Top tips for designing and manufacturing custom printed circuit boards

By:Admin

With over [number of years] years of experience in the industry, Custom PCB has built a solid reputation for delivering top-notch PCB solutions to their clients. Their team of experienced engineers and technicians work tirelessly to ensure that every product meets the highest standards of quality and reliability. The company's dedication to continuous improvement and customer satisfaction has propelled them to the forefront of the PCB industry, and their latest product line is a testament to their commitment to excellence.

The new custom PCB solutions offered by Custom PCB are designed to meet the evolving needs of the electronics industry. Whether it's for consumer electronics, automotive applications, industrial equipment, or aerospace systems, Custom PCB has the expertise and capabilities to deliver custom PCB solutions that are tailored to the specific requirements of their clients. The company's comprehensive range of services includes PCB design, prototyping, assembly, and testing, allowing them to provide end-to-end solutions that are unmatched in the industry.

One of the key highlights of Custom PCB's latest product line is their advanced manufacturing capabilities. The company has invested heavily in state-of-the-art equipment and cutting-edge technologies to ensure that they can produce custom PCB solutions that meet the strictest quality standards. From HDI PCBs to high-frequency PCBs, the company's manufacturing capabilities cover a wide range of technologies, allowing them to cater to the diverse needs of their clients.

In addition to their manufacturing capabilities, Custom PCB also offers a range of value-added services to enhance the functionality and reliability of their products. Their team of engineers works closely with clients to provide design optimization, design for manufacturability, and design for testing services, ensuring that the final product meets the highest standards of performance and reliability. With a focus on innovation and continuous improvement, Custom PCB is constantly pushing the boundaries of what is possible in the PCB industry.

Furthermore, Custom PCB takes pride in their commitment to quality and reliability. The company adheres to strict quality control processes at every stage of the manufacturing process, ensuring that every product meets the highest standards of quality and reliability. Their rigorous testing and inspection procedures guarantee that their custom PCB solutions are free from defects and are built to last, earning the trust and confidence of their clients.

With the launch of their latest product line, Custom PCB has once again demonstrated their position as a leader in the PCB industry. Their dedication to excellence, commitment to innovation, and relentless pursuit of customer satisfaction have set them apart from their competitors, making them the go-to partner for custom PCB solutions.

The team at Custom PCB is excited about the possibilities that their latest product line brings to the table. They are confident that their new custom PCB solutions will revolutionize the way that companies approach PCB design and manufacturing, allowing them to unlock new levels of performance and reliability in their electronic products.

In conclusion, Custom PCB's latest product line represents a significant milestone for the company and the PCB industry as a whole. With their advanced manufacturing capabilities, value-added services, and unwavering commitment to quality, Custom PCB is well-positioned to continue leading the way in the PCB industry, providing their clients with custom PCB solutions that are second to none. Whether it's for prototyping, small-scale production, or high-volume manufacturing, Custom PCB has the expertise and capabilities to deliver custom PCB solutions that meet the highest standards of quality and reliability.

Company News & Blog

A Comparison of Hasl and Enig: Which is the better choice?

Hasl and Enig are two of the most commonly used surface finishes for printed circuit boards (PCBs). Both have their own advantages and disadvantages, and the choice between the two often depends on the specific needs of a particular application.Hasl, or Hot Air Solder Leveling, is a widely used surface finish for PCBs. It involves dipping the PCB into a bath of molten solder, and then using hot air to blow off the excess solder, leaving a thin and even coating on the surface of the PCB. Hasl is known for its excellent solderability and relatively low cost, making it a popular choice for many PCB applications.On the other hand, Enig, or Electroless Nickel Immersion Gold, is a surface finish that consists of an electroless nickel plating covered with a thin layer of immersion gold. Enig is known for its excellent corrosion resistance, flatness, and suitability for fine pitch components. It is often chosen for applications that require a high level of reliability and performance.Recently, a debate has emerged in the PCB industry regarding the relative merits of Hasl and Enig. Some industry experts argue that Enig is superior to Hasl in terms of overall performance and reliability, especially for high-frequency and high-speed applications. They point to Enig’s superior flatness and excellent solderability as key advantages over Hasl.On the other hand, proponents of Hasl argue that it is a cost-effective and well-established surface finish that has been used for decades with great success. They also argue that Hasl is easier to inspect and repair compared to Enig, making it a more practical choice for many applications.In light of this debate, {company name} has been at the forefront of developing and providing advanced PCB surface finishing solutions that meet the diverse needs of their customers. With extensive experience in the PCB industry and a strong track record of innovation, {company name} is well-positioned to provide expert guidance on the choice between Hasl and Enig.{company name} offers a comprehensive range of PCB surface finishing options, including both Hasl and Enig, as well as other advanced surface finishes such as OSP (Organic Solderability Preservatives) and Immersion Silver. Their team of experts works closely with customers to understand their specific requirements and recommend the most suitable surface finish for their PCBs.In response to the ongoing debate between Hasl and Enig, {company name} emphasizes the importance of taking a holistic view of PCB surface finishing. They advise customers to carefully consider their application requirements, budget, and long-term reliability needs when choosing between Hasl and Enig. They also highlight the importance of working with a trusted and experienced PCB manufacturer that can provide expert guidance and support throughout the PCB manufacturing process.As the debate between Hasl and Enig continues to unfold in the PCB industry, {company name} remains committed to offering the most advanced and reliable PCB surface finishing solutions to their customers. With a focus on innovation, quality, and customer satisfaction, {company name} is well-equipped to address the diverse and evolving needs of the PCB market.In conclusion, the choice between Hasl and Enig as a PCB surface finish ultimately depends on the specific requirements of a particular application. {company name} stands ready to provide expert guidance and support to customers as they navigate this important decision, ensuring that their PCBs meet the highest standards of performance, reliability, and quality.

Revolutionizing Electronic Assembly: The Advantages of Surface Mount Technology

[Company Name Removed] Sets New Standards with Advanced Surface Mounting Technology[City, Date] - [Company Name Removed], a leading player in the technology industry, is revolutionizing the market with cutting-edge Surface Mounting Technology (SMT). As a result of extensive research and development efforts, the company has introduced a game-changing innovation that is set to redefine the way electronic components are manufactured.SMT is a crucial process in electronic manufacturing, where components are mounted directly onto the surface of printed circuit boards (PCBs). With the demand for smaller, lighter, and more powerful electronic devices on the rise, the need for advanced SMT technology has become imminent. [Company Name Removed] recognized this demand and has risen to the challenge by developing an unparalleled solution.The new SMT technology developed by [Company Name Removed] offers several distinct advantages over conventional methods. By utilizing state-of-the-art robotic assembly systems and advanced automation techniques, the company has created a highly efficient manufacturing process. This enables faster production cycles, reducing time-to-market for electronic devices. Additionally, the precise placement of components ensures higher levels of accuracy, improving overall product reliability.One of the key highlights of [Company Name Removed]'s SMT technology is its ability to support miniaturized components. As electronic devices continue to shrink in size, it is critical for manufacturers to utilize smaller and more compact components. The advanced machinery and techniques employed by [Company Name Removed] enable the assembly of components as small as one square millimeter, setting a new benchmark in the industry.Another distinguishing feature of [Company Name Removed]'s SMT technology is its versatility. The company's advanced assembly systems can handle a wide range of electronic components, including passive components (resistors, capacitors), active components (transistors, diodes), integrated circuits, and more. This flexibility ensures that [Company Name Removed] can cater to various industries, from consumer electronics to automotive and aerospace.[Company Name Removed]'s commitment to sustainability is evident in its SMT technology innovation as well. The company recognizes the growing concerns of waste generation in electronic manufacturing and has taken steps to address this issue. By optimizing material usage and minimizing scrap, [Company Name Removed] ensures a more eco-friendly manufacturing process.The introduction of [Company Name Removed]'s advanced SMT technology has garnered significant attention in the industry. Market analysts predict that this innovation will not only revolutionize electronic device manufacturing but also have a ripple effect across multiple sectors. With faster production cycles, higher accuracy, and increased reliability, electronic manufacturers can expect to deliver superior products to meet consumers' evolving needs.In conclusion, [Company Name Removed]'s Surface Mounting Technology is poised to reshape the electronic manufacturing landscape. By leveraging advanced machinery, automation, and precision placement, the company has established a new standard in the industry. With the ability to support miniaturized components and accommodate various electronic devices, [Company Name Removed] is well-positioned to meet the demands of a rapidly evolving market. Furthermore, their commitment to sustainability sets them apart from their competitors, making them a frontrunner in the industry. As [Company Name Removed] paves a new path for electronic manufacturing, the future of the industry looks brighter than ever before.

Quality PCB Manufacturer Offers Multi-Circuit Boards for Various Applications

Multi Circuit Board, a leading provider of high-quality printed circuit boards (PCBs), has announced the launch of a new product line that is set to revolutionize the electronics industry. The company, known for its commitment to innovation and customer satisfaction, is excited to introduce the new line of PCBs that are designed to meet the evolving needs of the market.As the demand for smaller, faster, and more efficient electronic devices continues to grow, Multi Circuit Board has recognized the need for PCBs that can deliver high performance and reliability in a compact form factor. The new product line is the result of extensive research and development, and is poised to set a new standard for PCB technology.The key features of the new PCBs include advanced multi-layer designs, high-density interconnects, and enhanced thermal management capabilities. These features are essential for meeting the demands of today's electronic devices, which require increasingly complex circuitry in a limited amount of space.Additionally, the new PCBs are manufactured using state-of-the-art materials and processes, ensuring exceptional quality and durability. This is in line with Multi Circuit Board's commitment to providing its customers with products that exceed industry standards and deliver exceptional value."We are thrilled to introduce our new line of PCBs, which are the result of our dedication to innovation and excellence," said a spokesperson for Multi Circuit Board. "We have invested heavily in research and development to ensure that our new products meet and exceed the expectations of our customers. We believe that these PCBs will enable our customers to create cutting-edge electronic devices that are smaller, faster, and more reliable than ever before."In addition to the new product line, Multi Circuit Board is also expanding its range of services to offer comprehensive support to its customers. This includes design assistance, prototyping, and full-scale production, as well as quality control and testing. The company's goal is to provide its customers with a seamless and efficient experience, from initial concept to final product.Multi Circuit Board has established itself as a trusted partner for a wide range of industries, including aerospace, telecommunications, medical devices, and automotive. With a track record of delivering high-quality PCBs and unparalleled customer service, the company has earned a reputation for excellence in the industry.The launch of the new product line reaffirms Multi Circuit Board's commitment to staying at the forefront of PCB technology. By continuously investing in research and development, the company aims to lead the way in providing innovative solutions that address the evolving needs of the electronics industry."We are dedicated to pushing the boundaries of PCB technology and delivering products that empower our customers to bring their ideas to life," the spokesperson added. "With this new product line, we are confident that we will continue to set new benchmarks for performance, reliability, and efficiency in the electronics industry."As the electronics industry continues to evolve at a rapid pace, Multi Circuit Board is well-positioned to meet the demands of its customers and drive innovation in PCB technology. With its new product line and expanded range of services, the company is poised to further solidify its reputation as a leader in the industry.

Top Manufacturer of Pcb Solder Resist for High-Quality Circuit Board Assembly

Title: Leading Pcb Solder Resist Manufacturer Poised for Unmatched Growth and InnovationIntroduction:In the ever-evolving field of electronics manufacturing, one company has consistently stood out as a leading innovator in the production of Printed Circuit Board (PCB) solder resist solutions. This manufacturer, renowned for its commitment to quality and cutting-edge technology, has continuously raised the bar in the industry, satisfying the demands of customers worldwide. With an extensive range of products combined with advanced manufacturing techniques, the company has positioned itself for unrivaled growth on a global scale.Expanding Product Line:As a frontrunner in the field, this prominent PCB solder resist manufacturer has an impressive array of products tailored to meet the diverse needs of the industry. From single-sided to multilayered PCBs, the company offers customized solder resist solutions that ensure the highest level of quality and reliability. Moreover, with constant research and development efforts, they have successfully introduced new variations of solder resist materials catering to the ever-evolving demands of modern electronics manufacturing.Advanced Manufacturing Techniques:To maintain their industry-leading position, the manufacturer consistently implements state-of-the-art manufacturing techniques throughout their production process. They leverage cutting-edge automation technologies and machinery to ensure precision and efficiency, resulting in solder resist solutions of unparalleled quality. By investing in advanced equipment and continuously upgrading their facilities, the manufacturer highlights their commitment to delivering products with the highest industry standards.Commitment to Environmental Sustainability:In addition to their focus on product excellence, this leading PCB solder resist manufacturer harbors a strong commitment to environmental sustainability. Recognizing the need for eco-friendly alternatives, they have developed a comprehensive range of environmentally-conscious solder resist solutions. These products adhere to strict regulations regarding hazardous substances, minimizing their environmental impact while maintaining the highest performance standards. Through this dedication, the company helps electronics manufacturers operate responsibly and reduce their carbon footprint.Customer-Centric Approach:At the heart of this manufacturer's success lies its dedication to customer satisfaction. By fostering strong relationships with clients, they understand the unique needs of each partner and provide tailored solutions accordingly. Through close collaboration, the manufacturer ensures the delivery of top-tier products that meet or exceed customer expectations. Additionally, their customer support team provides efficient and reliable assistance, helping clients navigate any challenges they may encounter.Global Reach and Market Presence:Owing to their unwavering commitment to quality, innovation, and exceptional customer service, this PCB solder resist manufacturer has established a robust global presence. Their products are widely recognized for their reliability, making the company the brand of choice amongst top electronic manufacturers across the globe. This market presence reflects the confidence and trust that industry leaders place in the manufacturer’s products, further securing their position as a global industry leader.Future Outlook:In an ever-expanding global marketplace, this leading manufacturer remains at the forefront of technological advancements in the PCB solder resist industry. With plans to enhance production capabilities further and continuously invest in research and development, the company aims to solidify its position as an unparalleled innovator. Their future endeavors include the introduction of new, advanced materials, which will shape the future of electronics manufacturing, ensuring their long-lasting success.Conclusion:With an unrivaled commitment to quality, advanced manufacturing techniques, and a customer-centric approach, this PCB solder resist manufacturer continues to set new benchmarks in the industry. Their dedication to eco-friendly solutions, combined with a global market presence, positions them not just as a manufacturer but also as a trusted partner in the evolving world of electronics manufacturing. As they embark on a journey towards unmatched growth and innovation, the industry eagerly awaits the next groundbreaking developments from this leading player.

Master the Art of PCB Board Design with These Expert Tips!

Title: Innovative PCB Manufacturing Company Revolutionizes Electronics DesignIntroduction (100 words):Leading the charge in cutting-edge electronic design, [Company Name] is a trailblazing PCB manufacturing company that is set to transform the electronics industry. With a relentless dedication to quality and innovation, [Company Name] has become a trusted partner for businesses seeking next-generation PCB boards that outperform traditional designs. By seamlessly integrating advanced technology and creative design techniques, the company offers bespoke solutions tailored to individual needs. As a result, [Company Name] is at the forefront of delivering high-performance PCBs that are versatile, efficient, and enable groundbreaking applications across various sectors.Body:I. Redefining PCB Design and Manufacturing (200 words):[Company Name] has revolutionized PCB design and manufacturing by adopting cutting-edge methodologies that maximize efficiency and minimize time to market. Utilizing state-of-the-art techniques, the company's expert engineers work closely with clients to understand their unique requirements and design boards that meet their exact specifications.The company's PCBs are fabricated using top-notch materials and advanced manufacturing processes to ensure optimal performance. Through continuous research and development, [Company Name] has successfully reduced the size, weight, and power consumption of their boards, making them ideal for portable devices, IoT applications, medical equipment, and aerospace systems.II. Advanced Technology Integration (200 words):At the heart of [Company Name]'s success lies its commitment to integrating advanced technologies into every PCB design. The company has invested heavily in research and development, constantly exploring emerging technologies to provide clients with innovative solutions. Whether it's mixed-signal circuits, high-speed signal integrity, or high-density interconnects, [Company Name] has a proven track record of delivering cutting-edge solutions.The integration of advanced technologies also allows for enhanced functionality and improved reliability. From single-layer to multilayer, flexible to rigid-flex, [Company Name] engineers ensure their designs are optimized for performance, durability, and functionality. By closely collaborating with clients and utilizing sophisticated tools and software, the company creates PCBs that meet even the most demanding technical requirements.III. Unmatched Quality and Strict Compliance (200 words):[Company Name] places quality at the core of its operations. The company follows rigorous manufacturing standards and adheres to strict quality control protocols to ensure that each PCB leaving its facility performs flawlessly. Through the use of cutting-edge testing equipment and procedures, every board undergoes comprehensive quality checks before being delivered to clients.Operating in accordance with international quality regulations and certifications, [Company Name] maintains the highest standards of compliance. This serves as a testament to the company's dedication to providing reliable, durable, and superior PCBs.IV. Driving Innovation and Partnering for Success (200 words):[Company Name]'s commitment to fostering innovation has led to successful collaborations with various industries and technology-driven companies. By closely partnering with clients, the company gains substantial insights into the specific needs of each sector, enabling them to design and manufacture PCBs that fuel progress and drive success.The company's agile manufacturing processes ensure that projects are completed on time, without any compromise in quality. With a customer-centric approach and exceptional technical expertise, [Company Name] strives to be the go-to choice for businesses looking to stay ahead in the rapidly evolving electronics market.Conclusion (100 words):[Company Name] continues to redefine PCB design with their innovative and client-focused approach. By leveraging advanced technologies and adopting stringent quality control measures, the company consistently delivers high-performance circuit boards, catering to diverse industries and applications. With an unwavering commitment to partnership and unparalleled expertise, [Company Name] is set to shape the future of electronics and remain at the forefront of PCB design and manufacturing.

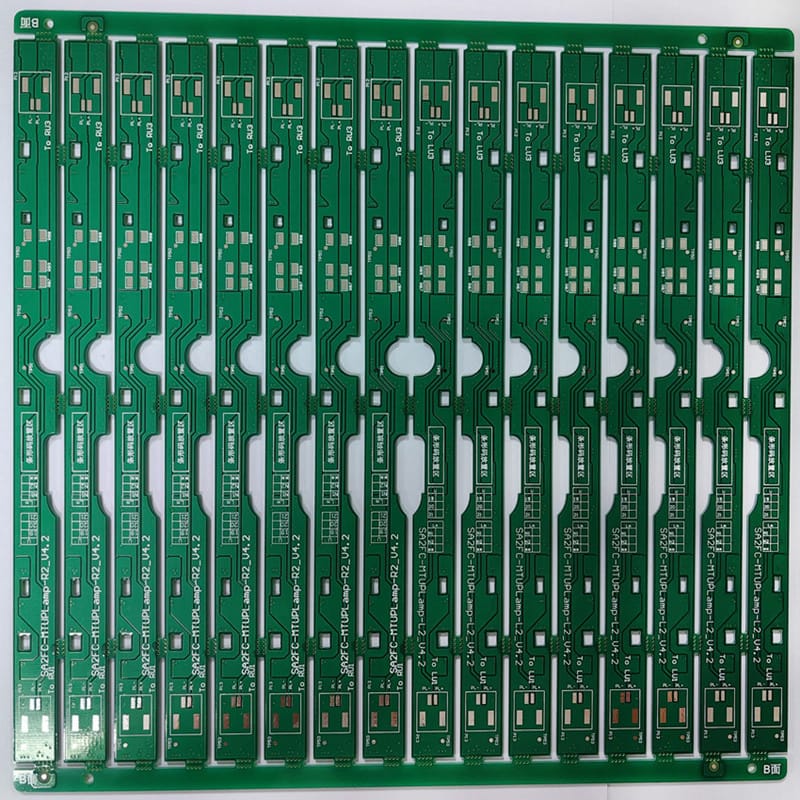

High-Quality Strip Circuit Board for Your Electronic Devices

Strip Circuit Board (SCB) is a leading manufacturer of high-quality circuit boards that are used in various electronic devices and equipment. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, SCB is at the forefront of the industry, providing innovative solutions and superior products to meet the needs of its customers.The company's commitment to quality and excellence has made it a trusted supplier for many leading electronics companies around the world. SCB's circuit boards are known for their reliability, durability, and performance, making them the top choice for a wide range of applications, from consumer electronics to industrial equipment.One of the key products that SCB specializes in is the strip circuit board, which is used in a variety of devices and equipment. Strip circuit boards are a type of flexible circuit board that are designed to be used in applications where space is limited and a high degree of flexibility is required. These circuit boards are used in a wide range of products, including mobile phones, digital cameras, and automotive electronics, among others.SCB's strip circuit boards are manufactured using advanced technologies and high-quality materials to ensure the highest level of performance and reliability. The company's state-of-the-art manufacturing facilities are equipped with the latest equipment and machinery, allowing for precise and efficient production processes.In addition to its commitment to quality and excellence, SCB is also dedicated to providing superior customer service and support. The company works closely with its customers to understand their specific requirements and provide customized solutions to meet their needs. SCB's team of engineers and technicians are highly knowledgeable and experienced, and are always available to provide technical support and assistance to customers.With a focus on innovation and continuous improvement, SCB is constantly pushing the boundaries of what is possible in the field of circuit board manufacturing. The company invests heavily in research and development to stay ahead of the curve and develop cutting-edge technologies and solutions for its customers.In recent years, SCB has expanded its operations and has established a strong presence in the global market. The company's products are now used in a wide range of industries and applications, and its reputation for quality and reliability continues to grow.As the demand for high-quality circuit boards continues to grow, SCB is well-positioned to meet the needs of its customers and continue to lead the industry. With its dedication to excellence, innovation, and customer satisfaction, SCB is set to remain a key player in the circuit board manufacturing industry for years to come.

Ultimate Guide to PCB Classification: A Comprehensive Overview

PCB (Printed Circuit Board) is a crucial component in electronic devices, serving as the foundation for the electrical connections and components that make modern technology possible. As technology continues to advance, the demand for high-quality and reliable PCBs is more important than ever. With the increasing complexity of electronic devices, the classification of PCBs has become a key factor in ensuring efficient and reliable performance.Classifications of PCBs are based on several factors such as the number of layers, materials used, and the technology and design requirements of the specific application. PCBs can be classified into single-sided, double-sided, and multilayer boards based on the number of conductive layers they have. Single-sided PCBs have conductive copper tracks on only one side of the board, while double-sided PCBs have tracks on both sides. Multilayer PCBs consist of more than two conductive layers, interconnected by through-hole plating or vias.In addition to the number of layers, PCBs can also be classified based on the materials used in their construction. FR-4 is the most common material used for PCBs due to its excellent electrical insulation properties and high mechanical strength. Other materials such as polyimide, ceramic, and metal core can also be used for specific applications requiring higher temperature resistance or thermal conductivity.Another important factor in the classification of PCBs is the technology and design requirements of the specific application. For example, rigid PCBs are most commonly used in consumer electronics and industrial applications, while flexible and rigid-flex PCBs are used in applications where space and weight are critical considerations, such as portable devices and aerospace applications."Company X" is a renowned manufacturer of high-quality PCBs, specializing in the production of multilayer PCBs using state-of-the-art technology and precision manufacturing processes. Their PCBs are widely used in a variety of industries including telecommunications, automotive, medical devices, and consumer electronics. With a focus on quality and reliability, "Company X" is committed to meeting the unique requirements of their customers by offering customized solutions and advanced PCB technology.The classification of PCBs is essential for ensuring that the right type of board is used for a specific application, taking into account the performance, cost, and design requirements. A thorough understanding of the classification of PCBs is crucial for design engineers, as it enables them to make informed decisions regarding the selection of the most suitable PCB for their products. By choosing the right type of PCB, manufacturers can ensure the performance, reliability, and longevity of their electronic devices.As technology continues to advance, the demand for specialized PCBs tailored to specific applications is expected to grow. With the expertise and capabilities of companies like "Company X", the industry is well-positioned to meet the increasing demand for high-quality and reliable PCBs. By staying at the forefront of technological advancements and continuously improving manufacturing processes, "Company X" and other leading PCB manufacturers are shaping the future of electronic devices with innovative and efficient PCB solutions.In conclusion, the classification of PCBs plays a vital role in the design and manufacturing of electronic devices, ensuring the optimal performance and reliability of the final product. With the advancement of technology and the increasing complexity of electronic devices, the demand for high-quality, specialized PCBs is on the rise. Companies like "Company X" are at the forefront of this industry, pushing the boundaries of PCB technology and providing tailored solutions to meet the evolving needs of the market.

China's Electronic Manufacturing Plant: Circuit Assembly Factory Production Goes Into Full Swing

article about the assembly factory and its services.China Circuit Assembly Factory: Providing Reliable and High-Quality Assembly ServicesThe advancement of technology has drastically changed the way we live, communicate, and work. One of the most notable innovations that have revolutionized multiple industries is the development of electronics. They have become an essential part of our daily routine. The creation, designing, and manufacturing of electronic products require different types of components and precise assembly procedures. Assembling electronic devices involves assembling individual components in a specifically designed circuit board. Many companies rely on outsourcing their circuit board assembly processes to reliable and experienced circuit assembly factories to ensure product quality. In China, one of the most trusted circuit assembly companies is the China Circuit Assembly Factory.About the CompanyChina Circuit Assembly Factory is a Chinese-based company that specializes in printed circuit board (PCB) assembly services. It is a subsidiary of a well-established electronic manufacturing service provider, with over two decades of experience in the industry. The company comprises a team of experienced professionals who have an excellent understanding of the assembly processes and use the latest technologies to ensure high-quality products. They offer circuit board assembly services for different electronics products, including but not limited to, consumer electronics, telecommunications, automotive, industrial, medical, aerospace, and military.Service OfferingsChina Circuit Assembly Factory offers a wide range of PCB assembly services to their clients. These services include:1. Surface Mount Technology (SMT) AssemblySMT is a widely used technique in building modern circuit boards that use surface-mounted components. It is a process of assembling a circuit board by attaching the components directly to the surface of the board instead of running wires or inserting leads through holes. The process involves using high-precision automated equipment to ensure component accuracy and consistency. China Circuit Assembly Factory uses state-of-the-art equipment and processes to ensure efficient and reliable SMT assembly services.2. Through-Hole AssemblyThrough-hole assembly is a traditional method of assembling a PCB by running leads through holes in the board and soldering the components from the top side. This technique is suitable for applications that require high mechanical strength. China Circuit Assembly Factory has skilled technicians to provide quality through-hole assembly services using the latest techniques and equipment.3. Box Build AssemblyBox build assembly is the process of assembling a finished product by integrating the circuit boards and other components into an enclosure or packaging. This process includes mechanical assembly, wire harnessing, and testing. China Circuit Assembly Factory offers reliable and cost-effective box build assembly services to their clients.4. Prototype AssemblyPrototype assembly is an essential step in the development of any electronic product. It is the process of assembling a few units of the product to test the design, function, and performance. China Circuit Assembly Factory has a team of skilled engineers who can assist their clients in the prototype development phase by providing high-quality assembly services.Quality AssuranceChina Circuit Assembly Factory understands that quality is essential in the electronics industry. They have implemented a strict quality control system for all their services to ensure that their clients get only the best products. The quality control process includes the use of high-quality raw materials, robust assembly processes, and rigorous testing procedures. They also have a team of dedicated quality inspectors who oversee the manufacturing process to ensure compliance with the quality standards.ConclusionThe China Circuit Assembly Factory is a reliable and trustworthy assembly company that offers high-quality and cost-effective circuit board assembly services. Their commitment to providing only the best services has earned them a reputation among their clients as the go-to assembly factory in China. With their state-of-the-art equipment, skilled technicians, and strict quality control, they can meet the demands of different industries and provide reliable and consistent services. If you are looking for a reliable circuit assembly factory, China Circuit Assembly Factory is the perfect choice.

Top PCB Fabricators in the News: Latest Updates and Trends

Pcb Fabricators, a leading manufacturer of printed circuit boards for various industries, continues to uphold its reputation as a trusted provider of high-quality electronic components. With a commitment to innovation and excellence, the company has established itself as a reliable partner for businesses in need of reliable PCB solutions.Since its inception, Pcb Fabricators has been at the forefront of technological advancements in the PCB manufacturing industry. The company's state-of-the-art facilities and cutting-edge equipment enable it to produce a wide range of PCBs that meet the stringent requirements of its clients. Whether it's a single-layer PCB for a simple application or a multi-layered circuit board for a complex electronic device, Pcb Fabricators has the capability to deliver tailor-made solutions that precisely match its clients' specifications.One of the key strengths of Pcb Fabricators is its dedication to quality. The company adheres to rigorous quality control processes at every stage of the production process, ensuring that each PCB that leaves its facility is free from defects and built to last. This unwavering commitment to quality has earned Pcb Fabricators the trust and loyalty of its customers, who rely on the company to provide them with PCBs that consistently meet their performance expectations.Furthermore, Pcb Fabricators is known for its flexibility and responsiveness. The company understands that the needs of its clients may vary, and as such, it offers a wide range of customization options to accommodate specific requirements. From choosing the right materials and finishes to providing design assistance and engineering support, Pcb Fabricators works closely with its clients to ensure that their unique needs are met.In addition to its manufacturing capabilities, Pcb Fabricators is also committed to sustainability and environmental responsibility. The company takes proactive measures to minimize its impact on the environment, including the responsible use of resources and the implementation of environmentally-friendly practices in its operations. By prioritizing sustainability, Pcb Fabricators is not only contributing to a greener future but also setting an example for the industry as a whole.Looking ahead, Pcb Fabricators is poised for continued growth and success. The company remains dedicated to investing in research and development to stay ahead of the curve and anticipate the evolving needs of its clients. By staying abreast of the latest technological advancements and industry trends, Pcb Fabricators is well-positioned to remain a leader in the PCB manufacturing industry for years to come.As a testament to its commitment to excellence, Pcb Fabricators has received accolades and recognition from industry experts and regulatory bodies. The company's adherence to strict quality standards and its track record of delivering exceptional PCB solutions have earned it the respect and admiration of its peers.In conclusion, Pcb Fabricators stands as a shining example of a company that consistently delivers superior products and services to its clients. With its unwavering commitment to quality, its focus on customization, and its dedication to sustainability, Pcb Fabricators has established itself as a reliable partner for businesses seeking top-notch PCB solutions. As the company looks to the future, it is well-positioned to build on its success and continue serving the needs of its clients with excellence and innovation.

The Importance of Understanding the Thickness of 1oz Copper for Industrial Applications

The Thickness of 1oz Copper, Here's what you need to know.In the world of electronics, copper is an essential material for creating printed circuit boards (PCBs) that form the backbone of modern devices. Copper is widely used for its excellent conductivity, durability, and resistance to corrosion. In the manufacturing of PCBs, the thickness of copper used is a crucial factor that directly impacts the performance and reliability of the final product. One of the leading companies in the industry is {}, a renowned manufacturer of high-quality copper laminates and PCB materials. With years of experience and expertise in the field, {} has established itself as a trusted supplier to some of the biggest names in the electronics industry.When it comes to PCB manufacturing, 1oz copper is a standard thickness that is widely used for various applications. The term "1oz" refers to the weight of copper in one square foot of the material, which is approximately 34.8 microns thick. This thickness is ideal for producing reliable and high-performance PCBs while maintaining a balance between cost and functionality. One of the key benefits of using 1oz copper is its ability to efficiently carry current without overheating or causing voltage drops. This makes it suitable for a wide range of electronic devices, from small consumer gadgets to large industrial equipment. In addition, the uniformity and consistency of the copper thickness ensure that the PCBs perform reliably across different operating conditions and environments.{}As a leading supplier of copper laminates and PCB materials, {} offers a comprehensive range of 1oz copper products to meet the diverse needs of its customers. From standard FR-4 laminates to advanced high-frequency materials, {} provides a wide selection of options to cater to various PCB designs and applications. The company's commitment to quality and innovation has made it a preferred choice for OEMs, contract manufacturers, and design engineers around the globe.In addition to providing high-quality materials, {} also offers technical support and expertise to help customers optimize their PCB designs and manufacturing processes. With a team of experienced engineers and a state-of-the-art R&D facility, {} is dedicated to helping its customers achieve the best performance and reliability in their electronic products.In conclusion, the thickness of 1oz copper is a critical aspect of PCB manufacturing, and {} stands out as a reliable and innovative supplier of copper laminates and PCB materials. With its commitment to quality, technical expertise, and customer satisfaction, {} continues to be a driving force in the electronics industry, shaping the future of PCB technology and innovation. Whether you are a small electronics startup or a large multinational corporation, {} is the partner you can trust for all your copper laminate needs.