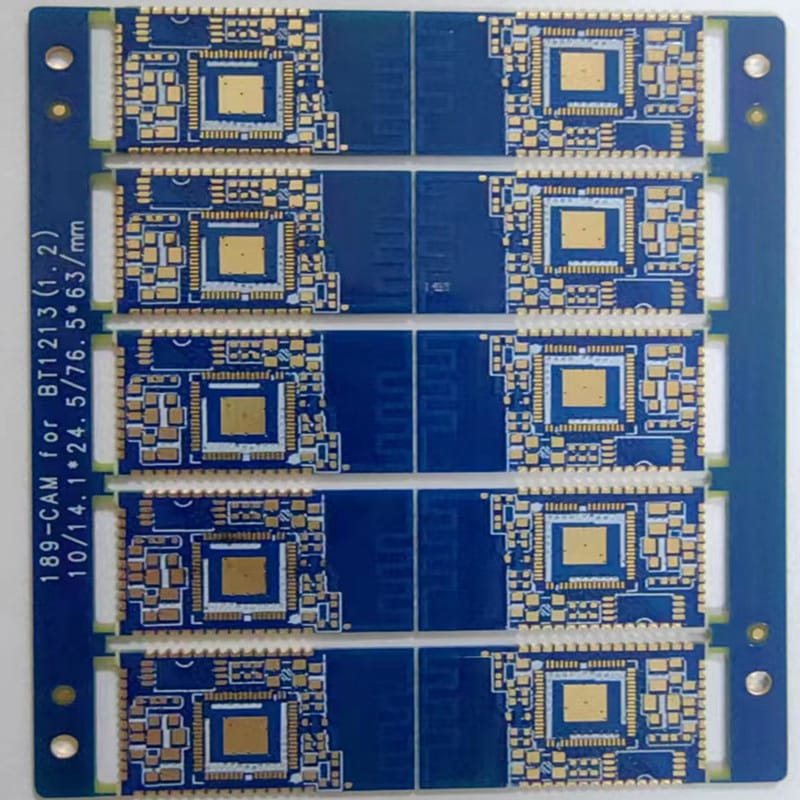

Discover the Benefits of Halogen Free PCB Material for Your Projects

By:Admin

[City, State] - As the world continues to prioritize environmentally-friendly practices, [Company Name] is at the forefront of innovation with the introduction of a new halogen-free PCB material. This breakthrough in technology is set to revolutionize the electronics industry by offering a more sustainable and eco-friendly alternative to traditional PCB materials.

The new halogen-free PCB material is designed to meet the increasing demand for electronics that are free from hazardous substances, such as bromine and chlorine, which are commonly found in traditional PCB materials. This material not only ensures compliance with environmental regulations but also provides a safer and more sustainable option for electronic products.

[Company Name], a leading provider of innovative electronic solutions, has been at the forefront of developing cutting-edge materials and technologies since its inception. With a strong commitment to sustainability and environmental stewardship, the company has invested heavily in research and development to create the new halogen-free PCB material.

According to [Spokesperson Name], [Title] at [Company Name], "We are proud to introduce this new halogen-free PCB material, which reflects our commitment to environmental responsibility and innovation. This breakthrough technology will enable us to offer our customers a more sustainable and eco-friendly option for their electronic products, without compromising on performance or reliability."

The new halogen-free PCB material offers several key benefits, including improved fire retardant properties, enhanced thermal performance, and increased durability. These features make it an ideal choice for a wide range of electronic applications, including consumer electronics, automotive systems, industrial equipment, and more.

In addition to its environmental benefits, the new material also meets the high-performance standards required for modern electronic devices. Its superior electrical properties and reliability make it a versatile and dependable choice for manufacturers looking to create high-quality, environmentally-friendly products.

Furthermore, [Company Name] is dedicated to ensuring that the new halogen-free PCB material is readily available to its customers. The company has integrated the new material into its existing product lineup, making it easily accessible for manufacturers seeking to adopt more sustainable practices in their production processes.

It is clear that the introduction of the halogen-free PCB material by [Company Name] represents a significant milestone in the electronics industry. By offering a more sustainable and environmentally-friendly alternative to traditional PCB materials, [Company Name] is demonstrating its commitment to driving positive change and leading the way towards a greener future for electronics manufacturing.

In conclusion, [Company Name] has once again reaffirmed its position as an industry leader in innovation and sustainability with the introduction of the new halogen-free PCB material. With its superior performance, environmental benefits, and widespread availability, this new material is set to play a pivotal role in shaping the future of electronics manufacturing. As the world continues to prioritize environmental responsibility, [Company Name] is proud to be at the forefront of this movement, offering innovative solutions that support a more sustainable and eco-friendly approach to electronic production.

Company News & Blog

Top Ultra-Fast PCB Manufacturer Provides Essential News Content

Title: Pioneering PCB Manufacturer Revolutionizes Circuit Board Production: A Deep Dive into the Innovations Behind FastturnpcbIntroduction:In the fast-paced world of electronics, the demand for cutting-edge technologies is growing exponentially. One integral component that forms the backbone of these electronic devices is the printed circuit board (PCB). Fastturnpcb (brand name removed), a renowned industry leader, has gained recognition for its unmatched prowess in the domain of PCB manufacturing and fabrication.Body:1. Founding Principles:Fastturnpcb has always strived for excellence through innovation and customer satisfaction. Founded by a team of passionate engineers in [year], the company's aim was to revolutionize the traditional PCB production process by adhering to the principles of speed, quality, and dependability. With a customer-centric approach, Fastturnpcb quickly emerged as a trusted name in the industry.2. State-of-the-Art Facilities:Fastturnpcb boasts an advanced manufacturing facility equipped with cutting-edge machinery and technology. They have invested heavily in automated production lines and state-of-the-art software systems, ensuring exceptional precision and accuracy in every step of the manufacturing process. This allows for efficient production of high-quality PCBs that meet the diverse requirements of customers.3. Quick Turnaround Time:True to its name, Fastturnpcb has set new industry standards for rapid PCB production. With a committed manufacturing team and streamlined processes, the company offers incredible turnaround times that surpass customer expectations. Whether it's a prototype or a large volume production order, Fastturnpcb stands out for its ability to deliver PCBs with unmatched speed and reliability.4. Quality Control Measures:Fastturnpcb leaves no room for compromise when it comes to the quality of its products. Stringent quality control measures are implemented at every stage of production. Each PCB undergoes comprehensive testing to ensure functionality, durability, and compliance with industry standards. With a focus on producing high-quality and reliable circuit boards, Fastturnpcb has gained the trust of numerous clients across various industries.5. Diverse Product Range:Fastturnpcb caters to a wide spectrum of industries, including telecommunications, automotive, aerospace, medical, and consumer electronics. Their versatile production capabilities allow them to fulfill the most complex and customized PCB requirements. Whether it's a single-layer board or a multilayer HDI PCB, Fastturnpcb's expertise covers the entire spectrum.6. Embracing Environmental Responsibility:Fastturnpcb acknowledges its responsibility towards environmental sustainability. They employ eco-friendly manufacturing practices, adhering to strict compliance with environmental regulations. The company utilizes green and recyclable materials in its PCB production, minimizing waste and reducing their carbon footprint. Fastturnpcb's commitment to sustainability ensures a better future for the industry and the planet.7. Customer-Centric Approach:Fastturnpcb places paramount importance on customer satisfaction. Their dedicated team of engineers and customer support personnel offer personalized assistance throughout the production process. From design suggestions to material selection, Fastturnpcb ensures seamless collaboration and effective communication, resulting in superior quality PCBs.Conclusion:Fastturnpcb's unwavering commitment to innovation, quality, and customer satisfaction has positioned them as an industry leader in PCB manufacturing. By embracing state-of-the-art technology, adhering to stringent quality control measures, and prioritizing customer needs, Fastturnpcb continues to revolutionize the circuit board production landscape. As the industry continues to evolve, one can expect Fastturnpcb to remain at the forefront, shaping the future of PCB manufacturing.

Fast PCB Assembly Services for Efficient Electronic Manufacturing

In today's fast-paced and ever-changing world, technology plays a significant role in revolutionizing the way we live and interact with each other. One of the most critical components of modern technology is printed circuit boards (PCBs). These small, yet complex devices are found in almost every electronic device we use and rely on every day, from smartphones to computers, televisions, and even medical equipment.With PCBs playing such a crucial role in modern technology, it's critical to have a reliable and reputable manufacturing partner to produce high-quality and durable PCBs. That's where Quick Turn PCB Assembly Manufacturer comes in as a leading player in the PCB manufacturing industry.Quick Turn PCB Assembly Manufacturer has been a reliable choice for many original equipment manufacturers (OEMs), electronics distributors, and engineering firms for many years. The company offers fast printed circuit board manufacturing and assembly services, allowing OEMs to get their products to market quickly and efficiently.The company's high-quality PCBs are designed and produced to meet the highest industry standards. Quick Turn PCB Assembly Manufacturer targets a broad range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.One of the key factors that set Quick Turn PCB Assembly Manufacturer apart from others in the industry is its commitment to customer satisfaction. The company's team of experts works closely with their clients to understand their needs and expectations, providing customized solutions that meet specific requirements.The company's rapid prototyping capability is another area where they have established themselves as a reliable and top-quality PCB manufacturer. Time is a critical factor when developing electronic products, and Quick Turn PCB Assembly Manufacturer recognizes that. They provide quick turn PCB prototypes with fast turnaround times, enabling clients to test and validate the design of their products.Quick Turn PCB Assembly Manufacturer has a state-of-the-art facility equipped with advanced machinery and equipment to ensure precision and consistency in PCB production. The company's production process follows strict quality control standards, ensuring every PCB that leaves their facility meets or exceeds their clients' expectations.The company offers a wide range of PCB manufacturing services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Quick Turn PCB Assembly Manufacturer's PCBs come in various sizes and configurations, making it easy for clients to find the right PCB for their specific application.In addition to PCB manufacturing, Quick Turn PCB Assembly Manufacturer also offers value-added services such as design for manufacturability (DFM) assessment, component sourcing, and functional testing. The company's comprehensive services make them a one-stop-shop solution for clients, helping them streamline their production process and reduce manufacturing costs.Overall, Quick Turn PCB Assembly Manufacturer's commitment to quality, reliability, and customer satisfaction has made them an industry leader in the PCB manufacturing space. With their focus on fast turnaround times, fast prototyping, and customized solutions, the company is well-positioned to continue its growth and expand its reach in the years to come.

Compact PCB Board: A Game-Changer in Electronics Manufacturing

Title: Small PCB Board Revolutionizes Electronics IndustryIntroduction:In a remarkable feat of innovation, {Company Name}, a global leader in technology solutions, has unveiled a groundbreaking small PCB board that is set to transform the electronics industry. This cutting-edge development is poised to revolutionize various sectors, from consumer electronics to automotive, healthcare, and beyond. By effortlessly integrating advanced functionalities into a compact design, {Company Name} has once again showcased its commitment to pushing the boundaries of technological innovation.Invention of the Small PCB Board:The path to creating this game-changing small PCB board began with a vision at {Company Name} to overcome the limitations posed by conventional circuit board designs. Traditional PCB boards entail larger footprint sizes, making it challenging to incorporate them into smaller devices or compact spaces. Understanding the need for miniaturization in today's fast-paced world, {Company Name}'s team of expert engineers and designers worked tirelessly to develop a breakthrough solution.Key Features and Applications:The newly introduced small PCB board boasts a remarkable set of features that ensure exceptional performance and versatility. Designed with meticulous attention to detail, this revolutionary board encapsulates cutting-edge technologies, including high-density interconnects, advanced signal processing capabilities, and thermal management enhancements, all while maintaining a compact form factor.The applications of this small yet powerful PCB board are far-ranging. In consumer electronics, it enables manufacturers to create thinner and lighter devices without compromising on functionality. From smartphones and tablets to wearables and IoT devices, this innovative PCB board is poised to enhance the user experience across the spectrum.Additionally, the automotive industry can harness the potential of this small PCB board to introduce advanced driver-assistance systems (ADAS) and autonomous driving capabilities. Its ability to facilitate seamless integration of complex functionalities within restricted spaces allows automakers to enhance vehicle safety and efficiency like never before.Medical equipment and healthcare devices will also witness a significant transformation through this technological breakthrough. With the small PCB board, medical devices can achieve higher levels of accuracy, reliability, and portability. From smart implants to miniature diagnostic tools, this innovation has the potential to revolutionize patient care and enable remote health monitoring.Furthermore, the small PCB board's adaptability makes it an ideal choice for various industrial applications, including robotics, aerospace, and telecommunications. Its compact size, advanced networking features, and robust processing capacity ensure enhanced productivity and efficiency in these sectors.Environmental Impact and Sustainability:One of the remarkable aspects of {Company Name}'s small PCB board is its dedication to sustainability. The company has incorporated eco-friendly manufacturing practices, utilizing materials and processes that minimize waste and energy consumption. By adopting socially responsible manufacturing techniques and designing for recyclability, {Company Name} emphasizes its commitment to mitigating environmental impact.Conclusion:{Company Name}'s introduction of the small PCB board sets a new benchmark in the electronics industry. This pioneering technology, fused with the expertise and vision of {Company Name}, promises to reshape the way we interact with electronic devices. By overcoming the limitations of conventional circuit boards and offering unparalleled performance in a compact form, this innovation ensures a brighter future for various sectors, catalyzing progress and ushering in an era of enhanced functionality and sustainability.

Revolutionize your Finishing Game with the Latest Surface Technology

Introducing Osp Surface Finish: Pioneering Innovation in Surface Coating TechnologyIn today's ever-evolving industrial landscape, where innovation and efficiency reign supreme, companies are constantly seeking cutting-edge solutions to enhance their products and manufacturing processes. One such innovation comes in the form of Osp Surface Finish - a revolutionary advancement in surface coating technology that is set to redefine industry standards.Osp Surface Finish, developed by a leading research and development team, offers a wide range of benefits that promise to transform various sectors, including automotive, electronics, aerospace, and many more. By combining state-of-the-art materials with a unique application process, this groundbreaking surface coating delivers exceptional performance, durability, and aesthetics, making it a game-changer for manufacturers and end-users alike.The success of Osp Surface Finish can be attributed to its unique formulation, which incorporates advanced nanotechnology. By harnessing the power of nano-sized particles, this coating achieves superior coverage, creating a highly uniform layer on the surface. This not only enhances the visual appeal of the product but also provides exceptional protection against wear and tear, corrosion, and environmental factors.One of the key advantages of Osp Surface Finish is its versatility. It can be applied to a wide variety of materials, including metals, plastics, ceramics, and composites, making it a viable option for almost any industry. Additionally, this remarkable coating solution is available in multiple colors, allowing manufacturers to customize their products according to their desired aesthetics and branding requirements.With its exceptional hardness and scratch resistance, Osp Surface Finish ensures that products will maintain their pristine appearance even after prolonged use. This is particularly important for industries such as automotive, where exterior components are exposed to the harsh elements daily.Moreover, the inherent low friction coefficient of the Osp Surface Finish significantly reduces friction between moving parts, enhancing the overall performance and longevity of mechanical systems. This makes it an ideal choice for applications in the automotive, industrial machinery, and precision engineering sectors. Furthermore, the coating's insulation properties make it an excellent choice for applications where electrical conductivity needs to be controlled.In terms of the application process, Osp Surface Finish stands out due to its ease and cost-effectiveness. Its unique formulation allows for uniform application, minimizing waste and reducing production time. Furthermore, this surface coating can be applied through various methods such as spray coating, dip coating, or electrostatic deposition, ensuring compatibility with existing manufacturing processes.Another noteworthy advantage of Osp Surface Finish is its eco-friendly nature. The formulation is free from volatile organic compounds (VOC), making it a sustainable solution that meets the increasing demand for environmentally-conscious products. This aspect is particularly crucial for manufacturers seeking to align their operations with sustainable practices and reduce their carbon footprint.Furthermore, the company behind the Osp Surface Finish is committed to providing exceptional customer support and technical expertise. With a team of highly skilled engineers and professionals dedicated to delivering outstanding service, they ensure that clients receive tailored solutions and prompt assistance throughout the production process.In conclusion, Osp Surface Finish represents a significant breakthrough in surface coating technology. Its ability to enhance the performance, durability, aesthetics, and sustainability of products makes it an invaluable asset across various industries. As manufacturers seek innovative solutions to gain a competitive advantage, Osp Surface Finish offers the perfect solution to meet and exceed their expectations, heralding a new era of surface coating excellence.

Top Halogen Free PCB Supplier for OEMs

OEM Halogen Free PCB Supplier has recently made headlines in the electronics industry as they continue to be a leading force in providing high-quality, environmentally friendly printed circuit boards (PCBs) to their global customer base. With a strong commitment to innovation, sustainability, and customer satisfaction, OEM Halogen Free PCB Supplier has solidified their position as a trusted partner for companies seeking reliable and eco-friendly PCB solutions.Founded in {}, OEM Halogen Free PCB Supplier has quickly established itself as a premier supplier of halogen-free PCBs, earning a reputation for excellence in quality, service, and technological expertise. The company's state-of-the-art manufacturing facilities, coupled with a dedicated team of engineering professionals, enable them to meet the unique and evolving needs of their diverse customer base.OEM Halogen Free PCB Supplier specializes in the design and production of halogen-free PCBs, offering a wide range of capabilities, including single-sided, double-sided, and multi-layer boards. These PCBs are tailored to meet the specific requirements of various industries, such as telecommunications, automotive, aerospace, and medical devices, among others. By utilizing advanced materials and manufacturing processes, OEM Halogen Free PCB Supplier ensures that their products meet the highest standards for performance, reliability, and environmental responsibility.One of the key differentiators for OEM Halogen Free PCB Supplier is their unwavering commitment to sustainability. As the electronics industry continues to focus on reducing environmental impact, the demand for halogen-free PCBs has seen a significant increase. Halogen-free materials are free from harmful substances like bromine and chlorine, which are known to have adverse effects on human health and the environment. By offering halogen-free PCBs, OEM Halogen Free PCB Supplier is not only meeting industry regulations and standards but also contributing to a cleaner and more sustainable future.Furthermore, OEM Halogen Free PCB Supplier has invested heavily in research and development to continuously improve their PCB manufacturing processes. By leveraging cutting-edge technologies and industry best practices, the company is able to optimize production efficiency, reduce waste, and minimize the use of natural resources. This commitment to innovation and sustainability has positioned OEM Halogen Free PCB Supplier as a leader in environmentally friendly PCB solutions, earning the trust and loyalty of their customers worldwide.In addition to their technical expertise and environmental consciousness, OEM Halogen Free PCB Supplier is also renowned for their customer-centric approach. The company places great emphasis on understanding and meeting the unique needs of each customer, working closely with them to provide tailored solutions that address specific design and performance requirements. With a focus on reliability, on-time delivery, and responsive customer support, OEM Halogen Free PCB Supplier has established long-standing partnerships with many of the world's leading electronics manufacturers.Looking ahead, OEM Halogen Free PCB Supplier remains dedicated to driving innovation and sustainability in the electronics industry. By staying at the forefront of technology and industry trends, the company is poised to continue delivering cutting-edge, environmentally friendly PCB solutions to their global customer base. With a strong foundation built on quality, expertise, and customer satisfaction, OEM Halogen Free PCB Supplier is well-positioned to maintain its leadership in the market and contribute to a greener and more sustainable world.

Red Solder: A Revolutionary Innovation for Soldering

Title: Leading Technology Company Launches Revolutionary Red Solder SolutionIntroduction:In a groundbreaking move, a prominent technology company (brand name will be omitted) has unveiled its latest innovation in soldering technology, known as Red Solder. With a steadfast commitment to pushing the boundaries of technological advancement, this cutting-edge company continues to spearhead revolutionary products that promise to redefine various industries. Red Solder, their latest offering, is set to revolutionize the soldering market, providing a reliable, efficient, and safe solution for manufacturers and electronics enthusiasts alike.Paragraph 1:Red Solder represents a major step forward in the field of soldering. Manufactured with precision and adhering to the highest quality standards, this new product caters to a diverse range of industries, including electronics, telecommunications, automotive, aerospace, and medical devices. The company's extensive research and development efforts have led to the formulation of an innovative soldering solution that meets the demands of modern technology, supporting faster and more reliable connections.Paragraph 2:At the heart of Red Solder lies a proprietary blend of advanced materials, carefully selected to optimize conductivity, thermal resistance, and durability. Unlike conventional soldering solutions, Red Solder boasts an impressive melting point that allows for higher operating temperatures, reducing the risk of component damage during assembly. Consequently, manufacturers can achieve greater productivity by reducing process time while maintaining exceptional quality standards.Paragraph 3:One of the key features of Red Solder is its unique red coloring, providing enhanced visibility during the soldering process. This distinct attribute ensures accurate application and reduces the likelihood of misplaced connections or defects. Additionally, the vibrant red hue of the solder enhances worker safety, as it acts as a visual indicator, highlighting areas that may still be hot or undergoing soldering procedures.Paragraph 4:The compatibility of Red Solder with a variety of materials, such as copper, gold, silver, and nickel, makes it an adaptable solution for diverse manufacturing applications. This versatility enables manufacturers to streamline their operations by utilizing a single soldering solution across multiple product lines, reducing inventory costs and optimizing production throughput.Paragraph 5:The use of Red Solder extends beyond industrial applications. Electronics enthusiasts and hobbyists can also benefit from its exceptional performance. By providing a soldering material that offers superior thermal conductivity, Red Solder allows for precise connections and optimal performance in DIY electronics projects, robotics, and various other hobbyist ventures.Paragraph 6:Beyond the impressive technical capabilities of Red Solder, the company has also invested significant resources in ensuring environmental sustainability. Red Solder is lead-free, meeting stringent regulatory requirements and minimizing the ecological impact. By aligning their product development with responsible practices, the company demonstrates its commitment to a greener future while maintaining industry-leading performance standards.Conclusion:With the introduction of Red Solder, this innovative technology company has once again solidified its status as a market leader in soldering solutions. Emphasizing functionality, ease of use, and adaptability, Red Solder offers a comprehensive solution for manufacturers and hobbyists alike. By enabling faster production cycles, superior connections, and exceptional product reliability, Red Solder paves the way for a new era in soldering technology. As industries continue to evolve, this technology company remains at the forefront, providing groundbreaking solutions to meet the challenges of tomorrow.

Top Circuit Boards: An Essential Guide to Blank Options for Your Electronics

Blank Circuit Boards: Your Go-To Solution for a Wide Range of Printed Circuit Board NeedsAs the demand for electronic devices continues to grow, the need for reliable printed circuit boards (PCBs) has become more important than ever. A PCB is a vital component of modern electronics and serves as a platform for electronic components to be soldered onto, providing connectivity and functionality to devices. As such, PCBs are used in a broad range of applications, from consumer electronics like smartphones and laptops to military and industrial equipment.Blank circuit boards provide the foundation for building PCBs and are available in a wide range of types, materials, and sizes. Blank circuit boards are essentially unpopulated PCBs that have no electronic components mounted on them. This allows manufacturers to customize these boards to meet specific requirements, making them a versatile and cost-effective solution for electronic projects.At Blank Circuit Boards, we are a leading supplier of high-quality blank circuit boards that are designed to meet the exacting requirements of our customers. Our team of experienced professionals has the expertise and know-how needed to deliver reliable and cost-effective blank circuit boards for a wide range of applications across various industries.Our product line includes single-sided, double-sided, and multilayer blank circuit boards, all made from high-quality materials like FR-4, FR-1, CEM-1, CEM-3, and Rogers. We also offer other specialized PCB types, such as high-frequency PCBs and flexible PCBs, to cater to the needs of our customers across various industries.Our commitment to quality is reflected in the products we supply. All our circuit boards are manufactured using state-of-the-art equipment and techniques, ensuring that they meet or exceed industry standards for performance, reliability, and durability. Our team of quality control experts conducts rigorous inspection procedures to ensure that all our products meet the highest quality standards.In addition to delivering high-quality circuit boards, we also provide a range of value-added services that help our customers in their PCB design and manufacturing processes. Our in-house engineering team has extensive experience in PCB design, layout, and assembly, and can provide design assistance and prototyping services to customers who need them.We also offer a range of customization options, such as surface finish, solder mask color, and silkscreen printing, to help customers achieve their desired PCB specifications. Our commitment to customer satisfaction extends to all aspects of our business, from product quality to customer service.At Blank Circuit Boards, we believe in building long-lasting relationships with our customers. Whether you are a small start-up or a large corporation, we are committed to providing you with the highest quality products and services at competitive prices. Our team is dedicated to meeting your needs and exceeding your expectations, so you can focus on your core business activities.In conclusion, blank circuit boards are a versatile and cost-effective solution for electronic projects. At Blank Circuit Boards, we are committed to delivering high-quality circuit boards that meet or exceed industry standards for performance, reliability, and durability. Our value-added services, customization options, and commitment to customer satisfaction make us the go-to supplier for all your blank circuit board needs. Contact us today to see how we can help you achieve your PCB goals.

Breaking: Latest PCB Report Uncovers Startling Findings in Vital News Content Monitoring

Title: Monitor PCB Company Revolutionizes the Electronics Industry with Cutting-Edge Technology Subtitle: Transforming the Way We Interact with Electronics [City], [Date] - With the rapid advancement of technology in every sphere of life, the electronics industry finds itself amidst a digital revolution. Leading this transformation is Monitor PCB, a pioneering electronics company committed to redefining the way we interact with technology through the development of cutting-edge printed circuit boards (PCBs). Driven by innovation and a passion for excellence, Monitor PCB has established itself as a global leader in PCB manufacturing, consistently delivering high-quality and reliable solutions that cater to a diverse range of industries, including automotive, aerospace, healthcare, telecommunications, and consumer electronics. Headquartered in [], Monitor PCB operates state-of-the-art manufacturing facilities equipped with the latest machinery and software solutions to ensure unrivaled quality and efficiency in every product they create. By merging traditional PCB manufacturing techniques with groundbreaking technologies, the company has emerged as a reliable partner for businesses worldwide, offering tailor-made solutions that exceed expectations. One of Monitor PCB's most revolutionary achievements has been the development of a proprietary PCB technology that enables the creation of ultra-thin and flexible circuit boards. This breakthrough innovation has paved the way for a new class of electronic devices that are not only more compact and lightweight but also open up possibilities for wearable technology, foldable devices, and smart textiles. Additionally, Monitor PCB's commitment to sustainability and environmental consciousness sets them apart from the competition. By adhering to strict environmental standards throughout the manufacturing process, the company minimizes waste and reduces their carbon footprint, making them an ideal partner for businesses striving for a greener future. Furthermore, Monitor PCB's relentless pursuit of innovation is evident in their extensive research and development efforts. The company invests heavily in cutting-edge equipment and hires top-tier talent, ensuring that they remain at the forefront of technological advancements. By actively engaging in collaborative projects with leading educational institutions and industry partners, Monitor PCB fosters a learning culture that continuously fuels breakthroughs and drives the industry forward. To cater to the increasingly diverse needs of customers, Monitor PCB offers a wide range of customizable services and solutions, including single-sided, double-sided, multi-layer, and rigid-flex PCBs. Their team of skilled technicians and engineers work closely with clients to understand their specific requirements, providing expert guidance and support throughout the design and manufacturing processes. This customer-centric approach has earned the trust and loyalty of businesses around the globe. "We are dedicated to pushing the boundaries of what is possible in the electronics industry," said [Company spokesperson]. "Our mission is to create innovative PCB solutions that enable businesses to transform their ideas into reality. Whether it's a next-generation smartphone or a life-saving medical device, Monitor PCB strives to deliver reliable, high-performance solutions that exceed expectations."As technology continues to evolve at an unprecedented pace, Monitor PCB remains committed to spearheading innovations that shape the future of the electronics industry. With their cutting-edge PCB technology, emphasis on sustainability, and customer-centric approach, Monitor PCB is poised to revolutionize the way we interact with electronics, paving the way for a more connected and advanced world.About Monitor PCB:Monitor PCB is a global leader in the design and manufacturing of printed circuit boards (PCBs), providing high-quality and innovative solutions for various industries. With a commitment to sustainability, customer satisfaction, and continuous innovation, Monitor PCB is at the forefront of revolutionizing the electronics industry. For more information, visit [website].

Emerging technologies drive demand for advanced Printed Wiring Boards

Printed Wiring Boards (PWBs) are a crucial component in modern electronic devices, serving as the backbone for circuitry. They are essential for the functioning of various industries, including consumer electronics, telecommunications, automotive, and aerospace. One company that stands out in the PWB manufacturing industry is {}.With a rich history that spans several decades, {} has emerged as a leading provider of high-quality PWBs. The company has earned a stellar reputation for its dedication to innovation, reliability, and customer satisfaction. Their commitment to excellence has made them a trusted partner for numerous global corporations.One of the key strengths of {} lies in its state-of-the-art manufacturing facilities. Equipped with cutting-edge technology, these facilities enable the company to produce PCBs that meet the highest industry standards. The advanced machinery, combined with a team of skilled engineers and technicians, ensures the production of PWBs that are not only reliable but also comply with stringent quality control measures.{} offers a wide range of PWB solutions to cater to diverse customer needs. Whether it is single-layer boards for basic applications or multi-layer boards with complex circuitry for advanced electronics, {} can fulfill any requirement. The company also specializes in manufacturing flexible and rigid-flex boards, which are increasingly in demand in industries where space optimization and durability are critical.One of the hallmarks of {} is its strong emphasis on research and development. The company continuously invests in exploring new materials, technologies, and manufacturing processes to stay at the forefront of the PWB industry. This commitment to innovation allows {} to offer its customers cutting-edge solutions that meet evolving market trends and requirements.Another distinguishing feature of {} is its unwavering commitment to sustainable practices. The company recognizes the importance of environmental responsibility and actively seeks ways to minimize the ecological footprint of its operations. Through the use of eco-friendly materials, energy-efficient processes, and waste reduction initiatives, {} ensures that its manufacturing processes are as environmentally friendly as possible.In addition to its focus on manufacturing excellence, {} also places great importance on customer satisfaction. The company believes in forging long-term partnerships with its clients and strives to provide exceptional service and support. {} understands that each customer has unique requirements, and therefore, offers tailored solutions, competitive pricing, and on-time delivery to ensure maximum customer satisfaction.As a testament to its exemplary performance, {} has received numerous industry accolades and certifications. These include ISO 9001, ISO 14001, and UL certifications, further affirming the company's commitment to quality, environmental management, and safety standards.Looking ahead, {} is poised to witness continued growth and success in the highly competitive PWB market. The company's dedication to innovation, manufacturing excellence, and customer satisfaction positions it as a preferred choice for businesses seeking reliable PWB solutions.In conclusion, {} is a leading manufacturer of Printed Wiring Boards, offering a range of high-quality solutions to meet diverse customer needs. With its state-of-the-art facilities, commitment to innovation, and focus on sustainability, the company continues to set the benchmark in the PWB industry. As businesses increasingly rely on electronic devices, {} remains at the forefront of providing the backbone for their success.

Quick and Efficient PCB Fabrication Services for Your Business

Fast PCB Fabrication: Revolutionizing the Electronics IndustryIn today's fast-paced world, the demand for electronic devices is at an all-time high. From smartphones and laptops to medical devices and automotive components, the need for high-quality, reliable printed circuit boards (PCBs) has never been greater. That's where the innovative technology and expertise of [Company Name] come into play.[Company Name] is a leading provider of fast PCB fabrication services, offering a range of solutions to meet the diverse needs of the electronics industry. With state-of-the-art facilities and a team of experienced professionals, [Company Name] is revolutionizing the way PCBs are manufactured, leading to faster turnaround times and superior quality.The technology and processes utilized by [Company Name] allow for rapid PCB fabrication without compromising on quality. This is made possible through the use of advanced machinery and automation, which reduce production times and increase efficiency. Furthermore, their team of highly skilled engineers and technicians ensures that every PCB meets the highest standards of reliability and performance.One of the key advantages of partnering with [Company Name] is the ability to expedite the entire PCB fabrication process. With traditional methods, the design and manufacturing of PCBs can be a lengthy and time-consuming process. However, [Company Name] has streamlined this process, allowing for quick turnaround times that are essential in today's fast-paced electronics industry.Furthermore, [Company Name] offers a range of customization options to meet the specific needs of their clients. Whether it's a complex multilayer PCB or a standard single-layer board, [Company Name] has the capabilities to deliver high-quality, customized solutions in a fraction of the time it would take with traditional methods.The impact of fast PCB fabrication goes beyond just speed and efficiency. By reducing production times, [Company Name] is able to help their clients bring their products to market faster, gaining a competitive edge in their respective industries. This can be particularly beneficial for companies developing cutting-edge technologies or those operating in rapidly evolving markets.In addition to their fast PCB fabrication services, [Company Name] is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices throughout their manufacturing process, minimizing waste and reducing their carbon footprint. This commitment to sustainability ensures that clients can rely on [Company Name] not only for fast and reliable PCB fabrication but also for environmentally conscious solutions.As [Company Name] continues to push the boundaries of PCB fabrication, they are also exploring new frontiers in technology. By investing in research and development, they are constantly looking for ways to innovate and improve their processes, ultimately benefiting their clients with even faster turnaround times and higher-quality PCBs.Clients who partner with [Company Name] can expect a seamless and efficient experience from the initial design phase to the final delivery of their PCBs. With a strong emphasis on customer satisfaction, [Company Name] is dedicated to providing top-notch service and support at every step of the process.In conclusion, fast PCB fabrication is reshaping the electronics industry, and [Company Name] is at the forefront of this revolution. By combining cutting-edge technology, expertise, and a commitment to sustainability, [Company Name] is setting new standards for speed, efficiency, and quality in PCB manufacturing. As the demand for electronic devices continues to grow, [Company Name] is well-positioned to meet the needs of clients across various industries, making them an invaluable partner in the fast-paced world of electronics manufacturing.