Top Quality Pcb Prototype Board Suppliers in China

By:Admin

China-based PCB prototype board suppliers are making waves in the electronics industry, as they continue to expand their market reach and offer high-quality and innovative solutions to customers worldwide.

With the increasing demand for PCB prototype boards in various industries such as automotive, telecommunications, and consumer electronics, China-based suppliers have been stepping up their game to meet the growing needs of the market. These suppliers have been investing in state-of-the-art manufacturing facilities and employing a team of experienced engineers and technicians to ensure the production of top-notch PCB prototype boards.

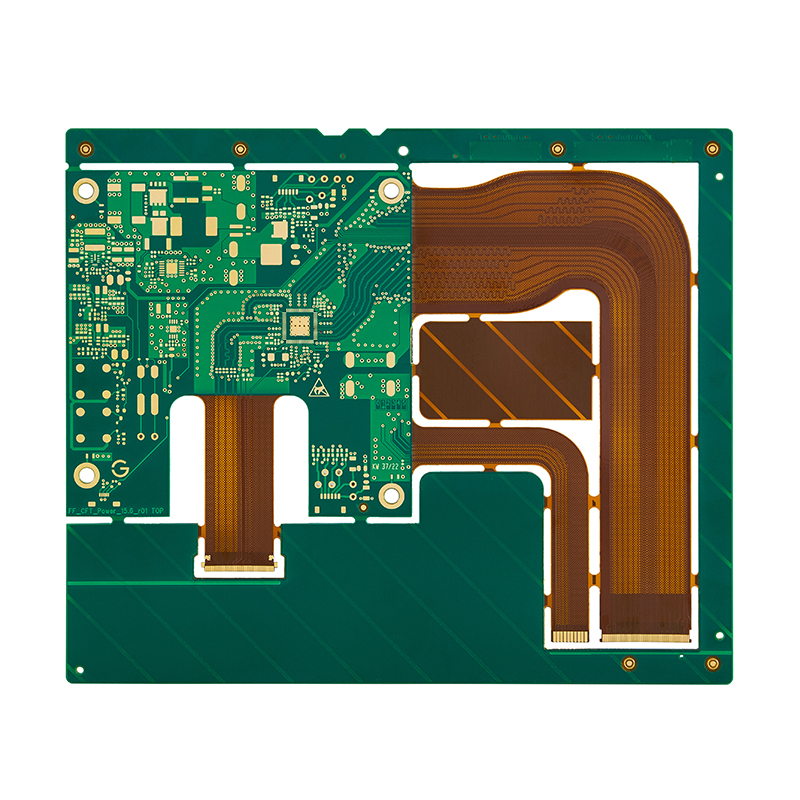

One of the leading China-based PCB prototype board suppliers, has been at the forefront of this market expansion. With a strong commitment to quality, reliability, and customer satisfaction, they have been able to build a solid reputation for themselves in the industry. They have been providing a wide range of PCB prototype boards, including rigid, flexible, and rigid-flex boards, with various materials and surface finishes to meet the diverse requirements of their customers.

Their PCB prototype boards are known for their high precision, excellent performance, and reliability, making them ideal for use in advanced electronic devices and applications. In addition, they offer quick turnaround times and competitive pricing, catering to the needs of both small businesses and large corporations.

The company's dedication to research and development has allowed them to stay ahead of the curve in terms of technology and innovation. They continue to invest in cutting-edge equipment and software to improve their manufacturing processes and develop new products that meet the evolving needs of the market.

Furthermore, their commitment to environmental sustainability has also set them apart from their competitors. They have implemented eco-friendly practices in their production processes, such as waste reduction and energy conservation, to minimize their environmental impact and contribute to a greener and more sustainable future.

With a strong focus on customer satisfaction, they have established a robust customer support system to provide personalized and efficient services to their clients. Whether it's technical assistance, product customization, or after-sales support, they are dedicated to meeting the specific needs and requirements of each customer.

Moreover, they have also been actively expanding their global market reach by establishing partnerships and collaborations with distributors and agencies in key regions around the world. This strategic approach has allowed them to gain a stronger foothold in international markets and serve a wider customer base.

As a result of their efforts, they have seen a significant increase in demand for their PCB prototype boards from customers in Europe, North America, and Asia. They have successfully penetrated new markets and secured long-term partnerships with leading companies in various industries, further solidifying their position as a trustworthy and reliable supplier of PCB prototype boards.

Looking ahead, they remain committed to pushing the boundaries of innovation and excellence in the field of PCB prototype boards. They will continue to invest in research and development, expand their production capacity, and enhance their global presence to meet the ever-changing needs of the electronics industry.

In conclusion, China-based PCB prototype board suppliers are making significant strides in the global market, thanks to their commitment to quality, innovation, and customer satisfaction. As they continue to expand their reach and capabilities, they are poised to play a crucial role in driving the advancement of electronic technologies and powering the next generation of innovative devices and applications.

Company News & Blog

Top Motor Controller PCB Supplier for High-Quality Products

Motor Controller PCB Supplier, a leading provider of innovative printed circuit boards for motor controllers, has announced the launch of their latest range of high-performance PCBs for use in a wide variety of motor control applications. The company has established a strong reputation as a reliable and trusted supplier of PCBs to the motor control industry, and this latest product release is set to further solidify their position in the market.With a focus on delivering high-quality, reliable, and cost-effective solutions, Motor Controller PCB Supplier has quickly become the go-to source for motor controller PCBs for many companies in the industry. Their team of experienced engineers and designers work closely with customers to develop custom PCB solutions that meet their specific requirements, ensuring that their products are able to deliver exceptional performance in the most demanding applications.The latest range of PCBs from Motor Controller PCB Supplier is designed to provide superior performance and reliability, making them an ideal choice for a wide range of motor control applications. Whether it's for use in industrial automation, robotics, electric vehicles, or any other motor control system, their PCBs are built to deliver the level of performance that customers demand.In addition to their commitment to delivering high-quality products, Motor Controller PCB Supplier also takes pride in offering exceptional customer service. They understand the importance of providing support and assistance to their customers throughout the entire product development and manufacturing process, and their team is always on hand to offer expert advice and guidance.One of the key advantages of working with Motor Controller PCB Supplier is their ability to provide custom solutions that are tailored to the specific needs of their customers. Their team is able to work closely with customers to understand their requirements and develop PCB solutions that are perfectly suited to their applications. This level of customization allows customers to benefit from PCBs that are optimized for their specific needs, delivering the best possible performance and reliability.As a company, Motor Controller PCB Supplier is committed to staying at the forefront of technological advancements in the motor control industry. They invest heavily in research and development to ensure that their products are able to meet the evolving needs of their customers, and their latest range of PCBs is a testament to this commitment. By leveraging the latest technologies and manufacturing processes, they are able to deliver PCB solutions that offer unparalleled performance and reliability.With their latest range of high-performance PCBs for motor controllers, Motor Controller PCB Supplier is well-positioned to continue their success in the industry. Their commitment to delivering high-quality products, exceptional customer service, and innovative solutions has set them apart as a leader in the market, and their latest product release only serves to further solidify that position. As the motor control industry continues to evolve, Motor Controller PCB Supplier remains a trusted partner for companies looking for reliable and high-performance PCB solutions.

Top 8 Layer PCB Manufacturers: Exemplary Options for Quality Circuit Boards

article on the importance of PCBs in modern electronics.In today's world, electronic devices play an integral role in our daily lives. From mobile phones to laptops to medical equipment, we rely heavily on these gadgets. As we continue to advance technologically, the need for smaller, faster, and more efficient devices increases. This is where PCBs become critical, as they provide a crucial foundation for electronic components.Printed Circuit Boards (PCBs) are thin, flat boards made from insulating material with conductive pathways etched on its surface. These pathways or copper traces connect the electronic components and provide electrical connections between them. The use of PCBs has replaced the traditional wire-based circuits, as they are more reliable, robust, and compact. Moreover, PCBs enable designers to create intricate circuits and reduce the overall electronic device size significantly.One of the major advantages of PCBs is their versatility. They can design and manufacture in various shapes and sizes, depending on the application. They can feature a single layer with a few components or a multi-layered board with hundreds of components. Furthermore, PCBs can work over a wide range of frequencies, from radio frequencies to high-speed digital data rates.The PCB manufacturing process is complex and follows a set of procedures to ensure that the end product is of high quality. The manufacturing starts with designing the circuit layout on a computer-aided design software (CAD). The layout specifies the placement of components and traces, which should work correctly to achieve the desired output. After this, the design is exported to a manufacturing machine, which etches the copper traces on the board. Once the traces are complete, the board goes through a series of quality checks to avoid any defects. The next phase is to drill holes for the components and apply a solder mask to prevent any short circuits. Finally, the board is tested for electrical continuity and quality.A PCB manufacturer plays a crucial role in determining the performance and reliability of the electronic device. A manufacturer with experience and expertise can ensure that the board meets the desired specifications and standards. Furthermore, a good PCB manufacturer continuously upgrades its technologies and manufacturing techniques to cater to the increasing demand for high-performance devices.In light of this, 8 Layer PCB Manufacturer is one of the leading companies in the industry. With more than 20 years of experience, the company has established itself as a provider of high-quality PCBs. The company specializes in manufacturing multi-layered boards, rigid-flex, and HDI PCBs. 8 Layer PCB Manufacturer follows strict quality control procedures and provides 24/7 customer support to ensure that its clients get the best products and services.The importance of PCBs can be seen in various industries, such as automotive, healthcare, aerospace, and consumer electronics. They are used in critical applications, such as pacemakers, airplanes, and control systems. These industries demand high-quality, reliable, and efficient PCBs to meet their specific requirements.In conclusion, PCBs are an essential component of electronic devices, and their importance will continue to grow as we advance technologically. With the increasing demand for compact, fast, and efficient devices, the role of PCBs becomes even more crucial. A reliable and competent PCB manufacturer, such as 8 Layer PCB Manufacturer, is vital to meeting the demands of the industry. The use of high-quality PCBs ensures that electronic devices are reliable, robust, and efficient, which is crucial in today's interconnected world.

The Importance of PCB Board Thickness in Electronics Manufacturing

Introducing the PCB Board Thickness NewsIn the fast-paced world of technology, Printed Circuit Boards (PCBs) play a crucial role in powering electronic devices. These boards are the backbone of most electronic devices, providing the necessary connections and pathways for electrical components to function seamlessly. The thickness of PCB boards is a critical factor in determining their performance and reliability. In this news release, we will delve into the importance of PCB board thickness and how it impacts the overall functionality of electronic devices.The thickness of a PCB board is a key consideration in its design and manufacturing process. It directly affects the board's mechanical strength, impedance control, and overall performance. A thinner PCB board may offer a reduced form factor and lighter weight, but it may also be more prone to bending or warping, which can lead to electrical issues and component failure. On the other hand, a thicker PCB board provides better mechanical stability and can withstand higher levels of stress and vibration, making it ideal for applications where durability is paramount.In the world of PCB manufacturing, the standard thickness of a PCB board is typically denoted in millimeters (mm) or mils (1/1000 of an inch). The most commonly used PCB thickness is 1.6mm, which is suitable for a wide range of electronic applications. However, the demand for thinner and more lightweight PCB boards has been steadily increasing, driven by the evolution of compact and portable electronic devices. As a result, PCB manufacturers are constantly striving to develop innovative solutions that offer both thinness and durability.{Company Introduction} is at the forefront of PCB manufacturing and has been a pioneer in developing cutting-edge PCB technologies. With a strong focus on quality, innovation, and customer satisfaction, {Company Name} has consistently delivered high-performance PCB solutions to a diverse range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Their state-of-the-art manufacturing facilities and extensive industry experience have positioned them as a trusted leader in the field of PCB manufacturing.Recognizing the growing demand for thinner PCB boards, {Company Name} has dedicated significant resources to research and development efforts aimed at producing ultra-thin yet durable PCB solutions. By leveraging advanced fabrication techniques and materials, {Company Name} has successfully engineered PCB boards with reduced thicknesses while maintaining superior mechanical and electrical performance. These advancements have opened up new possibilities for designing smaller, lighter, and more efficient electronic devices, driving innovation across various industries.{Company Name} understands the critical role that PCB board thickness plays in the performance and reliability of electronic devices. By offering a diverse portfolio of PCB solutions with varying thickness options, {Company Name} ensures that their customers have access to the most suitable PCB boards for their specific application requirements. Whether it's a compact, handheld device or a rugged, industrial application, {Company Name} can tailor their PCB solutions to meet the exacting standards of their customers, providing unmatched reliability and performance.In conclusion, the thickness of PCB boards is a crucial factor that directly impacts the functionality and reliability of electronic devices. As the demand for thinner and more lightweight PCB boards continues to rise, {Company Name} remains committed to delivering innovative, high-performance PCB solutions that meet the evolving needs of the industry. Through their dedication to research and development, {Company Name} is shaping the future of PCB manufacturing, offering advanced solutions that empower the next generation of electronic devices. With a steadfast commitment to quality and excellence, {Company Name} is a trusted partner for businesses seeking cutting-edge PCB solutions.

Rapid PCB Factory in China - Speedy Manufacturing for Printed Circuit Boards

Title: China's Rapidly Expanding PCB Manufacturing Industry: Catalyzing Global Technological AdvancementsIntroduction:Over the past decade, China's PCB manufacturing industry has seen exponential growth, leading the way in meeting global demands for printed circuit boards (PCBs). One of the key players, China Fast Turn PCB Factory (name removed), has emerged as a major contributor to the country's success in this sector. With its state-of-the-art facilities and commitment to delivering efficient and high-quality products, China Fast Turn PCB Factory has become a prominent force in the realm of PCB manufacturing.Company Overview:China Fast Turn PCB Factory, based in [location], has positioned itself as a leading provider of PCB manufacturing services, serving both domestic and international clients. With a rich experience spanning [number of years] years, the factory has continually strived to improve its services to meet the dynamic requirements of the industry.The factory's dedication to innovation and cutting-edge technology has propelled it to the forefront of the PCB manufacturing sector. Its extensive range of offerings includes single-sided, double-sided, and multi-layer PCBs, catering to various industries such as automotive, telecommunications, consumer electronics, and more.State-of-the-Art Facilities:China Fast Turn PCB Factory boasts modern manufacturing facilities equipped with advanced machinery and production lines. The factory has heavily invested in technological advancements to enhance production efficiency and accuracy. Through the utilization of automated production processes, the factory significantly reduces turnaround times while maintaining the highest standards of quality.Quality Assurance:At China Fast Turn PCB Factory, quality is a top priority. The factory adheres to rigorous quality control measures throughout the production process to ensure the reliability and performance of its PCBs. Stringent inspections are conducted at each stage, from the procurement of raw materials to the final delivery, to guarantee that every product meets or exceeds industry standards.Commitment to Sustainability:China Fast Turn PCB Factory is committed to environmentally responsible practices. The factory actively adopts eco-friendly manufacturing techniques and materials, minimizing waste generation and promoting recycling initiatives. By adhering to sustainable production methods, China Fast Turn PCB Factory not only reduces its environmental impact but also aligns itself with global sustainability goals.Market Reach:With a customer-oriented approach, China Fast Turn PCB Factory has established a robust global market presence. Its diverse clientele includes renowned electronics manufacturers, research institutions, and startups, illustrating the broad range of industries the factory caters to. By maintaining strong partnerships with customers and continuously adapting to their evolving needs, China Fast Turn PCB Factory consolidates its position as a trusted and reliable PCB supplier.Driving Technological Advancements:As China Fast Turn PCB Factory plays a pivotal role in the PCB manufacturing sector, its relentless pursuit of technological advancements contributes to the overall growth and innovation of the global electronics industry. By providing cutting-edge PCB solutions, the factory supports the development of state-of-the-art technologies such as 5G, Internet of Things (IoT), artificial intelligence, and electric vehicles.Conclusion:China Fast Turn PCB Factory's emergence as a dominant player in China's PCB manufacturing industry has propelled the country's technological advancements on a global scale. With state-of-the-art facilities, commitment to quality, and a customer-centric approach, the factory continues to meet the ever-increasing demands of the electronics industry. As China Fast Turn PCB Factory continues to evolve, it will undoubtedly remain at the forefront of PCB manufacturing, shaping the future of the global technology landscape.

Exploring the Efficiency and Quality of Quick Turn PCB Fabrication in China

China, a global manufacturing powerhouse, has been known for its rapid turnaround time and high-quality products. In line with this reputation, the country's quick turn PCB fabrication industry has seen remarkable growth in recent years. One of the leading players in this sector is a prominent company that has made a name for itself in the PCB fabrication market.Established in (Year), (Company Name) has quickly emerged as a frontrunner in quick turn PCB fabrication in China. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, the company has been able to cater to the growing demand for fast and reliable PCB fabrication services.The success of (Company Name) can be attributed to several factors. Firstly, their commitment to quality sets them apart from their competitors. The company adheres to stringent quality control measures at every stage of the manufacturing process to ensure that the PCBs they produce meet the highest industry standards. This dedication to quality has earned them a reputation for delivering flawless PCBs consistently.In addition to their commitment to quality, (Company Name) emphasizes speed and efficiency. The company understands the time-sensitive nature of the PCB fabrication industry and is fully equipped to handle quick turnaround times. Through streamlined processes and cutting-edge technology, they are able to rapidly produce PCBs without compromising on quality.Furthermore, (Company Name) offers a wide range of PCB fabrication services to cater to the diverse needs of their clients. Whether it is single-layer, double-layer, or multi-layer PCBs, the company has the expertise and resources to handle any project. They also have the capability to manufacture PCBs of various sizes and complexities, ensuring that they can meet the unique requirements of their customers.Another strength of (Company Name) lies in their commitment to customer satisfaction. The company values open communication and collaboration with their clients, ensuring that every project is tailored to meet their specific needs. This customer-centric approach has earned them a loyal customer base and numerous positive testimonials.As a leading player in the quick turn PCB fabrication market, (Company Name) also places great importance on innovation. They constantly invest in research and development to stay ahead of industry trends and technologies. By keeping up with the latest advancements in PCB fabrication, they are able to offer their clients cutting-edge solutions that meet their evolving needs.Looking ahead, (Company Name) has ambitious plans for expansion. They aim to further strengthen their position in the quick turn PCB fabrication industry by continuously improving their manufacturing capabilities and exploring new markets. With China's booming manufacturing sector and their competitive advantage, the company is well poised to achieve its growth goals.In conclusion, (Company Name) has established itself as a leader in quick turn PCB fabrication in China by focusing on quality, speed, customer satisfaction, and innovation. With their unwavering commitment to excellence, the company has proven to be a reliable partner for businesses seeking fast and reliable PCB fabrication services. As China's manufacturing industry continues to flourish, (Company Name) is well-positioned to capitalize on the growing demand for quick turn PCBs and further expand its presence in the market.

Explore the Benefits of Using Lead-Free Manufacturers for Your Product Needs

Hasl Lead Free Manufacturer Leads the Charge Towards a Sustainable FutureAs the world becomes increasingly aware of the environmental impact of industrial processes and products, companies across all sectors are under increasing pressure to incorporate sustainability into their business models. In the electronics manufacturing industry, one key area that has come under scrutiny is the use of lead in the manufacturing process. Hasl Lead Free Manufacturer, however, is leading the charge towards a more sustainable future.Founded in 2005, Hasl Lead Free Manufacturer has established itself as a leading provider of high-quality printed circuit boards (PCBs) and related services, with a particular focus on the development and production of environmentally-friendly products. By replacing lead-based components with eco-friendly alternatives, the company has been able to significantly reduce its environmental impact without sacrificing quality or performance.One of the key challenges facing the electronics industry is the disposal of waste materials, particularly those that contain hazardous substances. Traditional lead-based PCB manufacturing processes have been identified as a major contributor to this problem, as they generate large quantities of lead waste that can be difficult to handle, store, and dispose of safely.Hasl Lead Free Manufacturer, however, has embraced a more sustainable approach to manufacturing. By using lead-free components and implementing environmentally-friendly production processes, the company has significantly reduced its waste output. In addition, the company has implemented an extensive recycling program, which recovers and reuses materials that would otherwise be discarded as waste.This commitment to sustainability extends beyond the manufacturing process. Hasl Lead Free Manufacturer takes an end-to-end approach to sustainable business practices, from sourcing raw materials to the final delivery of finished products. The company’s supply chain is carefully evaluated to ensure that all suppliers meet strict environmental and ethical standards, and all products are shipped using eco-friendly packaging materials.In addition to its sustainability efforts, Hasl Lead Free Manufacturer is known for its commitment to quality and innovation. The company’s team of experienced engineers and technicians work closely with clients to understand their unique needs and develop custom solutions that meet and exceed their expectations. This customer-centric approach has earned the company a reputation for exceptional service and high-quality products.Hasl Lead Free Manufacturer’s commitment to sustainability has made it a leader in the electronics manufacturing industry, and its success has not gone unnoticed. In 2020, the company was recognized with the prestigious Green Award for its outstanding efforts to reduce its environmental impact and promote sustainability in the industry.Looking ahead, Hasl Lead Free Manufacturer is committed to continuing its work towards a more sustainable future. The company is investing in new technologies and processes that will further reduce its environmental impact, and is actively seeking out partnerships and collaborations with other like-minded companies and organizations.In a world where environmental concerns are at the forefront of public consciousness, Hasl Lead Free Manufacturer has established itself as a trailblazer in the electronics industry. Its commitment to sustainability, quality, and innovation has set the standard for others to follow, and its future looks brighter than ever as it continues to lead the charge towards a more sustainable future.

Ultimate Guide to Soldering a Prototype Board

The demand for electronic prototypes and small-scale production runs is on the rise, and as a result, many companies are turning to {Company Name} for their prototype board soldering needs. {Company Name} is a leading provider of electronic manufacturing services, offering a wide range of solutions for the design and production of electronic components and assemblies.One of the key services offered by {Company Name} is prototype board soldering, which is a crucial step in the manufacturing process for electronic devices. Prototype board soldering involves the assembly of electronic components onto a prototype board using advanced soldering techniques. This process requires precision and expertise to ensure the reliability and functionality of the final product.{Company Name} has a team of highly skilled and experienced technicians who are experts in prototype board soldering. They have the knowledge and expertise to work with a wide range of electronic components and materials, and they use the latest soldering equipment and techniques to ensure the highest quality results.In addition to prototype board soldering, {Company Name} offers a comprehensive range of electronic manufacturing services, including PCB assembly, cable and wire harness assembly, box build assembly, and testing and inspection services. The company's state-of-the-art facility is equipped with the latest technology and machinery to handle any project, large or small.{Company Name} takes pride in its commitment to quality and customer satisfaction. The company is ISO 9001 certified, which demonstrates its dedication to maintaining the highest standards of quality in its manufacturing processes. {Company Name} also follows strict quality control measures at every stage of the production process to ensure that all products meet the highest standards of performance and reliability.The company's dedication to excellence has earned it a reputation as a trusted partner for electronic manufacturing services. {Company Name} has built strong relationships with a wide range of clients, including startups, small businesses, and large corporations. The company's ability to deliver high-quality, reliable products on time and within budget has made it a preferred choice for many companies in need of electronic manufacturing services.{Company Name} is committed to staying at the forefront of the electronic manufacturing industry. The company continuously invests in research and development to explore new technologies and techniques that can improve its manufacturing processes and deliver even better results for its clients. {Company Name} also places a strong emphasis on sustainability and environmental responsibility, striving to minimize its impact on the environment through eco-friendly manufacturing practices.With its comprehensive range of electronic manufacturing services, state-of-the-art facility, and commitment to quality and innovation, {Company Name} is well-positioned to meet the growing demand for prototype board soldering and other electronic manufacturing services. The company's relentless focus on excellence and customer satisfaction sets it apart as a leader in the industry, and its dedication to staying ahead of the curve ensures that it will continue to be a trusted partner for electronic manufacturing needs for years to come.

Top 5 Best PC Circuit Boards for Your Computer

**PC Circuit Board Company Unveils Cutting-Edge Technology to Revolutionize the Industry****Introduction:**PC Circuit Board Company, a leading provider of high-quality circuit boards, has unveiled a new cutting-edge technology that is set to revolutionize the industry. The company has been at the forefront of innovation in the field of electronic components and has a strong track record of providing state-of-the-art products to its customers.With a commitment to excellence and a focus on research and development, PC Circuit Board Company has positioned itself as a market leader in the production of circuit boards for various applications. The company's dedication to quality, reliability, and customer satisfaction has earned it a solid reputation in the industry.**News Content:**PC Circuit Board Company has announced the launch of its latest innovation in circuit board technology, which promises to set a new standard for performance and reliability in electronic components. The new technology, developed after years of research and development, is a result of the company's commitment to pushing the boundaries of what is possible in the field of circuit board manufacturing.The new circuit board technology boasts several key features that set it apart from traditional products. One of the most significant advancements is the use of advanced materials that offer improved durability and resistance to environmental factors such as temperature fluctuations and moisture. This ensures that the circuit boards can withstand harsh conditions and maintain their performance over an extended lifespan.In addition to its enhanced durability, the new technology also offers improved electrical performance, with reduced signal loss and higher signal integrity. This is particularly important in high-speed applications where maintaining signal integrity is crucial for the overall performance of electronic systems.Furthermore, the new circuit board technology incorporates advanced manufacturing processes that enable tighter tolerances and finer traces, resulting in increased precision and reliability. This level of precision is essential for applications where space is limited, and complex circuitry needs to be integrated into compact designs.The introduction of this cutting-edge technology solidifies PC Circuit Board Company's position as a leader in the industry. The company has once again demonstrated its commitment to innovation and excellence, delivering solutions that meet the evolving needs of its customers."We are thrilled to introduce this state-of-the-art circuit board technology to the market," said [Company Spokesperson]. "This innovation represents a significant leap forward in the capabilities of electronic components, and we are confident that it will make a meaningful impact across various industries."The new circuit board technology is already generating significant interest among industry professionals, with several leading manufacturers expressing interest in incorporating it into their products. The potential applications for this technology are vast, ranging from consumer electronics to aerospace and defense systems.PC Circuit Board Company is set to begin mass production of the new circuit boards in the coming months, with initial shipments expected to be available to customers by the end of the year. The company is also ramping up its marketing efforts to raise awareness of the new technology and showcase its capabilities to potential customers.As the industry continues to evolve, PC Circuit Board Company remains committed to pushing the boundaries of what is possible in circuit board technology. With a solid track record of innovation and a dedication to customer satisfaction, the company is well-positioned to maintain its leadership in the market and continue driving progress in the field of electronic components.

Understanding the Layers of Printed Circuit Boards: An In-Depth Look

Printed Circuit Board Layers: Enhancing Connectivity and Efficiency in Electronic DevicesIn today's fast-paced world, electronic devices have become an integral part of our lives. From smartphones and tablets to smart appliances and wearable technology, these devices have transformed the way we communicate, work, and relax. At the core of these electronic marvels lies a crucial component known as the Printed Circuit Board, or PCB. Printed Circuit Board Layers play a pivotal role in enhancing connectivity and efficiency in electronic devices.A PCB is a flat board made of non-conductive material, such as fiberglass, with electronic components mounted on it. Layers of conductive material, such as copper, are etched onto the board to create pathways for electric currents to flow, enabling the transfer of information and power between the various components. These layers are implemented through a highly precise and intricate process, ensuring optimal functionality and reliability.One of the key aspects of a PCB is its layer structure. The number of layers in a PCB is determined by the complexity of the device it is being designed for. A simple electronic device may require only a single-layer PCB, while more complex devices, such as advanced medical equipment or high-performance computing systems, may require multiple layers to accommodate numerous components and circuits.The PCB layer formation process involves laminating multiple layers of etched copper sheets with insulating material in between. The number, arrangement, and interconnections of these layers are determined by the specific requirements of the device. These layers are meticulously designed to minimize noise, maximize signal integrity, and ensure efficient functioning of the device.As the demand for smaller, faster, and more powerful electronic devices continues to rise, the importance of PCB layer technology becomes increasingly evident. Multilayer PCBs offer several advantages over their single-layer counterparts. Firstly, the compact design of multilayer PCBs allows for increased component density. This leads to more functionality in a smaller form factor, making devices slimmer and more lightweight. Secondly, multilayer PCBs enable the implementation of complex interconnections between components, resulting in improved signal integrity and reduced interference. This translates to faster data transfer rates and enhanced overall performance. Additionally, the use of multilayer PCBs allows for better heat dissipation, ensuring that electronic devices operate within their optimal temperature range, thereby increasing their lifespan.Furthermore, advancements in PCB layer technology have brought about the development of High-Density Interconnect (HDI) PCBs. HDI PCBs provide even greater design flexibility and reliability. They boast smaller vias and microvias, allowing for higher component density, improved signal integrity, and reduced power consumption. HDI PCBs are particularly beneficial in applications where space is limited, such as in mobile phones, smartwatches, and automotive electronics.The market for Printed Circuit Board Layers is witnessing significant growth due to the escalating demand for advanced electronic devices and the ongoing technological advancements in the industry. Several companies have emerged as pioneers in the field, employing cutting-edge manufacturing processes and innovative designs to meet the evolving needs of the market.One such company, {}, is at the forefront of PCB layer technology. With years of experience and a commitment to excellence, they offer a wide range of PCB layer solutions tailored to different industries and applications. Their expertise lies in the development of multilayer and HDI PCBs that deliver exceptional performance, reliability, and quality. By leveraging their in-house engineering expertise and state-of-the-art facilities, they ensure that their PCB layers meet the stringent standards of today's electronic devices.In conclusion, Printed Circuit Board Layers are vital components that enable the seamless functioning of electronic devices. Whether it's improving connectivity, enhancing performance, or reducing size, the layer structure plays a critical role. With advancements in technology, multilayer PCBs and HDI PCBs have revolutionized the industry, enabling the creation of smaller, more powerful, and energy-efficient devices. As companies like {} continue to push the boundaries of innovation, the potential for further advancements in PCB layer technology remains promising, driving the evolution of the electronic devices we rely on every day.

Quick and Efficient PCB Fabrication Services for Your Business

Fast PCB Fabrication: Revolutionizing the Electronics IndustryIn today's fast-paced world, the demand for electronic devices is at an all-time high. From smartphones and laptops to medical devices and automotive components, the need for high-quality, reliable printed circuit boards (PCBs) has never been greater. That's where the innovative technology and expertise of [Company Name] come into play.[Company Name] is a leading provider of fast PCB fabrication services, offering a range of solutions to meet the diverse needs of the electronics industry. With state-of-the-art facilities and a team of experienced professionals, [Company Name] is revolutionizing the way PCBs are manufactured, leading to faster turnaround times and superior quality.The technology and processes utilized by [Company Name] allow for rapid PCB fabrication without compromising on quality. This is made possible through the use of advanced machinery and automation, which reduce production times and increase efficiency. Furthermore, their team of highly skilled engineers and technicians ensures that every PCB meets the highest standards of reliability and performance.One of the key advantages of partnering with [Company Name] is the ability to expedite the entire PCB fabrication process. With traditional methods, the design and manufacturing of PCBs can be a lengthy and time-consuming process. However, [Company Name] has streamlined this process, allowing for quick turnaround times that are essential in today's fast-paced electronics industry.Furthermore, [Company Name] offers a range of customization options to meet the specific needs of their clients. Whether it's a complex multilayer PCB or a standard single-layer board, [Company Name] has the capabilities to deliver high-quality, customized solutions in a fraction of the time it would take with traditional methods.The impact of fast PCB fabrication goes beyond just speed and efficiency. By reducing production times, [Company Name] is able to help their clients bring their products to market faster, gaining a competitive edge in their respective industries. This can be particularly beneficial for companies developing cutting-edge technologies or those operating in rapidly evolving markets.In addition to their fast PCB fabrication services, [Company Name] is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices throughout their manufacturing process, minimizing waste and reducing their carbon footprint. This commitment to sustainability ensures that clients can rely on [Company Name] not only for fast and reliable PCB fabrication but also for environmentally conscious solutions.As [Company Name] continues to push the boundaries of PCB fabrication, they are also exploring new frontiers in technology. By investing in research and development, they are constantly looking for ways to innovate and improve their processes, ultimately benefiting their clients with even faster turnaround times and higher-quality PCBs.Clients who partner with [Company Name] can expect a seamless and efficient experience from the initial design phase to the final delivery of their PCBs. With a strong emphasis on customer satisfaction, [Company Name] is dedicated to providing top-notch service and support at every step of the process.In conclusion, fast PCB fabrication is reshaping the electronics industry, and [Company Name] is at the forefront of this revolution. By combining cutting-edge technology, expertise, and a commitment to sustainability, [Company Name] is setting new standards for speed, efficiency, and quality in PCB manufacturing. As the demand for electronic devices continues to grow, [Company Name] is well-positioned to meet the needs of clients across various industries, making them an invaluable partner in the fast-paced world of electronics manufacturing.