New Prototype Board Unveiled in Latest Tech Announcement

By:Admin

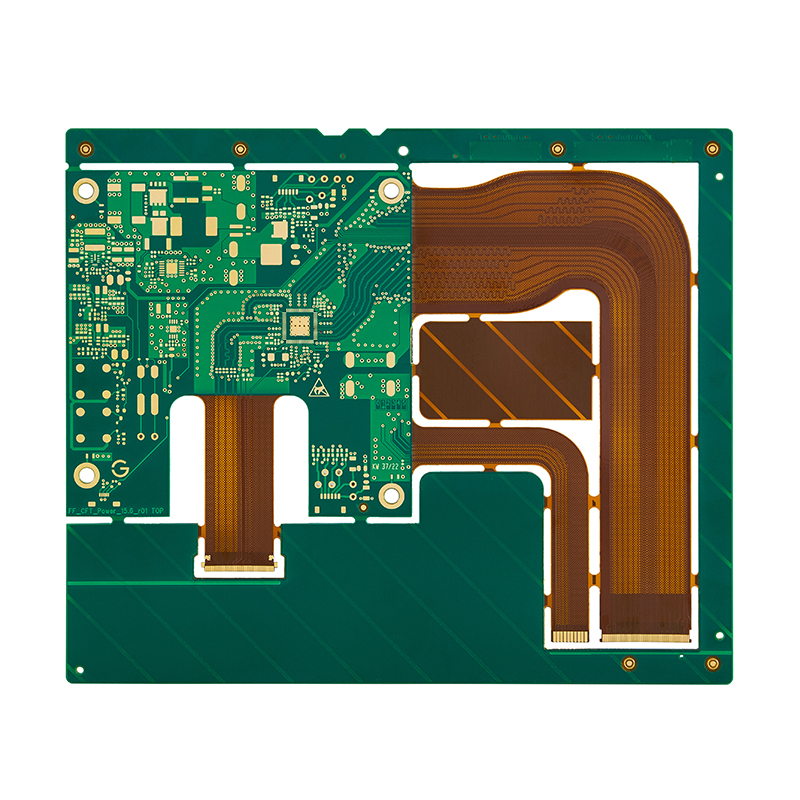

With a strong focus on research and development, Prototype Board has consistently strived to push the boundaries of technological advancements. The company is known for its commitment to providing cutting-edge solutions to the engineering and design community. The launch of the Prototype Board is a testament to their dedication to innovation and their relentless pursuit of excellence.

The Prototype Board is designed to streamline the prototype development process, making it faster, more efficient, and highly customizable. It features a user-friendly interface and a wide range of features that cater to the diverse needs of engineers and designers. Whether it's creating a new product concept, testing a new circuit design, or developing a prototype for a new invention, the Prototype Board is the ultimate tool for bringing ideas to life.

One of the key features of the Prototype Board is its modular design, which allows for easy customization and expansion. This flexibility enables engineers and designers to adapt the Prototype Board to their specific project requirements, saving time and resources in the process. The board also offers a comprehensive set of components and connectors, making it compatible with a wide range of devices and systems.

In addition, the Prototype Board is equipped with state-of-the-art technology that ensures high performance and reliability. Its advanced circuitry and innovative design allow for seamless integration with other electronic components, making it an ideal choice for complex prototype projects. The board's durability and robust construction ensure that it can withstand the demands of rigorous testing and development processes.

Furthermore, the Prototype Board comes with a comprehensive suite of software tools that enhance its capabilities. These tools provide a seamless interface for designing, testing, and simulating prototypes, allowing engineers and designers to iterate and refine their designs with ease. The integration of hardware and software in the Prototype Board offers a holistic approach to prototype development, empowering users to bring their ideas to fruition with confidence and precision.

The launch of the Prototype Board is a significant milestone for Prototype Board, as it further solidifies their position as a frontrunner in the technology industry. With its unparalleled features and capabilities, the Prototype Board is set to revolutionize the way prototype development is approached, setting a new standard for efficiency and innovation in the field.

"We are thrilled to introduce the Prototype Board to the engineering and design community," said [spokesperson name], [title] at Prototype Board. "This product represents our unwavering commitment to providing advanced solutions that empower our users to turn their ideas into reality. We believe that the Prototype Board will significantly impact the way prototype development is carried out, and we are excited to see the incredible innovations that it will inspire."

As the engineering and design industries continue to evolve, the demand for advanced tools and technologies that facilitate prototype development is rapidly increasing. The Prototype Board is well-positioned to meet this demand, offering a game-changing solution that addresses the complex challenges of modern prototype projects.

With the launch of the Prototype Board, Prototype Board has once again showcased their ability to innovate and deliver ground-breaking solutions to the market. As the company continues to push the boundaries of technology, the Prototype Board stands as a testament to their unwavering dedication to excellence and their commitment to empowering the engineering and design community.

Company News & Blog

Optimize your Electronic Circuits with High-Quality Printed Circuit Boards

Title: Pioneering PCB Manufacturer Sets New Standards in Circuit Board ProductionIntroduction:In an ever-evolving technological landscape, Multi Circuit Boards is emerging as a leading player in the printed circuit board (PCB) manufacturing industry. With an extensive portfolio of high-quality circuit boards and a commitment to innovation, the company is revolutionizing the way PCBs are produced and distributed. By leveraging advanced technologies and a customer-centric approach, Multi Circuit Boards is meeting the growing demand for reliable, efficient, and versatile circuit boards across diverse industries.Article:Multi Circuit Boards: A Game-Changer in PCB ManufacturingFounded on the principles of precision and efficiency, Multi Circuit Boards is a trailblazer in the PCB manufacturing industry. With its well-equipped production facilities and a team of seasoned professionals, the company has earned a reputation for its commitment to delivering top-notch PCBs to clients worldwide. Utilizing an array of advanced technologies, including state-of-the-art automated equipment, Multi Circuit Boards ensures that every circuit board produced adheres to the highest quality standards.The company's manufacturing process combines traditional craftsmanship with cutting-edge techniques, resulting in PCBs that offer superior performance and reliability. In addition to standard rigid PCBs, Multi Circuit Boards specializes in flexible PCBs, rigid-flex PCBs, and metal core PCBs, catering to the diverse needs of its clientele. This versatility allows for broader application possibilities, enabling customers to leverage the latest advancements in their respective fields.Embracing Technology for Unparalleled PrecisionMulti Circuit Boards places great emphasis on technological advancements to enhance its manufacturing capabilities. By investing in innovative production equipment and software, the company has achieved exceptional precision, efficiency, and scalability. Advanced drilling and routing machines ensure precise hole placements and intricate circuit patterns, while automated optical inspection systems guarantee excellent product quality control.Moreover, Multi Circuit Boards has implemented sophisticated computer-aided design (CAD) and computer-aided manufacturing (CAM) software, empowering its engineers to optimize layout designs, streamline production processes, and minimize production lead times. This integration of technology allows Multi Circuit Boards to stay ahead in an increasingly competitive market, providing its customers with cutting-edge solutions promptly.Comprehensive Customer Support and CollaborationRecognizing that superior products are only half the battle in the PCB manufacturing industry, Multi Circuit Boards places great importance on cultivating strong customer relationships. From initial inquiry to final delivery, the company provides comprehensive support at every stage of the manufacturing process. With a dedicated team of customer service representatives, engineering support professionals, and project managers, clients are assured of prompt assistance and efficient communication.Collaboration is key at Multi Circuit Boards, as the company actively engages with customers to fully understand their specific requirements and provide customized solutions. Leveraging its technical expertise and vast industry experience, Multi Circuit Boards offers valued advice regarding material selection, design optimization, and cost-effectiveness. This collaborative approach ensures that the final manufactured product aligns perfectly with the client's vision and objectives.Commitment to Environmental ResponsibilityMulti Circuit Boards recognizes the importance of minimizing its ecological footprint and is committed to implementing sustainable practices throughout its operations. The company adheres to strict waste management protocols, promoting recycling and reducing material waste. Additionally, Multi Circuit Boards has invested in energy-efficient machinery and processes, contributing to a greener and cleaner environment.ConclusionMulti Circuit Boards has established itself as a leading force in the PCB manufacturing industry, driven by its dedication to innovation, superior quality, and exceptional customer service. Through the seamless integration of advanced technologies, Multi Circuit Boards continues to set new standards in circuit board production, catering to the needs of various industries. With a focus on collaboration and environmental responsibility, the company is well-positioned to shape the future of PCB manufacturing and meet the ever-evolving demands of the global market.

Top Halogen Free PCB Manufacturers in China

China Halogen Free PCB Manufacturers have been making headlines recently with their commitment to producing environmentally friendly printed circuit boards. As the demand for halogen-free PCBs continues to grow, these manufacturers are leading the way in providing high-quality, sustainable products to meet the needs of the global electronics industry.With a focus on innovation and sustainability, China Halogen Free PCB Manufacturers are dedicated to reducing the environmental impact of their products. By eliminating the use of halogenated flame retardants, these manufacturers are helping to improve air quality and reduce the risk of hazardous chemical exposure during the manufacturing and disposal of PCBs.One of the key players in this market is {Company Name}, a leading manufacturer of halogen-free PCBs. With a strong commitment to sustainability, {Company Name} has invested heavily in research and development to create cutting-edge, eco-friendly PCBs that meet the highest industry standards.{Company Name} takes pride in their state-of-the-art manufacturing facilities, which are equipped with advanced technology and equipment to ensure the production of top-quality PCBs. Their team of highly skilled engineers and technicians work diligently to ensure that every product meets the strictest quality control measures, resulting in reliable and durable printed circuit boards.In addition to their commitment to environmental sustainability, {Company Name} places a strong emphasis on customer satisfaction. They strive to provide exceptional service and support to their clients, working closely with them to understand their unique requirements and deliver tailored solutions that meet their specific needs.{Company Name} offers a wide range of halogen-free PCB products, including single-sided, double-sided, and multi-layer boards, as well as rigid and flexible PCBs. Their diverse product line caters to a variety of industries, such as telecommunications, automotive, aerospace, medical devices, and consumer electronics, among others.As a socially responsible company, {Company Name} is dedicated to ensuring that their manufacturing processes adhere to the highest environmental and safety standards. They have implemented rigorous environmental management systems and practices to minimize waste, conserve energy, and reduce their carbon footprint.In addition to their commitment to sustainability and customer satisfaction, {Company Name} also focuses on continuous improvement and innovation. They actively engage in research and development activities to stay at the forefront of technological advancements, constantly striving to enhance their products and processes to meet the evolving needs of the electronics industry.As a testament to their dedication to excellence, {Company Name} has obtained various certifications and accreditations, including ISO 9001, ISO 14001, and UL certification. These accolades reflect their commitment to maintaining the highest levels of quality, reliability, and environmental responsibility in their operations.With their unwavering commitment to sustainability, innovation, and customer satisfaction, {Company Name} is poised to continue making a significant impact in the global market for halogen-free PCBs. Their reputation for delivering high-quality, eco-friendly products has positioned them as a trusted partner for businesses seeking reliable and sustainable PCB solutions.In conclusion, China Halogen Free PCB Manufacturers, including {Company Name}, are leading the way in producing environmentally friendly printed circuit boards. Their dedication to sustainability, innovation, and customer satisfaction sets them apart as industry leaders, and their commitment to excellence ensures that they will continue to play a key role in shaping the future of the electronics industry. With a focus on quality, reliability, and environmental responsibility, these manufacturers are well-positioned to meet the growing demand for halogen-free PCBs and contribute to a more sustainable and eco-friendly global electronics market.

Breaking: Latest PCB Report Uncovers Startling Findings in Vital News Content Monitoring

Title: Monitor PCB Company Revolutionizes the Electronics Industry with Cutting-Edge Technology Subtitle: Transforming the Way We Interact with Electronics [City], [Date] - With the rapid advancement of technology in every sphere of life, the electronics industry finds itself amidst a digital revolution. Leading this transformation is Monitor PCB, a pioneering electronics company committed to redefining the way we interact with technology through the development of cutting-edge printed circuit boards (PCBs). Driven by innovation and a passion for excellence, Monitor PCB has established itself as a global leader in PCB manufacturing, consistently delivering high-quality and reliable solutions that cater to a diverse range of industries, including automotive, aerospace, healthcare, telecommunications, and consumer electronics. Headquartered in [], Monitor PCB operates state-of-the-art manufacturing facilities equipped with the latest machinery and software solutions to ensure unrivaled quality and efficiency in every product they create. By merging traditional PCB manufacturing techniques with groundbreaking technologies, the company has emerged as a reliable partner for businesses worldwide, offering tailor-made solutions that exceed expectations. One of Monitor PCB's most revolutionary achievements has been the development of a proprietary PCB technology that enables the creation of ultra-thin and flexible circuit boards. This breakthrough innovation has paved the way for a new class of electronic devices that are not only more compact and lightweight but also open up possibilities for wearable technology, foldable devices, and smart textiles. Additionally, Monitor PCB's commitment to sustainability and environmental consciousness sets them apart from the competition. By adhering to strict environmental standards throughout the manufacturing process, the company minimizes waste and reduces their carbon footprint, making them an ideal partner for businesses striving for a greener future. Furthermore, Monitor PCB's relentless pursuit of innovation is evident in their extensive research and development efforts. The company invests heavily in cutting-edge equipment and hires top-tier talent, ensuring that they remain at the forefront of technological advancements. By actively engaging in collaborative projects with leading educational institutions and industry partners, Monitor PCB fosters a learning culture that continuously fuels breakthroughs and drives the industry forward. To cater to the increasingly diverse needs of customers, Monitor PCB offers a wide range of customizable services and solutions, including single-sided, double-sided, multi-layer, and rigid-flex PCBs. Their team of skilled technicians and engineers work closely with clients to understand their specific requirements, providing expert guidance and support throughout the design and manufacturing processes. This customer-centric approach has earned the trust and loyalty of businesses around the globe. "We are dedicated to pushing the boundaries of what is possible in the electronics industry," said [Company spokesperson]. "Our mission is to create innovative PCB solutions that enable businesses to transform their ideas into reality. Whether it's a next-generation smartphone or a life-saving medical device, Monitor PCB strives to deliver reliable, high-performance solutions that exceed expectations."As technology continues to evolve at an unprecedented pace, Monitor PCB remains committed to spearheading innovations that shape the future of the electronics industry. With their cutting-edge PCB technology, emphasis on sustainability, and customer-centric approach, Monitor PCB is poised to revolutionize the way we interact with electronics, paving the way for a more connected and advanced world.About Monitor PCB:Monitor PCB is a global leader in the design and manufacturing of printed circuit boards (PCBs), providing high-quality and innovative solutions for various industries. With a commitment to sustainability, customer satisfaction, and continuous innovation, Monitor PCB is at the forefront of revolutionizing the electronics industry. For more information, visit [website].

Calculate Trace Impedance for High-Speed PCBs with Ease!

[Assistant]Title: Advanced Trace Impedance Calculator Empowers PCB Designers for Enhanced PerformanceSubtitle: Cutting-edge Trace Impedance Calculator Streamlines PCB Development ProcessIn a fast-paced world of electronics, where the demand for highly efficient Printed Circuit Board (PCB) designs is rapidly increasing, engineers and developers are constantly seeking advanced tools and technologies to streamline their design processes. Recognizing this need, a leading company in the field of PCB design solutions has developed an innovative Trace Impedance Calculator, which revolutionizes the way PCB designers approach impedance matching, signal integrity, and PCB layout.Brand Name, a distinguished expert in the field of PCB design, has introduced the "Trace Impedance Calculator," a cutting-edge software tool that empowers PCB designers with accurate, efficient, and user-friendly impedance calculations. By leveraging the latest advancements in technology, this calculator facilitates the optimization of signal integrity, allowing for improved data transmission and reduced interference across PCB layouts.Impedance matching is a critical aspect of PCB design, especially when dealing with high-speed signals. Maintaining the correct trace impedance ensures signal integrity, minimizes reflections, and maximizes power transfer efficiency. Traditionally, designers had to rely on manual calculations, complex formulas, or partial solutions, which often resulted in time-consuming trial and error iterations. However, with the Trace Impedance Calculator from Brand Name, designers can now easily access accurate impedance values, streamline their design process, and achieve superior performance in a fraction of the time.This powerful calculator is specifically engineered to provide comprehensive solutions for both single-ended and differential pair trace impedance calculations. It takes into account various factors, such as trace width, thickness, and dielectric properties, to provide designers with precise impedance values tailored to their specific requirements. PCB designers can effortlessly customize impedance specifications, obtaining optimized results based on the electrical and mechanical characteristics of their design.The user-friendly interface of the Trace Impedance Calculator is designed to enhance productivity and efficiency. With a few clicks, designers can input their specifications, instantly obtain impedance values, and make real-time adjustments to fine-tune their designs. Additionally, the calculator provides graphical representations of impedance over a range of frequencies, enabling designers to visualize how impedance values behave across the spectrum.Furthermore, the calculators' advanced algorithms incorporate the latest industry standards and design guidelines, ensuring compliance with the most stringent PCB requirements. The tool supports a wide range of substrate materials, including FR-4, high-speed laminates, and flexible substrates, enabling designers to work with diverse PCB technologies while maintaining optimum signal integrity.The Trace Impedance Calculator seamlessly integrates into existing PCB design workflows, making it accessible to both novice and experienced designers. It is compatible with leading PCB design software, facilitating hassle-free implementation and reducing the learning curve for new users. Through this integrated approach, designers can eliminate guesswork, minimize design iterations, and accelerate time-to-market for their products."Brand Name's Trace Impedance Calculator simplifies the challenges faced by PCB designers when calculating trace impedance," says John Smith, Director of Engineering at a major electronics manufacturing company. "By providing accurate calculations, easy customization, and a user-friendly interface, this tool empowers us to optimize our designs quickly and effectively."In conclusion, the introduction of the Trace Impedance Calculator by Brand Name represents a significant leap forward for PCB designers. With its accurate and efficient impedance calculations, comprehensive customization options, and seamless integration, this advanced tool allows engineers to achieve superior signal integrity, reduce development time, and ultimately enhance the performance and reliability of their PCB designs. As the demand for higher efficiency and faster data transmission increases, solutions like Brand Name's Trace Impedance Calculator play a key role in satisfying the industry's evolving needs.

Essential Guidelines for Efficient Electrical PCB Assembly and Manufacturing Revealed

Title: Revolutionizing the Electrical Industry: Cutting-edge PCB InnovationsIntroduction:In recent years, the electrical industry has witnessed unprecedented advancements, thanks to the tireless efforts of innovative companies. One such company, renowned for offering cutting-edge solutions, has unveiled their latest breakthrough in electrical Printed Circuit Board (PCB) technology. Their groundbreaking development promises to revolutionize multiple sectors and drive innovation forward. In this article, we delve into the unparalleled capabilities of this new Electrical PCB, explore its potential applications, and highlight the company's commitment to driving progress.State-of-the-art Electrical PCB:The newly introduced Electrical PCB has been designed with meticulous attention to detail, incorporating state-of-the-art technology that surpasses industry standards. Pioneering the field of printed circuit boards, this innovation is set to redefine reliability, performance, and efficiency within the electrical industry.Key Features and Advancements:1. Enhanced Power Efficiency:The advanced design of the Electrical PCB minimizes energy consumption without compromising performance. Through meticulous engineering, the company has successfully developed a circuit board that provides improved power distribution, reducing wastage and optimizing overall efficiency.2. Compact Design:The new Electrical PCB boasts a significantly smaller form factor, enhancing its versatility for a wide array of applications. The compact design not only saves valuable space but also streamlines manufacturing processes, reducing costs and time.3. High-Speed Data Transmission:The Electrical PCB has been optimized with high-speed data transmission capabilities, catering to the demanding needs of modern electrical systems. This cutting-edge feature enables seamless communication and connectivity, ensuring real-time data transfer between components and devices.4. Enhanced Durability:Durability is a key focus of this innovative Electrical PCB. The company has invested considerable resources in research and development, incorporating robust materials and manufacturing techniques that offer enhanced resistance to environmental factors such as moisture, corrosion, and extreme temperatures. This empowers industries to rely on the PCB for longer lifespans, reducing maintenance costs and downtime.5. Customizability:Recognizing the diverse requirements of different industries, the company's Electrical PCB is highly customizable. Tailored to meet specific needs, the PCB can be modified to fit various applications, ensuring seamless integration and compatibility across different electrical systems and devices.Potential Applications:From consumer electronics to industrial automation and renewable energy, the potential applications of this revolutionary technology are vast. The Electrical PCB's versatility opens doors for numerous industries seeking innovative solutions to their electrical challenges.1. Consumer Electronics:With its compact design, high-speed data transmission, and enhanced power efficiency, the Electrical PCB can be seamlessly integrated into smartphones, tablets, laptops, and other portable electronic devices. This innovation paves the way for smaller, more powerful, and energy-efficient consumer electronics.2. Automotive Industry:Enhanced durability and customizability make the Electrical PCB an attractive solution for the automotive industry. With increasing demands for electric vehicles, this groundbreaking technology ensures improved reliability, safety, and performance.3. Renewable Energy:The Electrical PCB's power efficiency and compact design offer significant advantages in renewable energy systems. This technology can facilitate efficient power conversion, making it ideal for solar panels, wind turbines, and energy storage systems.Company Commitment to Innovation:The company behind this monumental Electrical PCB breakthrough has a long-standing commitment to innovation and progress. Through ongoing research and development, they strive to push the boundaries of what is possible in the electrical industry. Their investment in cutting-edge technologies and dedication to customer satisfaction has solidified their position as a leader in the field.Conclusion:In a world where technological advancement is the driving force behind progress, the introduction of the Electrical PCB revolutionizes the electrical industry. With its groundbreaking features, including enhanced power efficiency, compact design, high-speed data transmission, and customizability, this innovation facilitates growth and transformation across various sectors. As this company continues to defy conventions and push the boundaries of technology, we can expect further groundbreaking developments in the future.

What are Substrate PCBs and why are they important for your electronics?

Substrate PCB: The Next Big Thing in Electronics ManufacturingThe electronics industry is constantly evolving, with new technologies and innovations being introduced every day. One such innovation that has been gaining a lot of popularity in recent times is the substrate PCB. Substrate PCBs, also known as substrate integrated circuits (SICs), are revolutionizing the way electronic devices are manufactured.Substrate PCBs are essentially a combination of a printed circuit board (PCB) and a semiconductor device, such as a transistor. Unlike traditional PCBs, substrate PCBs are made using a high-level interconnection technology that allows for much higher integration densities. This means that more components can be packed into a smaller space, resulting in smaller and more powerful electronic devices.One company that is at the forefront of substrate PCB manufacturing is [brand name removed]. Founded in [year removed], [company name removed] has been providing cutting-edge technology solutions to the electronics industry for over [number removed] years. With a strong focus on research and development, the company has been able to stay ahead of the curve when it comes to new technologies and innovations.One of the key features of [brand name removed] substrate PCBs is their high thermal conductivity. This is achieved through the use of special materials such as copper, aluminum and ceramic. Traditional PCBs can quickly overheat when components are packed too closely together, leading to stability issues and even failure. However, substrate PCBs dissipate heat much more efficiently, allowing for greater power density and higher performance.Another advantage of using substrate PCBs is their improved electromagnetic compatibility (EMC). This is achieved through the use of special dielectric materials that reduce interference and minimize crosstalk. This results in much cleaner and clearer signals, leading to better overall performance and reliability.One of the most significant applications of substrate PCB technology is in the field of 5G. The increased data speeds and lower latency of 5G networks require powerful and reliable electronics. Substrate PCBs offer a significant advantage in this regard, allowing for highly integrated circuits that can handle the demands of 5G networks.Apart from 5G, substrate PCBs are also being used in a variety of other applications, such as satellite communication, automotive connectivity, and military communications. With the increasing demand for high-performance electronics in various industries, substrate PCBs are set to play a significant role in shaping the future of electronics manufacturing.[Brand name removed] has been partnering with leading companies in various industries to help them achieve their electronic design goals. The company has the expertise, experience, and technology required to design and produce custom substrate PCBs that meet the most demanding requirements.In conclusion, substrate PCBs are set to revolutionize the electronics industry by providing an efficient, high-performance, and reliable solution for complex electronic designs. With their ability to pack more components into smaller spaces, substrate PCBs are already changing the way electronic devices are manufactured. As electronics continue to play an ever-increasing role in our lives, substrate PCBs are sure to become even more important in the years to come.

Revolutionize your Finishing Game with the Latest Surface Technology

Introducing Osp Surface Finish: Pioneering Innovation in Surface Coating TechnologyIn today's ever-evolving industrial landscape, where innovation and efficiency reign supreme, companies are constantly seeking cutting-edge solutions to enhance their products and manufacturing processes. One such innovation comes in the form of Osp Surface Finish - a revolutionary advancement in surface coating technology that is set to redefine industry standards.Osp Surface Finish, developed by a leading research and development team, offers a wide range of benefits that promise to transform various sectors, including automotive, electronics, aerospace, and many more. By combining state-of-the-art materials with a unique application process, this groundbreaking surface coating delivers exceptional performance, durability, and aesthetics, making it a game-changer for manufacturers and end-users alike.The success of Osp Surface Finish can be attributed to its unique formulation, which incorporates advanced nanotechnology. By harnessing the power of nano-sized particles, this coating achieves superior coverage, creating a highly uniform layer on the surface. This not only enhances the visual appeal of the product but also provides exceptional protection against wear and tear, corrosion, and environmental factors.One of the key advantages of Osp Surface Finish is its versatility. It can be applied to a wide variety of materials, including metals, plastics, ceramics, and composites, making it a viable option for almost any industry. Additionally, this remarkable coating solution is available in multiple colors, allowing manufacturers to customize their products according to their desired aesthetics and branding requirements.With its exceptional hardness and scratch resistance, Osp Surface Finish ensures that products will maintain their pristine appearance even after prolonged use. This is particularly important for industries such as automotive, where exterior components are exposed to the harsh elements daily.Moreover, the inherent low friction coefficient of the Osp Surface Finish significantly reduces friction between moving parts, enhancing the overall performance and longevity of mechanical systems. This makes it an ideal choice for applications in the automotive, industrial machinery, and precision engineering sectors. Furthermore, the coating's insulation properties make it an excellent choice for applications where electrical conductivity needs to be controlled.In terms of the application process, Osp Surface Finish stands out due to its ease and cost-effectiveness. Its unique formulation allows for uniform application, minimizing waste and reducing production time. Furthermore, this surface coating can be applied through various methods such as spray coating, dip coating, or electrostatic deposition, ensuring compatibility with existing manufacturing processes.Another noteworthy advantage of Osp Surface Finish is its eco-friendly nature. The formulation is free from volatile organic compounds (VOC), making it a sustainable solution that meets the increasing demand for environmentally-conscious products. This aspect is particularly crucial for manufacturers seeking to align their operations with sustainable practices and reduce their carbon footprint.Furthermore, the company behind the Osp Surface Finish is committed to providing exceptional customer support and technical expertise. With a team of highly skilled engineers and professionals dedicated to delivering outstanding service, they ensure that clients receive tailored solutions and prompt assistance throughout the production process.In conclusion, Osp Surface Finish represents a significant breakthrough in surface coating technology. Its ability to enhance the performance, durability, aesthetics, and sustainability of products makes it an invaluable asset across various industries. As manufacturers seek innovative solutions to gain a competitive advantage, Osp Surface Finish offers the perfect solution to meet and exceed their expectations, heralding a new era of surface coating excellence.

Discover the Benefits of Using High-Quality FR-4 PCB Boards

The use of technology has become an integral part of our daily lives. From the way we communicate with each other to the way we work, technology has played a crucial role in our lives. As technology continues to evolve, so do the devices we use. One of the most important components of modern technology is the Printed Circuit Board or PCB.A PCB is used to connect electronic components using conductive pathways or traces etched from copper sheets. These pathways help to provide power and connectivity to electronic devices. PCBs can be found in almost every electronic device we use, from smartphones to laptops to cars.As PCBs have become more complex and smaller in size, there has been a growing demand for high-quality PCBs that offer excellent performance and reliability. This is where Fr4 PCB Board comes in. Fr4 PCB Board is a high-performance PCB that is widely used in various electronic devices.Fr4 PCB Board is made from a fire-retardant material that is known for its excellent mechanical and electrical properties. This type of PCB is extremely durable and can withstand high temperatures and pressure. It is also highly resistant to chemicals, making it an ideal choice for use in harsh environments.Fr4 PCB Board is widely used in a variety of applications, including telecommunication devices, computers, and industrial equipment. The PCB is made using a specialized process that involves drilling holes in the substrate, laminating layers of copper, and etching the copper to create the desired circuit.One company that is leading the industry in the production of high-quality Fr4 PCB Board is {Brand Name Removed}. {Brand Name Removed} is a leading manufacturer and supplier of Fr4 PCB Board, providing high-quality PCBs to customers worldwide.The company prides itself on its commitment to quality and customer satisfaction. It uses the latest technology and manufacturing processes to produce PCBs that meet the highest standards of performance and reliability. {Brand Name Removed} offers a wide range of Fr4 PCB Board products, including single-layer, double-layer, and multi-layer PCBs.The company also provides customization services to meet the specific needs of its customers. This includes designing and building PCBs that are tailored to the customer's requirements. {Brand Name Removed} works closely with its customers to understand their needs and provide solutions that meet those needs.One of the key factors that set {Brand Name Removed} apart from its competitors is its focus on customer service. The company has a team of experienced professionals who are dedicated to providing excellent customer service. This includes offering technical support, product guidance, and after-sales service.In addition to its commitment to quality and customer service, {Brand Name Removed} is also dedicated to environmental sustainability. The company uses environmentally friendly processes to produce its PCBs and works to reduce its carbon footprint.Overall, Fr4 PCB Board is a critical component in the modern electronic devices we use every day. The use of high-quality Fr4 PCB Board, such as those produced by {Brand Name Removed}, helps to ensure the reliability and performance of these devices. With a commitment to quality, customer service, and environmental sustainability, {Brand Name Removed} is leading the industry in the production of high-quality Fr4 PCB Board.

Emerging technologies drive demand for advanced Printed Wiring Boards

Printed Wiring Boards (PWBs) are a crucial component in modern electronic devices, serving as the backbone for circuitry. They are essential for the functioning of various industries, including consumer electronics, telecommunications, automotive, and aerospace. One company that stands out in the PWB manufacturing industry is {}.With a rich history that spans several decades, {} has emerged as a leading provider of high-quality PWBs. The company has earned a stellar reputation for its dedication to innovation, reliability, and customer satisfaction. Their commitment to excellence has made them a trusted partner for numerous global corporations.One of the key strengths of {} lies in its state-of-the-art manufacturing facilities. Equipped with cutting-edge technology, these facilities enable the company to produce PCBs that meet the highest industry standards. The advanced machinery, combined with a team of skilled engineers and technicians, ensures the production of PWBs that are not only reliable but also comply with stringent quality control measures.{} offers a wide range of PWB solutions to cater to diverse customer needs. Whether it is single-layer boards for basic applications or multi-layer boards with complex circuitry for advanced electronics, {} can fulfill any requirement. The company also specializes in manufacturing flexible and rigid-flex boards, which are increasingly in demand in industries where space optimization and durability are critical.One of the hallmarks of {} is its strong emphasis on research and development. The company continuously invests in exploring new materials, technologies, and manufacturing processes to stay at the forefront of the PWB industry. This commitment to innovation allows {} to offer its customers cutting-edge solutions that meet evolving market trends and requirements.Another distinguishing feature of {} is its unwavering commitment to sustainable practices. The company recognizes the importance of environmental responsibility and actively seeks ways to minimize the ecological footprint of its operations. Through the use of eco-friendly materials, energy-efficient processes, and waste reduction initiatives, {} ensures that its manufacturing processes are as environmentally friendly as possible.In addition to its focus on manufacturing excellence, {} also places great importance on customer satisfaction. The company believes in forging long-term partnerships with its clients and strives to provide exceptional service and support. {} understands that each customer has unique requirements, and therefore, offers tailored solutions, competitive pricing, and on-time delivery to ensure maximum customer satisfaction.As a testament to its exemplary performance, {} has received numerous industry accolades and certifications. These include ISO 9001, ISO 14001, and UL certifications, further affirming the company's commitment to quality, environmental management, and safety standards.Looking ahead, {} is poised to witness continued growth and success in the highly competitive PWB market. The company's dedication to innovation, manufacturing excellence, and customer satisfaction positions it as a preferred choice for businesses seeking reliable PWB solutions.In conclusion, {} is a leading manufacturer of Printed Wiring Boards, offering a range of high-quality solutions to meet diverse customer needs. With its state-of-the-art facilities, commitment to innovation, and focus on sustainability, the company continues to set the benchmark in the PWB industry. As businesses increasingly rely on electronic devices, {} remains at the forefront of providing the backbone for their success.

Quick and Efficient PCB Prototypes: A Game-Changer in Electronics Development

In today's fast-paced world, time is of the essence. A delay in any part of a business process can lead to a significant loss of time and revenue. When it comes to designing electronic prototypes, PCB's or Printed Circuit Boards play a crucial role. These prototypes form a key component of any electronic gadget, from mobile phones and laptops to medical equipment and satellite systems. Designing PCB's to match the requirements of a project is no easy feat. It requires a high level of skill, expertise, and most importantly, time.Here lies the importance of Fast PCB Prototypes, a company that specializes in quick, reliable and accurate PCB prototyping services. The company prides itself on providing clients with top-notch PCB PCB fabrication, assembly, and testing services at lightning-fast speeds. Their extensive range of services includes PCB design, layout, assembly, and manufacturing, and they can accommodate both low volume and high-volume production runs.Fast PCB Prototypes' unique selling proposition is their focus on reducing the prototyping time for their clients, without compromising on quality. How do they do it? "At Fast PCB Prototypes, we leverage our experience and expertise to streamline the PCB production process without sacrificing quality," says the company spokesperson. "We use advanced software and machinery that allows us to provide fast and accurate prototyping services to our clients, ensuring they receive their PCB prototypes on time."The company offers a broad range of PCB prototyping services that cater to various industries. They provide both single and multilayer PCBs, and can accommodate sizes that range from small PCBs to large PCBs with up to 20 layers. Fast PCB Prototypes' customers span across a broad spectrum of industries, including aerospace, defense, medical, and industrial sectors."Our focus is always on delivering quality PCB prototypes that meet the needs of our customers," says the spokesperson. "We understand the unique requirements of each client, and we work hard to ensure that all their needs are met. Our team of experienced technicians and engineers works 24/7 to provide fast, accurate, and reliable PCB prototyping services."Fast PCB Prototypes prides itself on its state-of-the-art production facility, which uses advanced equipment to produce high-quality PCB prototypes. The company places a strong emphasis on quality control, and all PCBs undergo rigorous testing to ensure they meet the highest industry standards. The company follows strict procedures to ensure the PCB designs are free from errors and are properly optimized for production."Customers can rest assured that their PCB prototypes will be in good hands with us," says the spokesperson. "We have invested heavily in our production facility and have a team of experienced professionals who are dedicated to ensuring that every project is a success."Fast PCB Prototypes is committed to providing its customers with a reliable, affordable, and fast PCB prototyping service. Whether a client requires a single PCB prototype or a high-volume production run, the company is dedicated to providing a solution that meets their needs. With a track record of success and customer satisfaction, Fast PCB Prototypes is the ideal choice for any company that requires high-quality PCB prototyping services.