How to Use Red Solder: Tips and Techniques

By:Admin

The success of Red Solder can be attributed to the company's commitment to innovation, quality, and customer satisfaction. The company's products are known for their superior performance and reliability, making them the top choice for professionals and hobbyists alike.

Red Solder offers a wide range of soldering products, including solder wire, solder paste, flux, and soldering irons. The company's products are designed to meet the needs of a variety of industries, including electronics manufacturing, automotive, aerospace, and telecommunications.

One of the key factors that sets Red Solder apart from its competitors is its dedication to research and development. The company has a team of experienced engineers and technicians who are constantly working to improve and expand its product line. This commitment to innovation has allowed Red Solder to stay ahead of the curve and provide its customers with the latest and most advanced soldering solutions.

In addition to its focus on product quality, Red Solder also places a strong emphasis on customer satisfaction. The company prides itself on its responsive and knowledgeable customer service team, who are always ready to assist customers with any questions or concerns they may have. Red Solder also offers a comprehensive warranty and support program to ensure that its customers are fully satisfied with their purchases.

Red Solder's dedication to excellence has not gone unnoticed. The company has received numerous awards and accolades for its products, including the prestigious "Innovation Award" from the Electronics Industry Association. This recognition is a testament to the company's commitment to pushing the boundaries of soldering technology and delivering exceptional products to its customers.

Looking ahead, Red Solder is focused on continuing to expand its product line and reach new markets. The company is constantly exploring new opportunities for growth and is committed to maintaining its position as a leader in the soldering industry.

"We are excited about the future of Red Solder," said the company's CEO. "Our team is dedicated to developing new and innovative products that will continue to meet the needs of our customers and provide them with the best soldering solutions available."

As Red Solder continues to thrive in the electronics industry, it is clear that the company's commitment to excellence and innovation will continue to drive its success. With its dedication to quality, customer satisfaction, and innovation, Red Solder is poised to remain a leading force in the soldering industry for years to come.

Company News & Blog

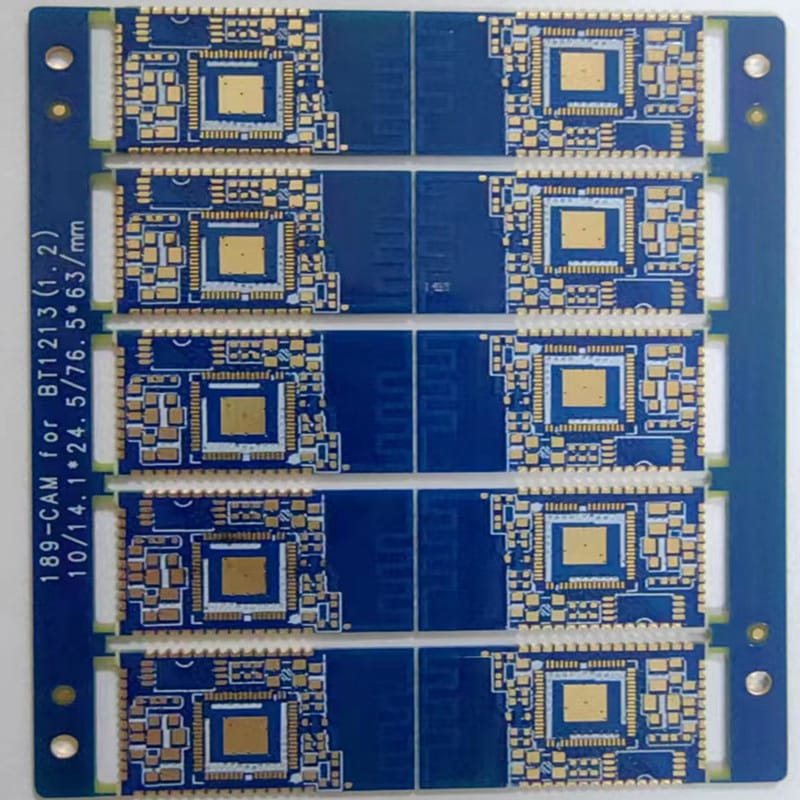

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.

Discover the Latest PCB Solder Manufacturers in China: A Comprehensive Overview

China PCBA Solder Manufacturers Continues to Serve Global Market with High-End Electronics ProductsChina has been dominating the electronics market in recent years, and with an ever-growing demand for consumer electronics, China PCB Solder Manufacturers continues to provide high-end products to customers all over the world. The company, established in 2004, has been consistently providing high-quality Printed Circuit Board Assembly (PCBA) Solder products while keeping up with the latest advancements in technology.With the ambition to cater to the diverse needs of customers from various industries, China PCB Solder Manufacturers has invested in globally advanced equipment and technology. This has enabled the company to deliver products that meet international standards. As a result, the company has become a leading player in electronic manufacturing services both locally and globally.The company offers a wide range of products, including PCB assembly services, through-hole assembly, surface mount technology, BGA assembly, and reflow soldering solutions. In addition, the company has a self-owned molding department that allows it to provide customized components and solutions as per customer's requirements.China PCB Solder Manufacturers also puts a strong emphasis on quality control. The company has implemented a strict quality control system that ensures all products undergo rigorous testing to meet customer specifications. Furthermore, the company is ISO and RoHS certified, further cementing its reputation as a reliable manufacturer of PCBA Solder products in the global market.One of the factors that have enabled China PCB Solder Manufacturers to continue dominating the electronics market is its ability to innovate new technologies. The company has an R&D department comprising of highly trained personnel that is constantly researching, exploring, and testing new ways of improving its products' efficiency.With over 16 years of experience in the electronic manufacturing industry, China PCB Solder Manufacturers has built a broad customer base in different parts of the world. The company caters to customers from various industries, including telecommunications, medical, automotive, security, industrial control, and consumer electronics, to name a few.It is no surprise that the company has a strong reputation among customers worldwide. China PCB Solder Manufacturers is committed to providing high-quality and reliable PCBA Solder products that meet the ever-growing customer requirements. The company strives to deliver products that are environmentally friendly, cost-effective, and optimized for maximum performance, making it a preferred partner for many customers worldwide.Despite the current global challenges brought about by the COVID-19 pandemic, China PCB Solder Manufacturers is still dedicated to serving its customers. The company has put measures in place to ensure that it continues to provide quality products while maintaining the safety of its employees. As part of efforts to meet clients' demands, the company has also increased its production capacity, allowing it to fulfill customer orders efficiently.In conclusion, China PCB Solder Manufacturers is a leading player in the PCBA Solder products manufacturing industry. The company has continuously invested in technology and equipment, in addition to the implementation of strict quality control measures that ensure customer satisfaction. With an unwavering commitment to innovation and customer satisfaction, the company is expected to continue dominating the electronics market and serve its clients worldwide with high-end electronic products.

Compact PCB Board: A Game-Changer in Electronics Manufacturing

Title: Small PCB Board Revolutionizes Electronics IndustryIntroduction:In a remarkable feat of innovation, {Company Name}, a global leader in technology solutions, has unveiled a groundbreaking small PCB board that is set to transform the electronics industry. This cutting-edge development is poised to revolutionize various sectors, from consumer electronics to automotive, healthcare, and beyond. By effortlessly integrating advanced functionalities into a compact design, {Company Name} has once again showcased its commitment to pushing the boundaries of technological innovation.Invention of the Small PCB Board:The path to creating this game-changing small PCB board began with a vision at {Company Name} to overcome the limitations posed by conventional circuit board designs. Traditional PCB boards entail larger footprint sizes, making it challenging to incorporate them into smaller devices or compact spaces. Understanding the need for miniaturization in today's fast-paced world, {Company Name}'s team of expert engineers and designers worked tirelessly to develop a breakthrough solution.Key Features and Applications:The newly introduced small PCB board boasts a remarkable set of features that ensure exceptional performance and versatility. Designed with meticulous attention to detail, this revolutionary board encapsulates cutting-edge technologies, including high-density interconnects, advanced signal processing capabilities, and thermal management enhancements, all while maintaining a compact form factor.The applications of this small yet powerful PCB board are far-ranging. In consumer electronics, it enables manufacturers to create thinner and lighter devices without compromising on functionality. From smartphones and tablets to wearables and IoT devices, this innovative PCB board is poised to enhance the user experience across the spectrum.Additionally, the automotive industry can harness the potential of this small PCB board to introduce advanced driver-assistance systems (ADAS) and autonomous driving capabilities. Its ability to facilitate seamless integration of complex functionalities within restricted spaces allows automakers to enhance vehicle safety and efficiency like never before.Medical equipment and healthcare devices will also witness a significant transformation through this technological breakthrough. With the small PCB board, medical devices can achieve higher levels of accuracy, reliability, and portability. From smart implants to miniature diagnostic tools, this innovation has the potential to revolutionize patient care and enable remote health monitoring.Furthermore, the small PCB board's adaptability makes it an ideal choice for various industrial applications, including robotics, aerospace, and telecommunications. Its compact size, advanced networking features, and robust processing capacity ensure enhanced productivity and efficiency in these sectors.Environmental Impact and Sustainability:One of the remarkable aspects of {Company Name}'s small PCB board is its dedication to sustainability. The company has incorporated eco-friendly manufacturing practices, utilizing materials and processes that minimize waste and energy consumption. By adopting socially responsible manufacturing techniques and designing for recyclability, {Company Name} emphasizes its commitment to mitigating environmental impact.Conclusion:{Company Name}'s introduction of the small PCB board sets a new benchmark in the electronics industry. This pioneering technology, fused with the expertise and vision of {Company Name}, promises to reshape the way we interact with electronic devices. By overcoming the limitations of conventional circuit boards and offering unparalleled performance in a compact form, this innovation ensures a brighter future for various sectors, catalyzing progress and ushering in an era of enhanced functionality and sustainability.

Sustainable Copper Circuit Boards: Key Material for Electronic Devices

In recent years, Circuit Board Copper has been making waves in the electronics industry, providing efficient and reliable copper materials for a range of applications. The company is renowned for its quality copper products that deliver precise and stable performance, ensuring the success of critical projects.Founded over a decade ago, Circuit Board Copper has forged a reputation for excellence in the industry with an unwavering commitment to quality and customer satisfaction. The company has invested in advanced technology and skilled engineers to ensure that it is at the frontline of innovation. As such, it has become a trusted supplier of high-performance copper materials for various industries, including electronics, energy, transportation, and telecommunications.For instance, the electronics industry is one of the main beneficiaries of the company's products, as it requires high-quality copper materials for the production of printed circuit boards (PCBs). PCBs are critical components used in electronic devices, and they are essential for the functionality and durability of the devices. Circuit Board Copper's copper materials deliver superior conductivity, thermal dissipation, and mechanical strength, making them ideal for PCB manufacturing.Besides electronics, Circuit Board Copper's products are also suitable for the energy sector. As the world shifts towards renewable energy, the need for efficient and cost-effective energy storage solutions has increased. Some of the critical components of these solutions are batteries, which require copper materials for their wiring and interconnects. Circuit Board Copper's high-performance copper materials are ideal for battery manufacturing, as they offer excellent electrical conductivity, corrosion resistance, and thermal management properties.Similarly, the transportation industry is another sector that benefits from Circuit Board Copper's products. The company's copper materials are used in the production of hybrid and electric vehicles (EVs). EVs require efficient power and data transmission, and copper materials play a critical role in enabling this. As such, Circuit Board Copper's copper products deliver optimal performance in terms of thermal management, conductivity, and durability, ensuring that EVs operate effectively.Moreover, the telecommunications industry is also a significant consumer of Circuit Board Copper's copper materials. With the increasing demand for high-speed data transmission, telecommunication companies require copper materials that can facilitate efficient data transmission and prevent signal loss. Circuit Board Copper's products are ideal for this purpose, as they deliver high electrical conductivity and low attenuation, making them reliable for data transfer.Circuit Board Copper's commitment to quality and innovation has earned it a reputation as a leading supplier of copper materials in the industry. The company has implemented rigorous quality control measures to ensure that its products meet or exceed industry standards. Additionally, it has a team of skilled engineers who work tirelessly to research and develop new products that cater to the evolving needs of the industry.In conclusion, Circuit Board Copper's contribution to the electronics industry, energy sector, transportation, and telecommunications is undeniable. The company's high-quality copper materials have played a crucial role in the manufacturing of critical components in these industries, enabling them to deliver products that meet the needs of consumers. As the world continues to demand better and more efficient products, Circuit Board Copper is well-positioned to meet these demands with its cutting-edge technology and dedication to excellence.

Top Circuit Boards: An Essential Guide to Blank Options for Your Electronics

Blank Circuit Boards: Your Go-To Solution for a Wide Range of Printed Circuit Board NeedsAs the demand for electronic devices continues to grow, the need for reliable printed circuit boards (PCBs) has become more important than ever. A PCB is a vital component of modern electronics and serves as a platform for electronic components to be soldered onto, providing connectivity and functionality to devices. As such, PCBs are used in a broad range of applications, from consumer electronics like smartphones and laptops to military and industrial equipment.Blank circuit boards provide the foundation for building PCBs and are available in a wide range of types, materials, and sizes. Blank circuit boards are essentially unpopulated PCBs that have no electronic components mounted on them. This allows manufacturers to customize these boards to meet specific requirements, making them a versatile and cost-effective solution for electronic projects.At Blank Circuit Boards, we are a leading supplier of high-quality blank circuit boards that are designed to meet the exacting requirements of our customers. Our team of experienced professionals has the expertise and know-how needed to deliver reliable and cost-effective blank circuit boards for a wide range of applications across various industries.Our product line includes single-sided, double-sided, and multilayer blank circuit boards, all made from high-quality materials like FR-4, FR-1, CEM-1, CEM-3, and Rogers. We also offer other specialized PCB types, such as high-frequency PCBs and flexible PCBs, to cater to the needs of our customers across various industries.Our commitment to quality is reflected in the products we supply. All our circuit boards are manufactured using state-of-the-art equipment and techniques, ensuring that they meet or exceed industry standards for performance, reliability, and durability. Our team of quality control experts conducts rigorous inspection procedures to ensure that all our products meet the highest quality standards.In addition to delivering high-quality circuit boards, we also provide a range of value-added services that help our customers in their PCB design and manufacturing processes. Our in-house engineering team has extensive experience in PCB design, layout, and assembly, and can provide design assistance and prototyping services to customers who need them.We also offer a range of customization options, such as surface finish, solder mask color, and silkscreen printing, to help customers achieve their desired PCB specifications. Our commitment to customer satisfaction extends to all aspects of our business, from product quality to customer service.At Blank Circuit Boards, we believe in building long-lasting relationships with our customers. Whether you are a small start-up or a large corporation, we are committed to providing you with the highest quality products and services at competitive prices. Our team is dedicated to meeting your needs and exceeding your expectations, so you can focus on your core business activities.In conclusion, blank circuit boards are a versatile and cost-effective solution for electronic projects. At Blank Circuit Boards, we are committed to delivering high-quality circuit boards that meet or exceed industry standards for performance, reliability, and durability. Our value-added services, customization options, and commitment to customer satisfaction make us the go-to supplier for all your blank circuit board needs. Contact us today to see how we can help you achieve your PCB goals.

New Technology Emerges with Through-Hole PCB in China

China PCB Through Hole Expands Production Capabilities to Meet Growing DemandChina PCB Through Hole, a leading manufacturer of printed circuit boards in China, announced the expansion of its production capabilities to meet the growing demand for high-quality PCBs in various industries, including electronics, automotive, and telecommunications.The company, which was established in 2008, has been providing a wide range of PCB services to customers worldwide. With its state-of-the-art manufacturing facilities and advanced technologies, China PCB Through Hole has earned a reputation for excellence in the PCB industry and has become a trusted partner for many electronics manufacturers.In recent years, the demand for PCBs has been increasing rapidly, driven by the growth of the electronics industry and the increasing adoption of advanced technologies such as artificial intelligence and the internet of things. As a result, many PCB manufacturers are investing in expanding their production capabilities to meet the growing demand.China PCB Through Hole is no exception. The company has recently invested heavily in its production facilities and equipment, including new state-of-the-art equipment for drilling, plating, and imaging. With these investments, the company has significantly increased its production capacity and improved its efficiency and quality."We are excited to announce the expansion of our production capabilities," said a spokesperson for China PCB Through Hole. "We are committed to meeting the demand for high-quality PCBs in various industries and providing our customers with the best possible service and support."The expanded production capabilities will allow China PCB Through Hole to offer a wider range of PCB services, including single-sided, double-sided, and multi-layer PCBs, among others. The company also offers a range of surface finishes, including lead-free HASL, OSP, ENIG, and immersion silver.In addition to its high-quality PCBs, China PCB Through Hole also offers a range of value-added services to its customers, including PCB assembly, component sourcing, and testing services. The company has a team of experienced engineers and technicians who can work closely with customers to provide tailored solutions to their specific needs."Our goal is to provide our customers with a one-stop solution for all their PCB needs," said the spokesperson. "We strive to make the process as easy and seamless as possible, from design to delivery."With its expanded production capabilities and commitment to excellence, China PCB Through Hole is well-positioned to meet the growing demand for high-quality PCBs in various industries. The company's dedication to customer satisfaction and continuous improvement ensures that it will remain a trusted partner for electronics manufacturers worldwide.About China PCB Through Hole:China PCB Through Hole is a leading manufacturer of printed circuit boards in China. With its state-of-the-art manufacturing facilities and advanced technologies, the company provides a wide range of PCB services to customers worldwide, including single-sided, double-sided, and multi-layer PCBs, as well as surface finishes, PCB assembly, component sourcing, and testing services. The company's dedication to quality and customer satisfaction has earned it a reputation for excellence in the PCB industry.

Comparison of Gold Plating vs Electroless Nickel Immersion Gold (ENIG)

Title: Comparing Two Prominent Circuit Board Finishes: A Case of Hasl vs. EnigIntroduction:In the realm of circuit board manufacturing, the choice of surface finish plays a critical role in determining the performance and reliability of electronic devices. This article aims to explore the two popular finishes - commonly referred to as Hasl and Enig (considered the industry standard in surface finishes, recommended beyond brand names). We will delve into the key features, advantages, and considerations associated with each finish, ensuring that engineers, hobbyists, and electronics enthusiasts make informed decisions for their projects.I. Hasl Finish:Hasl, an acronym for Hot Air Solder Leveling, is a widely used surface finish technique in the electronic manufacturing industry. It involves coating the copper surface with a layer of tin-lead solder, which is then leveled through a hot air process. Let us examine its notable features:1. Cost-Effective: Hasl is widely preferred due to its cost-effectiveness, making it an excellent choice for low to medium volume production runs. Its affordability has made it a popular option for many manufacturers globally.2. Robust and Durable: Due to the thick solder coating, Hasl finish offers excellent protection against oxidization, thus ensuring enhanced durability over time. This makes it ideal for applications exposed to harsh environments or those requiring extended lifecycles.3. Solderability: Hasl is known for its excellent solderability, facilitating easy and reliable soldering of electronic components onto the board surface. The tin-lead solder layer acts as an effective wetting agent, promoting better adhesion and thermal conduction.II. Enig Finish:Electroless Nickel Immersion Gold (Enig) is another widely used surface finish technique that has gained popularity due to its notable advantages. Let us explore the key features associated with this finish:1. Flat Surface and Uniform Thickness: Enig enables a uniform deposition of nickel and gold layers on the copper surface, resulting in a flat and consistent finish. This surface smoothness aids in achieving precise component placement, especially for fine-pitch devices.2. Excellent Solderability: Enig provides excellent solderability and offers superior wetting characteristics required for solder joint formation. The gold layer acts as a protective barrier against oxidization, maintaining solderability even after prolonged storage periods.3. Increased Shelf Life: The gold layer in Enig finish prevents the underlying nickel layer from oxidizing, extending shelf life for the circuit boards. This makes Enig an ideal choice for applications that require longer storage times before assembly.III. Considerations and Recommendations:While both Hasl and Enig finishes have their unique advantages, certain considerations should be taken into account depending on the application requirements:1. Lead-Free Legislation: It is crucial to evaluate the regulatory compliance of each finish with respect to specific regions' lead-free legislation. Hasl, being a tin-lead finish, may not be suitable for applications requiring RoHS compliance.2. Fine-Pitch Devices: Enig's flat surface and precise coating make it more suitable for fine-pitch devices where component placement accuracy is essential. Hasl, due to its relatively thicker solder layer, may hinder placement precision for such devices.3. Environmental Impact: Enig employs gold, a precious metal, which raises concerns regarding its environmental impact. Manufacturers should consider the sustainability aspect when making surface finish choices.Conclusion:In conclusion, the choice between Hasl and Enig surface finishes depends on the specific requirements of the project at hand. Hasl offers cost-effectiveness, robustness, and excellent solderability, while Enig provides a flat surface, uniform thickness, and superior shelf life. Engineers and manufacturers must carefully analyze their needs, regulatory standards, and environmental impact factors to make an informed decision when selecting the appropriate surface finish for their circuit boards.

Discover the Benefits of Using High-Quality FR-4 PCB Boards

The use of technology has become an integral part of our daily lives. From the way we communicate with each other to the way we work, technology has played a crucial role in our lives. As technology continues to evolve, so do the devices we use. One of the most important components of modern technology is the Printed Circuit Board or PCB.A PCB is used to connect electronic components using conductive pathways or traces etched from copper sheets. These pathways help to provide power and connectivity to electronic devices. PCBs can be found in almost every electronic device we use, from smartphones to laptops to cars.As PCBs have become more complex and smaller in size, there has been a growing demand for high-quality PCBs that offer excellent performance and reliability. This is where Fr4 PCB Board comes in. Fr4 PCB Board is a high-performance PCB that is widely used in various electronic devices.Fr4 PCB Board is made from a fire-retardant material that is known for its excellent mechanical and electrical properties. This type of PCB is extremely durable and can withstand high temperatures and pressure. It is also highly resistant to chemicals, making it an ideal choice for use in harsh environments.Fr4 PCB Board is widely used in a variety of applications, including telecommunication devices, computers, and industrial equipment. The PCB is made using a specialized process that involves drilling holes in the substrate, laminating layers of copper, and etching the copper to create the desired circuit.One company that is leading the industry in the production of high-quality Fr4 PCB Board is {Brand Name Removed}. {Brand Name Removed} is a leading manufacturer and supplier of Fr4 PCB Board, providing high-quality PCBs to customers worldwide.The company prides itself on its commitment to quality and customer satisfaction. It uses the latest technology and manufacturing processes to produce PCBs that meet the highest standards of performance and reliability. {Brand Name Removed} offers a wide range of Fr4 PCB Board products, including single-layer, double-layer, and multi-layer PCBs.The company also provides customization services to meet the specific needs of its customers. This includes designing and building PCBs that are tailored to the customer's requirements. {Brand Name Removed} works closely with its customers to understand their needs and provide solutions that meet those needs.One of the key factors that set {Brand Name Removed} apart from its competitors is its focus on customer service. The company has a team of experienced professionals who are dedicated to providing excellent customer service. This includes offering technical support, product guidance, and after-sales service.In addition to its commitment to quality and customer service, {Brand Name Removed} is also dedicated to environmental sustainability. The company uses environmentally friendly processes to produce its PCBs and works to reduce its carbon footprint.Overall, Fr4 PCB Board is a critical component in the modern electronic devices we use every day. The use of high-quality Fr4 PCB Board, such as those produced by {Brand Name Removed}, helps to ensure the reliability and performance of these devices. With a commitment to quality, customer service, and environmental sustainability, {Brand Name Removed} is leading the industry in the production of high-quality Fr4 PCB Board.

China's Pioneering PCB LED Light Technology Takes the Market by Storm

China PCB LED Light Industry Booms Amidst Growing DemandIn recent years, the China PCB LED Light industry has experienced a significant boom, driven by the increasing demand for energy-efficient lighting solutions. The market has witnessed a proliferation of innovative companies, one of the prominent players being [Company Name], a leading manufacturer and supplier of high-quality PCB LED lights.[Company Name], founded in [Year], has emerged as a trailblazer in the industry, leveraging cutting-edge technology and a commitment to product excellence. The company specializes in the design, production, and distribution of a vast array of PCB LED lights, catering to a diverse range of sectors and applications. With a strong emphasis on research and development, [Company Name] has consistently introduced groundbreaking lighting solutions that have garnered widespread acclaim.The rise of the China PCB LED Light industry can be attributed to several factors. Firstly, the global push for energy efficiency has led to a surging demand for LED lights. With their superior energy-saving capabilities compared to traditional lighting options, PCB LED lights have become the preferred choice for consumers, businesses, and industries alike. This growing demand has presented lucrative opportunities for Chinese manufacturers to expand their production capacities and capture a significant market share.Furthermore, advancements in PCB manufacturing technology have revolutionized the LED lighting sector. China has been at the forefront of these technological advancements, offering state-of-the-art facilities and expertise in PCB production. This has allowed companies like [Company Name] to develop PCB LED lights that are not only energy-efficient but also durable, versatile, and aesthetically pleasing.Another driving force behind the success of the China PCB LED Light industry is the government's supportive policies and incentives. The Chinese government, recognizing the potential of the LED lighting market, has implemented measures to promote its growth. These policies include subsidies for energy-efficient lighting projects, tax incentives for manufacturers, and regulations mandating the use of LED lights in public infrastructure. Such favorable conditions have further stimulated the demand for PCB LED lights and encouraged companies to invest in research and development.[Company Name] has been quick to capitalize on these opportunities and has established itself as a trusted brand in the industry. The company's extensive product portfolio covers a wide range of applications, including residential, commercial, industrial, and outdoor lighting. Their LED lights are known for their high luminous efficacy, long lifespan, and efficient heat dissipation. By prioritizing customer satisfaction, [Company Name] strives to provide tailor-made lighting solutions that meet the specific requirements of each client.In addition to its product excellence, [Company Name] also places a strong emphasis on sustainability. The company adheres to stringent environmental standards throughout its manufacturing process, ensuring that its products are eco-friendly and compliant with international regulations. By investing in research and development efforts focused on energy efficiency and environmental conservation, [Company Name] is driving the green revolution in the PCB LED Light industry.Looking ahead, the future of the China PCB LED Light industry seems promising. With continued advancements in technology, increasing urbanization, and growing environmental awareness, the demand for energy-efficient lighting solutions is expected to surge further. As a trusted industry leader, [Company Name] is well-positioned to meet this demand with its innovative product offerings. The company's dedication to quality, sustainability, and customer satisfaction will undoubtedly fuel its growth and contribute to the overall development of the China PCB LED Light industry.

Leading PCB Manufacturing Facility in China Receives UL Certification

Title: Leading Chinese PCB Manufacturer Achieves UL Certification for Enhanced Quality and ReliabilityIntroduction:In an impressive feat of technological advancement and quality control, China PCB UL Factory, one of the country's leading printed circuit board manufacturing facilities, has recently achieved UL certification. This recognition underscores the company's commitment to providing top-notch products while reinforcing its position as a trusted partner for diverse industries such as automotive, telecommunications, consumer electronics, and more. With this new certification, China PCB UL Factory aims to further establish itself as a global leader in the PCB manufacturing industry.Body:1. The Road to UL Certification:China PCB UL Factory has continuously invested in cutting-edge technology and innovative manufacturing processes, enabling the company to produce high-quality PCBs that meet the stringent standards set by UL. The certification process involved rigorous assessments conducted by UL experts, evaluating factors such as design, material selection, manufacturing processes, and product performance. China PCB UL Factory successfully met all the necessary criteria, demonstrating its dedication to excellence.2. Advantages of UL Certification:Obtaining UL (Underwriters Laboratories) certification is no small accomplishment and speaks to a company's commitment to safety, reliability, and environmental sustainability. The UL mark instills trust in customers and reassures them that the products offered have been thoroughly tested and meet the highest industry standards. China PCB UL Factory's certification contributes to the company's reputation for top-tier quality, opening doors to new business opportunities and collaborations with global partners.3. Enhanced Product Reliability:UL certification signifies China PCB UL Factory's ability to manufacture products that adhere to strict quality control methodologies. The rigorous testing and auditing procedures conducted during UL assessments ensure that the PCBs not only meet performance benchmarks but also comply with safety regulations. By acquiring UL certification, the factory has bolstered its reputation for delivering reliable and durable PCBs, crucial components for various industries.4. Benefits for Collaborative Industries:China PCB UL Factory's achievement of UL certification offers many advantages to industries that rely on high-quality PCBs. The automotive sector, for instance, often demands exceptional performance and reliability in circuit boards used in electronic control units, sensors, and infotainment systems. With UL certification, China PCB UL Factory can position itself as a preferred PCB supplier for automotive manufacturers, enhancing its portfolio and expanding its global market share.5. Commitment to Environmental Responsibility:UL certification extends beyond product reliability; it also emphasizes a company's adherence to environmental safety protocols. China PCB UL Factory's compliance with UL standards underscores its commitment to minimizing environmental impact. The factory optimizes its manufacturing processes to reduce waste, supports the responsible disposal of hazardous materials, and promotes energy-efficient technologies. By prioritizing sustainable practices in PCB production, the company aligns itself with environmentally conscious partners and businesses.6. Market Competitiveness and Growth Prospects:The UL certification places China PCB UL Factory among an elite group of manufacturers that have met globally recognized standards for quality and safety. This achievement strengthens the company's position in the highly competitive global PCB market, enabling it to attract customers who prioritize reliability and adhere to stringent industry regulations. By capitalizing on its UL certification, China PCB UL Factory can explore new partnerships and expand its footprint in emerging sectors, such as Internet of Things (IoT), artificial intelligence (AI), and renewable energy.7. Future Outlook and Continued Excellence:Obtaining UL certification serves as a critical milestone in China PCB UL Factory's growth journey, but it is only the beginning of the company's commitment to continuous improvement. The factory plans to invest further in research and development to stay at the forefront of technological advancements, ensuring that its PCBs are compatible with evolving industry needs. By prioritizing customer satisfaction and emphasizing consistent quality, China PCB UL Factory strives to solidify its standing as a trusted PCB manufacturer worldwide.Conclusion:China PCB UL Factory's recent achievement of UL certification highlights its unwavering dedication to producing high-quality, reliable, and environmentally sustainable PCBs. This significant accomplishment positions the factory as a preferred partner for industries seeking superior electronic solutions. Through continued innovation and customer-centric practices, China PCB UL Factory is poised to further enhance its market competitiveness and drive the growth of the global PCB manufacturing industry.