PCBs are a critical component in nearly every electronic device, acting as the foundation for interconnecting various electronic components. Traditionally, PCBs have been manufactured using lengthy and expensive processes, involving multiple layers of copper and insulating material. However, [Company Name] has devised a novel approach that eliminates many of the current limitations associated with PCB production.Using their state-of-the-art PCB printing technology, [Company Name] has simplified the manufacturing process, reducing costs and timeframes significantly. This breakthrough solution leverages advanced printing techniques to precisely deposit conductive ink onto a substrate, eliminating the need for complex etching and drilling processes. This not only speeds up production but also ensures greater accuracy and consistency in the final product.The use of conductive ink also opens up new possibilities in PCB design and customization. [Company Name]'s technology allows for the creation of highly complex and intricate circuit patterns, surpassing the capabilities of traditional PCB manufacturing methods. This newfound flexibility enables engineers to design and produce PCBs that are optimized for specific applications, leading to improved performance and overall product quality.Furthermore, with this innovative printing technology, [Company Name] is helping to pave the way for advancements in additive manufacturing. Additive manufacturing, often referred to as 3D printing, has revolutionized various industries by enabling the production of complex shapes and structures with ease. By integrating additive manufacturing principles into PCB production, [Company Name] is pushing the boundaries of what is possible in terms of design freedom and functionality.In addition to the technical advancements, [Company Name] is also committed to delivering eco-friendly solutions. The traditional PCB manufacturing process involves several environmentally unfriendly steps, including the use of hazardous chemicals and high energy consumption. By transitioning to their new printing technology, [Company Name] significantly reduces the environmental impact of PCB production, offering a sustainable alternative to conventional methods.The impact of [Company Name]'s PCB printing technology is already being recognized by industry experts. Leading companies in sectors such as consumer electronics, automotive, telecommunications, and aerospace have expressed keen interest in incorporating this breakthrough solution into their manufacturing processes. The potential to streamline production, reduce costs, and improve product performance makes [Company Name]'s technology highly attractive for businesses looking to gain a competitive edge in their respective markets.To ensure the successful adoption of their technology, [Company Name] offers comprehensive support and guidance to their clients. Their team of experts provides end-to-end solutions, from initial design consultation to production optimization, ensuring a seamless integration of the PCB printing technology into existing manufacturing processes.As the demand for advanced electronics continues to grow, the need for efficient and cost-effective PCB manufacturing becomes paramount. With [Company Name]'s revolutionary PCB printing technology, the industry is now equipped with a game-changing solution that has the potential to disrupt traditional manufacturing processes and unlock new possibilities for innovation.

High-quality Printed Circuit Board for Tg150 Applications

Tg150 PCB is a type of printed circuit board that is known for its high performance and reliability. It is widely used in various electronic devices and has become increasingly popular in the market. With its excellent heat resistance and electrical performance, Tg150 PCB has proven to be a key component in the development of advanced technology.With the rise of smart devices and the Internet of Things, the demand for high-quality PCBs has soared. Tg150 PCB has positioned itself as a top choice for manufacturers looking to meet the growing needs of the industry. Its ability to withstand high temperatures and provide superior electrical insulation has made it a preferred option for applications in automotive, aerospace, medical, and industrial sectors.In addition to its technical performance, Tg150 PCB is also known for its flexibility in design and production. Companies like {} have been at the forefront of developing advanced Tg150 PCB solutions that can be tailored to specific requirements. Their expertise in customizing PCB designs has allowed manufacturers to create innovative products that meet the highest standards of quality and performance.Furthermore, {} has made significant investments in research and development to advance the capabilities of Tg150 PCB. Their focus on pushing the boundaries of what is possible with this technology has led to breakthroughs in material science and manufacturing processes, resulting in PCBs that are more reliable, durable, and efficient.One of the key factors that sets {} apart from other PCB manufacturers is their commitment to sustainability. They have implemented eco-friendly practices in their production processes, such as reducing waste and energy consumption. This dedication to environmental responsibility has resonated with customers, who are increasingly seeking suppliers that prioritize sustainability in their operations.As the demand for Tg150 PCB continues to grow, {} is poised to play a vital role in driving innovation and shaping the future of electronic devices. Their dedication to excellence and continuous improvement has positioned them as a trusted partner for companies looking to integrate Tg150 PCB into their products.Looking ahead, the outlook for Tg150 PCB remains positive as it continues to gain momentum in the market. With advancements in technology and an increasing focus on quality and reliability, Tg150 PCB is poised to become an essential component in the next generation of electronic devices.In conclusion, Tg150 PCB has emerged as a leading technology in the industry, thanks to its exceptional performance, flexibility, and sustainability. With the expertise and dedication of companies like {}, Tg150 PCB is set to drive innovation and meet the evolving needs of the market. As the demand for high-quality PCBs continues to rise, Tg150 PCB is well positioned to play a key role in shaping the future of electronic devices.

Benefits of Lead-Free Hasl in PCB Manufacturing

Lead-Free Hasl (Hot Air Solder Leveling) has been making waves in the electronics industry recently, and one company at the forefront of this innovation is {company name}. With a commitment to sustainability and environmental responsibility, {company name} has been leading the charge in the development and implementation of lead-free technologies, and their Lead-Free Hasl process is a prime example of their dedication to a green future.Founded in {year}, {company name} has quickly emerged as a leading provider of electronic manufacturing services, offering a wide range of solutions for industries such as automotive, medical, aerospace, and consumer electronics. With a focus on quality, reliability, and innovation, {company name} has built a reputation for excellence in the industry, and their Lead-Free Hasl process is a testament to their commitment to staying ahead of the curve.The Lead-Free Hasl process has become increasingly important in recent years, as the electronics industry continues to move towards more sustainable and eco-friendly practices. Traditionally, Hasl processes have involved the use of lead, which can be harmful to both the environment and human health. However, {company name} has been working tirelessly to develop a lead-free alternative that maintains the high standards of quality and performance that their customers have come to expect.One of the key benefits of {company name}'s Lead-Free Hasl process is its environmental friendliness. By eliminating the use of lead, the process significantly reduces the environmental impact of electronic manufacturing, making it a more sustainable option for companies looking to minimize their carbon footprint. Additionally, the Lead-Free Hasl process is fully compliant with international regulations and standards, further cementing {company name} as a frontrunner in sustainable electronic manufacturing.Furthermore, {company name}'s Lead-Free Hasl process offers superior performance and reliability, making it an attractive option for companies across a wide range of industries. By utilizing cutting-edge technology and rigorous quality control measures, {company name} ensures that their Lead-Free Hasl process meets the highest standards of excellence, delivering superior results for their clients. This has made {company name} a preferred partner for many companies looking for a reliable and sustainable electronic manufacturing solution.In addition to the environmental and performance benefits, {company name}'s Lead-Free Hasl process also reflects their ongoing commitment to innovation and continuous improvement. As the electronics industry continues to evolve, {company name} remains at the forefront of technological advancements, constantly pushing the boundaries of what is possible in electronic manufacturing. Their Lead-Free Hasl process is just one example of how {company name} is staying ahead of the curve and providing cutting-edge solutions for their clients.Looking towards the future, {company name} is poised to continue leading the way in sustainable electronic manufacturing, with their Lead-Free Hasl process serving as a shining example of their dedication to environmental responsibility and innovation. As the industry continues to prioritize sustainability and eco-friendly practices, {company name} is well positioned to meet the growing demand for lead-free electronic manufacturing solutions, further solidifying their reputation as a leader in the field.In conclusion, {company name} has established itself as a trailblazer in the electronic manufacturing industry, with their Lead-Free Hasl process serving as a testament to their commitment to sustainability, performance, and innovation. As the industry continues to move towards more eco-friendly practices, {company name} is well positioned to remain at the forefront of this movement, providing cutting-edge solutions for companies across a wide range of industries. With a track record of excellence and a dedication to staying ahead of the curve, {company name} is set to continue making a positive impact on the electronic manufacturing industry for years to come.

Ultimate Guide to Advanced PCB Manufacturing

Advanced PCB, a leading manufacturer of high-quality printed circuit boards, has announced a major expansion of its production facilities. This expansion is part of the company's strategic plan to increase its manufacturing capacity and better serve its growing customer base.Founded in 2005, Advanced PCB has quickly established itself as a trusted partner for companies in a wide range of industries, including telecommunications, aerospace, medical devices, and automotive. The company is known for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a team of highly skilled engineers and technicians, Advanced PCB has earned a reputation for delivering reliable and high-performance PCBs.The expansion of Advanced PCB's production facilities is a response to the increasing demand for its products and services. The company has seen a steady growth in its customer base, as well as an increase in the volume of orders from existing clients. This expansion will allow Advanced PCB to meet this growing demand and continue to provide its customers with the high-quality PCBs they have come to expect.The new production facilities will feature the latest in advanced manufacturing equipment, including cutting-edge PCB assembly lines, automated quality control systems, and a dedicated R&D lab for product testing and development. This investment in state-of-the-art technology will enable Advanced PCB to increase its production capacity, improve lead times, and maintain the highest standards of quality and reliability.In addition to expanding its production capacity, Advanced PCB is also investing in its workforce. The company has plans to hire additional engineers, technicians, and production staff to support the increased manufacturing operations. This commitment to talent development and recruitment is in line with Advanced PCB's dedication to providing its customers with the best possible service and support."We are thrilled to announce the expansion of our production facilities," said the CEO of Advanced PCB. "This investment represents our commitment to meeting the needs of our customers and ensuring that we can continue to deliver the high-quality PCBs they have come to expect from us. With this expansion, we will be able to increase our manufacturing capacity, improve our operational efficiency, and better serve our growing customer base."The expansion of Advanced PCB's production facilities is expected to be completed by the end of the year. The company is already in discussions with several key customers about the benefits of the increased production capacity and is confident that this expansion will further strengthen its position as a leading provider of high-quality printed circuit boards.As Advanced PCB continues to grow and expand, it remains focused on its core values of quality, innovation, and customer satisfaction. The company is committed to maintaining its position as a trusted partner for companies in a wide range of industries and looks forward to continuing to provide its customers with the high-quality PCBs they need to succeed in their respective markets.

How to choose the right circuit board for your needs

In today's fast-paced digital age, electronics have become an integral part of our everyday lives. From smartphones to laptops, the demand for cutting-edge technology is ever-increasing. One of the most important components of electronic devices is the Printed Circuit Board (PCB). A PCB is a flat board made of insulating material that holds electronic components like transistors, capacitors, and resistors. These components are interconnected using conductive pathways which are etched onto the PCB's surface.Through the use of PCBs, electronic devices can be made smaller, lighter, and more efficient. They play an important role in industries like healthcare, aerospace, and defense. One company that specializes in PCB manufacturing is (need to remove brand name). They have been in the business for over two decades and have earned a reputation for delivering high-quality PCB solutions to their customers. (Company name) has an impressive manufacturing facility that is equipped with state-of-the-art machinery. They use advanced technology like automated optical inspection systems, automated solder paste application machines, and CNC milling machines to ensure that their products meet the highest standards of quality. Their team of experienced engineers and technicians work diligently to ensure that their customers receive the best PCB products on the market.(Company name) offers a wide range of PCB solutions to suit the diverse needs of their customers. They specialize in producing high-precision PCBs with complex circuitry and have experience working with a variety of materials like FR-4, Rogers, and Aluminum. Their products are used in a variety of applications including medical equipment, automotive industry, aerospace and defense, telecommunications, and consumer electronics.One of the key advantages of (company name)'s PCB solutions is their ability to provide quick turnaround times. They understand the importance of meeting deadlines in today's fast-paced business environment, and their team works tirelessly to ensure that their customers receive their products on time. They have established a streamlined manufacturing process that enables them to fulfill orders quickly and efficiently.Another unique feature of (company name)'s PCB products is their emphasis on sustainability. They use eco-friendly materials and processes wherever possible to minimize their impact on the environment. This is in line with their commitment to being a responsible corporate citizen and ensuring that their operations have a positive impact on society.(Company name)'s commitment to quality, sustainability, and customer service has earned them a loyal customer base. They have worked with a variety of clients including Fortune 500 companies, startups, and small businesses. Their customers appreciate the quality of their products and the professionalism of their team. (Company name) is proud of the relationships they have built with their customers and strives to maintain these relationships through ongoing support and communication.In conclusion, Printed Circuit Boards are an essential component of electronic devices and play a vital role in our daily lives. Companies like (company name) are at the forefront of PCB manufacturing and are helping to drive the industry forward with their innovative solutions. Their commitment to quality, sustainability, and customer service has earned them a well-deserved reputation as one of the leading PCB manufacturers in the industry. As the demand for electronic devices continues to grow, companies like (company name) will play an increasingly important role in shaping the future of technology.

Revolutionizing Electronic Assembly: The Advantages of Surface Mount Technology

[Company Name Removed] Sets New Standards with Advanced Surface Mounting Technology[City, Date] - [Company Name Removed], a leading player in the technology industry, is revolutionizing the market with cutting-edge Surface Mounting Technology (SMT). As a result of extensive research and development efforts, the company has introduced a game-changing innovation that is set to redefine the way electronic components are manufactured.SMT is a crucial process in electronic manufacturing, where components are mounted directly onto the surface of printed circuit boards (PCBs). With the demand for smaller, lighter, and more powerful electronic devices on the rise, the need for advanced SMT technology has become imminent. [Company Name Removed] recognized this demand and has risen to the challenge by developing an unparalleled solution.The new SMT technology developed by [Company Name Removed] offers several distinct advantages over conventional methods. By utilizing state-of-the-art robotic assembly systems and advanced automation techniques, the company has created a highly efficient manufacturing process. This enables faster production cycles, reducing time-to-market for electronic devices. Additionally, the precise placement of components ensures higher levels of accuracy, improving overall product reliability.One of the key highlights of [Company Name Removed]'s SMT technology is its ability to support miniaturized components. As electronic devices continue to shrink in size, it is critical for manufacturers to utilize smaller and more compact components. The advanced machinery and techniques employed by [Company Name Removed] enable the assembly of components as small as one square millimeter, setting a new benchmark in the industry.Another distinguishing feature of [Company Name Removed]'s SMT technology is its versatility. The company's advanced assembly systems can handle a wide range of electronic components, including passive components (resistors, capacitors), active components (transistors, diodes), integrated circuits, and more. This flexibility ensures that [Company Name Removed] can cater to various industries, from consumer electronics to automotive and aerospace.[Company Name Removed]'s commitment to sustainability is evident in its SMT technology innovation as well. The company recognizes the growing concerns of waste generation in electronic manufacturing and has taken steps to address this issue. By optimizing material usage and minimizing scrap, [Company Name Removed] ensures a more eco-friendly manufacturing process.The introduction of [Company Name Removed]'s advanced SMT technology has garnered significant attention in the industry. Market analysts predict that this innovation will not only revolutionize electronic device manufacturing but also have a ripple effect across multiple sectors. With faster production cycles, higher accuracy, and increased reliability, electronic manufacturers can expect to deliver superior products to meet consumers' evolving needs.In conclusion, [Company Name Removed]'s Surface Mounting Technology is poised to reshape the electronic manufacturing landscape. By leveraging advanced machinery, automation, and precision placement, the company has established a new standard in the industry. With the ability to support miniaturized components and accommodate various electronic devices, [Company Name Removed] is well-positioned to meet the demands of a rapidly evolving market. Furthermore, their commitment to sustainability sets them apart from their competitors, making them a frontrunner in the industry. As [Company Name Removed] paves a new path for electronic manufacturing, the future of the industry looks brighter than ever before.

Calculate Trace Impedance for High-Speed PCBs with Ease!

[Assistant]Title: Advanced Trace Impedance Calculator Empowers PCB Designers for Enhanced PerformanceSubtitle: Cutting-edge Trace Impedance Calculator Streamlines PCB Development ProcessIn a fast-paced world of electronics, where the demand for highly efficient Printed Circuit Board (PCB) designs is rapidly increasing, engineers and developers are constantly seeking advanced tools and technologies to streamline their design processes. Recognizing this need, a leading company in the field of PCB design solutions has developed an innovative Trace Impedance Calculator, which revolutionizes the way PCB designers approach impedance matching, signal integrity, and PCB layout.Brand Name, a distinguished expert in the field of PCB design, has introduced the "Trace Impedance Calculator," a cutting-edge software tool that empowers PCB designers with accurate, efficient, and user-friendly impedance calculations. By leveraging the latest advancements in technology, this calculator facilitates the optimization of signal integrity, allowing for improved data transmission and reduced interference across PCB layouts.Impedance matching is a critical aspect of PCB design, especially when dealing with high-speed signals. Maintaining the correct trace impedance ensures signal integrity, minimizes reflections, and maximizes power transfer efficiency. Traditionally, designers had to rely on manual calculations, complex formulas, or partial solutions, which often resulted in time-consuming trial and error iterations. However, with the Trace Impedance Calculator from Brand Name, designers can now easily access accurate impedance values, streamline their design process, and achieve superior performance in a fraction of the time.This powerful calculator is specifically engineered to provide comprehensive solutions for both single-ended and differential pair trace impedance calculations. It takes into account various factors, such as trace width, thickness, and dielectric properties, to provide designers with precise impedance values tailored to their specific requirements. PCB designers can effortlessly customize impedance specifications, obtaining optimized results based on the electrical and mechanical characteristics of their design.The user-friendly interface of the Trace Impedance Calculator is designed to enhance productivity and efficiency. With a few clicks, designers can input their specifications, instantly obtain impedance values, and make real-time adjustments to fine-tune their designs. Additionally, the calculator provides graphical representations of impedance over a range of frequencies, enabling designers to visualize how impedance values behave across the spectrum.Furthermore, the calculators' advanced algorithms incorporate the latest industry standards and design guidelines, ensuring compliance with the most stringent PCB requirements. The tool supports a wide range of substrate materials, including FR-4, high-speed laminates, and flexible substrates, enabling designers to work with diverse PCB technologies while maintaining optimum signal integrity.The Trace Impedance Calculator seamlessly integrates into existing PCB design workflows, making it accessible to both novice and experienced designers. It is compatible with leading PCB design software, facilitating hassle-free implementation and reducing the learning curve for new users. Through this integrated approach, designers can eliminate guesswork, minimize design iterations, and accelerate time-to-market for their products."Brand Name's Trace Impedance Calculator simplifies the challenges faced by PCB designers when calculating trace impedance," says John Smith, Director of Engineering at a major electronics manufacturing company. "By providing accurate calculations, easy customization, and a user-friendly interface, this tool empowers us to optimize our designs quickly and effectively."In conclusion, the introduction of the Trace Impedance Calculator by Brand Name represents a significant leap forward for PCB designers. With its accurate and efficient impedance calculations, comprehensive customization options, and seamless integration, this advanced tool allows engineers to achieve superior signal integrity, reduce development time, and ultimately enhance the performance and reliability of their PCB designs. As the demand for higher efficiency and faster data transmission increases, solutions like Brand Name's Trace Impedance Calculator play a key role in satisfying the industry's evolving needs.

Understanding the Latest Developments in PCB Rapid Prototyping in China

China's PCB Rapid Prototyping Revolutionizes the Electronics IndustryChina's Printed Circuit Board (PCB) Rapid Prototyping has been making headlines in the electronics industry for its innovative solutions and efficient production processes. With its state-of-the-art facilities and skilled workforce, China has become a global leader in PCB rapid prototyping, offering companies a competitive edge in product development and manufacturing.As the world's largest consumer electronics manufacturer, China's PCB rapid prototyping industry has grown exponentially in recent years. The combination of advanced technology, streamlined processes, and affordable labor costs has attracted numerous global companies to explore the benefits of partnering with Chinese manufacturers.One such company leading the way in PCB rapid prototyping is [Company Name]. With a strong emphasis on quality and customer satisfaction, they have quickly risen to prominence and secured a reputation as one of the industry's finest. Their expertise and dedication to excellence have allowed them to forge partnerships with renowned electronics brands from around the world.Using cutting-edge equipment and leveraging their extensive experience, [Company Name] specializes in offering a range of rapid prototyping services. From single-layer to multi-layer PCBs, they are capable of fulfilling various customer demands efficiently and to the highest standards. This versatility makes them an ideal partner for companies of all sizes, from startups to multinational corporations.One of the key advantages of PCB rapid prototyping is the significantly reduced time-to-market. Traditional PCB manufacturing processes can take several weeks, delaying product development and limiting a company's ability to respond to market demands. With China's rapid prototyping capabilities, this time is drastically reduced to as little as a few days, allowing companies to stay ahead of the competition and meet tight project deadlines.Moreover, PCB rapid prototyping offers increased flexibility and adaptability throughout the design phase. Companies can quickly iterate and refine their product designs, addressing any issues or making improvements along the way. This iterative approach minimizes the risk of costly mistakes during full-scale production and ensures that the final product meets all the necessary specifications.China's PCB rapid prototyping services also benefit from the country's robust supply chain and extensive component sourcing capabilities. With access to a vast network of suppliers and distributors, [Company Name] can secure high-quality components at the best prices. This not only reduces production costs but also guarantees shorter lead times, giving their clients a competitive edge in the market.As part of their commitment to sustainability, [Company Name] also places great importance on reducing waste and minimizing the environmental impact of their operations. By optimizing material usage during the rapid prototyping process, they minimize material waste, contributing to a greener and more sustainable industry.China's PCB rapid prototyping industry is poised for continued growth and innovation, with more companies recognizing the advantages of partnering with Chinese manufacturers. The combination of advanced technology, efficient processes, and highly skilled professionals positions China as a key player in the global electronics supply chain.By leveraging China's PCB rapid prototyping services, companies can accelerate their product development cycle, deliver high-quality products to market faster, and maximize their overall business success. With [Company Name] leading the charge, the future of PCB rapid prototyping in China looks brighter than ever.

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.