Top Fast Turn PCB Manufacturers in China for Quick Production

By:Admin

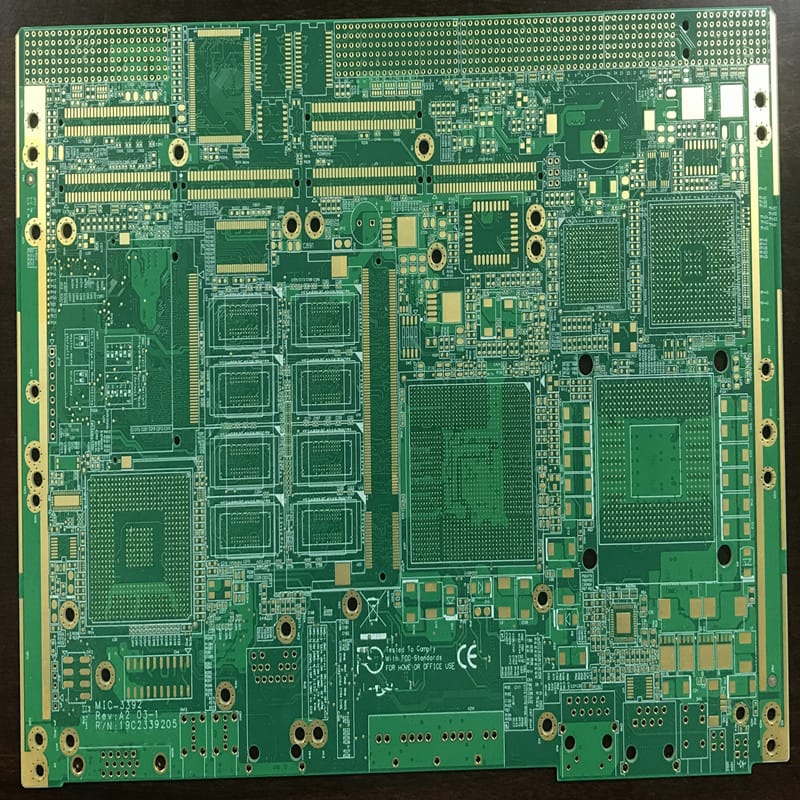

With the rapid development of the technology industry in recent years, the need for fast turn PCB manufacturing has become increasingly important. Businesses are constantly under pressure to bring their products to market quickly, and the ability to produce high-quality PCBs in a short amount of time is crucial. This is where China Fast Turn PCB Manufacturers come into play.

One of the leading players in this space is {company name}. They have established themselves as a go-to solution for businesses looking for fast turn PCB manufacturing services. With a focus on efficiency and precision, {company name} has solidified its reputation as a trusted partner for businesses in need of high-quality PCBs on a tight deadline.

{Company name} prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology. Their advanced manufacturing processes enable them to produce high-quality PCBs in a fraction of the time it takes traditional manufacturers. This allows businesses to streamline their production processes and bring their products to market faster than ever before.

In addition to their technological capabilities, {company name} also places a strong emphasis on quality control. Every PCB that comes out of their facilities undergoes rigorous testing to ensure that it meets the highest standards. This commitment to quality has earned {company name} a stellar reputation in the industry, making them a top choice for businesses seeking fast turn PCB manufacturing.

The company's customer-centric approach is another factor that sets them apart from the competition. {Company name} understands the unique needs of businesses in today's fast-paced market, and they strive to provide personalized solutions that meet those needs. From understanding specific technical requirements to delivering on tight deadlines, {company name} goes above and beyond to ensure customer satisfaction.

Another key aspect of {company name}'s success is their commitment to innovation. As technology continues to evolve, so does the demand for PCBs with increasingly complex designs. {Company name} has made it a priority to stay at the forefront of technological advancements, allowing them to meet the evolving needs of their customers.

Furthermore, {company name} understands the importance of sustainability in manufacturing. They have implemented eco-friendly practices and processes to minimize their environmental impact, aligning with the global trend towards sustainable and responsible manufacturing.

As a result of these strengths, {company name} has become a preferred partner for businesses across various industries. Whether it's a startup looking to launch a new product or an established corporation seeking to streamline their production processes, {company name} has proven to be a reliable and efficient partner.

In conclusion, as the demand for fast turn PCB manufacturing continues to rise, China Fast Turn PCB Manufacturers are playing a crucial role in meeting this demand. {Company name} stands out as a leader in the industry, offering efficient, high-quality, and reliable solutions for businesses worldwide. With their cutting-edge technology, commitment to quality, customer-centric approach, and dedication to innovation, {company name} has solidified its position as a trusted partner for businesses seeking fast turn PCB manufacturing.

Company News & Blog

Top PCB Manufacturer: Providing High-Quality UL Certified PCBs

UL PCB Manufacturer (ULPCB), a leading provider of high-quality printed circuit boards, is proud to announce the expansion of their production capabilities to meet the growing demand for their products. With a commitment to excellence and a focus on customer satisfaction, ULPCB has established itself as a trusted partner for businesses across a wide range of industries.Since its inception, ULPCB has been dedicated to delivering innovative solutions that meet the unique needs of their customers. By investing in state-of-the-art equipment and employing a team of highly skilled professionals, the company has been able to consistently exceed industry standards and deliver superior products. As a result, ULPCB has earned a reputation for reliability and excellence, making them the go-to choice for businesses in need of high-quality printed circuit boards.The expansion of ULPCB's production capabilities comes at a time of increased demand for their products. With the rise of advanced technologies such as 5G, IoT, and AI, the need for reliable and high-performance printed circuit boards has never been greater. ULPCB's expanded production facilities will allow them to meet this growing demand and continue to provide their customers with the premium products and services they have come to expect."Our decision to expand our production capabilities is a reflection of our commitment to meeting the needs of our customers," said the CEO of ULPCB. "We understand the critical role that printed circuit boards play in the success of our customers' products, and we are dedicated to providing them with the highest quality boards available. By expanding our production capabilities, we are ensuring that we can continue to meet the growing demand for our products and maintain our position as a leader in the industry."In addition to their expanded production capabilities, ULPCB is also committed to sustainability and environmental responsibility. The company has implemented a number of initiatives to reduce their environmental impact, including investing in energy-efficient equipment and utilizing environmentally friendly manufacturing processes. By prioritizing sustainability, ULPCB is not only minimizing their environmental footprint, but also ensuring the long-term availability of critical resources for their industry.As ULPCB continues to grow and expand, they remain dedicated to their core values of quality, innovation, and customer satisfaction. With a focus on continuous improvement and a dedication to meeting the evolving needs of their customers, ULPCB is well-positioned to remain a leader in the printed circuit board industry for years to come. Whether businesses are in need of standard PCBs, flexible PCBs, or any other advanced PCB technology, ULPCB is the partner they can trust to deliver exceptional results.With their expanded production capabilities, focus on sustainability, and unwavering commitment to excellence, ULPCB is poised to continue providing their customers with the high-quality printed circuit boards they need to succeed in an increasingly competitive marketplace. As the demand for advanced technologies continues to grow, businesses can trust ULPCB to be their reliable partner for all of their printed circuit board needs.

Top Pcb Solder Manufacturers Embrace New Technologies in China" -> "Revolutionary Pcb Solder Manufacturing in China Leads by Example

Title: China's PCB Solder Manufacturers Innovate for a Resilient Electronics IndustryIntroduction:With the continuous advancement of technology, the global electronics industry has experienced unprecedented growth. In China, leading the charge in innovation and production in this sector, PCB solder manufacturers have become an essential component in powering this rapid development. In this article, we will delve into the world of China's prominent PCB solder manufacturers and explore their quest for innovation and resilience in this dynamic industry.Company Introduction:One of the key players in China's PCB solder manufacturing industry is {Company Name}. Founded in {Year}, the company has established itself as a trusted and reliable provider of high-quality solder products. With a commitment to innovation and customer satisfaction, {Company Name} has built a solid reputation both domestically and internationally.In line with China's focus on technological advancements, {Company Name} has consistently invested in research and development to enhance their product offerings. By leveraging their expertise and a highly skilled workforce, the company has been able to deliver solder products that meet the ever-evolving demands of the electronics sector.Key Strategies and Innovations:To stay ahead in a fiercely competitive market, China's PCB solder manufacturers have implemented several strategies and innovations. One such strategy is to improve the efficiency and effectiveness of the soldering process. Advanced equipment and automated systems have been introduced, resulting in higher production yields, reduced defect rates, and enhanced product quality.In addition to process improvements, these manufacturers have also focused on the development of eco-friendly soldering materials. As environmental concerns come to the forefront, the industry has realized the need to shift towards lead-free and RoHS-compliant solder alloys. China's PCB solder manufacturers have been at the forefront of this transition, developing innovative soldering solutions that meet global environmental standards.Collaboration and Partnerships:Recognizing the importance of collaboration, China's PCB solder manufacturers have actively sought partnerships with other industry players to foster innovation and exchange of knowledge. By working closely with electronic device manufacturers, component suppliers, and research institutions, these manufacturers have been able to gain insights into emerging trends and requirements, enabling them to develop tailor-made soldering solutions.Moreover, international collaborations have also played a significant role in the growth of China's PCB solder manufacturing industry. Through joint ventures and technology transfers, Chinese manufacturers have gained access to cutting-edge technologies and expanded their global presence.Export Opportunities:China's PCB solder manufacturers have consistently strengthened their export capabilities, catering to the international market's increasing demand for reliable soldering solutions. The country's efficient supply chains, competitive pricing, and stringent quality control have positioned Chinese manufacturers as preferred partners for multinational electronics companies.As the global electronics industry continues to expand, China's PCB solder manufacturers are well-positioned to further benefit from this growth. With their commitment to innovation, emphasis on research and collaboration, and adherence to international standards, Chinese solder manufacturers are primed to dominate the global market.Conclusion:China's PCB solder manufacturers have established themselves as vital players in the country's robust electronics industry. Through ongoing innovation, strategic partnerships, and commitment to environmental responsibility, these manufacturers have maintained their competitive edge. As demand for electronic devices and components continues to surge, China's PCB solder manufacturers are poised to thrive, driving the industry forward and shaping the future of technology.

The Importance of PCB Board Thickness in Electronics Manufacturing

Introducing the PCB Board Thickness NewsIn the fast-paced world of technology, Printed Circuit Boards (PCBs) play a crucial role in powering electronic devices. These boards are the backbone of most electronic devices, providing the necessary connections and pathways for electrical components to function seamlessly. The thickness of PCB boards is a critical factor in determining their performance and reliability. In this news release, we will delve into the importance of PCB board thickness and how it impacts the overall functionality of electronic devices.The thickness of a PCB board is a key consideration in its design and manufacturing process. It directly affects the board's mechanical strength, impedance control, and overall performance. A thinner PCB board may offer a reduced form factor and lighter weight, but it may also be more prone to bending or warping, which can lead to electrical issues and component failure. On the other hand, a thicker PCB board provides better mechanical stability and can withstand higher levels of stress and vibration, making it ideal for applications where durability is paramount.In the world of PCB manufacturing, the standard thickness of a PCB board is typically denoted in millimeters (mm) or mils (1/1000 of an inch). The most commonly used PCB thickness is 1.6mm, which is suitable for a wide range of electronic applications. However, the demand for thinner and more lightweight PCB boards has been steadily increasing, driven by the evolution of compact and portable electronic devices. As a result, PCB manufacturers are constantly striving to develop innovative solutions that offer both thinness and durability.{Company Introduction} is at the forefront of PCB manufacturing and has been a pioneer in developing cutting-edge PCB technologies. With a strong focus on quality, innovation, and customer satisfaction, {Company Name} has consistently delivered high-performance PCB solutions to a diverse range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Their state-of-the-art manufacturing facilities and extensive industry experience have positioned them as a trusted leader in the field of PCB manufacturing.Recognizing the growing demand for thinner PCB boards, {Company Name} has dedicated significant resources to research and development efforts aimed at producing ultra-thin yet durable PCB solutions. By leveraging advanced fabrication techniques and materials, {Company Name} has successfully engineered PCB boards with reduced thicknesses while maintaining superior mechanical and electrical performance. These advancements have opened up new possibilities for designing smaller, lighter, and more efficient electronic devices, driving innovation across various industries.{Company Name} understands the critical role that PCB board thickness plays in the performance and reliability of electronic devices. By offering a diverse portfolio of PCB solutions with varying thickness options, {Company Name} ensures that their customers have access to the most suitable PCB boards for their specific application requirements. Whether it's a compact, handheld device or a rugged, industrial application, {Company Name} can tailor their PCB solutions to meet the exacting standards of their customers, providing unmatched reliability and performance.In conclusion, the thickness of PCB boards is a crucial factor that directly impacts the functionality and reliability of electronic devices. As the demand for thinner and more lightweight PCB boards continues to rise, {Company Name} remains committed to delivering innovative, high-performance PCB solutions that meet the evolving needs of the industry. Through their dedication to research and development, {Company Name} is shaping the future of PCB manufacturing, offering advanced solutions that empower the next generation of electronic devices. With a steadfast commitment to quality and excellence, {Company Name} is a trusted partner for businesses seeking cutting-edge PCB solutions.

Fast PCB Assembly Services for Efficient Electronic Manufacturing

In today's fast-paced and ever-changing world, technology plays a significant role in revolutionizing the way we live and interact with each other. One of the most critical components of modern technology is printed circuit boards (PCBs). These small, yet complex devices are found in almost every electronic device we use and rely on every day, from smartphones to computers, televisions, and even medical equipment.With PCBs playing such a crucial role in modern technology, it's critical to have a reliable and reputable manufacturing partner to produce high-quality and durable PCBs. That's where Quick Turn PCB Assembly Manufacturer comes in as a leading player in the PCB manufacturing industry.Quick Turn PCB Assembly Manufacturer has been a reliable choice for many original equipment manufacturers (OEMs), electronics distributors, and engineering firms for many years. The company offers fast printed circuit board manufacturing and assembly services, allowing OEMs to get their products to market quickly and efficiently.The company's high-quality PCBs are designed and produced to meet the highest industry standards. Quick Turn PCB Assembly Manufacturer targets a broad range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.One of the key factors that set Quick Turn PCB Assembly Manufacturer apart from others in the industry is its commitment to customer satisfaction. The company's team of experts works closely with their clients to understand their needs and expectations, providing customized solutions that meet specific requirements.The company's rapid prototyping capability is another area where they have established themselves as a reliable and top-quality PCB manufacturer. Time is a critical factor when developing electronic products, and Quick Turn PCB Assembly Manufacturer recognizes that. They provide quick turn PCB prototypes with fast turnaround times, enabling clients to test and validate the design of their products.Quick Turn PCB Assembly Manufacturer has a state-of-the-art facility equipped with advanced machinery and equipment to ensure precision and consistency in PCB production. The company's production process follows strict quality control standards, ensuring every PCB that leaves their facility meets or exceeds their clients' expectations.The company offers a wide range of PCB manufacturing services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Quick Turn PCB Assembly Manufacturer's PCBs come in various sizes and configurations, making it easy for clients to find the right PCB for their specific application.In addition to PCB manufacturing, Quick Turn PCB Assembly Manufacturer also offers value-added services such as design for manufacturability (DFM) assessment, component sourcing, and functional testing. The company's comprehensive services make them a one-stop-shop solution for clients, helping them streamline their production process and reduce manufacturing costs.Overall, Quick Turn PCB Assembly Manufacturer's commitment to quality, reliability, and customer satisfaction has made them an industry leader in the PCB manufacturing space. With their focus on fast turnaround times, fast prototyping, and customized solutions, the company is well-positioned to continue its growth and expand its reach in the years to come.

What Is FR4 Material PCB and How Does It Work?

article about the benefits of using FR4 material PCBs in electronic manufacturing.Electronic manufacturing is one of the most critical industries in the world, with virtually every aspect of modern life being dependent on electronic devices and systems. One crucial component of electronic manufacturing is printed circuit boards (PCBs), which play an essential role in the functioning of electronic devices. In recent times, FR4 material PCB has emerged as one of the most reliable and cost-effective options for electronic manufacturing.FR4 material PCBs are made using a specific kind of fiberglass impregnated with epoxy resin, which makes them highly durable, flexible, and resistant to high temperatures. This makes FR4 material PCBs ideal for use in a wide range of electronic devices, ranging from simple consumer electronics to advanced military installations.One of the key benefits of using FR4 material PCBs is that they offer high mechanical strength, which makes them ideal for applications that require complex and intricate designs. Due to their high mechanical strength, FR4 material PCBs can withstand high levels of vibration, shock, and impact without sustaining damage. This makes them ideal for use in rugged environments such as aerospace, military, and industrial applications.Another benefit of using FR4 material PCBs is that they are highly resistant to high temperatures, which makes them ideal for use in high-temperature applications such as power electronics. They can also withstand sudden changes in temperature without losing their structural integrity, which allows them to be used in harsh environments.FR4 material PCBs are also highly resistant to moisture and chemicals, which makes them ideal for use in applications that are exposed to harsh chemicals or extreme weather conditions. They resist chemical reactions, which helps prevent corrosion and oxidation from occurring. This guarantees that the circuit board remains functional even in adverse conditions.In addition to their physical properties, FR4 material PCBs are also very easy to manufacture, which helps reduce production costs and lead times. Since they are highly versatile and robust, they can be used in a wide range of electronic devices. This reduces the need for manufacturers to invest in multiple types of PCBs, resulting in cost savings.Furthermore, FR4 material PCBs offer excellent electrical performance, which makes them ideal for use in high-speed applications such as computer motherboards. They have a low dielectric constant, making them ideal for high-frequency applications. They can also handle high voltage and current, making them ideal for use in power electronics.Overall, the benefits of using FR4 material PCBs are numerous, making them the ideal choice for electronic manufacturing applications that require high durability, flexibility, and performance. With their robustness, versatility, and affordability, FR4 material PCBs are rapidly becoming the go-to choice for electronics manufacturers worldwide.{Brand name removed} is a leading supplier of FR4 material PCBs, providing high-quality products to customers in a wide range of industries. With years of experience in the electronic manufacturing sector, {Brand name removed} has the expertise and resources to design, manufacture, and supply FR4 material PCBs that meet the most stringent industry standards. Their products are highly reliable, durable, and cost-effective, making them the preferred choice of electronics manufacturers worldwide.In conclusion, electronic manufacturers looking to produce high-quality electronic devices must consider using FR4 material PCBs due to their unique properties and benefits. While traditional PCB materials have their advantages, FR4 material PCBs offer superior strength, durability, versatility, and performance, making them ideal for a wide range of applications. {Brand name removed} offers a wide range of FR4 material PCB products that meet the needs and requirements of modern electronic manufacturers, ensuring that their products are reliable, high-performing, and meet the most stringent industry standards.

Quick and Efficient PCB Prototypes: A Game-Changer in Electronics Development

In today's fast-paced world, time is of the essence. A delay in any part of a business process can lead to a significant loss of time and revenue. When it comes to designing electronic prototypes, PCB's or Printed Circuit Boards play a crucial role. These prototypes form a key component of any electronic gadget, from mobile phones and laptops to medical equipment and satellite systems. Designing PCB's to match the requirements of a project is no easy feat. It requires a high level of skill, expertise, and most importantly, time.Here lies the importance of Fast PCB Prototypes, a company that specializes in quick, reliable and accurate PCB prototyping services. The company prides itself on providing clients with top-notch PCB PCB fabrication, assembly, and testing services at lightning-fast speeds. Their extensive range of services includes PCB design, layout, assembly, and manufacturing, and they can accommodate both low volume and high-volume production runs.Fast PCB Prototypes' unique selling proposition is their focus on reducing the prototyping time for their clients, without compromising on quality. How do they do it? "At Fast PCB Prototypes, we leverage our experience and expertise to streamline the PCB production process without sacrificing quality," says the company spokesperson. "We use advanced software and machinery that allows us to provide fast and accurate prototyping services to our clients, ensuring they receive their PCB prototypes on time."The company offers a broad range of PCB prototyping services that cater to various industries. They provide both single and multilayer PCBs, and can accommodate sizes that range from small PCBs to large PCBs with up to 20 layers. Fast PCB Prototypes' customers span across a broad spectrum of industries, including aerospace, defense, medical, and industrial sectors."Our focus is always on delivering quality PCB prototypes that meet the needs of our customers," says the spokesperson. "We understand the unique requirements of each client, and we work hard to ensure that all their needs are met. Our team of experienced technicians and engineers works 24/7 to provide fast, accurate, and reliable PCB prototyping services."Fast PCB Prototypes prides itself on its state-of-the-art production facility, which uses advanced equipment to produce high-quality PCB prototypes. The company places a strong emphasis on quality control, and all PCBs undergo rigorous testing to ensure they meet the highest industry standards. The company follows strict procedures to ensure the PCB designs are free from errors and are properly optimized for production."Customers can rest assured that their PCB prototypes will be in good hands with us," says the spokesperson. "We have invested heavily in our production facility and have a team of experienced professionals who are dedicated to ensuring that every project is a success."Fast PCB Prototypes is committed to providing its customers with a reliable, affordable, and fast PCB prototyping service. Whether a client requires a single PCB prototype or a high-volume production run, the company is dedicated to providing a solution that meets their needs. With a track record of success and customer satisfaction, Fast PCB Prototypes is the ideal choice for any company that requires high-quality PCB prototyping services.

Custom Printed Circuit Board Manufacturing for LED Applications

The demand for more efficient and sustainable lighting solutions has been steadily increasing in recent years. In response to this growing need, {company name} has announced the development of a cutting-edge innovation in the realm of LED printed circuit boards (PCBs). This breakthrough technology promises to revolutionize the way in which LED lighting systems are designed and produced, offering a range of benefits that are set to have a significant impact on the industry as a whole.The new LED PCBs developed by {company name} have been specifically engineered to deliver enhanced performance and reliability in LED lighting applications. By leveraging state-of-the-art manufacturing processes and materials, the company has succeeded in creating a superior product that stands out in terms of energy efficiency, longevity, and overall quality. This development represents a major leap forward in the evolution of LED lighting, and is poised to set a new standard for the industry.One of the key features of {company name}'s LED PCBs is their exceptional thermal management capabilities. By utilizing advanced thermal materials and designs, the PCBs are able to effectively dissipate heat generated by the LEDs, resulting in improved performance and longevity. This aspect is particularly crucial in applications where LED lighting systems are required to operate continuously for extended periods of time, such as in commercial and industrial settings.Furthermore, the {company name} LED PCBs have been engineered to maximize energy efficiency, thereby reducing operational costs and environmental impact. The PCBs are designed to minimize power consumption while maintaining optimal performance, making them an ideal choice for those seeking to implement sustainable lighting solutions. As the global trend towards energy conservation and sustainability continues to gain momentum, the demand for such innovative and eco-friendly technologies is only expected to increase.In addition to their technical prowess, {company name}'s LED PCBs also offer a high degree of flexibility and customization. This allows for greater design freedom, enabling lighting manufacturers to create products that meet the specific requirements of their applications. Whether it be in the realm of architectural lighting, automotive lighting, or horticultural lighting, the versatility of these PCBs makes them a highly adaptable solution for a wide range of lighting needs.The development of these advanced LED PCBs is a testament to {company name}'s commitment to pushing the boundaries of what is possible in the field of LED lighting. As a leading provider of cutting-edge electronic solutions, the company has a long-standing track record of driving innovation and delivering high-performance products that meet the evolving demands of the market. With the introduction of these new LED PCBs, {company name} is once again demonstrating its ability to anticipate and address the needs of the industry, while also setting new benchmarks for performance and quality.Given the promising potential of this new technology, industry experts are eagerly anticipating the impact that {company name}'s LED PCBs will have on the market. As the demand for energy-efficient and sustainable lighting solutions continues to grow, the arrival of these innovative PCBs is expected to be met with great enthusiasm. With their unrivaled thermal management capabilities, energy efficiency, and flexibility, these LED PCBs are poised to play a pivotal role in shaping the future of LED lighting, and to set a new standard for excellence in the industry.

Efficient and Fast PCB Prototyping Services for Your Business

Quick PCB Prototyping Technological Advancement Propels {} to the Forefront of Electronic ManufacturingIn the fast-paced world of electronic manufacturing, time is of the essence. To meet the demand for rapid prototyping and production of printed circuit boards (PCBs), {} has emerged as a leader in providing quick and efficient PCB prototyping services.The process of PCB prototyping is essential in the development of electronic products. It involves creating a prototype of a PCB before moving on to mass production. Traditionally, this process has been time-consuming and costly, with lead times often stretching over weeks or even months. However, advancements in technology have made it possible to significantly reduce the prototyping time without compromising on quality.With the help of state-of-the-art equipment and advanced manufacturing techniques, {} has perfected the art of quick PCB prototyping. Their streamlined and efficient processes allow them to deliver high-quality prototypes in a matter of days, rather than weeks or months. This accelerated timeline gives their clients a competitive edge in the market, allowing them to bring their products to market faster and more efficiently.The key to {}'s success in quick PCB prototyping lies in their commitment to innovation and investment in cutting-edge technology. Their manufacturing facility is equipped with the latest machinery, including precision milling machines, laser drilling systems, and automated assembly lines. This high-tech infrastructure enables them to produce prototypes with unparalleled speed and accuracy, meeting the evolving needs of the electronic industry.Moreover, {}'s team of highly skilled engineers and technicians ensures that every prototype meets the highest standards of quality and reliability. With their expertise and attention to detail, they are able to troubleshoot and refine the design during the prototyping phase, ensuring that the final product is flawless.The advantages of quick PCB prototyping are not limited to speed and efficiency. By quickly iterating through design revisions, manufacturers can test and validate their concepts, identify potential issues, and make necessary adjustments before mass production. This not only saves time and money but also reduces the risk of costly errors down the line.Furthermore, quick PCB prototyping allows for greater flexibility in product development. Manufacturers can explore multiple design options and make changes on the fly, responding to market demands and staying ahead of the competition. This agility is crucial in today's fast-paced and dynamic electronic industry, and {} is at the forefront of enabling it.As a result of their commitment to innovation and excellence, {} has gained a reputation as a trusted partner for quick PCB prototyping. Their clientele includes a wide range of industries, from consumer electronics and telecommunications to automotive and aerospace. This diverse portfolio is a testament to their ability to meet the unique needs of each customer and deliver tailor-made solutions.Looking ahead, {} remains dedicated to pushing the boundaries of quick PCB prototyping, embracing new technologies, and staying ahead of industry trends. Their unwavering commitment to excellence and customer satisfaction has positioned them as a leading force in the electronic manufacturing landscape, and they are poised to continue shaping the future of quick PCB prototyping.In conclusion, the technological advancement in quick PCB prototyping has propelled {} to the forefront of electronic manufacturing. Their dedication to innovation, investment in cutting-edge technology, and commitment to excellence have enabled them to deliver high-quality prototypes with unparalleled speed and precision. As the electronic industry continues to evolve, {} remains a trusted partner for companies seeking to bring their products to market faster and more efficiently.

How to Use Red Solder: Tips and Techniques

Red Solder, created by {company name}, is making waves in the electronics industry with its innovative and high-quality products. The company, based in Silicon Valley, California, has been a leading manufacturer of soldering products for over 30 years and has established itself as a trusted name in the industry.The success of Red Solder can be attributed to the company's commitment to innovation, quality, and customer satisfaction. The company's products are known for their superior performance and reliability, making them the top choice for professionals and hobbyists alike.Red Solder offers a wide range of soldering products, including solder wire, solder paste, flux, and soldering irons. The company's products are designed to meet the needs of a variety of industries, including electronics manufacturing, automotive, aerospace, and telecommunications.One of the key factors that sets Red Solder apart from its competitors is its dedication to research and development. The company has a team of experienced engineers and technicians who are constantly working to improve and expand its product line. This commitment to innovation has allowed Red Solder to stay ahead of the curve and provide its customers with the latest and most advanced soldering solutions.In addition to its focus on product quality, Red Solder also places a strong emphasis on customer satisfaction. The company prides itself on its responsive and knowledgeable customer service team, who are always ready to assist customers with any questions or concerns they may have. Red Solder also offers a comprehensive warranty and support program to ensure that its customers are fully satisfied with their purchases.Red Solder's dedication to excellence has not gone unnoticed. The company has received numerous awards and accolades for its products, including the prestigious "Innovation Award" from the Electronics Industry Association. This recognition is a testament to the company's commitment to pushing the boundaries of soldering technology and delivering exceptional products to its customers.Looking ahead, Red Solder is focused on continuing to expand its product line and reach new markets. The company is constantly exploring new opportunities for growth and is committed to maintaining its position as a leader in the soldering industry."We are excited about the future of Red Solder," said the company's CEO. "Our team is dedicated to developing new and innovative products that will continue to meet the needs of our customers and provide them with the best soldering solutions available."As Red Solder continues to thrive in the electronics industry, it is clear that the company's commitment to excellence and innovation will continue to drive its success. With its dedication to quality, customer satisfaction, and innovation, Red Solder is poised to remain a leading force in the soldering industry for years to come.

Top Ultra-Fast PCB Manufacturer Provides Essential News Content

Title: Pioneering PCB Manufacturer Revolutionizes Circuit Board Production: A Deep Dive into the Innovations Behind FastturnpcbIntroduction:In the fast-paced world of electronics, the demand for cutting-edge technologies is growing exponentially. One integral component that forms the backbone of these electronic devices is the printed circuit board (PCB). Fastturnpcb (brand name removed), a renowned industry leader, has gained recognition for its unmatched prowess in the domain of PCB manufacturing and fabrication.Body:1. Founding Principles:Fastturnpcb has always strived for excellence through innovation and customer satisfaction. Founded by a team of passionate engineers in [year], the company's aim was to revolutionize the traditional PCB production process by adhering to the principles of speed, quality, and dependability. With a customer-centric approach, Fastturnpcb quickly emerged as a trusted name in the industry.2. State-of-the-Art Facilities:Fastturnpcb boasts an advanced manufacturing facility equipped with cutting-edge machinery and technology. They have invested heavily in automated production lines and state-of-the-art software systems, ensuring exceptional precision and accuracy in every step of the manufacturing process. This allows for efficient production of high-quality PCBs that meet the diverse requirements of customers.3. Quick Turnaround Time:True to its name, Fastturnpcb has set new industry standards for rapid PCB production. With a committed manufacturing team and streamlined processes, the company offers incredible turnaround times that surpass customer expectations. Whether it's a prototype or a large volume production order, Fastturnpcb stands out for its ability to deliver PCBs with unmatched speed and reliability.4. Quality Control Measures:Fastturnpcb leaves no room for compromise when it comes to the quality of its products. Stringent quality control measures are implemented at every stage of production. Each PCB undergoes comprehensive testing to ensure functionality, durability, and compliance with industry standards. With a focus on producing high-quality and reliable circuit boards, Fastturnpcb has gained the trust of numerous clients across various industries.5. Diverse Product Range:Fastturnpcb caters to a wide spectrum of industries, including telecommunications, automotive, aerospace, medical, and consumer electronics. Their versatile production capabilities allow them to fulfill the most complex and customized PCB requirements. Whether it's a single-layer board or a multilayer HDI PCB, Fastturnpcb's expertise covers the entire spectrum.6. Embracing Environmental Responsibility:Fastturnpcb acknowledges its responsibility towards environmental sustainability. They employ eco-friendly manufacturing practices, adhering to strict compliance with environmental regulations. The company utilizes green and recyclable materials in its PCB production, minimizing waste and reducing their carbon footprint. Fastturnpcb's commitment to sustainability ensures a better future for the industry and the planet.7. Customer-Centric Approach:Fastturnpcb places paramount importance on customer satisfaction. Their dedicated team of engineers and customer support personnel offer personalized assistance throughout the production process. From design suggestions to material selection, Fastturnpcb ensures seamless collaboration and effective communication, resulting in superior quality PCBs.Conclusion:Fastturnpcb's unwavering commitment to innovation, quality, and customer satisfaction has positioned them as an industry leader in PCB manufacturing. By embracing state-of-the-art technology, adhering to stringent quality control measures, and prioritizing customer needs, Fastturnpcb continues to revolutionize the circuit board production landscape. As the industry continues to evolve, one can expect Fastturnpcb to remain at the forefront, shaping the future of PCB manufacturing.