What Is FR4 Material PCB and How Does It Work?

By:Admin

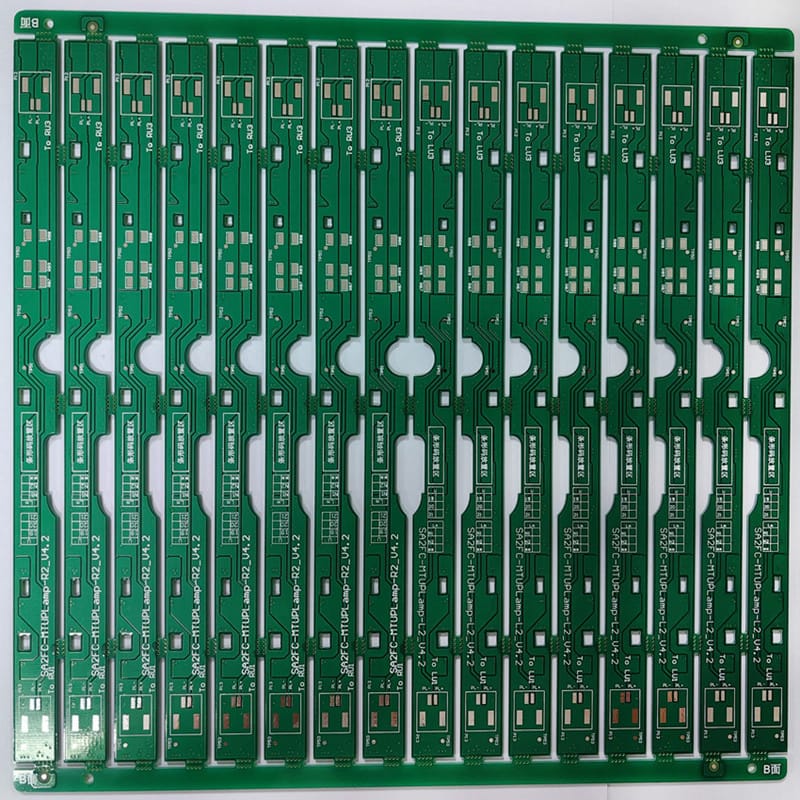

Electronic manufacturing is one of the most critical industries in the world, with virtually every aspect of modern life being dependent on electronic devices and systems. One crucial component of electronic manufacturing is printed circuit boards (PCBs), which play an essential role in the functioning of electronic devices. In recent times, FR4 material PCB has emerged as one of the most reliable and cost-effective options for electronic manufacturing.

FR4 material PCBs are made using a specific kind of fiberglass impregnated with epoxy resin, which makes them highly durable, flexible, and resistant to high temperatures. This makes FR4 material PCBs ideal for use in a wide range of electronic devices, ranging from simple consumer electronics to advanced military installations.

One of the key benefits of using FR4 material PCBs is that they offer high mechanical strength, which makes them ideal for applications that require complex and intricate designs. Due to their high mechanical strength, FR4 material PCBs can withstand high levels of vibration, shock, and impact without sustaining damage. This makes them ideal for use in rugged environments such as aerospace, military, and industrial applications.

Another benefit of using FR4 material PCBs is that they are highly resistant to high temperatures, which makes them ideal for use in high-temperature applications such as power electronics. They can also withstand sudden changes in temperature without losing their structural integrity, which allows them to be used in harsh environments.

FR4 material PCBs are also highly resistant to moisture and chemicals, which makes them ideal for use in applications that are exposed to harsh chemicals or extreme weather conditions. They resist chemical reactions, which helps prevent corrosion and oxidation from occurring. This guarantees that the circuit board remains functional even in adverse conditions.

In addition to their physical properties, FR4 material PCBs are also very easy to manufacture, which helps reduce production costs and lead times. Since they are highly versatile and robust, they can be used in a wide range of electronic devices. This reduces the need for manufacturers to invest in multiple types of PCBs, resulting in cost savings.

Furthermore, FR4 material PCBs offer excellent electrical performance, which makes them ideal for use in high-speed applications such as computer motherboards. They have a low dielectric constant, making them ideal for high-frequency applications. They can also handle high voltage and current, making them ideal for use in power electronics.

Overall, the benefits of using FR4 material PCBs are numerous, making them the ideal choice for electronic manufacturing applications that require high durability, flexibility, and performance. With their robustness, versatility, and affordability, FR4 material PCBs are rapidly becoming the go-to choice for electronics manufacturers worldwide.

{Brand name removed} is a leading supplier of FR4 material PCBs, providing high-quality products to customers in a wide range of industries. With years of experience in the electronic manufacturing sector, {Brand name removed} has the expertise and resources to design, manufacture, and supply FR4 material PCBs that meet the most stringent industry standards. Their products are highly reliable, durable, and cost-effective, making them the preferred choice of electronics manufacturers worldwide.

In conclusion, electronic manufacturers looking to produce high-quality electronic devices must consider using FR4 material PCBs due to their unique properties and benefits. While traditional PCB materials have their advantages, FR4 material PCBs offer superior strength, durability, versatility, and performance, making them ideal for a wide range of applications. {Brand name removed} offers a wide range of FR4 material PCB products that meet the needs and requirements of modern electronic manufacturers, ensuring that their products are reliable, high-performing, and meet the most stringent industry standards.

Company News & Blog

Understanding the Importance and Advantages of UL PCBs in China

China UL PCB Manufacturer: Leading the Way in Quality and InnovationIn the world of electronics manufacturing, quality is of utmost importance. Achieving the highest standards in the production of Printed Circuit Boards (PCBs) requires not only cutting-edge technology but also a commitment to continuous improvement. China UL PCB Manufacturer, a renowned industry leader, has proven time and again their dedication to providing superior products and services. With an impressive track record and a client base that spans the globe, this company is at the forefront of innovation and reliability in the PCB manufacturing industry.Founded in 2003, China UL PCB Manufacturer has established itself as a powerhouse in the competitive electronics market. With a state-of-the-art manufacturing facility, equipped with the latest machinery and a team of highly skilled professionals, they are capable of producing a wide range of UL certified PCBs to meet the diverse needs of their clients. The company prides itself on offering a comprehensive suite of services, including design, prototyping, manufacturing, and assembly, ensuring a seamless and efficient production process.One of the key factors that sets China UL PCB Manufacturer apart from its competitors is their unwavering commitment to quality. With certifications from reputable organizations such as Underwriters Laboratories (UL), they adhere strictly to international quality standards. UL certification ensures that their PCBs are manufactured using the best practices, materials, and components, resulting in products that are safe, reliable, and durable. This commitment to quality has earned China UL PCB Manufacturer a solid reputation among their clients, who rely on them for the most critical and demanding applications.Furthermore, China UL PCB Manufacturer recognizes that innovation is crucial to staying ahead in the rapidly evolving electronics industry. They invest heavily in research and development, constantly exploring new technologies and processes to enhance the performance and functionality of their PCBs. By leveraging cutting-edge techniques, such as HDI (High-Density Interconnect) and multilayer PCB construction, they are able to produce boards with higher circuit density, smaller form factors, and improved signal integrity.Aside from their technological advancements, China UL PCB Manufacturer also places great emphasis on providing exceptional customer service. Their dedicated team of engineers and support staff work closely with clients throughout the entire manufacturing process, fostering strong relationships and ensuring that all specifications and requirements are met to the highest degree of satisfaction. With a commitment to on-time delivery and prompt communication, they strive to exceed customer expectations at every opportunity.Global demand for PCBs continues to grow, and China UL PCB Manufacturer is well-positioned to meet this increasing market need. Their reputation for excellence, coupled with their competitive pricing, has allowed them to establish a strong presence not only in their domestic market but also in international markets, including North America, Europe, and Asia-Pacific. With an ever-expanding client base, partnerships with leading companies, and a reputation for delivering on their promises, China UL PCB Manufacturer is poised for continued success.In conclusion, China UL PCB Manufacturer has emerged as a leader and trailblazer in the field of PCB manufacturing. Their unwavering commitment to quality, continuous innovation, and exceptional customer service have propelled them to the forefront of the industry. With their state-of-the-art facility, advanced manufacturing techniques, and a team of dedicated professionals, they are equipped to handle the most demanding projects, ensuring reliable and high-performance PCBs for a rapidly advancing electronics market. As the demand for quality and technologically advanced PCBs continues to soar, China UL PCB Manufacturer remains the go-to choice for clients seeking reliable products and exceptional service.

Explore the Benefits of Using Lead-Free Manufacturers for Your Product Needs

Hasl Lead Free Manufacturer Leads the Charge Towards a Sustainable FutureAs the world becomes increasingly aware of the environmental impact of industrial processes and products, companies across all sectors are under increasing pressure to incorporate sustainability into their business models. In the electronics manufacturing industry, one key area that has come under scrutiny is the use of lead in the manufacturing process. Hasl Lead Free Manufacturer, however, is leading the charge towards a more sustainable future.Founded in 2005, Hasl Lead Free Manufacturer has established itself as a leading provider of high-quality printed circuit boards (PCBs) and related services, with a particular focus on the development and production of environmentally-friendly products. By replacing lead-based components with eco-friendly alternatives, the company has been able to significantly reduce its environmental impact without sacrificing quality or performance.One of the key challenges facing the electronics industry is the disposal of waste materials, particularly those that contain hazardous substances. Traditional lead-based PCB manufacturing processes have been identified as a major contributor to this problem, as they generate large quantities of lead waste that can be difficult to handle, store, and dispose of safely.Hasl Lead Free Manufacturer, however, has embraced a more sustainable approach to manufacturing. By using lead-free components and implementing environmentally-friendly production processes, the company has significantly reduced its waste output. In addition, the company has implemented an extensive recycling program, which recovers and reuses materials that would otherwise be discarded as waste.This commitment to sustainability extends beyond the manufacturing process. Hasl Lead Free Manufacturer takes an end-to-end approach to sustainable business practices, from sourcing raw materials to the final delivery of finished products. The company’s supply chain is carefully evaluated to ensure that all suppliers meet strict environmental and ethical standards, and all products are shipped using eco-friendly packaging materials.In addition to its sustainability efforts, Hasl Lead Free Manufacturer is known for its commitment to quality and innovation. The company’s team of experienced engineers and technicians work closely with clients to understand their unique needs and develop custom solutions that meet and exceed their expectations. This customer-centric approach has earned the company a reputation for exceptional service and high-quality products.Hasl Lead Free Manufacturer’s commitment to sustainability has made it a leader in the electronics manufacturing industry, and its success has not gone unnoticed. In 2020, the company was recognized with the prestigious Green Award for its outstanding efforts to reduce its environmental impact and promote sustainability in the industry.Looking ahead, Hasl Lead Free Manufacturer is committed to continuing its work towards a more sustainable future. The company is investing in new technologies and processes that will further reduce its environmental impact, and is actively seeking out partnerships and collaborations with other like-minded companies and organizations.In a world where environmental concerns are at the forefront of public consciousness, Hasl Lead Free Manufacturer has established itself as a trailblazer in the electronics industry. Its commitment to sustainability, quality, and innovation has set the standard for others to follow, and its future looks brighter than ever as it continues to lead the charge towards a more sustainable future.

What are Substrate PCBs and why are they important for your electronics?

Substrate PCB: The Next Big Thing in Electronics ManufacturingThe electronics industry is constantly evolving, with new technologies and innovations being introduced every day. One such innovation that has been gaining a lot of popularity in recent times is the substrate PCB. Substrate PCBs, also known as substrate integrated circuits (SICs), are revolutionizing the way electronic devices are manufactured.Substrate PCBs are essentially a combination of a printed circuit board (PCB) and a semiconductor device, such as a transistor. Unlike traditional PCBs, substrate PCBs are made using a high-level interconnection technology that allows for much higher integration densities. This means that more components can be packed into a smaller space, resulting in smaller and more powerful electronic devices.One company that is at the forefront of substrate PCB manufacturing is [brand name removed]. Founded in [year removed], [company name removed] has been providing cutting-edge technology solutions to the electronics industry for over [number removed] years. With a strong focus on research and development, the company has been able to stay ahead of the curve when it comes to new technologies and innovations.One of the key features of [brand name removed] substrate PCBs is their high thermal conductivity. This is achieved through the use of special materials such as copper, aluminum and ceramic. Traditional PCBs can quickly overheat when components are packed too closely together, leading to stability issues and even failure. However, substrate PCBs dissipate heat much more efficiently, allowing for greater power density and higher performance.Another advantage of using substrate PCBs is their improved electromagnetic compatibility (EMC). This is achieved through the use of special dielectric materials that reduce interference and minimize crosstalk. This results in much cleaner and clearer signals, leading to better overall performance and reliability.One of the most significant applications of substrate PCB technology is in the field of 5G. The increased data speeds and lower latency of 5G networks require powerful and reliable electronics. Substrate PCBs offer a significant advantage in this regard, allowing for highly integrated circuits that can handle the demands of 5G networks.Apart from 5G, substrate PCBs are also being used in a variety of other applications, such as satellite communication, automotive connectivity, and military communications. With the increasing demand for high-performance electronics in various industries, substrate PCBs are set to play a significant role in shaping the future of electronics manufacturing.[Brand name removed] has been partnering with leading companies in various industries to help them achieve their electronic design goals. The company has the expertise, experience, and technology required to design and produce custom substrate PCBs that meet the most demanding requirements.In conclusion, substrate PCBs are set to revolutionize the electronics industry by providing an efficient, high-performance, and reliable solution for complex electronic designs. With their ability to pack more components into smaller spaces, substrate PCBs are already changing the way electronic devices are manufactured. As electronics continue to play an ever-increasing role in our lives, substrate PCBs are sure to become even more important in the years to come.

Essential Guidelines for Efficient Electrical PCB Assembly and Manufacturing Revealed

Title: Revolutionizing the Electrical Industry: Cutting-edge PCB InnovationsIntroduction:In recent years, the electrical industry has witnessed unprecedented advancements, thanks to the tireless efforts of innovative companies. One such company, renowned for offering cutting-edge solutions, has unveiled their latest breakthrough in electrical Printed Circuit Board (PCB) technology. Their groundbreaking development promises to revolutionize multiple sectors and drive innovation forward. In this article, we delve into the unparalleled capabilities of this new Electrical PCB, explore its potential applications, and highlight the company's commitment to driving progress.State-of-the-art Electrical PCB:The newly introduced Electrical PCB has been designed with meticulous attention to detail, incorporating state-of-the-art technology that surpasses industry standards. Pioneering the field of printed circuit boards, this innovation is set to redefine reliability, performance, and efficiency within the electrical industry.Key Features and Advancements:1. Enhanced Power Efficiency:The advanced design of the Electrical PCB minimizes energy consumption without compromising performance. Through meticulous engineering, the company has successfully developed a circuit board that provides improved power distribution, reducing wastage and optimizing overall efficiency.2. Compact Design:The new Electrical PCB boasts a significantly smaller form factor, enhancing its versatility for a wide array of applications. The compact design not only saves valuable space but also streamlines manufacturing processes, reducing costs and time.3. High-Speed Data Transmission:The Electrical PCB has been optimized with high-speed data transmission capabilities, catering to the demanding needs of modern electrical systems. This cutting-edge feature enables seamless communication and connectivity, ensuring real-time data transfer between components and devices.4. Enhanced Durability:Durability is a key focus of this innovative Electrical PCB. The company has invested considerable resources in research and development, incorporating robust materials and manufacturing techniques that offer enhanced resistance to environmental factors such as moisture, corrosion, and extreme temperatures. This empowers industries to rely on the PCB for longer lifespans, reducing maintenance costs and downtime.5. Customizability:Recognizing the diverse requirements of different industries, the company's Electrical PCB is highly customizable. Tailored to meet specific needs, the PCB can be modified to fit various applications, ensuring seamless integration and compatibility across different electrical systems and devices.Potential Applications:From consumer electronics to industrial automation and renewable energy, the potential applications of this revolutionary technology are vast. The Electrical PCB's versatility opens doors for numerous industries seeking innovative solutions to their electrical challenges.1. Consumer Electronics:With its compact design, high-speed data transmission, and enhanced power efficiency, the Electrical PCB can be seamlessly integrated into smartphones, tablets, laptops, and other portable electronic devices. This innovation paves the way for smaller, more powerful, and energy-efficient consumer electronics.2. Automotive Industry:Enhanced durability and customizability make the Electrical PCB an attractive solution for the automotive industry. With increasing demands for electric vehicles, this groundbreaking technology ensures improved reliability, safety, and performance.3. Renewable Energy:The Electrical PCB's power efficiency and compact design offer significant advantages in renewable energy systems. This technology can facilitate efficient power conversion, making it ideal for solar panels, wind turbines, and energy storage systems.Company Commitment to Innovation:The company behind this monumental Electrical PCB breakthrough has a long-standing commitment to innovation and progress. Through ongoing research and development, they strive to push the boundaries of what is possible in the electrical industry. Their investment in cutting-edge technologies and dedication to customer satisfaction has solidified their position as a leader in the field.Conclusion:In a world where technological advancement is the driving force behind progress, the introduction of the Electrical PCB revolutionizes the electrical industry. With its groundbreaking features, including enhanced power efficiency, compact design, high-speed data transmission, and customizability, this innovation facilitates growth and transformation across various sectors. As this company continues to defy conventions and push the boundaries of technology, we can expect further groundbreaking developments in the future.

China's Electronic Manufacturing Plant: Circuit Assembly Factory Production Goes Into Full Swing

article about the assembly factory and its services.China Circuit Assembly Factory: Providing Reliable and High-Quality Assembly ServicesThe advancement of technology has drastically changed the way we live, communicate, and work. One of the most notable innovations that have revolutionized multiple industries is the development of electronics. They have become an essential part of our daily routine. The creation, designing, and manufacturing of electronic products require different types of components and precise assembly procedures. Assembling electronic devices involves assembling individual components in a specifically designed circuit board. Many companies rely on outsourcing their circuit board assembly processes to reliable and experienced circuit assembly factories to ensure product quality. In China, one of the most trusted circuit assembly companies is the China Circuit Assembly Factory.About the CompanyChina Circuit Assembly Factory is a Chinese-based company that specializes in printed circuit board (PCB) assembly services. It is a subsidiary of a well-established electronic manufacturing service provider, with over two decades of experience in the industry. The company comprises a team of experienced professionals who have an excellent understanding of the assembly processes and use the latest technologies to ensure high-quality products. They offer circuit board assembly services for different electronics products, including but not limited to, consumer electronics, telecommunications, automotive, industrial, medical, aerospace, and military.Service OfferingsChina Circuit Assembly Factory offers a wide range of PCB assembly services to their clients. These services include:1. Surface Mount Technology (SMT) AssemblySMT is a widely used technique in building modern circuit boards that use surface-mounted components. It is a process of assembling a circuit board by attaching the components directly to the surface of the board instead of running wires or inserting leads through holes. The process involves using high-precision automated equipment to ensure component accuracy and consistency. China Circuit Assembly Factory uses state-of-the-art equipment and processes to ensure efficient and reliable SMT assembly services.2. Through-Hole AssemblyThrough-hole assembly is a traditional method of assembling a PCB by running leads through holes in the board and soldering the components from the top side. This technique is suitable for applications that require high mechanical strength. China Circuit Assembly Factory has skilled technicians to provide quality through-hole assembly services using the latest techniques and equipment.3. Box Build AssemblyBox build assembly is the process of assembling a finished product by integrating the circuit boards and other components into an enclosure or packaging. This process includes mechanical assembly, wire harnessing, and testing. China Circuit Assembly Factory offers reliable and cost-effective box build assembly services to their clients.4. Prototype AssemblyPrototype assembly is an essential step in the development of any electronic product. It is the process of assembling a few units of the product to test the design, function, and performance. China Circuit Assembly Factory has a team of skilled engineers who can assist their clients in the prototype development phase by providing high-quality assembly services.Quality AssuranceChina Circuit Assembly Factory understands that quality is essential in the electronics industry. They have implemented a strict quality control system for all their services to ensure that their clients get only the best products. The quality control process includes the use of high-quality raw materials, robust assembly processes, and rigorous testing procedures. They also have a team of dedicated quality inspectors who oversee the manufacturing process to ensure compliance with the quality standards.ConclusionThe China Circuit Assembly Factory is a reliable and trustworthy assembly company that offers high-quality and cost-effective circuit board assembly services. Their commitment to providing only the best services has earned them a reputation among their clients as the go-to assembly factory in China. With their state-of-the-art equipment, skilled technicians, and strict quality control, they can meet the demands of different industries and provide reliable and consistent services. If you are looking for a reliable circuit assembly factory, China Circuit Assembly Factory is the perfect choice.

Top Manufacturer of Pcb Solder Resist for High-Quality Circuit Board Assembly

Title: Leading Pcb Solder Resist Manufacturer Poised for Unmatched Growth and InnovationIntroduction:In the ever-evolving field of electronics manufacturing, one company has consistently stood out as a leading innovator in the production of Printed Circuit Board (PCB) solder resist solutions. This manufacturer, renowned for its commitment to quality and cutting-edge technology, has continuously raised the bar in the industry, satisfying the demands of customers worldwide. With an extensive range of products combined with advanced manufacturing techniques, the company has positioned itself for unrivaled growth on a global scale.Expanding Product Line:As a frontrunner in the field, this prominent PCB solder resist manufacturer has an impressive array of products tailored to meet the diverse needs of the industry. From single-sided to multilayered PCBs, the company offers customized solder resist solutions that ensure the highest level of quality and reliability. Moreover, with constant research and development efforts, they have successfully introduced new variations of solder resist materials catering to the ever-evolving demands of modern electronics manufacturing.Advanced Manufacturing Techniques:To maintain their industry-leading position, the manufacturer consistently implements state-of-the-art manufacturing techniques throughout their production process. They leverage cutting-edge automation technologies and machinery to ensure precision and efficiency, resulting in solder resist solutions of unparalleled quality. By investing in advanced equipment and continuously upgrading their facilities, the manufacturer highlights their commitment to delivering products with the highest industry standards.Commitment to Environmental Sustainability:In addition to their focus on product excellence, this leading PCB solder resist manufacturer harbors a strong commitment to environmental sustainability. Recognizing the need for eco-friendly alternatives, they have developed a comprehensive range of environmentally-conscious solder resist solutions. These products adhere to strict regulations regarding hazardous substances, minimizing their environmental impact while maintaining the highest performance standards. Through this dedication, the company helps electronics manufacturers operate responsibly and reduce their carbon footprint.Customer-Centric Approach:At the heart of this manufacturer's success lies its dedication to customer satisfaction. By fostering strong relationships with clients, they understand the unique needs of each partner and provide tailored solutions accordingly. Through close collaboration, the manufacturer ensures the delivery of top-tier products that meet or exceed customer expectations. Additionally, their customer support team provides efficient and reliable assistance, helping clients navigate any challenges they may encounter.Global Reach and Market Presence:Owing to their unwavering commitment to quality, innovation, and exceptional customer service, this PCB solder resist manufacturer has established a robust global presence. Their products are widely recognized for their reliability, making the company the brand of choice amongst top electronic manufacturers across the globe. This market presence reflects the confidence and trust that industry leaders place in the manufacturer’s products, further securing their position as a global industry leader.Future Outlook:In an ever-expanding global marketplace, this leading manufacturer remains at the forefront of technological advancements in the PCB solder resist industry. With plans to enhance production capabilities further and continuously invest in research and development, the company aims to solidify its position as an unparalleled innovator. Their future endeavors include the introduction of new, advanced materials, which will shape the future of electronics manufacturing, ensuring their long-lasting success.Conclusion:With an unrivaled commitment to quality, advanced manufacturing techniques, and a customer-centric approach, this PCB solder resist manufacturer continues to set new benchmarks in the industry. Their dedication to eco-friendly solutions, combined with a global market presence, positions them not just as a manufacturer but also as a trusted partner in the evolving world of electronics manufacturing. As they embark on a journey towards unmatched growth and innovation, the industry eagerly awaits the next groundbreaking developments from this leading player.

Fast and Efficient PCB Fabrication: Discover the Benefits

Quick Turn PCB Fabrication Company is an emerging leader in the realm of electronics and Printed Circuit Board production. With years of experience providing exceptional customer service, innovative technology, and unparalleled quality assurance, the company has managed to build a reputation as a reliable and trustworthy partner in the industry. The company has recently announced the launch of its newest product line, providing even faster turnaround times and more convenience to its clients.PCB production is a crucial aspect of the electronics industry, providing a foundation for the technology that powers modern devices. Quick Turn PCB Fabrication Company recognized the need for a streamlined production process that would allow manufacturers to obtain their PCBs quickly and efficiently. The company has been dedicated to providing innovative solutions for its clients, developing new technologies to improve the speed and quality of its services.The company attributes its success in the industry to its team's commitment to excellence. The company's engineers are known for their expertise in cutting-edge circuit board technology, using the latest design and production tools to ensure that every product meets the highest quality standards. The company prioritizes its clients' needs, providing tailor-made solutions to meet the unique requirements of each customer.Quick Turn PCB Fabrication Company's new product line promises to revolutionize the industry, offering customers even faster turnaround times without sacrificing quality. Clients can now submit their designs and receive their finished PCBs in record time, thanks to the company's state-of-the-art production technology. The company's new line is especially beneficial for clients working on time-sensitive projects, allowing them to meet their deadlines without compromising on quality.The company's commitment to innovation and efficiency is also reflected in its environmental policy. Quick Turn PCB Fabrication Company aims to minimize its impact on the environment by using sustainable production practices and reducing its carbon footprint. The company's engineers are trained to ensure that every product is produced in an environmentally-friendly manner, reducing waste and using materials that are safe for the environment.Quick Turn PCB Fabrication Company takes pride in its ability to cultivate long-term relationships with its clients. The company's reputation for exceptional customer service has helped it establish long-standing partnerships with some of the industry's leading manufacturers. The company's commitment to client satisfaction has also led to frequent referrals, with many new clients seeking out the company based on positive recommendations.Quick Turn PCB Fabrication Company's ability to respond quickly to clients' needs has been a major contributing factor to its success. The company maintains an extensive inventory of components and materials, enabling it to quickly source what it needs to produce high-quality PCBs to tight deadlines. Clients can count on the company's knowledgeable staff to guide them through the production process and ensure that their needs are met at every step.In conclusion, Quick Turn PCB Fabrication Company's dedication to innovation, excellence, and customer service has made it a leader in the electronics industry. The company's new product line promises even faster turnaround times and greater convenience for clients, while its commitment to sustainability ensures that it remains a responsible corporate citizen. With a strong track record of success and a culture of continuous improvement, Quick Turn PCB Fabrication Company is poised to continue its growth trajectory and become an even more significant player in the industry in the years to come.

Leading PCB Manufacturing Facility in China Receives UL Certification

Title: Leading Chinese PCB Manufacturer Achieves UL Certification for Enhanced Quality and ReliabilityIntroduction:In an impressive feat of technological advancement and quality control, China PCB UL Factory, one of the country's leading printed circuit board manufacturing facilities, has recently achieved UL certification. This recognition underscores the company's commitment to providing top-notch products while reinforcing its position as a trusted partner for diverse industries such as automotive, telecommunications, consumer electronics, and more. With this new certification, China PCB UL Factory aims to further establish itself as a global leader in the PCB manufacturing industry.Body:1. The Road to UL Certification:China PCB UL Factory has continuously invested in cutting-edge technology and innovative manufacturing processes, enabling the company to produce high-quality PCBs that meet the stringent standards set by UL. The certification process involved rigorous assessments conducted by UL experts, evaluating factors such as design, material selection, manufacturing processes, and product performance. China PCB UL Factory successfully met all the necessary criteria, demonstrating its dedication to excellence.2. Advantages of UL Certification:Obtaining UL (Underwriters Laboratories) certification is no small accomplishment and speaks to a company's commitment to safety, reliability, and environmental sustainability. The UL mark instills trust in customers and reassures them that the products offered have been thoroughly tested and meet the highest industry standards. China PCB UL Factory's certification contributes to the company's reputation for top-tier quality, opening doors to new business opportunities and collaborations with global partners.3. Enhanced Product Reliability:UL certification signifies China PCB UL Factory's ability to manufacture products that adhere to strict quality control methodologies. The rigorous testing and auditing procedures conducted during UL assessments ensure that the PCBs not only meet performance benchmarks but also comply with safety regulations. By acquiring UL certification, the factory has bolstered its reputation for delivering reliable and durable PCBs, crucial components for various industries.4. Benefits for Collaborative Industries:China PCB UL Factory's achievement of UL certification offers many advantages to industries that rely on high-quality PCBs. The automotive sector, for instance, often demands exceptional performance and reliability in circuit boards used in electronic control units, sensors, and infotainment systems. With UL certification, China PCB UL Factory can position itself as a preferred PCB supplier for automotive manufacturers, enhancing its portfolio and expanding its global market share.5. Commitment to Environmental Responsibility:UL certification extends beyond product reliability; it also emphasizes a company's adherence to environmental safety protocols. China PCB UL Factory's compliance with UL standards underscores its commitment to minimizing environmental impact. The factory optimizes its manufacturing processes to reduce waste, supports the responsible disposal of hazardous materials, and promotes energy-efficient technologies. By prioritizing sustainable practices in PCB production, the company aligns itself with environmentally conscious partners and businesses.6. Market Competitiveness and Growth Prospects:The UL certification places China PCB UL Factory among an elite group of manufacturers that have met globally recognized standards for quality and safety. This achievement strengthens the company's position in the highly competitive global PCB market, enabling it to attract customers who prioritize reliability and adhere to stringent industry regulations. By capitalizing on its UL certification, China PCB UL Factory can explore new partnerships and expand its footprint in emerging sectors, such as Internet of Things (IoT), artificial intelligence (AI), and renewable energy.7. Future Outlook and Continued Excellence:Obtaining UL certification serves as a critical milestone in China PCB UL Factory's growth journey, but it is only the beginning of the company's commitment to continuous improvement. The factory plans to invest further in research and development to stay at the forefront of technological advancements, ensuring that its PCBs are compatible with evolving industry needs. By prioritizing customer satisfaction and emphasizing consistent quality, China PCB UL Factory strives to solidify its standing as a trusted PCB manufacturer worldwide.Conclusion:China PCB UL Factory's recent achievement of UL certification highlights its unwavering dedication to producing high-quality, reliable, and environmentally sustainable PCBs. This significant accomplishment positions the factory as a preferred partner for industries seeking superior electronic solutions. Through continued innovation and customer-centric practices, China PCB UL Factory is poised to further enhance its market competitiveness and drive the growth of the global PCB manufacturing industry.

Discover the Latest PCB Solder Manufacturers in China: A Comprehensive Overview

China PCBA Solder Manufacturers Continues to Serve Global Market with High-End Electronics ProductsChina has been dominating the electronics market in recent years, and with an ever-growing demand for consumer electronics, China PCB Solder Manufacturers continues to provide high-end products to customers all over the world. The company, established in 2004, has been consistently providing high-quality Printed Circuit Board Assembly (PCBA) Solder products while keeping up with the latest advancements in technology.With the ambition to cater to the diverse needs of customers from various industries, China PCB Solder Manufacturers has invested in globally advanced equipment and technology. This has enabled the company to deliver products that meet international standards. As a result, the company has become a leading player in electronic manufacturing services both locally and globally.The company offers a wide range of products, including PCB assembly services, through-hole assembly, surface mount technology, BGA assembly, and reflow soldering solutions. In addition, the company has a self-owned molding department that allows it to provide customized components and solutions as per customer's requirements.China PCB Solder Manufacturers also puts a strong emphasis on quality control. The company has implemented a strict quality control system that ensures all products undergo rigorous testing to meet customer specifications. Furthermore, the company is ISO and RoHS certified, further cementing its reputation as a reliable manufacturer of PCBA Solder products in the global market.One of the factors that have enabled China PCB Solder Manufacturers to continue dominating the electronics market is its ability to innovate new technologies. The company has an R&D department comprising of highly trained personnel that is constantly researching, exploring, and testing new ways of improving its products' efficiency.With over 16 years of experience in the electronic manufacturing industry, China PCB Solder Manufacturers has built a broad customer base in different parts of the world. The company caters to customers from various industries, including telecommunications, medical, automotive, security, industrial control, and consumer electronics, to name a few.It is no surprise that the company has a strong reputation among customers worldwide. China PCB Solder Manufacturers is committed to providing high-quality and reliable PCBA Solder products that meet the ever-growing customer requirements. The company strives to deliver products that are environmentally friendly, cost-effective, and optimized for maximum performance, making it a preferred partner for many customers worldwide.Despite the current global challenges brought about by the COVID-19 pandemic, China PCB Solder Manufacturers is still dedicated to serving its customers. The company has put measures in place to ensure that it continues to provide quality products while maintaining the safety of its employees. As part of efforts to meet clients' demands, the company has also increased its production capacity, allowing it to fulfill customer orders efficiently.In conclusion, China PCB Solder Manufacturers is a leading player in the PCBA Solder products manufacturing industry. The company has continuously invested in technology and equipment, in addition to the implementation of strict quality control measures that ensure customer satisfaction. With an unwavering commitment to innovation and customer satisfaction, the company is expected to continue dominating the electronics market and serve its clients worldwide with high-end electronic products.

How Printed Circuit Boards Revolutionized the Electronics Industry

[Company Name] Launches Advanced Printed Circuit Technology for Enhanced Performance and Reliability[Location], [Date] - [Company Name], a leading provider of advanced electronic solutions, has announced the launch of its latest innovative printed circuit technology, revolutionizing the industry with its unparalleled performance and reliability.Printed circuit boards (PCBs) are at the heart of electronic systems, enabling the smooth flow of electrical current between various components. As technology evolves, the demand for more advanced and efficient circuitry has increased, driving development in this sector. [Company Name] has always been at the forefront of this progress, consistently delivering cutting-edge solutions.The introduction of [Company Name]'s new printed circuit technology represents a significant leap forward in the development of advanced PCBs. By incorporating state-of-the-art materials and design techniques, the technology offers enhanced electrical connectivity, smaller form factors, and improved thermal management.One of the key advancements in this new technology is the use of advanced materials that offer higher electrical conductivity. This enables faster signal transmission and reduces the risk of signal loss or distortion. These enhanced electrical properties are particularly beneficial for high-frequency applications, such as telecommunication systems and data centers, where the reliable and rapid transfer of data is essential.Moreover, [Company Name] has implemented innovative design techniques to optimize the circuit layout and reduce power consumption. This not only improves the overall efficiency of electronic systems but also minimizes the generation of heat. By incorporating advanced thermal management, the printed circuit technology allows for better heat dissipation, preventing overheating and increasing the reliability and lifespan of electronic devices.To ensure the quality and reliability of their printed circuits, [Company Name] employs rigorous testing procedures and adheres to the industry's highest standards. Each circuit board undergoes meticulous inspections and quality control measures during the manufacturing process to detect any potential defects or inconsistencies. This dedication to quality assurance ensures that customers receive products of the highest caliber.The launch of this advanced printed circuit technology is expected to have a profound impact on various industries, including consumer electronics, automotive, aerospace, and medical sectors. For instance, in the automotive industry, the technology's improved thermal management capabilities will prove crucial for electric vehicles, where efficient cooling is vital for battery performance and longevity.Furthermore, the smaller form factor enables the creation of more compact and lightweight devices, making it ideal for aerospace applications where weight reduction is essential. Additionally, the enhanced electrical connectivity ensures the seamless operation of critical medical equipment, improving patient care and safety.As part of its commitment to sustainability, [Company Name] utilizes eco-friendly manufacturing practices and materials to minimize the environmental impact of its operations. This includes the reduction of hazardous substances in its products and adopting energy-efficient processes. By investing in advanced printed circuit technology, customers not only benefit from superior performance but also contribute to a greener future.[Company Name] continues to push the boundaries of what is possible in printed circuit technology, delivering innovative solutions to meet the evolving needs of the electronics industry. With its latest advancements, [Company Name] solidifies its position as a trusted and innovative partner, ensuring that businesses and consumers alike can rely on high-performance electronics for years to come.For more information about [Company Name]'s advanced printed circuit technology and other electronic solutions, please visit [company website].About [Company Name]:[Company Name] is a leading provider of advanced electronic solutions, specializing in the development and manufacturing of innovative printed circuit technology. With a commitment to excellence, [Company Name] offers a wide range of products and services tailored to meet the unique requirements of various industries. Through continuous research and development, [Company Name] aims to deliver cutting-edge solutions that drive technological advancements and facilitate progress.