Top Tips for Designing an Electrical PCB for Effective Circuitry

By:Admin

One company that has established a strong presence in the PCB industry is {}. With their state-of-the-art manufacturing facilities and commitment to innovation, they have become a trusted partner for companies looking for high-quality PCB solutions.

Founded in {}, {}, has grown to become a leading manufacturer of PCBs, offering a wide range of products to meet the diverse needs of their customers. They are known for their expertise in producing complex multi-layer PCBs, high-density interconnect (HDI) boards, and flexible PCBs, among others.

In addition to their extensive product range, the company also prides itself on its commitment to quality and reliability. They adhere to strict quality control processes throughout the manufacturing process, ensuring that each PCB meets the highest standards of performance and durability. This commitment to quality has earned them a solid reputation in the industry and has helped them build long-lasting relationships with their customers.

Furthermore, the company has made significant investments in research and development, allowing them to stay at the forefront of technological advancements in the PCB industry. Their team of experienced engineers and technicians are constantly exploring new materials, processes, and design techniques to improve the performance and functionality of their PCBs.

One of the key strengths of {} is their ability to provide custom PCB solutions to meet the unique requirements of their clients. They work closely with their customers to understand their specific needs and then develop tailored PCB solutions that address those needs effectively.

Another notable aspect of the company is their commitment to environmental sustainability. They have implemented eco-friendly manufacturing processes and are dedicated to reducing their carbon footprint. By using recyclable materials and minimizing waste, they are contributing to a greener and more sustainable future.

In recent news, {} has announced the launch of a new line of advanced PCB products that are designed to meet the growing demand for high-performance and reliable electronic devices. These new PCBs leverage the latest technologies and materials to deliver enhanced functionality and durability, making them ideal for a wide range of applications.

The company's CEO, {} stated, "We are excited to introduce our latest line of PCB products, which represent the culmination of our ongoing commitment to innovation and excellence. These new PCBs are the result of extensive research and development, and we are confident that they will set new standards for performance and reliability in the industry."

With their dedication to quality, innovation, and customer satisfaction, {} continues to be a leading force in the PCB industry. Their relentless pursuit of excellence and their ability to adapt to the evolving needs of the market have positioned them as a trusted partner for companies seeking high-quality PCB solutions. As they continue to push the boundaries of PCB technology, they are set to make even greater contributions to the advancement of electronic devices in the years to come.

Company News & Blog

Top 8 Layer PCB Manufacturers: Exemplary Options for Quality Circuit Boards

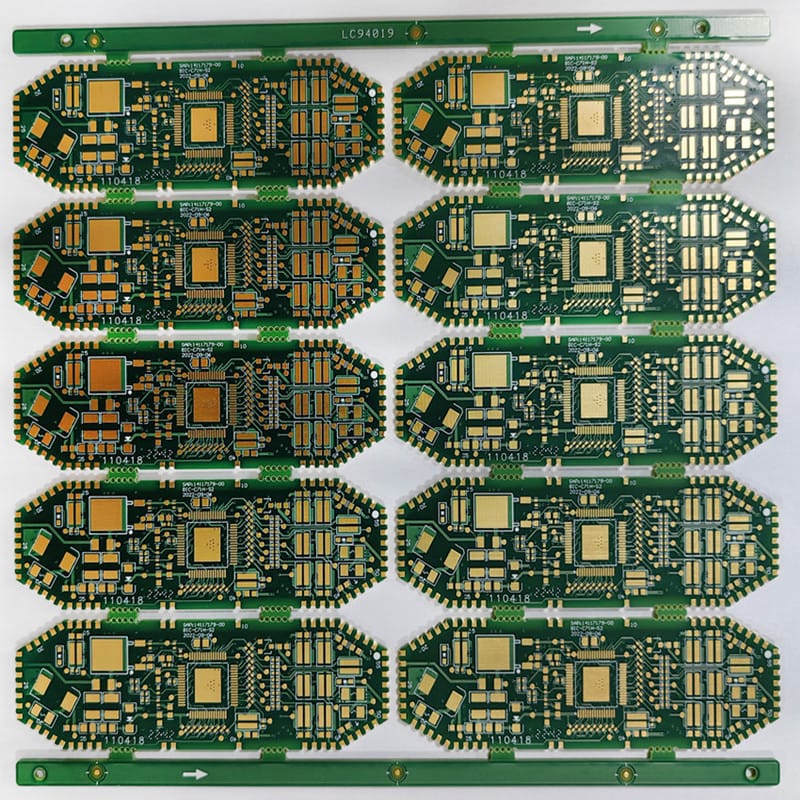

article on the importance of PCBs in modern electronics.In today's world, electronic devices play an integral role in our daily lives. From mobile phones to laptops to medical equipment, we rely heavily on these gadgets. As we continue to advance technologically, the need for smaller, faster, and more efficient devices increases. This is where PCBs become critical, as they provide a crucial foundation for electronic components.Printed Circuit Boards (PCBs) are thin, flat boards made from insulating material with conductive pathways etched on its surface. These pathways or copper traces connect the electronic components and provide electrical connections between them. The use of PCBs has replaced the traditional wire-based circuits, as they are more reliable, robust, and compact. Moreover, PCBs enable designers to create intricate circuits and reduce the overall electronic device size significantly.One of the major advantages of PCBs is their versatility. They can design and manufacture in various shapes and sizes, depending on the application. They can feature a single layer with a few components or a multi-layered board with hundreds of components. Furthermore, PCBs can work over a wide range of frequencies, from radio frequencies to high-speed digital data rates.The PCB manufacturing process is complex and follows a set of procedures to ensure that the end product is of high quality. The manufacturing starts with designing the circuit layout on a computer-aided design software (CAD). The layout specifies the placement of components and traces, which should work correctly to achieve the desired output. After this, the design is exported to a manufacturing machine, which etches the copper traces on the board. Once the traces are complete, the board goes through a series of quality checks to avoid any defects. The next phase is to drill holes for the components and apply a solder mask to prevent any short circuits. Finally, the board is tested for electrical continuity and quality.A PCB manufacturer plays a crucial role in determining the performance and reliability of the electronic device. A manufacturer with experience and expertise can ensure that the board meets the desired specifications and standards. Furthermore, a good PCB manufacturer continuously upgrades its technologies and manufacturing techniques to cater to the increasing demand for high-performance devices.In light of this, 8 Layer PCB Manufacturer is one of the leading companies in the industry. With more than 20 years of experience, the company has established itself as a provider of high-quality PCBs. The company specializes in manufacturing multi-layered boards, rigid-flex, and HDI PCBs. 8 Layer PCB Manufacturer follows strict quality control procedures and provides 24/7 customer support to ensure that its clients get the best products and services.The importance of PCBs can be seen in various industries, such as automotive, healthcare, aerospace, and consumer electronics. They are used in critical applications, such as pacemakers, airplanes, and control systems. These industries demand high-quality, reliable, and efficient PCBs to meet their specific requirements.In conclusion, PCBs are an essential component of electronic devices, and their importance will continue to grow as we advance technologically. With the increasing demand for compact, fast, and efficient devices, the role of PCBs becomes even more crucial. A reliable and competent PCB manufacturer, such as 8 Layer PCB Manufacturer, is vital to meeting the demands of the industry. The use of high-quality PCBs ensures that electronic devices are reliable, robust, and efficient, which is crucial in today's interconnected world.

Discover the Benefits of Lead-Free Technology in the Latest News Update

[News Title]: A New Era in Environmental Responsibility: Introducing Hass Lead Free[News Introduction]:In a world increasingly conscious of the environmental impact of industrial practices, the need for responsible and sustainable solutions has become paramount. Today, we are excited to introduce Hass Lead Free (name removed), a groundbreaking innovation that addresses the issue of lead pollution in an unprecedented way. Developed by an industry-leading company whose commitment to sustainability is second to none, this pioneering technology is set to revolutionize the manufacturing landscape.[News Body]:Lead, a highly toxic heavy metal, has long been a subject of concern due to its detrimental effects on human health and the environment. While efforts have been made to reduce its presence in various products, such as gasoline and paint, its integration into manufacturing processes has posed a significant challenge. This is where Hass Lead Free comes in.Developed by the ingenious minds at a renowned company, Hass Lead Free represents a breakthrough in the quest for safe and sustainable manufacturing practices. Building on years of research and development, this cutting-edge technology eliminates the need for lead throughout the entire manufacturing process, offering a viable alternative that reduces pollution and minimizes health risks.The implications of this innovation are far-reaching. Not only does Hass Lead Free reduce the environmental impact of manufacturing, but it also ensures safer working conditions for the employees involved. By completely removing lead from the equation, the risk of occupational exposure to this hazardous material is effectively nullified, safeguarding the well-being of all those involved in the production process.Furthermore, as the global demand for environmentally responsible products continues to rise, companies that embrace sustainable practices gain a competitive edge. Hass Lead Free allows manufacturers to align themselves with the growing consumer preference for eco-friendly products, enhancing their brand reputation and fostering long-term growth.The company behind this groundbreaking technology understands the importance of collaboration in addressing complex environmental challenges. With a strong commitment to corporate social responsibility, they have actively engaged in partnerships with industry leaders, governmental agencies, and research institutions to ensure the widest possible dissemination and implementation of their innovation. By sharing their knowledge and expertise, they are driving the transition towards a more sustainable future for all.Hass Lead Free also provides a cost-effective solution for manufacturers. By streamlining production processes, eliminating the need to handle and dispose of lead, and reducing the risk of regulatory non-compliance, companies can significantly decrease their operational costs and increase overall efficiency. This translates into a win-win scenario, where profitability goes hand in hand with environmental responsibility.Looking to the future, the developers of Hass Lead Free envision a world where lead pollution is a thing of the past. By pioneering this technology, they are setting the stage for a paradigm shift in manufacturing practices, inspiring others to follow suit and make sustainability a core principle of their operations. The potential positive impact on the environment, human health, and the economy is immeasurable.In conclusion, Hass Lead Free represents a significant step forward in the global effort to create a sustainable and responsible manufacturing industry. This revolutionary technology, developed by a leading company committed to environmental stewardship, has the potential to reshape the way we produce and consume goods. With greater awareness and adoption of such innovations, we can pave the way for a greener and more prosperous future.

Top Circuit Board Layout Factory in China - A Leader in PCB Design and Manufacturing

China Circuit Board Layout Factory Embarks on a Mission to Revolutionize Electronics ManufacturingWith the rapid advancements in technology, the demand for high-quality and efficient circuit boards has been on the rise. In order to meet this demand, China's leading circuit board layout factory is making groundbreaking strides in electronics manufacturing. The factory, located in the heart of China's industrial hub, has been at the forefront of innovation in the field of circuit board layout and manufacturing. With state-of-the-art equipment and a team of highly skilled engineers and technicians, the factory is able to produce high-quality and reliable circuit boards that meet the strictest industry standards. One of the key factors that sets this factory apart from its competitors is its commitment to excellence and innovation. The company invests heavily in research and development, constantly seeking new ways to improve the efficiency and reliability of its products. This dedication to innovation has resulted in the development of cutting-edge manufacturing techniques and technologies that have revolutionized the electronics manufacturing industry. In addition to its commitment to excellence, the factory also places a strong emphasis on sustainability and environmental responsibility. The company has implemented stringent environmental management systems, ensuring that its manufacturing processes have minimal impact on the environment. This commitment to sustainability has not only earned the factory recognition from industry regulators, but has also helped it build a strong reputation among environmentally-conscious customers. Furthermore, the factory's dedication to quality and reliability has made it a preferred supplier for many leading electronics manufacturers around the world. By consistently delivering products that exceed customer expectations, the factory has managed to build strong and long-lasting partnerships with its clients. In fact, the factory's reputation for reliability has led to an increase in demand for its products, prompting the company to expand its manufacturing capabilities in order to meet this growing demand. As part of its expansion plans, the factory has recently invested in new production lines and equipment, significantly increasing its manufacturing capacity. This expansion is not only expected to benefit the company's clients by ensuring a steady and reliable supply of circuit boards, but is also projected to create new employment opportunities in the region. Looking ahead, the factory aims to further expand its reach in the global electronics market. With its commitment to excellence, innovation, and sustainability, the company is well-positioned to become a leading player in the industry. By continuing to invest in cutting-edge technologies and manufacturing processes, the factory is confident that it will be able to meet the evolving needs of the electronics market and remain at the forefront of the industry. In conclusion, China's leading circuit board layout factory is on a mission to revolutionize electronics manufacturing. With its dedication to excellence, innovation, and sustainability, the company is set to make a lasting impact on the industry. By continuing to invest in research and development, expand its manufacturing capabilities, and build strong partnerships with its clients, the factory is well-positioned to achieve its vision of becoming a global leader in electronics manufacturing.

Essential Steps to Designing a PCB Board for Your Project

Design A PCB Board with the Latest TechnologyIn the world of technology and electronics, PCB (Printed Circuit Board) plays a crucial role in ensuring the functionality and efficiency of devices. A well-designed PCB board can make all the difference in the performance of electronic products, and that's why {Company Name} is proud to announce the release of its latest PCB board, designed with cutting-edge technology and innovation.{Company Name} is a leading provider of electronic components and solutions, with a strong focus on delivering high-quality PCB boards to meet the demands of various industries. With years of experience and expertise in PCB design and manufacturing, {Company Name} has established itself as a trusted partner for businesses looking for reliable and efficient electronic components.The newly designed PCB board from {Company Name} is a testament to the company's commitment to innovation and excellence. Using the latest technology and state-of-the-art manufacturing processes, the PCB board is built to deliver superior performance and reliability. Whether it's for consumer electronics, industrial equipment, medical devices, or automotive applications, the PCB board is designed to meet the highest standards and specifications.One of the key highlights of the new PCB board is its advanced design that allows for greater flexibility and customization. With a focus on miniaturization and space-saving capabilities, the PCB board is ideal for compact and portable electronic devices. Its high-density interconnects and multi-layer design enable greater functionality and performance, making it perfect for modern electronic applications.Furthermore, the PCB board is engineered to deliver exceptional signal integrity and power efficiency. With meticulous attention to detail and stringent quality control measures, {Company Name} ensures that the PCB board meets the industry's most demanding requirements, including high-speed data transmission, EMI/EMC compliance, and thermal management.In addition to its technical prowess, {Company Name} also takes pride in its environmental responsibility. The PCB board is manufactured using environmentally friendly materials and processes, ensuring that it meets RoHS and REACH compliance standards. This commitment to sustainability and eco-friendliness reflects {Company Name}'s dedication to ethical and responsible business practices.To complement the release of the new PCB board, {Company Name} also offers customized design and engineering services to meet the specific needs of its customers. Whether it's for prototyping, testing, or mass production, {Company Name} provides comprehensive support and expertise to help businesses bring their electronic products to market with confidence and success.As the demand for high-performance electronic components continues to grow, {Company Name} remains at the forefront of innovation, delivering reliable and efficient solutions to its customers worldwide. With the introduction of the latest PCB board, {Company Name} reaffirms its position as a leading provider of cutting-edge electronic components, setting new standards for quality, performance, and reliability in the industry.In conclusion, the release of the new PCB board from {Company Name} signifies a significant advancement in electronic design and manufacturing. With its state-of-the-art technology, advanced features, and commitment to excellence, the PCB board is set to make a lasting impact in various industries, empowering businesses to create innovative and competitive electronic products. For businesses looking for a trusted partner in electronic components, {Company Name} stands ready to deliver exceptional solutions that meet and exceed expectations.

What are LED Circuit Board Lights and How Do They Work?

Title: Illuminating the Future: Revolutionary LED Circuit Board Lights Set to Transform the Lighting IndustryIntroduction:In a breakthrough development that promises to revolutionize the lighting industry, a leading company has unveiled an innovative range of LED circuit board lights. Stripping off the traditional brand name, these state-of-the-art lighting solutions not only offer unparalleled energy efficiency but also boast superior brightness, longevity, and customization options to meet the diverse needs of consumers worldwide. As sustainable lighting becomes increasingly important, this groundbreaking introduction is set to leave a lasting impact on both domestic and commercial sectors.Unveiling the LED Circuit Board Lights:The latest offering from the company represents a significant leap forward in the lighting industry. By integrating cutting-edge LED technology into efficient circuit boards, these lights are able to provide brilliant illumination while consuming minimal energy. This impressive efficiency can lead to substantial cost savings and reduced carbon footprint, positioning the LED circuit board lights as a viable, eco-friendly alternative to conventional lighting solutions.Exceptional Brightness and Longevity:One key advantage of these LED circuit board lights is their ability to produce an exceptional level of brightness. Thanks to advanced light-emitting diodes, these lights emit a crisp and uniform illumination that enhances any space. The extended lifespan of LED technology ensures that these lights will provide unrivaled longevity, significantly reducing maintenance costs for both residential and commercial users.Customization Options:Recognizing the diverse needs of consumers, these LED circuit board lights are available in various shapes and sizes to cater to specific requirements. Whether it's for ambient lighting, task lighting, or accent lighting, these lights have the flexibility to transform any environment. Moreover, the customizable color spectrum allows users to tailor the lighting experience according to their preferences, creating an ambiance that perfectly complements any setting.Energy Efficiency and Environmental Sustainability:At a time when energy efficiency is of utmost importance, the LED circuit board lights have emerged as a game-changer. Consuming considerably less energy compared to traditional incandescent lights, they contribute to substantial energy savings and a reduced carbon footprint. The adoption of LEDs will undoubtedly aid in combating climate change and reducing electricity bills for eco-conscious consumers worldwide.Versatile Applications:The versatility of these LED circuit board lights opens up a plethora of applications across various sectors. From residential spaces to commercial establishments, these lights are ideal for lighting up homes, offices, restaurants, hotels, and retail outlets. Their exceptional design and functionality allow for seamless integration into existing lighting systems, ensuring a hassle-free transition for businesses and homeowners alike.Advancements in Smart Technology Integration:The company's focus on innovation extends to incorporating smart technology compatibility into their LED circuit board lights. With Internet of Things (IoT) becoming increasingly prevalent, users can now control lighting settings remotely, create automated schedules, and monitor energy consumption through intuitive smartphone apps or voice assistants. This integration of smart technology enhances convenience, maximizes energy savings, and further solidifies the company's commitment to pushing the boundaries of lighting solutions.Conclusion:As the world clamors for energy-efficient lighting solutions, the unveiling of the LED circuit board lights by this pioneering company signifies a breakthrough that will transform the lighting industry. With unparalleled brightness, longevity, customizable options, and energy efficiency, these lights are set to revolutionize the way residences and businesses illuminate their spaces. Embodying environmental sustainability and versatility, these LED circuit board lights herald a bright and efficient future for the lighting industry.

High-Quality Rigid PCB: The Ultimate Guide for Your Electronic Projects

Rigid PCB, also known as printed circuit boards, are the backbone of most electronic devices, providing a platform for different electronic components to communicate with each other. One company that has been making significant strides in the field of rigid PCB manufacturing is {}. With a strong focus on innovation and quality, the company has established itself as a leader in the industry.The company prides itself on its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. Their expertise in rigid PCB manufacturing has enabled them to cater to a wide range of industries, including consumer electronics, automotive, aerospace, and telecommunications. They have a strong commitment to research and development, constantly looking for new and improved ways to manufacture rigid PCBs that are more efficient and cost-effective.One of the key factors that set {} apart from its competitors is its dedication to quality. The company adheres to strict quality control measures at every stage of the manufacturing process, ensuring that each product that leaves their facilities meets the highest standards. This commitment to quality has earned them a strong reputation for reliability and performance in the industry. They have also obtained various certifications to validate their adherence to international quality standards, further cementing their position as a trusted manufacturer of rigid PCBs.In addition to their focus on quality, {} is also known for its ability to customize rigid PCBs according to the specific requirements of their clients. They understand that each industry and application has unique demands, and their flexible manufacturing processes enable them to tailor their products to meet these requirements. Whether it's a complex multilayer PCB for a high-tech electronic device or a simple single-layer board for a consumer product, {} has the capabilities to deliver customized solutions that meet their clients' needs.The company is also committed to environmental sustainability in its manufacturing processes. They have implemented various eco-friendly practices in their facilities, including recycling and waste reduction measures, to minimize their impact on the environment. This dedication to sustainability has made them a preferred partner for clients who prioritize environmental responsibility in their supply chain.With a strong focus on innovation, quality, customization, and environmental sustainability, {} continues to be a driving force in the rigid PCB manufacturing industry. Their commitment to excellence has earned them a loyal customer base and has positioned them as a preferred supplier for companies across various industries. As the demand for electronic devices continues to grow, {} is well-positioned to meet the evolving needs of the market and remain a leader in the field of rigid PCB manufacturing.

Fast PCB Prototyping Factory Offers Rapid Circuit Board Manufacturing

Fast PCB Prototyping Factory Enhances Its Production Capabilities to Meet Increasing DemandWith the electronic manufacturing industry experiencing exponential growth in recent years, Fast PCB Prototyping Factory has upgraded and expanded its production capabilities. The company aims to ensure it can meet the rising demand for high-quality printed circuit boards (PCBs) from a wide range of industries.Fast PCB Prototyping Factory, a leading player in the electronics manufacturing service (EMS) sector, has made significant investments in its machinery, technology, and workforce. These upgrades will bolster its production output and enable the company to keep up with the increased demand for PCBs in sectors such as automotive, aerospace, telecommunications, and consumer electronics.The company has added state-of-the-art automated assembly equipment to its production line, allowing for faster and more efficient manufacturing processes. This will not only increase productivity but also improve accuracy, consistency, and overall quality of the PCBs being produced. By investing in advanced technology, Fast PCB Prototyping Factory aims to stay ahead of its competitors and remain at the forefront of the industry.In addition to the equipment upgrades, the factory has expanded its facility to accommodate the growing demand. The increased space will allow for a higher volume of PCB production and provide room for future expansion as well. Fast PCB Prototyping Factory is committed to ensuring that its production capabilities can keep pace with the rapidly evolving needs of its customers.As part of its expansion, the company has also hired additional skilled technicians and engineers to strengthen its workforce. These professionals bring their expertise and knowledge, further enhancing the company's capabilities in PCB manufacturing. Fast PCB Prototyping Factory understands the importance of a skilled workforce in ensuring the delivery of high-quality products to its clients.Furthermore, the company's commitment to quality is underscored by its stringent quality control measures. Fast PCB Prototyping Factory adheres to international standards and regulations to provide customers with reliable and durable PCBs. Each PCB undergoes thorough testing and inspection to ensure it meets the required specifications and functions flawlessly.Fast PCB Prototyping Factory's dedication to customer satisfaction is reflected in its customer-oriented approach. The company works closely with its clients to understand their specific requirements and provide customized solutions. By taking into account factors such as design specifications, budget constraints, and time frames, Fast PCB Prototyping Factory ensures that its customers receive tailor-made products that meet their needs.The increased production capabilities of Fast PCB Prototyping Factory have already had a positive impact on its customers. Many clients have experienced faster turnaround times, reduced lead times, and improved overall efficiency. These benefits not only contribute to the success of individual projects but also enhance the competitiveness of the industries they serve.Looking to the future, Fast PCB Prototyping Factory aims to continue its expansion and innovation efforts. The company is exploring emerging technologies, such as flexible PCBs and high-density interconnects, to stay at the forefront of the industry. By staying proactive and responsive to market trends, the company aims to further enhance its production capabilities and maintain its position as a leading PCB manufacturer.In conclusion, Fast PCB Prototyping Factory has upgraded its production capabilities through investments in machinery, technology, and workforce to meet the increasing demand for high-quality PCBs. Its commitment to quality, customer satisfaction, and continuous improvement positions the company as a key player in the electronic manufacturing service industry. As the industry continues to evolve, Fast PCB Prototyping Factory remains dedicated to providing its customers with innovative and reliable solutions.

Quick Turn Prototype PCB Manufacturer: Short Lead Times and High-Quality Services

OEM Quick Turn Prototype PCB Manufacturer, a leading provider of high-quality printed circuit board (PCB) solutions, is proud to announce its expansion and increased capacity to meet the growing demands of the electronics industry. With a strong focus on quick turn and prototype PCB manufacturing, the company has established itself as a reliable and efficient partner for businesses in need of fast and high-quality PCB solutions.The company's growth and success can be attributed to its dedication to customer satisfaction, continuous improvement, and investment in advanced technology and equipment. As a result, OEM Quick Turn Prototype PCB Manufacturer has become a trusted partner for businesses in various industries, including telecommunications, automotive, medical devices, consumer electronics, and more.One of the key factors that set OEM Quick Turn Prototype PCB Manufacturer apart from its competitors is its commitment to providing quick turn and prototype PCB manufacturing services. This means that customers can rely on the company to deliver high-quality PCB solutions within tight deadlines, allowing them to accelerate their product development and time-to-market.Furthermore, OEM Quick Turn Prototype PCB Manufacturer is known for its exceptional customer service and technical support. The company's team of experienced engineers and technicians work closely with clients to understand their specific requirements and provide tailored solutions that meet and exceed their expectations. This level of personalized service has earned OEM Quick Turn Prototype PCB Manufacturer a strong reputation for reliability and professionalism.In addition to its quick turn and prototype PCB manufacturing services, OEM Quick Turn Prototype PCB Manufacturer offers a comprehensive range of PCB solutions, including single-sided, double-sided, and multi-layer boards. The company utilizes advanced manufacturing processes and state-of-the-art equipment to ensure the highest level of quality and consistency in every PCB it produces.As part of its commitment to continuous improvement, OEM Quick Turn Prototype PCB Manufacturer has recently made significant investments in its production facilities and equipment. This expansion has increased the company's manufacturing capacity, allowing it to handle larger volumes of orders while maintaining its quick turn and prototype capabilities.The company's dedication to quality and customer satisfaction is further reflected in its certifications and compliance with industry standards. OEM Quick Turn Prototype PCB Manufacturer is proud to hold ISO 9001 and UL certifications, demonstrating its commitment to delivering products that meet the highest quality and safety standards.In light of its recent expansion and increased capacity, OEM Quick Turn Prototype PCB Manufacturer is well-equipped to meet the evolving needs of the electronics industry. The company's ability to deliver quick turn and prototype PCB solutions, combined with its commitment to quality, customer service, and continuous improvement, makes it an ideal partner for businesses seeking reliable and efficient PCB manufacturing services.With a focus on innovation and excellence, OEM Quick Turn Prototype PCB Manufacturer is positioned to continue its growth and success in the years to come. The company looks forward to serving its clients with the same level of dedication and professionalism that has earned it a reputation as a leader in the PCB manufacturing industry.

Understanding the Different Classifications of PCBs and How They Impact Electronics Manufacturing

Title: Advanced Pcb Classification Technology Revolutionizes Electronics IndustryIntroduction (100 words):In an era driven by technological advancements, the electronics industry has witnessed remarkable growth. Behind every electronic device lies a Printed Circuit Board (PCB), an essential component that connects and supports an array of electronic components. As a leading technology company focused on innovative solutions, our company has recently developed groundbreaking Pcb Classification technology that promises to transform the electronics industry fundamentally. By simplifying manufacturing processes, improving efficiency, and enhancing product reliability, this cutting-edge solution ensures faster and more cost-effective production of high-quality PCBs.1. The Significance of PCB Classification (150 words):PCBs serve as the backbone of modern electronic devices, providing a reliable platform for interconnecting electronic components such as transistors, capacitors, and resistors. With the aim to enhance the performance and functionality of electronic products, our company has invested substantial resources in developing advanced PCB Classification technology.Historically, the PCB manufacturing process relied on manual sorting and classification of components, resulting in time-consuming processes, higher costs, and increased chances of human errors. However, our proprietary technology streamlines and automates this process, leveraging machine learning algorithms to accurately identify and categorize various PCB components within seconds. By efficiently classifying components based on their specifications, our technology reduces production time and costs significantly, ultimately improving the overall productivity of PCB manufacturing.2. Key Features and Benefits of PCB Classification Technology (200 words):Our revolutionary PCB Classification technology is built on a comprehensive dataset of PCB components, encompassing a vast range of industry standards. Leveraging cutting-edge machine learning algorithms, our software analyzes and classifies PCB components based on their unique characteristics, such as size, shape, material, and technical specifications.The key features and benefits of our PCB Classification technology include:a) Improved Efficiency: By automating the classification process, our technology eliminates the need for manual inspection, accelerating the production process. This results in faster turnaround times and allows manufacturers to meet tight deadlines.b) Cost and Resource Optimization: By reducing the need for manual labor involved in traditional classification methods, our technology significantly decreases production costs. Additionally, accurate categorization minimizes waste and enhances resource optimization, thereby improving the overall cost-effectiveness of PCB manufacturing.c) Enhanced Product Reliability: Our PCB Classification technology ensures the accurate selection of components, minimizing the chances of production errors and faulty connections. This leads to improved product reliability, reducing the risk of product recalls and enhancing brand reputation.d) Streamlined Supply Chain: With standardized classification and component identification, our technology facilitates smooth communication and collaboration in the supply chain. By simplifying component sourcing and procurement processes, manufacturers can optimize inventory management and reduce delays.3. Industry Impact and Future Prospects (150 words):The integration of PCB Classification technology is set to revolutionize the electronics industry. As the demand for smaller, more efficient electronic devices continues to grow, efficient and automated PCB manufacturing processes become increasingly crucial. By eliminating inefficiencies and reducing costs, our technology paves the way for the production of affordable and innovative electronic devices.Furthermore, the versatility of our technology allows its application in various sectors such as consumer electronics, telecommunications, automotive, aerospace, and medical devices. As the electronics industry continues to evolve rapidly, our PCB Classification technology empowers manufacturers to keep pace with the industry's demands.In conclusion, our cutting-edge PCB Classification technology represents a significant breakthrough in the electronics industry. By streamlining manufacturing processes, reducing costs, and enhancing product quality, this revolutionary solution has the potential to shape the future of PCB manufacturing and redefine the way electronic devices are produced.

Top Pcb Solder Manufacturers Embrace New Technologies in China" -> "Revolutionary Pcb Solder Manufacturing in China Leads by Example

Title: China's PCB Solder Manufacturers Innovate for a Resilient Electronics IndustryIntroduction:With the continuous advancement of technology, the global electronics industry has experienced unprecedented growth. In China, leading the charge in innovation and production in this sector, PCB solder manufacturers have become an essential component in powering this rapid development. In this article, we will delve into the world of China's prominent PCB solder manufacturers and explore their quest for innovation and resilience in this dynamic industry.Company Introduction:One of the key players in China's PCB solder manufacturing industry is {Company Name}. Founded in {Year}, the company has established itself as a trusted and reliable provider of high-quality solder products. With a commitment to innovation and customer satisfaction, {Company Name} has built a solid reputation both domestically and internationally.In line with China's focus on technological advancements, {Company Name} has consistently invested in research and development to enhance their product offerings. By leveraging their expertise and a highly skilled workforce, the company has been able to deliver solder products that meet the ever-evolving demands of the electronics sector.Key Strategies and Innovations:To stay ahead in a fiercely competitive market, China's PCB solder manufacturers have implemented several strategies and innovations. One such strategy is to improve the efficiency and effectiveness of the soldering process. Advanced equipment and automated systems have been introduced, resulting in higher production yields, reduced defect rates, and enhanced product quality.In addition to process improvements, these manufacturers have also focused on the development of eco-friendly soldering materials. As environmental concerns come to the forefront, the industry has realized the need to shift towards lead-free and RoHS-compliant solder alloys. China's PCB solder manufacturers have been at the forefront of this transition, developing innovative soldering solutions that meet global environmental standards.Collaboration and Partnerships:Recognizing the importance of collaboration, China's PCB solder manufacturers have actively sought partnerships with other industry players to foster innovation and exchange of knowledge. By working closely with electronic device manufacturers, component suppliers, and research institutions, these manufacturers have been able to gain insights into emerging trends and requirements, enabling them to develop tailor-made soldering solutions.Moreover, international collaborations have also played a significant role in the growth of China's PCB solder manufacturing industry. Through joint ventures and technology transfers, Chinese manufacturers have gained access to cutting-edge technologies and expanded their global presence.Export Opportunities:China's PCB solder manufacturers have consistently strengthened their export capabilities, catering to the international market's increasing demand for reliable soldering solutions. The country's efficient supply chains, competitive pricing, and stringent quality control have positioned Chinese manufacturers as preferred partners for multinational electronics companies.As the global electronics industry continues to expand, China's PCB solder manufacturers are well-positioned to further benefit from this growth. With their commitment to innovation, emphasis on research and collaboration, and adherence to international standards, Chinese solder manufacturers are primed to dominate the global market.Conclusion:China's PCB solder manufacturers have established themselves as vital players in the country's robust electronics industry. Through ongoing innovation, strategic partnerships, and commitment to environmental responsibility, these manufacturers have maintained their competitive edge. As demand for electronic devices and components continues to surge, China's PCB solder manufacturers are poised to thrive, driving the industry forward and shaping the future of technology.